Abstract

Difficulties related to handling gases are a common bottleneck for applications. Although solid materials that release gas molecules under external stimuli exist, they require an external energy or a device for reliable operation. Herein, we report a CO2 stimulus for controlled release of p.p.m.-level functional gases from solid materials. A CO2-preferential anion-exchange property of layered double hydroxides and redox reactions in gas molecules are combined to release various gases (including H2S and NO) under ambient air from HS− and NO2−-incorporated layered double hydroxides, respectively. The profiles of gas release are mainly governed by the difference of pKa between H2CO3 and resulting acids (formed through protonation of interlayer anions), and are not so susceptible to the variation of relative humidity in air. Moreover, structural modulation of solid materials enables fine control of the gas release profiles. The use of safe, ubiquitous, and nearly constant (~400 p.p.m. in atmosphere) CO2 stimulus offers broad applications for functional gases.

Similar content being viewed by others

Introduction

Gas molecules play key roles in many research fields and their practical utility depends on the safety and cost-effectivity of the gas delivery system (particularly when gases are toxic, labile, or flammable)1,2,3. The use of high-pressure gas cylinders is often the source of safety concerns; therefore, solid materials that release gas molecules under external stimuli (e.g., heat, light, and vacuum) have attracted particular interest4,5,6. However, such conventional stimuli require external energy (e.g., electricity) and controlling device for reliable operation. By contrast, the use of aerial components as stimuli for gas release is attractive in that air is safe, charge-free, and available anytime anywhere. Some zeolites and metal organic frameworks that capture and release gases have been reported7,8,9. In particular, controlled release of H2S and NO is valuable for medical application, because these gases are physiologically active (i.e., they exhibit effects such as anti-inflammatory, anti-oxidative, cytoprotective, and vasodilatory effects) at p.p.m.-level concentrations but are toxic at higher concentrations and labile under air10,11,12. These solids bind gases at coordinatively unsaturated transition metal cation sites and release them under moist air through the replacement of gas molecules with water. However, the water-triggered gas-release system could be susceptible to the variation of relative humidity (RH) and long-term release of gases were, in most cases, demonstrated under fixed and low RH condition (10~20%RH)7,8. In addition, initial burst release of highly concentrated gases tends to be observed.

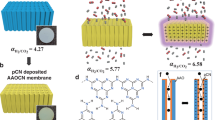

Layered double hydroxides (LDHs) are inorganic layered materials with the general formula MIIyMIII(OH)2(y+1)(Xn−)1/n·mH2O, where MII, MIII, Xn−, and mH2O are, respectively, a divalent metal cation (y is in the range of 2−4), a trivalent metal cation, an n-valent anion, and hydrated water (m depends on the humidity of the environment) (Fig. 1)13. MIIyMIII(OH)2(y+1) forms a positively charged two-dimensional (2D) layer and both charge-compensating anion (Xn−) and hydrated water (mH2O) are located within the interlayer. Previously, we reported that some conjugate anions of weak acids (e.g., acetate and carbonate) in the interlayer of Mg/Al-type LDHs tend to get exchanged with CO32− derived from aerial CO214,15,16. The CO2-stimulated anion-exchange phenomenon at the air–solid interface inspired us to explore a novel class of gas-releasing materials.

a Susceptibility of interlayer anions (Cl−, NO3−, NO2−, CO32−, acetate, and HS−) of LDHs for CO2-stimulated anion exchange, showing correlation with pKa values of the conjugate acids. Z− denotes a conjugate base of volatile weak acid. b Release of various gases (HZ, H2S, HNO2, or NO) from LDHs through anion exchange between interlayer anions (Z−, HS−, or NO2−) and aerial CO2 (eq. 1–3), disproportionation (eq. 4), and reduction (eq. 5). Note that interlayer- and aerial-H2O are available in eq. 1–3.

