Abstract

Coupling photocatalyst-coated optical fibers (P-OFs) with LEDs shows potential in environmental applications. Here we report a strategy to maximize P-OF light usage and quantify interactions between two forms of light energy (refracted light and evanescent waves) and surface-coated photocatalysts. Different TiO2-coated quartz optical fibers (TiO2-QOFs) are synthesized and characterized. An energy balance model is then developed by correlating different nano-size TiO2 coating structures with light propagation modes in TiO2-QOFs. By reducing TiO2 patchiness on optical fibers to 0.034 cm2/cm2 and increasing the average interspace distance between fiber surfaces and TiO2 coating layers to 114.3 nm, refraction is largely reduced when light is launched into TiO2-QOFs, and 91% of light propagated on the fiber surface is evanescent waves. 24% of the generated evanescent waves are not absorbed by nano-TiO2 and returned to optical fibers, thus increasing the quantum yield during degradation of a refractory pollutant (carbamazepine) in water by 32%. Our model also predicts that extending the TiO2-QOF length could fully use the returned light to double the carbamazepine degradation and quantum yield. Therefore, maximizing evanescent waves to activate photocatalysts by controlling photocatalyst coating structures emerges as an effective strategy to improve light usage in photocatalysis.

Similar content being viewed by others

Introduction

Heterogeneous photocatalysis has shown tremendous potential for solving environmental problems and reducing the energy crisis in the past few decades. Its applications include pollutant degradation, bacteria, and virus inactivation, water splitting for energy production, organic transformations, and more1,2,3,4,5,6. Upon absorption of light, photocatalysts generate hole-electron (h+-e−) pairs that subsequently undergo redox reactions with molecules adsorbed on photocatalyst surfaces7,8,9. However, current reactor configurations compromise the viability of photocatalytic processes because both slurry and fixed-bed reactors scatter and occlude light, consequently reducing the overall system energy efficiency10,11,12,13.

Launching light from energy-efficient and low-cost LEDs into optical fibers that are coated with photocatalysts is a new photocatalytic reactor design14,15,16,17,18. Such design shows dramatic improvements in quantum yields during pollutant degradation (i.e., moles of pollutants degraded per mole of photons absorbed by photocatalysts). As light propagates along photocatalyst-coated optical fibers (P-OFs), a fraction of the light is refracted from the lower refractive index optical fibers into the higher refractive index surface-coated photocatalyst layers (Supplementary Note 1). This produces reactive oxygen species (ROS), which degrade pollutants at the interface between photocatalysts and water containing the pollutants17,19,20. This configuration minimizes light loss due to scattering and occlusion and nearly doubles quantum yields of degradation of three pollutants when compared against slurry reactor systems at equivalent photocatalyst masses17,20,21. However, due to thick and dense photocatalyst layers dip-coated on optical fibers using highly concentrated suspension of photocatalysts in previous reports, most light delivered to the P-OFs refracts out of the fiber near the beginning sections of the coating19,20,22,23. As such, the majority of the refracted light escaped from the P-OFs without activating photocatalysts and lost its energy in water. Maximizing refracted light absorption by coating more photocatalysts improves light utilization, but thicker and more dense photocatalyst coating layers limited mass transfer of pollutants from water to ROS-producing sites24. The resulting quantum yields were thus not enhanced20. To realize the potential of reactor designs that can efficiently leverage LED technological advances, P-OFs achieving higher light utilization without compromising photocatalytic performance need to be developed.

To date, P-OF research has focused on managing refracted light. However, light has two energy forms when propagating along P-OFs: refracted light and evanescent waves. We hypothesized that maximizing evanescent wave energy, which is generated during total internal reflection (TIR) (details in Supplementary Note 2) is a better strategy to activate surface-coated photocatalysts than managing refracted light energy. Unlike refracted light, which propagates away from optical fibers and loses its energy in water, evanescent waves propagate on optical fiber surfaces. Evanescent wave energy that does not react with the photocatalyst returns and continues to propagate along the optical fiber where it can subsequently react with photocatalysts located further along the axial path of the optical fiber25,26. Thus, light reacts more efficiently with surface-coated photocatalysts through evanescent waves than refracted light.

In this work, to test our hypothesis, we evaluate the ability of TiO2-coated quartz optical fibers (TiO2-QOFs), which have novel tunable surface “patches” of TiO2 layers, to promote evanescent wave generation to activate TiO2 (Fig. 1a) and degrade a refractory pollutant (carbamazepine) by photocatalytic generated hydroxyl radicals (HO•) in bulk solution and pores in TiO2 coating layers (Fig. 1b). Compared with 6.5-cm TiO2-QOFs coated with thick and dense TiO2 layers, the 6.5-cm TiO2-QOFs coated with lower TiO2 patchiness increase quantum yield by 32% without compromising carbamazepine degradation efficiency. The TiO2-QOFs coated with low TiO2 patchiness are fabricated by dip-coating 4.8 μg/cm2 nano-TiO2 (P25, anatase/rutile 85/15, particle size 21 nm), which is selected for its wide use7, on the surfaces of quartz optical fibers, which are selected for their high UV transmission27. This coating strategy leaves only 3.4% of the optical fiber surface in direct contact with TiO2 and creates 114.3 nm, on-average, interspace distance between the fiber surfaces and the coated TiO2 layers. These coating structures are confirmed by scanning electron microscopy (SEM) and transmission electron microscopy (TEM). Based on the characterized TiO2 coating structures, an energy balance model is developed to describe the light propagation in the TiO2-QOFs as functions of the TiO2 coating layer structure parameters. From the experiments and model, we find that 91% of the radiant energy delivered to the low patchiness TiO2-QOFs propagates on the fiber surfaces as evanescent waves, and the behavior of evanescent waves interacting with the TiO2 coating results in a saving of 23% for the radiant energy delivered to the TiO2-QOFs. Extending the low patchiness TiO2-QOFs from 6.5 to 26 cm is even more beneficial, achieving about 2× carbamazepine degradation and also doubling quantum yields. In addition, the low patchiness coating on the 26 cm fiber uses 77% fewer photocatalysts than the TiO2-QOFs with thick and dense TiO2 coating layers. Thus, modulating TiO2 patchiness on the fiber surface emerges as a tunable parameter to optimize evanescent wave energy rather than refracted light energy to improve both quantum yield and pollutant degradation.

