Abstract

The reduced dimensionality of two-dimensional (2D) materials results in characteristic types of magnetically and electronically ordered phases. However, only few methods are available to study this order, in particular in ultrathin insulating antiferromagnets that couple weakly to magnetic and electronic probes. Here, we demonstrate that phase transitions in thin membranes of 2D antiferromagnetic FePS3, MnPS3 and NiPS3 can be probed mechanically via the temperature-dependent resonance frequency and quality factor. The observed relation between mechanical motion and antiferromagnetic order is shown to be mediated by the specific heat and reveals a strong dependence of the Néel temperature of FePS3 on electrostatically induced strain. The methodology is not restricted to magnetic order, as we demonstrate by probing an electronic charge-density-wave phase in 2H-TaS2. It thus offers the potential to characterize phase transitions in a wide variety of materials, including those that are antiferromagnetic, insulating or so thin that conventional bulk characterization methods become unsuitable.

Similar content being viewed by others

Introduction

Nanomechanical resonators made of two-dimensional (2D) materials offer interesting pathways for realizing high-performance devices1,2. Unique functionalities and phenomena emerge when combining nanomechanics with the types of magnetic and electronic phases that have recently been uncovered in 2D materials like magic-angle induced phase transitions3,4, 2D Ising antiferromagnets5 and ferromagnetism in 2D atomic layers6,7 and heterostructures8. Only a few methods are available to study these phases in 2D materials5,6,7,8,9. A universal method to characterize phase transitions in bulk crystals is via anomalies in the specific heat, that are present at the transition temperature according to Landau’s theory10. However, specific heat is difficult to measure in thin micron-sized samples with a mass of less than a picogram11,12.

We demonstrate that these phases are strongly coupled to mechanical motion: the temperature-dependent resonance frequency and quality factor of multilayer 2D material membranes show anomalies near the phase transition temperature. Although coupling between mechanical and electronic/magnetic degrees of freedom might not seem obvious, the intuitive picture behind this coupling is that changes in the electronic/magnetic order and entropy in a material are reflected in its specific heat, which in turn results in variations in the thermal expansion coefficient that affect the tension and resonance frequency. As the specific heat near a phase transition is expected to exhibit a discontinuity10, the temperature-dependent resonance frequency of a suspended membrane can thus be used to probe this transition.

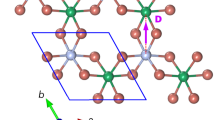

The coupling of mechanical degrees of freedom to magnetic and electronic order is attributed to thermodynamic relations. Nanomechanical resonators, therefore, offer the potential to characterize phase transitions and realize device concepts in a wide variety of systems, not restricted only to van der Waals materials but including those that are ultrathin, antiferromagnetic or insulating8. Here, we use nanomechanical motion to investigate magnetic order in membranes of semiconducting FePS3, NiPS3 and insulating MnPS3—antiferromagnetic members of the transition-metal phosphor trisulphides (MPS3)13, and subsequently discuss results on metallic 2H-TaS2, which exhibits a transition to a charge density wave state14.

Results

Antiferromagnetic mechanical resonators

FePS3 is an Ising-type antiferromagnet with a Néel temperature in bulk in the range of TN ~ 118–123 K5,13,15, exhibiting a distinct feature in its specific heat near TN15. Ionic layers in FePS3 are stacked in van der Waals planes, that can be exfoliated to thin the crystal down with atomic precision5. Using mechanical exfoliation and all-dry viscoelastic stamping16, we transfer thin flakes of FePS3 over circular cavities etched in an oxidised Si wafer, to form membranes (see the inset in Fig. 1a). Suspended FePS3 devices with thicknesses ranging from 8 to 45 nm are placed in a cryostat and cooled down to a temperature of 4 K. The resonance frequency of the nanodrums is then characterized using a laser interferometry technique17 (see Fig. 1a and “Methods”).

a Laser interferometry setup. Red interferometric detection laser: λred = 632 nm. Blue actuation laser diode: λblue = 405 nm. VNA, vector network analyzer, CM, cold mirror; PBS, polarizing beam splitter; PD, photodiode; LD, laser diode. Inset: optical image of a FePS3 membrane, including electrodes introducing an option for electrostatic control of strain in the membrane. Flake thickness: 45.2 ± 0.6 nm; membrane diameter: d = 10 μm. Scale bar: 30 μm. b–d Amplitude (A) and phase (ϕ) of the fundamental resonance at three different temperatures for the device shown in (a). Filled dots, measured data; solid lines, fit of the mechanical resonance used to determine f0 and Q17.