Herein, we report solid materials that autonomously release functional gases in response to CO2 stimulus. Anions of weak acids (Z−; pKa > ~2) involved in the interlayer of Mg/Al-type LDHs can be protonated by H2CO3 (pKa = 3.6) derived from aerial CO2 and interlayer H2O, leading to autonomous release of protic gases (HZ) (Fig. 1b, eq. 1). Interlayer HS− or NO2− in LDHs is protonated with aerial CO2 and H2O, resulting in the autonomous release of H2S or HNO2 under air (Fig. 1b, eq. 2 and 3). HNO2 is convertible to NO through an automatic disproportionation reaction or subsequent treatment with a reducing agent (Fig. 1b, eq. 4 and 5)17. Although there are some precedent reports of generating NO from NO2− through chemical reaction in solution18,19,20,21,22, NO2−-incorporated LDHs offer all-solid system for NO release. Profiles (concentration and duration) of gas release are basically dependent on the pKa of the resulting acids, because the protonation equilibrium between interlayer anions and H2CO3 (from CO2 and H2O) governs the chemical events. We also demonstrate that profiles of gas release can be controlled by various factors such as chemical composition of LDHs, diffusion of gases and ions, and chemical equilibrium. The profiles of gas release from LDH are not so susceptible to the variation of RH due to abundant water inherently present in the interlayer. This could be advantageous for release of functional gases under ambient air, because RH is quite variable from moment to moment. In contrast, concentration of CO2 in ambient air is almost constant (around ~400 p.p.m.), offering controlled release of functional gases without precise adjustment of conditions for gas release. Moreover, Mg/Al-type LDHs is transition-metal-free and biocompatible23. Thus, our low-cost and safe-to-handle materials are feasible for creating a disposable medical system for a controlled release of p.p.m.-level physiologically active gases under ambient air.

This work reveals that LDH is an attractive material for gas release and the CO2-driven system is potentially useful for expanding opportunities of utilizing functional gases in society.

Results and discussion

Synthesis and characterization of H2S-releasing LDHs

LDHs involving HS− or S2−, for H2S release, were synthesized by two-step anion-exchange reactions24. As starting materials, CO32−-type LDHs with Mg:Al ratio of 3:1 (Mg3Al(OH)8(CO32−)0.5·2H2O) and 2:1 (Mg2Al(OH)6(CO32−)0.5·2H2O) were utilized. The former is commercially available and the latter was synthesized by a hydrothermal reaction25. As CO32− of LDH is hardly exchangeable with other anions under normal anion-exchange conditions, CO32− in LDH was first replaced with Cl− using reported de-intercalation method26. Then, the resulting Cl−-type LDHs (Mg:Al = 2:1 or 3:1) dispersed in degassed deionized water were reacted with 10 equivalent (in mole) of NaHS∙nH2O or Na2S∙9H2O for 2 days under N2, as summarized in Supplementary Table 1. Solid materials were collected by filtration, washed with degassed deionized water, and then dried in vacuum (all performed under N2 atmosphere) to afford four types of products (NaHS-Mg/Al(2/1), NaHS-Mg/Al(3/1), Na2S-Mg/Al(2/1), and Na2S-Mg/Al(3/1); see Fig. 2a for a typical image). The products were preserved in a sealed pack for isolation from air (Supplementary Fig. 9). As far as we know, HS−- or S2−-incorporated LDHs produced in an inert atmosphere throughout syntheses and preservation have not been reported. Although there are some reports that claim the synthesis of HS−- or S2−-incorporated LDHs, they were synthesized and/or preserved under air27,28. As these materials are sensitive to air, their products produced without care about atmosphere must be different from ours. A scanning electron microscopy (SEM) image showed that the morphology (hexagonal plate) of LDH was maintained after multi-step anion-exchange reactions (Fig. 2b).