Results and discussion

Characterization and analysis of TiO2 coating layers

We fabricated three TiO2-QOFs (photos are shown in Supplementary Fig. 3) by dipping quartz optical fibers into P25 suspensions under different conditions19,20 (Table 1). They were labeled as TiO2-QOF-High, TiO2-QOF-Med, and TiO2-QOF-Low, which had 81.8, 16.9, and 4.8 μg TiO2 per cm2 of optical fiber, respectively. Electron microscopy revealed the exterior surface and cross-sectional morphologies of the uncoated optical fiber and the three TiO2-QOFs (Fig. 2a–h). As shown in the SEM images (Fig. 2a–d), the exterior surface of the uncoated optical fiber has no TiO2 attached (Fig. 2a), while the TiO2-QOFs had porous TiO2 coating layers. TiO2-QOF-High had the densest TiO2 coating layer (porosity of 62% (Fig. 2b)). TiO2-QOF-Med and TiO2-QOF-Low were more porous (71% and 90%, respectively) (Fig. 2c and d). The porous structures of TiO2 coating layers were also confirmed by atomic force microscopy (Supplementary Fig. 4). The cross-sections of the uncoated optical fiber and the three TiO2-QOFs were prepared by cutting them with a focused ion beam system, and their images (Fig. 2e–h) were obtained by TEM. As shown in Fig. 2e, there was no TiO2 attached to the uncoated optical fiber. On TiO2-QOF-High (Fig. 2f), TiO2 nanoparticles formed a porous TiO2 coating layer on the fiber surface. Around 56% of the optical fiber surface had direct contact with TiO2 nanoparticles, and interspaces were created between the optical fiber surface and the TiO2 coating layers. We define “patchiness” as the ratio (cm2/cm2) of the optical fiber surface area with direct TiO2 contact to the total optical fiber surface area. The calculated patchiness of TiO2-QOF-High, TiO2-QOF-Med, and TiO2-QOF-Low were 56%, 25%, and 8%, respectively (Fig. 2f–h). The decreasing patchiness from TiO2-QOF-High to TiO2-QOF-Low was also confirmed by a 3D optical profiler (Supplementary Fig. 6).

a–d Scanning electron microscope (SEM) surface images of the uncoated optical fiber, TiO2-QOF-High, TiO2-QOF-Med, and TiO2-QOF-Low, respectively; e–h transmission electron microscopy (TEM) images of cross-sectional morphologies of the uncoated optical fiber, TiO2-QOF-High, TiO2-QOF-Med, and TiO2-QOF-Low, respectively, in which an Au layer was deposited to capture images during the focus ion beam operation and a Pt layer was deposited to protect the TiO2 coating layers from damaging by focus ion beams; and i conceptualized images of TiO2 coating layers on the quartz optical fiber surfaces and proposed three light propagation modes at the interface.

Microscopy also allowed us to conceptualize the porous TiO2 coating layers on surfaces of optical fibers as shown in Fig. 2i. The interface is either (i) between the quartz fiber surface and the directly-contact TiO2 (termed quartz/TiO2 interface) or (ii) between the quartz fiber surface and water diffused from the bulk solution in clusters of TiO2 nanoparticles located adjacent to the quartz surface and within the porous coating (termed quartz/water/TiO2 interface). Based on the two interfaces, three modes of light propagation are proposed. In Mode 1, as light approaches the quartz/TiO2 interface, a large portion of radiant energy refracts into TiO2 and a small portion reflects back to quartz due to the higher refractive index of TiO2 than quartz. The amount of radiant energy transmitted into TiO2 and reflected to quartz is determined by Fresnel equation26,28 and is a function of the incident angle (θ) of light propagating through the fiber and interacting at the fiber surface, which is the angle between incident light and normal (Fig. 2i). In Mode 2, when light approaches the quartz/water/TiO2 interfaces (θ < the critical angle of TIR (θc)), radiant energy is also largely refracted out, and a small portion reflects. In Mode 3, when light approaches the quartz/water/TiO2 interfaces (θ > θc), TIR occurs and evanescent waves are generated. Evanescent waves propagate on the surface of optical fibers with a portion being absorbed by TiO2. The energy that was not absorbed returns to the optical fibers, making Mode 3 utilize light more efficiently than Modes 1 and 2. To promote Mode 3 of light propagation and generate more evanescent waves, it is desirable to have low TiO2 patchiness on the optical fibers. As shown in Fig. 2e–h, TiO2-QOF-Low met this requirement.