The resonance frequency of the fundamental membrane mode, f0(T), is measured in the temperature range from 4 to 200 K. Typical resonances are shown in Fig. 1b–d in the antiferromagnetic phase (80 K), near the transition (114 K) and in the paramagnetic phase (132 K), respectively. Figure 2a shows f0(T) of the same FePS3 membrane (solid blue curve). Near the phase transition, significant changes in amplitude, resonance frequency, and quality factor are observed.

In all panels, dashed vertical lines indicate the detected transition temperature, TN = 114 ± 3 K as determined from the peak in the temperature derivative of \({f}_{0}^{2}\). a Solid blue line—measured resonance frequency as a function of temperature. Solid magenta line—temperature derivative of \({f}_{0}^{2}\). b Solid blue line—experimentally derived specific heat and corresponding thermal expansion coefficient. Solid magenta line—the theoretical calculation of the magnetic specific heat as reported in Takano et al.15 added to the phononic specific heat from Debye model (dashed magenta line) with a Debye temperature of ΘD = 236 K15. c Mechanical quality factor Q(T) of the membrane fundamental resonance. d Solid orange line—measured mechanical damping Q−1(T) as a function temperature. Solid blue line—normalized cv(T) T term20,21 (see Supplementary equation (14)), with cv(T) taken from (b).

Resonance and specific heat

To analyze the data further, we first analyze the relation between f0 and the specific heat. The decrease in resonance frequency with increasing temperature in Fig. 2a is indicative of a reduction in strain due to thermal expansion of the membrane. The observed changes can be understood by considering the resonance frequency of a bi-axially tensile strained circular membrane:

where E is the Young’s modulus of the material, ν its Poisson’s ratio, ρ its mass density, ϵ(T) the strain and T the temperature. The linear thermal expansion coefficient of the membrane, αL(T), and silicon substrate, αSi(T), are related to the strain in the membrane18 as \(\frac{{\rm{d}}\epsilon (T)}{{\rm{d}}T}\approx -({\alpha }_{{\rm{L}}}(T)-{\alpha }_{{\rm{Si}}}(T))\), using the approximation \({\alpha }_{{{\rm{SiO}}}_{2}}\ll {\alpha }_{{\rm{Si}}}\) (see Supplementary Note 1). By combining the given expression for \(\frac{{\rm{d}}\epsilon (T)}{{\rm{d}}T}\) with equation (1) and by using the thermodynamic relation αL(T) = γcv(T)/(3KVM)19 between αL(T) and the specific heat (molar heat capacity) at constant volume, cv(T), we obtain:

Here, K is the bulk modulus, γ the Grüneisen parameter, VM = M/ρ the molar volume of the membrane and \(\mu =\frac{2.4048}{\pi d}\sqrt{\frac{E}{\rho (1-\nu )}}\), that are assumed to be only weakly temperature dependent. The small effect of non-constant volume (ν ≠ 0.5) on cv is neglected.

We use the equation (2) to analyze f0(T) and compare it to the calculated specific heat for FePS3 from literature15. In doing so, we estimate the Grüneisen parameter following the Belomestnykh − Tesleva relation \(\gamma \approx \frac{3}{2}\left(\frac{1+\nu }{2-3\nu }\right)\)19,22. This is an approximation to Leont’ev’s formula23, which is a good estimation of γ for bulk isotropic crystalline solids within ~10% of uncertainty19. Furthermore, we use literature values for the elastic parameters of FePS3 as obtained from first-principles theoretical calculations24 to derive E = 103 GPa, ν = 0.304 and ρ = 3375 kg m−3 (see Supplementary Note 2).

Detecting phase transitions

In Fig. 2a, the steepest part of the negative slope of f0(T) (solid blue curve) leads to a large peak in \(\frac{{\rm{d}}({f}_{0}^{2}(T))}{{\rm{d}}T}\) (solid magenta curve) near 114 K, the temperature which we define as TN and indicate by the vertical dashed lines. In Fig. 2b the specific heat curve of FePS3 (blue solid line) as estimated from the data in Fig. 2a and equation (2) is displayed. The results are compared to a theoretical model for the specific heat of FePS3 (magenta solid line in Fig. 2b), which is the sum of a phononic contribution from the Debye model (magenta dashed line) and a magnetic contribution as calculated by Takano et al.15. It is noted that other, e.g. electronic contributions to cv(T) are small and can be neglected in this comparison, as is supported by experiments on the specific heat in bulk FePS3 crystals15. The close correspondence in Fig. 2b between the experimental and theoretical data for cv(T) supports the applicability of equation (2). It also indicates that changes in the Young’s modulus near the phase transition, that can be of the order of a couple of percent25,26, are insignificant and that it is the anomaly in cv of FePS3 which produces the observed changes in resonance frequency and the large peak in \(\frac{{\rm{d}}({f}_{0}^{2})}{{\rm{d}}T}\) visible in Fig. 2a.

Effect of strain

The abrupt change in cv(T) of the membrane can be understood from Landau’s theory of phase transitions10. To illustrate this, we consider a simplified model for an antiferromagnetic system, like FePS3, with free energy, F, which includes a strain-dependent magnetostriction contribution (see Supplementary Note 3). Near the transition temperature and in the absence of a magnetic field it holds that:

Here, a and B are phenomenological positive constants, Lz is the order parameter in the out-of-plane direction and ζ(ϵ) = ηijϵij, a strain-dependent parameter with ηij a material-dependent tensor, that includes the strain and distance-dependent magnetic exchange interactions between neighboring magnetic moments. By minimizing equation (3) with respect to Lz, the equilibrium free energy, \({F}_{\min }\), and order parameter are obtained (see Supplementary Note 3). Two important observations can be made. Firstly, strain shifts the transition temperature according to:

where \({T}_{{\rm{N}}}^{* }\) is the Néel temperature, below which free energy minima \({F}_{\min }\) with finite order (Lz ≠ 0) appear. Secondly, since close to the transition the specific heat follows \({c}_{{\rm{v}}}(T)=-T\frac{{\partial }^{2}{F}_{\min }}{\partial {T}^{2}}\), this general model predicts a discontinuity in cv of magnitude \({T}_{{\rm{N}}}^{* }\frac{{a}^{2}}{2B}\) at the transition temperature \({T}_{{\rm{N}}}^{* }\), in accordance with the experimental jump in cv(T) and \(\frac{{\rm{d}}({f}_{0}^{2}(T))}{{\rm{d}}T}\) observed in Fig. 2a and b.

Temperature-dependent Q-factor

We now analyze the quality factor data shown in Fig. 2c, d. Just above TN, the quality factor of the resonance (Fig. 2c) shows a significant increase as the temperature is increased from 114 to 140 K. The observed minimum in the quality factor near the phase transition, suggests that dissipation in the material is linked to the thermodynamics and can be related to thermoelastic damping. We model the thermoelastic damping according to Zener20 and Lifshitz-Roukes21 that report dissipation of the form Q−1 = βcv(T) T, where β is the thermomechanical term (see Supplementary Note 4). Since we have obtained an estimate of cv(T) from the resonance frequency analysis (Fig. 2b), we use this relation to compare the experimental dissipation Q−1(T) (orange solid line) to a curve proportional to cv(T) T (blue solid line) in Fig. 2d. Both the measured dissipation and the thermoelastic term display a peak near TN ~ 114 K. The close qualitative correspondence between the two quantities is an indication that the thermoelastic damping related term indeed can account for the temperature dependence of Q(T) near the phase transition. We note that the temperature-dependent dissipation in thin membranes is still not well understood, and that more intricate effects might play a role in the observed temperature dependence.