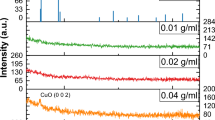

Radiant energy dissipation in TiO2-QOFs

To verify whether evanescent waves existed in our fabricated TiO2-QOFs when launching light to the fiber core from an LED, we measured the radiant energy dissipated in TiO2-QOFs (Edis) at different area-specific TiO2 coating densities (μg/cm2) (Fig. 3a). Edis is defined as the radiant energy delivered into but not transmitted through the TiO2-QOFs (see “Methods” for details), when TiO2-QOFs are exposed to either of two different media (air or water). TiO2-QOF-High at 81.8 μg/cm2 TiO2 showed no statistical difference (p > 0.05) in Edis between in air and in water. TiO2-QOF-Med at 16.9 μg/cm2 TiO2 and TiO2-QOF-Low at 4.8 μg/cm2 TiO2 showed a higher Edis in water than that in air (p < 0.05), and the differences were 16% and 98%, respectively.

a Radiant energy dissipated in the three TiO2-QOFs when TiO2-QOFs were exposed to air and water; b schematic of the normalization of the distances between the optical fiber surface and the coated TiO2 nanoparticles in an evanescent field (conditions: light intensity = 7.02 mW/cm2, wavelength = 365 nm, TiO2 coating length = 6.5 cm, irradiation duration = 4 h).

The higher Edis in water was due to the involvement of evanescent waves in TiO2-QOFs. Based on the three modes of light propagation illustrated in Fig. 2i, we surmised that Edis was caused by the two forms of energy (evanescent waves and refracted light). As the penetration depth of evanescent waves (Ʌ) is higher when going from quartz to water than from quartz to air, the radiant energy of evanescent waves dissipated in TiO2-QOFs (EE,dis) varies in either of the two media as shown in Eqs. (1) and (2)29,30,31.

where λ is the wavelength of light, nq and ne are the refractive index of quartz and external medium, respectively, Ei is the radiant energy of incident light, and zn is the normalized distance between the fiber surface and TiO2 nanoparticles at a TIR spot, which is equal to the average distance from the center of an evanescent field to the closest surrounding TiO2 nanoparticles within the evanescent field (δi), as shown in Fig. 3b32,33. In our study, the LED lamp source was fixed at one end of a quartz optical fiber, so θ remained the same and was always between 0.376π and 0.495π (calculation shown in Supplementary Note 5A). Ei and λ are inherent properties of the LED, nq is an inherent property of quartz optical fibers, and zn is a structural property of the TiO2 coating layer. As such, these values did not change during the experiments. The ne of water is higher than the ne of air (1.33 versus 1.00), so evanescent waves penetrate further from quartz to water than to air suggested by Eq. (1). Therefore, EE,dis in water is higher than EE,dis in air as given by Eq. (2).

Unlike in evanescence wave energy, the radiant energy of refracted light dissipated in TiO2-QOFs (ER,dis) is constant in the two media. At the quartz/air or quartz/water interface, θ was always greater than θc of TIR, which suggests no mode 2 of light propagation and no radiant energy refracted from quartz to air or from quartz to water. ER,dis only occurred on the quartz/TiO2 interface, calculated using Fresnel equation shown in Eq. (3):

where nq and nT are refractive indexes of quartz and TiO2, respectively. As demonstrated in Eq. (3), Ei and θ remained the same in the two media as mentioned before. nq and nT are inherent properties of quartz and TiO2, respectively, which also did not change. Thus, ER,dis remains constant regardless of the external medium being air or water. Therefore, the variable nature of EE,dis and constant feature of ER,dis cause differences in Edis and thus verify the existence of evanescent waves in TiO2-QOFs. The existence of evanescent waves was also proven by tracking the irradiance loss in a UV irradiated uncoated fiber immersed in methylene blue solutions (Supplementary Note 5B).

Modeling light propagation in TiO2-QOFs

We developed an energy balance model to simulate the light propagation along TiO2-QOFs using geometrical optics in accordance with our schematics of TiO2 coating layers on the quartz optical fibers and the 3 modes of light propagation. In this model, light rays at different angles are emitted from an LED light source and launched into the TiO2-QOFs. After entering TiO2-QOFs, each ray strikes the inner surface of TiO2-QOFs with θ between 0.376π and 0.495π. The model assumes θ is discrete with an increment of 0.0001π, and each light ray has the same amount of radiant energy (E0). Each light ray continuously strikes the inner TiO2-QOF surfaces, which (i) generates evanescent waves at the quartz/water/TiO2 interface and activates TiO2 and/or returns into the fiber, or (ii) activates attached TiO2 through refraction at the quartz/TiO2 interface with a small portion reflected to the fiber. Based on the above assumptions and Eqs. (1–3), the dissipated radiant energy of evanescent waves \(({E}_{{\mathrm{E}},{{\mathrm{dis}}}}{\prime})\) and that of refracted light \(({E}_{{\mathrm{R}},{{\mathrm{dis}}}}{\prime})\) of each light ray are represented by the summation of radiant energy dissipated at each TIR spot and refraction spot along TiO2-QOFs, respectively. The deterministic form of the equations is shown in Eqs. (4–6) (see Supplementary Note 5C for detailed derivation).