Electrostatic strain

Equation (4) predicts that the transition temperature is strain-dependent due to the distance-dependent interaction coefficient ζ(ϵ) between magnetic moments. To verify this effect, we use an 8 ± 0.5 nm thin sample of FePS3 suspended over a cavity of 4 μm in diameter. A gate voltage \({V}_{{\rm{G}}}^{{\rm{DC}}}\) is applied between the flake and the doped bottom Si substrate to introduce an electrostatic force that pulls the membrane down and thus strains it (see Supplementary Figs. 4 and 5). As shown in Fig. 3a, the resonance frequency of the membrane follows a W-shaped curve as a function of gate voltage. This is due to two counteracting effects27: at small gate voltages capacitive softening of the membrane occurs, while at higher voltages the membrane tension increases due to the applied electrostatic force, which causes the resonance frequency to increase.

a Resonance frequency as a function of gate voltage at 50 K. Inset: schematics of the electrostatic tuning principle. b Resonance frequency as a function of temperature for six different voltages. Inset: optical image of the sample, t = 8 ± 0.5 nm. Scale bar: 16 μm. c Derivative of \({f}_{0}^{2}\) as a function of gate voltage and temperature. Blue arrow, line colors and legend indicate the values of \({V}_{{\rm{G}}}^{{\rm{DC}}}\). Dashed gray lines indicate the decrease in transition temperature \(\Delta {T}_{{\rm{N}}}={T}_{{\rm{N}}}^{* }({V}_{{\rm{G}}}^{{\rm{DC}}})-{T}_{{\rm{N}}}(0\, {\mathrm{V}})\) with increasing \({V}_{{\rm{G}}}^{{\rm{DC}}}\). d Blue solid dots—shift in TN as a function of \({V}_{{\rm{G}}}^{{\rm{DC}}}\) extracted from the peak position in (c). Vertical blue bars—error bar in ΔTN estimated from determining the peak position in (c) within 2% accuracy in the measured maximum. Orange solid line—model of electrostatically induced strain Δϵ as a function of \({V}_{{\rm{G}}}^{{\rm{DC}}}\) (see Supplementary Note 5).

Figure 3b shows f0(T) for six different gate voltages. The shift of the point of steepest slope of f0(T) with increasing \({V}_{{\rm{G}}}^{{\rm{DC}}}\) is well visible in Fig. 3b and even more clear in Fig. 3c, where the peak in \(\frac{{\rm{d}}({f}_{0}^{2})}{{\rm{d}}T}\) shifts 6 K downward by electrostatic force induced strain. The observed reduction in \({T}_{{\rm{N}}}^{* }\) as determined by the peak position in \(\frac{{\rm{d}}({f}_{0}^{2})}{{\rm{d}}T}\) qualitatively agrees with the presented model and its strain dependence from equation (4), as shown in Fig. 3d indicative of a reduced coupling of magnetic moments with increasing distance between them due to tensile strain.

Discussion

Since the coupling between specific heat and the order parameter in materials is of a general thermodynamic nature, the presented methodology is applicable to a wide variety of materials provided that elastic properties of the material and Grüneisen parameter are weakly temperature dependent, the substrate satisfies the condition αsubstrate ≪ αmaterial and that the frequency shifts and changes in Q are large enough to be resolved. We further demonstrate the method by detecting magnetic phase transitions in NiPS3 and MnPS3. Compared to FePS3, the effect of the phase transitions in MnPS3 and NiPS3 on the resonances is more gradual (see Supplementary Fig. 2) with both materials showing broader maxima in \(\frac{{\rm{d}}({f}_{0}^{2}(T))}{{\rm{d}}T}\) near their TN at 76 K and 151 K, respectively, which is consistent with measurements of bulk crystals13,15.

In order to demonstrate the detection of an electronic phase transition, we now discuss results for 2H-TaS2 that in bulk exhibits a charge density wave (CDW) transition at TCDW ~ 77 K14. Figure 4a shows a transition-related anomaly in both f0(T) (solid blue line) and the temperature derivative of \({f}_{0}^{2}(T)\) (solid magenta line) that peaks at 75 ± 3 K. We convert \(\frac{{\rm{d}}({f}_{0}^{2}(T))}{{\rm{d}}T}\) to the corresponding cv(T) using the same approach as discussed before (see Supplementary Note 6). Figure 4b shows a downward step in the specific heat at 75 K (solid blue line), indicative of a phase transition from the CDW to the disordered high-temperature state10,28 with a close quantitative correspondence to cv measured in a bulk crystal14 (drawn magenta line). This anomaly occurs near the electrically determined phase transition temperature of ~77 K on the same flake (see Supplementary Fig. 6c) and is also consistent with the CDW transition temperature previously reported in 2H-TaS214. The Q-factor also shows a local minimum with a drop next to the transition temperature (see Fig. 4c). As discussed before20,21, Q−1(T) is expected to follow the same trend as cv(T) T. Both quantities are displayed in Fig. 4d and indeed show a good qualitative correspondence.

Dashed vertical line in all 4 panels indicates the detected TCDW, that is defined by the peak in \(\frac{{\rm{d}}({f}_{0}^{2}(T))}{{\rm{d}}T}\). a Solid blue line—resonance frequency as a function of temperature. Solid magenta line—temperature derivative of \({f}_{0}^{2}\). b Solid blue line—experimentally derived cv and thermal expansion coefficient as a function of temperature (see Supplementary Note 6). Solid magenta line—specific heat of bulk 2H-TaS2 as reported in Abdel-Hafiez et al.14. Inset: optical image of the sample. Scale bar: 20 μm. c Quality factor Q(T) as a function of temperature. d Solid orange line—measured mechanical damping Q−1(T) as a function of temperature. Solid blue line—curve proportional to the term cv(T) T20,21 (see Supplementary equation (14)), with cv(T) taken from the experimental data in (b).

In conclusion, we have demonstrated that there exist a strong coupling between mechanical motion and order in ultrathin membranes of 2D materials. An analytical equation for the relation between the specific heat of the material and the temperature-dependent resonance frequency is derived and shown to be in good agreement with experimental results. Since the materials are utilized in a suspended state, substrate effects on the electronic and magnetic properties of the thin materials are excluded. The technique is not only appealing for the characterisation of ultrathin membranes of antiferromagnetic and insulating materials that are difficult to characterize otherwise, but also for the development of device concepts exploiting the unique properties of the materials involved. It is anticipated that it can be applied to a large range of van der Waals materials8,9, 2D ferromagnets29, thin 2D complex oxide sheets30,31 and organic antiferromagnets32.

Methods

Sample fabrication

To realize electrical contact to the samples for electrostatic experiments, Ti/Au electrodes are pre-patterned by a lift-off technique. Cavities are defined by reactive ion etching of circular holes with a diameter of 4–10μm in oxidized doped silicon wafers with an SiO2 thickness of 285 nm. Flakes of van der Waals crystals are exfoliated from high quality synthetically grown crystals with known stoichiometry (see Supplementary Note 7). All flakes are transferred on a pre-patterned chip by an all-dry viscoelastic stamping directly after exfoliation. Subsequently, samples are kept in an oxygen-free environment to avoid degradation. In total, data on measurements of three FePS3, one 2H-TaS2, one NiPS3 and one MnPS3 devices is presented in this manuscript.

Controlled measurement environment

The samples are mounted on a piezo-based xy nanopositioning stage inside a chamber of a closed-cycle cryostat with optical access. A closed feedback loop controlled local sample heater is used to perform temperature sweeps at a rate of ~5 K per min, while keeping the pressure in the chamber below 10−6 mbar. During the data acquisition temperature is kept constant with ~10 mK stability.

Laser interferometry

A blue diode laser (λ = 405 nm), which is power-modulated by a vector network analyzer (VNA), is used to excite the membrane and optothermally drive it into motion. Displacements are detected by focusing a red He-Ne laser beam (λ = 632 nm) on the cavity formed by the membrane and Si substrate. The reflected light, which is modulated by the position-dependent membrane motion, is recorded by a photodiode and processed by a phase-sensitive VNA. All measurements are performed at incident laser powers of Pred < 10 μW and Pblue < 0.6 μW. It is checked for all membranes that the resonance frequency changes due to laser heating are insignificant. Laser spot size is on the order of ~1 μm. The uncertainty in measured transition temperatures is estimated from determining the peak position in \(-\frac{{\rm{d}}({f}_{0}^{2}(T))}{{\rm{d}}T}\) within 2% accuracy in the measured maximum. Information about the reproducibility of measurements is available in Supplementary Note 8.