where p is the TiO2 patchiness on quartz optical fibers (Fig. 4a), za is the average interspace distance between the optical fiber surface and the coated TiO2 layer (nm), which equals to the average value of zn at all TIR spots along the fiber length (Fig. 4b), L is the TiO2 coating length (cm), and d is the diameter of optical fibers (cm). Edis equals to the summation of \({E}_{{\mathrm{E}},{{\mathrm{dis}}}}{\prime}\) and \({E}_{{\mathrm{R}},{{\mathrm{dis}}}}{\prime}\) at all incident rays with θ from 0.376π to 0.495π as shown in Eq. (6).

a Schematic showing TiO2 patchiness on quartz optical fibers (p); b schematic showing average interspace distance between fiber surfaces and TiO2 coating layers (za); c TiO2 coating layer structure parameters (p and za) of the three TiO2-QOFs; and d modeling results of the dissipated radiant energy of evanescent waves (\({E}_{{\mathrm{E}},{{\mathrm{dis}}}}{\prime}\)) and refracted light (\({E}_{{\mathrm{R}},{{\mathrm{dis}}}}{\prime}\)) as well as the returned radiant energy of evanescent waves (EE,return) and the reflected radiant energy from refraction spots (ER,reflect) in the three TiO2-QOFs (conditions: light intensity = 7.02 mW/cm2, wavelength = 365 nm, TiO2 coating length = 6.5 cm, irradiation duration = 4 h).

For our aqueous pollutant degradation study, an LED was attached to a single quartz optical fiber centered in the axial (i.e., longitudinal direction) of a tubular reactor filled with water containing carbamazepine. Edis is a function of E0, L, d, and ne, while p and za are intrinsic properties of the TiO2 coating layer and relate only to the coating structure but not the experimental conditions. p and za for each TiO2-QOF can then be calculated by substituting E0, L, d, ne, and Edis in air or water obtained by optical measurements when a TiO2-QOF is surrounded by air or immersed in water into Eqs. (4–6). Three experimental conditions were used to calculate the average p and za of each TiO2-QOF (detailed calculations for each condition shown in Supplementary Note 5D). The results showed p and za under the three conditions varied by <5% (Supplementary Table 2). The model’s accuracy was also validated by comparing the measured Edis with the model-predicted values for incident light irradiance from 0.41 to 7.02 mW/cm2 (details in Supplementary Note 5E).

The average p and za for TiO2-QOF-High were 0.528 cm2/cm2 and 7.7 nm, respectively. For TiO2-QOF-Med, p and za were 0.206 cm2/cm2 and 52.9 nm, respectively, and for TiO2-QOF-Low, they were 0.034 cm2/cm2 and 114.3 nm, respectively (shown in Fig. 4c). These results were consistent with the TiO2 coating structure parameters we observed in the TEM images shown in Fig. 2. Within the same TiO2-QOF, similar p and za calculated from the model under the three conditions further confirmed they only related to the coating structures rather than to experimental conditions.

Based on the average p and za obtained above, \({E}_{{\mathrm{E}},{{\mathrm{dis}}}}{\prime}\) and \({E}_{{\mathrm{R}},{{\mathrm{dis}}}}{\prime}\) can be calculated using Eqs. (4) and (5). In addition, to close the energy balance, the returned radiant energy of evanescent waves (EE,return) and the reflected radiant energy from refraction spots (ER,reflect) were calculated using Eqs. (7) and (8) (see Supplementary Note 5F for derivation).

Fig. 4d compares the calculated \({E}_{{\mathrm{E}},{{\mathrm{dis}}}}{\prime}\), \({E}_{{\mathrm{R}},{{\mathrm{dis}}}}{\prime}\), EE,return, and ER,reflect in water against area-specific TiO2 coating densities. As the area-specific TiO2 coating density decreased from TiO2-QOF-High to TiO2-QOF-Med to TiO2-QOF-Low, the generated evanescent wave energy (EE,g)—i.e., the sum of \({E}_{{\mathrm{E}},{{\mathrm{dis}}}}{\prime}\) and EE,return,—increased from 0.44 to 0.56 to 0.69J, and the generated refracted light energy (ER,g)—i.e., the sum of \({E}_{{\mathrm{R}},{{\mathrm{dis}}}}{\prime}\) and ER,reflect,—decreased from 0.32 to 0.20 to 0.07J. The increasing EE,g and decreasing ER,g from TiO2-QOF-High to TiO2-QOF-Med and then to TiO2-QOF-Low confirmed that TiO2-QOF-Low, which has the lowest TiO2 patchiness, promotes Mode 3 and generates more evanescent waves.