Atomic force microscopy

AFM inspections to determine sample thickness are performed in tapping mode on a Bruker Dimension FastScan AFM. We use cantilevers with spring constants of k = 30–40 N m−1. Error bars on reported thickness values are determined by measuring three to five profile scans of the same flake.

Data availability

The data that support the findings of this study are available from the corresponding authors upon request.

References

Chen, C. et al. Performance of monolayer graphene nanomechanical resonators with electrical readout. Nat. Nanotechnol. 4, 861–867 (2009).

Chen, C. et al. Graphene mechanical oscillators with tunable frequency. Nat. Nanotechnol. 8, 923–927 (2013).

Cao, Y. et al. Unconventional superconductivity in magic-angle graphene superlattices. Nature 556, 43–50 (2018).

Sharpe, A. L. et al. Emergent ferromagnetism near three-quarters filling in twisted bilayer graphene. Science 365, 605–608 (2019).

Lee, J.-U. et al. Ising-type magnetic ordering in atomically thin FePS3. Nano Lett. 16, 7433–7438 (2016).

Huang, B. et al. Layer-dependent ferromagnetism in a van der Waals crystal down to the monolayer limit. Nature 546, 270–273 (2017).

Gong, C. et al. Discovery of intrinsic ferromagnetism in two-dimensional van der Waals crystals. Nature 546, 265–269 (2017).

Gibertini, M., Koperski, M., Morpurgo, A. F. & Novoselov, K. S. Magnetic 2D materials and heterostructures. Nat. Nanotechnol. 14, 408–419 (2019).

Novoselov, K. S., Mishchenko, A., Carvalho, A. & Neto, A. H. C. 2D materials and van der Waals heterostructures. Science 353, aac9439 (2016).

Landau, L. D., Pitaevskii, L. P. & Lifshitz, E. M. Electrodynamics of continuous media, vol. 8, 2 edn. (Butterworth, New York, 1984).

Morell, N. et al. Optomechanical measurement of thermal transport in two-dimensional MoSe2 lattices. Nano Lett. 19, 3143–3150 (2019).

Dolleman, R. J. et al. Transient thermal characterization of suspended monolayer MoS2. Phys. Rev. Mater. 2, 114008 (2018).

Joy, P. A. & Vasudevan, S. et al. Magnetism in the layered transition-metal thiophosphates MPS3 (M=Mn, Fe, and Ni). Phys. Rev. B 46, 5425–5433 (1992).

Abdel-Hafiez, M. et al. Enhancement of superconductivity under pressure and the magnetic phase diagram of tantalum disulfide single crystals. Sci. Rep. 6, 31824 (2016).

Takano, Y. et al. Magnetic properties and specific heat of MPS3 (M=Mn, Fe, Zn). J. Magn. Magn. Mat. 272-276, E593–E595 (2004).

Castellanos-Gomez, A. et al. Deterministic transfer of two-dimensional materials by all-dry viscoelastic stamping. 2D Mater. 1, 011002 (2014).

Castellanos-Gomez, A. et al. Single-layer MoS2 mechanical resonators. Adv. Mater. 25, 6719–6723 (2013).

Morell, N. et al. High quality factor mechanical resonators based on WSe2 monolayers. Nano Lett. 16, 5102–5108 (2016).

Sanditov, D. S. & Belomestnykh, V. N. Relation between the parameters of the elasticity theory and averaged bulk modulus of solids. Tech. Phys. 56, 1619–1623 (2011).

Zener, C. et al. Internal friction in solids I. Theory of internal friction in reeds. Phys. Rev. 52, 230–235 (1937).

Lifshitz, R. & Roukes, M. L. Thermoelastic damping in micro- and nanomechanical systems. Phys. Rev. B 61, 5600–5609 (2000).