We further compared the ratios of \({E}_{{\mathrm{R}},{{\mathrm{dis}}}}{\prime}\) to ER,g and those of \({E}_{{\mathrm{E}},{{\mathrm{dis}}}}{\prime}\) to EE,g in the three TiO2-QOFs. All ratios of \({E}_{{\mathrm{R}},{{\mathrm{dis}}}}{\prime}\) to ER,g were close to 1, confirming that refracted light mostly propagated away from TiO2-QOFs and its radiant energy dissipated out. However, with increasing EE,g from TiO2-QOF-High to TiO2-QOF-Low, the ratios of \({E}_{{\mathrm{E}},{{\mathrm{dis}}}}{\prime}\) to EE,g decreased from 0.98 to 0.74. This is because za of TiO2-QOFs modulates the evanescent wave energy returning to optical fibers. The value of za in TiO2-QOF-High (7.7 nm) is much smaller than the value of Λ from quartz to water (50–120 nm) (Supplementary Fig. 11), suggesting evanescent wave energy dissipates when they reach the closest TiO2 nanoparticles and a negligible amount of them returned to the optical fibers to give a highest ratio of \({E}_{{\mathrm{E}},{{\mathrm{dis}}}}{\prime}\) to EE,g. As increasing za from 7.7 nm in TiO2-QOF-High to 52.9 nm in TiO2-QOF-Med and 114.3 nm in TiO2-QOF-Low, more evanescent waves returned to the optical fibers (Supplementary Fig. 12) because they cannot reach the TiO2 coating layers to give lower ratios of \({E}_{{\mathrm{E}},{{\mathrm{dis}}}}{\prime}\) to EE,g. Those trends were also observed when the TiO2-QOFs were exposed to air (Supplementary Fig. 13). The above modeling results suggest the TiO2 layer structure parameters (p and za) are important to control the light energy within TiO2-QOFs, while the TiO2 coating thickness is not critical.

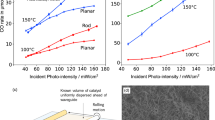

Degradation of carbamazepine by TiO2-QOFs

The above data, models, and insights were based on light measurements outside and along the length of fibers coated with TiO2. We then examined the impact of increasing energy efficiency of the low patchiness TiO2 coating layer to its photocatalytic performance in carbamazepine degradation. Control tests confirmed that carbamazepine was not adsorbed by TiO2-QOFs in the dark or not degraded when light was launched from LEDs into an uncoated optical fiber (Supplementary Figs. 14a and b). Even though the radiant energy dissipation varied in the three TiO2-QOFs, launching 365 nm light from an LED separately into the three TiO2-QOFs resulted in statistically the same (p = 0.450) pseudo-first-order degradation kinetics for carbamazepine in water (rate constants k, shown in Fig. 5a). The calculated quantum yields of carbamazepine degradation (i.e., moles of carbamazepine degraded per mole of photons absorbed by TiO2 coating layers) increased from 0.0189 in TiO2-QOF-High to 0.0248 in TiO2-QOF-Low (Fig. 5b). The improved quantum yield was attributed to the highest quantity of evanescent waves generated in TiO2-QOF-Low saving more radiant energy than the other two. The evanescent waves generated in TiO2-QOF-Low allow light to be evenly dissipated along the fiber, which prevents local photon oversaturation at the beginning sections of TiO2-QOFs and thus reduces its associated efficiency losses (Supplementary Note 6A). We also proved that the improved quantum yield was not attributed to the mass transfer limitation (Supplementary Note 6B) or carbamazepine adsorption (Supplementary Fig. 14c) of different TiO2 coating layers. We then fabricated two new TiO2-QOFs, i.e., TiO2-QOF-Low″ at p of 0.018 and za of 139.50 nm and TiO2-QOF-Low′ at p of 0.026 and za of 127.97 nm. Both degradation rate constants and quantum yields decreased with decreasing p and increasing za (Supplementary Table 5).

a Pseudo-first order degradation kinetics; b quantum yields of carbamazepine degradation by the three TiO2-QOFs; c the percentage of the radiant energy dissipation to the radiant energy delivered to TiO2-QOFs as a function of TiO2 coating length; and d comparison between degradation rate constants and apparent quantum yields by the UV irradiated TiO2-QOF-High at a coating length of 6.5 cm and TiO2-QOF-Low at a coating length of 26 cm in a 70 mL reactor (conditions: light intensity = 7.02 mW/cm2, light wavelength = 365 nm, [CBZ]0 = 2 μM, irradiation duration = 4 h).

Quantum yields of carbamazepine degradation by the TiO2-QOF-Low are 1–50× higher than those in the UV-based advanced oxidation processes34,35,36 (Supplementary Table 6). The quantum yield of TiO2-QOF-Low can be further increased by extending its length to fully utilize the returned radiant energy of evanescent waves in TiO2-QOF-Low and to increase its photocatalytic reactive sites. Figure 5c shows the percentage of radiant energy dissipation relative to total radiant energy delivered into TiO2-QOFs with different coatings. Denser coatings on TiO2-QOF-High resulted in >92% of the energy launched into the fiber being dissipated within the first 6.5 cm of the coated length, whereas low patchiness TiO2-QOF-Low utilized the same amount light over 26 cm of the coated length. The 4× increase in length also increased by 4× the surface areas available for ROS production that degrades pollutants, therefore, the 26-cm TiO2-QOF-Low was estimated to achieve 2× degradation rate constants and 2× apparent quantum yields (moles of carbamazepine degraded per moles of photons launched to optical fibers) compared with TiO2-QOF-High at a coating length of 6.5 cm (Supplementary Note 6D). The higher rate constant and apparent quantum yield of 26-cm TiO2-QOF-Low was further experimentally confirmed in a 70 mL reactor (Fig. 5d). Even if refracted light emitted from TiO2-QOF-High can be utilized by bundling TiO2-QOFs together37, optimizing evanescent waves to fully use transmitted light in longer TiO2-QOF-Low is 44–96% more efficient (in carbamazepine degradation rates and apparent quantum yields) than harvesting refracted light by using TiO2-QOF-High bundles (detailed see Supplementary Note 6E). By controlling surface patchiness and distance between fiber surface and photocatalyst coating layers, TiO2-QOF-Low not only prevent light oversaturation and its associated efficient losses, but also reduces light wasted by refraction and increase surface reactive sites. These features make TiO2-QOF-Low more energy-efficient to degrade pollutants. In addition, the 26-cm TiO2-QOF-Low used 77% fewer TiO2 than the 6.5-cm TiO2-QOF-High, although the former was 4× longer, and it had more surface areas available for photocatalytic reactions. The TiO2 coating in TiO2-QOF-Low is also stable, and there was no TiO2 coming off during the reaction (Supplementary Fig. 19).