Belomestnykh, V. N. & Tesleva, E. P. Interrelation between anharmonicity and lateral strain in quasi-isotropic polycrystalline solids. Tech. Phys. 49, 1098–1100 (2004).

Leont’ev, K. On connection between elastic and thermal properties of substances. Akusticheskij Zhurnal 27, 554–561 (1981).

Hashemi, A., Komsa, H.-P., Puska, M. & Krasheninnikov, A. V. Vibrational properties of metal phosphorus trichalcogenides from first-principles calculations. J. Phys. Chem. C 121, 27207–27217 (2017).

Barmatz, M., Testardi, L. R. & Salvo, F. J. D. Elasticity measurements in the layered dichalcogenides TaSe2 and NbSe2. Phys. Rev. B 12, 4367–4376 (1975).

Sengupta, S., Solanki, H. S., Singh, V., Dhara, S. & Deshmukh, M. M. Electromechanical resonators as probes of the charge density wave transition at the nanoscale in NbSe2. Phys. Rev. B 82, 155432 (2010).

Lee, J. et al. Electrically tunable single- and few-layer MoS2 nanoelectromechanical systems with broad dynamic range. Sci. Adv. 4, eaao6653 (2018).

Saint-Paul, M. & Monceau, P. Survey of the thermodynamic properties of the charge density wave systems. Adv. Condens. Matter Phys. 2019, 1–14 (2019).

Jiang, S., Xie, H., Shan, J. & Mak, K. F. Two-dimensional magnetic nanoelectromechanical resonators. Preprint at https://arxiv.org/abs/2001.03153v1 (2020).

Ji, D. et al. Freestanding crystalline oxide perovskites down to the monolayer limit. Nature 570, 87–90 (2019).

Davidovikj, D. et al. Ultrathin complex oxide nanomechanical resonators. Preprint at https://arxiv.org/abs/1905.00056v1 (2019).

López-Cabrelles, J. et al. Isoreticular two-dimensional magnetic coordination polymers prepared through pre-synthetic ligand functionalization. Nat. Chem. 10, 1001–1007 (2018).

Acknowledgements

M.Š., M.L., H.S.J.v.d.Z. and P.G.S. acknowledge funding from the European Union’s Horizon 2020 research and innovation program under grant agreement number 785219 and 881603. H.S.J.v.d.Z., E.C. and S.M.-V. thank COST Action MOLSPIN CA15128; E.C. and S.M.-V. thank ERC AdG Mol-2D 788222, the Spanish MINECO (Project MAT2017-89993-R co-financed by FEDER and the Unit of Excellence ‘Maria de Maeztu’ MDM-2015-0538) and the Generalitat Valenciana (Prometeo Programme).

Author information

Authors and Affiliations

Contributions

M.Š., M.L., E.C., H.S.J.v.d.Z. and P.G.S. conceived the experiments. M.Š. performed the laser interferometry measurements. M.L. fabricated and inspected the samples. S.M.-V. and E.C. synthesized and characterized the FePS3, MnPS3, NiPS3, and 2H-TaS2 crystals. M.Š., Y.M.B., and P.G.S. analyzed and modeled the experimental data. H.S.J.v.d.Z. and P.G.S. supervised the project. The paper was jointly written by all authors with a main contribution from M.Š. All authors discussed the results and commented on the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks Kirill Bolotin and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Šiškins, M., Lee, M., Mañas-Valero, S. et al. Magnetic and electronic phase transitions probed by nanomechanical resonators. Nat Commun 11, 2698 (2020). https://doi.org/10.1038/s41467-020-16430-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-020-16430-2

This article is cited by

-

Magnetic order in 2D antiferromagnets revealed by spontaneous anisotropic magnetostriction

Nature Communications (2023)

-

Spin-mediated shear oscillators in a van der Waals antiferromagnet

Nature (2023)

-

Reversible strain-induced magnetic phase transition in a van der Waals magnet

Nature Nanotechnology (2022)

-

A monolithically sculpted van der Waals nano-opto-electro-mechanical coupler

Light: Science & Applications (2022)

-

Dynamical criticality of spin-shear coupling in van der Waals antiferromagnets

Nature Communications (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.