Implications for photocatalytic reactor design

Photocatalytic processes have broad application in water and air treatment, energy production, organic synthesis, and other fields. Less than 1 in 100 papers address the critical barrier to making photocatalytic reactors more effective, namely light and energy management; the other papers focus largely on discovery of new or incremental improvement in existing photocatalyst materials10. An important but often overlooked aspect to limiting use of photocatalytic processes into engineering practice is the influence of photocatalytic reactor design, rather than material properties alone. To address the barrier of reactor design rather than material properties we show how quantum yields are effectively increased more significantly by managing the way light reaches the catalyst, than recent improvements in catalyst materials themselves. In addition to considering only refracted light in our optical fiber reactor, another key insight was the separation of photocatalyst activation by refracted light versus evanescent wave energy to activate the photocatalyst. We report for the first time here the relative importance of both mechanisms, as well as how to modulate their relative importance. Here, we developed a novel coating strategy that left 3.4% of the optical fiber surface in direct contact with TiO2 and, on-average, 114.3 nm interspace distance between the fiber surface and the coated TiO2 layers. This strategy successfully reduced refraction, generated evanescent waves in the TiO2-QOF, and thus allowed even dissipation of light along TiO2-QOF to prevent oversaturation of the light delivered to the fiber and its associated efficiency losses. The novel TiO2-QOF enables the design of a photocatalytic reactor that uses 77% less mass of photocatalysts but achieves up to 96% improvement in quantum yields compared with reactors built of fibers with densely coated TiO2 layers, mainly because optimizing evanescent waves to fully use transmitted light in longer TiO2-QOF-Low is more efficient than harvesting refracted light by using TiO2-QOF-High bundles. Moreover, such a strategy of managing evanescent wave energy is applicable to all photocatalysts and thus emerges as an important cost consideration especially when contemplating expensive photocatalysts.

A new platform can also be established using novel photocatalyst-coated optical fibers to allow evanescent wave energy to activate photocatalysts. This new platform can quantify performance of photocatalysts more precisely by minimizing the radiation scattering by photocatalysts and water parameters, preventing aggregation of photocatalysts to maximize the interaction between reactive sites and target compounds, and allowing easier and more accurate quantification of photons absorbed by photocatalysts.

Methods

Coating quartz optical fibers with TiO2 layers

Uncoated optical fibers (FT1000UMT, Thorlabs) were prepared by cutting the fibers into segments of specified lengths, stripping the buffer coating and cladding, and polishing both tips (described in Supplementary Method A). TiO2 suspension was prepared by dispersing TiO2 (P25) in double deionized water (18.2 MΩ-cm). TiO2-QOFs were fabricated by dipping the optical fiber segments in TiO2 suspension at different conditions (Table 1) to produce TiO2 layers with different area-specific TiO2 coating densities20. TiO2-QOF-High was fabricated by completing 5 cycles of dipping the segments in a 10,000 mg/L TiO2 suspension for 0.5 min and air drying for another 0.5 min. TiO2-QOF-Med was fabricated following a similar method, but with only one dip-coating/drying cycle. TiO2-QOF-Low was fabricated by dipping the segments in a 40 mg/L TiO2 suspension for 1 h followed by air drying.

Characterization of TiO2-QOFs

The images of coated and uncoated fiber surfaces were obtained by a SEM (JSM-6700F, JEOL) and an AFM (Dimension 3100, Digital Instruments). The cross-sections were prepared by a FIB following a standard preparation method38 (details in Supplementary Method B), before characterization by a TEM (JEM-100CXII, JEOL). The cross-sections were also characterized and confirmed by a 3D surface optical profilometer (Wyko NT 3300, Veeco). The TiO2 layer masses (mTiO2) on the optical fibers were measured gravimetrically by the weight of the optical fibers before and after the dip-coating/drying cycles. The porosity of the TiO2 coating layers, which is defined as the fraction of the total pore volume over the volume of the TiO2 layer, was calculated using Eq. (9).

where ρTiO2 is the true density of the TiO2 particles (4.26 g/mL at 25 °C obtained from Sigma-Aldrich), L is the TiO2 coating length, d is the diameter of optical fibers, and D is the thickness of the TiO2 coating layers, which was determined by the cross-sectional profiles of TiO2-QOFs from SEM images. The TiO2 patchiness was calculated by dividing the optical fiber surface in direct contact with TiO2 nanoparticles by the total surface of the optical fiber determining from TEM cross-section images.

Photocatalytic experiment

The photocatalytic experiment including irradiance measurement and carbamazepine degradation was conducted in a mixed batch reactor as shown in Supplementary Fig. 7. The reactor was composed of a cylindrical glass vessel (23 mL) with a length of 65 mm and an inner diameter of 25 mm, a magnetic stirrer (F203A0160, VELP) at the bottom for rapid mixing, a 365 nm LED light source (H44LV1C0, HPLighting), and an optical meter (RPS900-R, International Light Technologies). A single TiO2-QOF was fixed in the reactor with one end mounted to the LED and the other end connected to the optical meter to obtain the transmitted irradiance after the 6.5 cm light path. All the experiments were conducted in triplicate, and TiO2-QOFs were fabricated using the same preparation method in every repeated experiment. The radiant energy dissipated in the TiO2-QOFs (Edis: J) was expressed as the difference between radiant energy delivered into TiO2-QOFs (Ein) and the radiant energy transmitted to the terminal end (Eout). The radiant energy of the uncoated optical fiber measured at the terminal end in air was regarded as Ein, because light delivered into an uncoated optical fiber is totally reflected, and attenuation along the fiber is negligible in a very short propagation distance. Edis is expressed as Eq. (10).

where Ii is the irradiance measured from the optical meter (W/cm2), A is the cross-sectional area of optical fibers (cm2), and t is the irradiation duration (s). Carbamazepine concentrations were determined using a high-performance liquid chromatograph (VP series, Shimadzu) equipped with a Waters symmetry C18 column and a UV-Vis detector. The degradation kinetic was obtained by plotting carbamazepine concentration as a function of time to obtain the reaction order and rate constants (k: h−1). The quantum yields (η) of the degradation was calculated using Eq. (11).

where [CBZ]0 is the initial carbamazepine concentration (mole/L), V is the liquid volume (L), and Idis is the irradiance dissipated in the TiO2-QOFs (mol-photons/(cm2·h)).

Data availability

The authors declare that the data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Herrmann, J. M. Heterogeneous photocatalysis: fundamentals and applications to the removal of various types of aqueous pollutants. Catal. Today 53, 115–129 (1999).

Yin, R. et al. Degradation of aliphatic halogenated contaminants in water by UVA/Cu–TiO2 and UVA/TiO2 photocatalytic processes: Structure-activity relationship and role of reactive species. Chemosphere 260, 127644 (2020).

Carbonaro, S., Sugihara, M. N. & Strathmann, T. J. Continuous-flow photocatalytic treatment of pharmaceutical micropollutants: Activity, inhibition, and deactivation of TiO2 photocatalysts in wastewater effluent. Appl. Catal. B 129, 1–12 (2013).

Dalrymple, O. K., Stefanakos, E., Trotz, M. A. & Goswami, D. Y. A review of the mechanisms and modeling of photocatalytic disinfection. Appl. Catal. B 98, 27–38 (2010).

Kudo, A. & Miseki, Y. Heterogeneous photocatalyst materials for water splitting. Chem. Soc. Rev. 38, 253–278 (2009).

Lang, X., Chen, X. & Zhao, J. Heterogeneous visible light photocatalysis for selective organic transformations. Chem. Soc. Rev. 43, 473–486 (2014).

Fujishima, A., Rao, T. N. & Tryk, D. A. Titanium dioxide photocatalysis. J. Photochem. Photobiol. C. 1, 1–21 (2000).

Doll, T. E. & Frimmel, F. H. Photocatalytic degradation of carbamazepine, clofibric acid and iomeprol with P25 and Hombikat UV100 in the presence of natural organic matter (NOM) and other organic water constituents. Water Res. 39, 403–411 (2005).

Gaya, U. I. & Abdullah, A. H. Heterogeneous photocatalytic degradation of organic contaminants over titanium dioxide: A review of fundamentals, progress and problems. J. Photochem. Photobiol. C. 9, 1–12 (2008).

Loeb, S. K. et al. The technology horizon for photocatalytic water treatment: Sunrise or sunset? Environ. Sci. Technol. 53, 2937–2947 (2019).

Satuf, M. L., Brandi, R. J., Cassano, A. E. & Alfano, O. M. Quantum efficiencies of 4-chlorophenol photocatalytic degradation and mineralization in a well-mixed slurry reactor. Ind. Eng. Chem. Res. 46, 43–51 (2007).

Curcó, D., Giménez, J., Addardak, A., Cervera-March, S. & Esplugas, S. Effects of radiation absorption and catalyst concentration on the photocatalytic degradation of pollutants. Catal. Today 76, 177–188 (2002).

Blatchley, E. R. et al. Validation of large-scale, monochromatic UV disinfection systems for drinking water using dyed microspheres. Water Res. 42, 677–688 (2008).

Marinangeli, R. E. & Ollis, D. F. Photoassisted heterogeneous catalysis with optical fibers: I. Isolated single fiber. AIChE J. 23, 415–426 (1977).

Marinangeli, R. E. & Ollis, D. F. Photo-assisted heterogeneous catalysis with optical fibers II. Nonisothermal single fiber and fiber bundle. AIChE J. 26, 1000–1008 (1980).

Hofstadler, K., Bauer, R., Novallc, S. & Heisler, G. New reactor design for photocatalytic wastewater treatment with TiO2 immobilized on fused-silica glass fibers: photomineralization of 4-chlorophenol. Environ. Sci. Technol. 28, 670–674 (1994).

Peill, N. J. & Hoffmann, M. R. Development and optimization of a TiO2-coated fiber-optic cable reactor: photocatalytic degradation of 4-chlorophenol. Environ. Sci. Technol. 29, 2974–2981 (1995).

Zhang, S. et al. Design of H3PW12O40/TiO2 and Ag/H3PW12O40/TiO2 film-coated optical fiber photoreactor for the degradation of aqueous rhodamine B and 4-nitrophenol under simulated sunlight irradiation. Chem. Eng. J. 200–202, 300–309 (2012).

Choi, W., Ko, J. Y., Park, H. & Chung, J. S. Investigation on TiO2-coated optical fibers for gas-phase photocatalytic oxidation of acetone. Appl. Catal. B 31, 209–220 (2001).

Ling, L. et al. Coupling light emitting diodes with photocatalyst-coated optical fibers improves quantum yield of pollutant oxidation. Environ. Sci. Technol. 51, 13319–13326 (2017).

Danion, A., Disdier, J., Guillard, C. & Jaffrezic-Renault, N. Malic acid photocatalytic degradation using a TiO2-coated optical fiber reactor. J. Photochem. Photobiol. A 190, 135–140 (2007).

Peill, N. J. & Hoffmann, M. R. Chemical and physical characterization of a TiO2-coated fiber optic cable reactor. Environ. Sci. Technol. 30, 2806–2812 (1996).

Peill, N. J. & Hoffmann, M. R. Mathematical model of a photocatalytic fiber-optic cable reactor for heterogeneous photocatalysis. Environ. Sci. Technol. 32, 398–404 (1998).

Chen, D., Li, F. & Ray, A. K. Effect of mass transfer and catalyst layer thickness on photocatalytic reaction. AIChE J. 46, 1034–1045 (2000).

Chen, Y. et al. Study on the propagation mechanism of evanescent waves in one-dimensional periodic photonic crystal. Phys. Lett. A 379, 2257–2260 (2015).

Peatross, J. & Michael, W. Physics of Light and Optics (Brigham Young Univ. Press, 2017).

Essiambre, R. J., Tkach, R. W. & Ryf, R. in Optical Fiber Telecommunications VIB: Systems and Networks: Sixth Edition 1–43 (Academic Press, 2013).

Hui, R. & O’Sullivan, M. in Fiber Optic Measurement Techniques 1–128 (Academic Press, 2009).

Axelrod, D. Total internal reflection fluorescence microscopy in cell biology. Traffic 2, 764–774 (2001).

Sarkar, A., Robertson, R. B. & Fernandez, J. M. Simultaneous atomic force microscope and fluorescence measurements of protein unfolding using a calibrated evanescent wave. Proc. Natl Acad. Sci. USA 101, 12882–12886 (2004).

Lensun, L., Smith, T. A. & Gee, M. L. Partial denaturation of silica-adsorbed bovine serum albumin determined by time-resolved evanescent wave-induced fluorescence spectroscopy. Langmuir 18, 9924–9931 (2002).

Cragg, G. E. & So, P. T. Lateral resolution enhancement with standing evanescent waves. Opt. Lett. 25, 46–48 (2000).

Zhu, L. et al. Metal-dielectric waveguides for high efficiency fluorescence imaging. J. Phys. Chem. C. 119, 24081–24085 (2015).

Sun, J. et al. The influence of the UV/chlorine advanced oxidation of natural organic matter for micropollutant degradation on the formation of DBPs and toxicity during post-chlorination. Chem. Eng. J. 373, 870–879 (2019).

Pan, Y. et al. UV/chlorine treatment of carbamazepine: Transformation products and their formation kinetics. Water Res. 116, 254–265 (2017).

Keen, O. S., Baik, S., Linden, K. G., Aga, D. S. & Love, N. G. Enhanced biodegradation of carbamazepine after UV/H2O2 advanced oxidation. Environ. Sci. Technol. 46, 6222–6227 (2012).

O’Neal Tugaoen, H., Garcia-Segura, S., Hristovski, K. & Westerhoff, P. Compact light-emitting diode optical fiber immobilized TiO2 reactor for photocatalytic water treatment. Sci. Total Environ. 613–614, 1331–1338 (2018).

Sezen, M. in Modern Electron Microscopy in Physical and Life Sciences (IntechOpen Press, 2016).

Acknowledgements

This work was partially funded by the Hong Kong Research Grants Council (16202219 and T21-604/19-R) and the National Science Foundation (EEC-1449500) Nanosystems Engineering Research Center on Nanotechnology-Enabled Water Treatment.

Author information

Authors and Affiliations

Contributions

Y.S. and L.L. involve in the processes of conceived and designed the analysis, collected the data, contributed data or analysis tools, performed the analysis, and wrote the paper. P.W. and C.S. involve in the processes of performed the analysis and wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks Morio Nagata and the other, anonymous, reviewer for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Song, Y., Ling, L., Westerhoff, P. et al. Evanescent waves modulate energy efficiency of photocatalysis within TiO2 coated optical fibers illuminated using LEDs. Nat Commun 12, 4101 (2021). https://doi.org/10.1038/s41467-021-24370-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-021-24370-8

This article is cited by

-

Biofilm inhibition on surfaces by ultraviolet light side-emitted from optical fibres

Nature Water (2023)

-

Study of a TiO2/Ti4O7-coated plastic optic fiber photo-anode for advanced oxidation processes

Journal of Solid State Electrochemistry (2023)

-

Operando optical fiber monitoring of nanoscale and fast temperature changes during photo-electrocatalytic reactions

Light: Science & Applications (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.