a Photograph of NaHS-Mg/Al(2/1) embedded on membrane filter (stored in the glass vial purged with dry N2). b SEM image of NaHS-Mg/Al(2/1) after H2S release (scale bar: 2 μm). c H2S release from NaHS-Mg/Al(2/1) confirmed by detector tube. d Powder XRD pattern of black precipitate obtained by reaction of aqueous Pb2+ with released gas. e Continuous monitoring of H2S released from LDHs under standard flow condition; 0.020 mmol of LDHs (5.0 mg of Mg/Al(2/1) and 6.25 mg of Mg/Al(3/1)) were tested. Thermogravimetry-differential thermal analysis (TG-DTA) profiles (f), IR spectra (g), and powder XRD patterns (h) of NaHS-Mg/Al(2/1) before and after H2S release. For comparison, IR and XRD data of starting materials are also shown. i Optimizing amount of NaHS∙nH2O used in preparing NaHS-Mg/Al(2/1) from 40 mg of Cl−-type LDH; 20 mg of LDH was tested under standard flow condition.

NaHS-Mg/Al(2/1) released odor characteristic to H2S for over 1 h when exposed to air [CAUTION!!] and the response of the detector tube was positive (Fig. 2c). In addition, the released gas was confirmed as H2S through the formation of PbS upon interaction with Pb2+ (Fig. 2d). Moreover, SO2 was not detected (<0.01 p.p.m.) in ~10 p.p.m. H2S by the detector tube. The concentration of H2S released from LDHs was continuously monitored by an electrochemical sensor under the standard flow conditions employed in this study (air, 50%RH, 100 mL min−1, 20 °C) and NaHS-Mg/Al(2/1) demonstrated a release of ~10 p.p.m. H2S for 2 h (Fig. 2e). On the other hand, Na2S-Mg/Al(2/1) did not release H2S. NaHS-Mg/Al(3/1) and Na2S-Mg/Al(3/1) released concentrated (over 25 p.p.m.) H2S, but the release duration was not as long as that of NaHS-Mg/Al(2/1). A release profile of NaHS-Mg/Al(2/1) can be explained by a narrow interlayer distance of Mg/Al = 2/1-type LDHs16, which suppresses the interaction between interlayer anions and aerial components.

Thermogravimetry-differential thermal analysis showed that NaHS-Mg/Al(2/1) involves HS−, which demonstrate exothermal oxidation into S2O32− at around 65–100 °C in air (Fig. 2f)27,28. In contrast, exothermal signals were not observed for Na2S-Mg/Al(2/1) at 65–100 °C, indicating that sulfur sources were not incorporated (Supplementary Fig. 10). After H2S release ceased, Fourier-transform infrared (IR) and powder X-ray diffraction (XRD) analyses of NaHS-Mg/Al(2/1) indicated that HS− was partly replaced with CO32−(Fig. 2g, h), supporting the CO2-stimulated anion-exchange mechanism. After H2S release, only a trace amount of S2O32− (1000–1200 cm−1) was observed in the IR spectrum of NaHS-Mg/Al(2/1). In contrast, NaHS-Mg/Al(3/1), which ceased H2S release within a few minutes (Fig. 2e), showed an intense IR signal from S2O32− due to HS− oxidation (Supplementary Fig. 11)28. Thus, HS− tolerance against aerial oxidation is a crucial factor for long-term release of H2S.

The amount of NaHS∙nH2O used in the synthesis of NaHS-Mg/Al(2/1)-type LDH was varied to find the optimum condition for obtaining the largest H2S release (Fig. 2i). The concentration of the released H2S increased with an increase in the amount of NaHS∙nH2O from 0.98 mg to 18.3 mg for 40 mg Cl−-type LDH and the gross release reached maximum at 36.6 mg NaHS∙nH2O (=2.6 equivalent in mole for Cl−). However, further addition of NaHS∙nH2O would reduce the gross release of H2S, presumably due to increased basicity (i.e., OH−) and impurities involved in the reaction solution.

Assuming that the chemical composition of NaHS-Mg/Al(2/1) with a maximum gross release is Mg2Al(OH)6(HS−)·2H2O (Mw = 246.8 g mol−1), 20 mg of the product involves 81 μmol of HS−, which corresponds to a release of 76 p.p.m. H2S for 240 min (under 100 mL min−1). The actual amount of H2S released from NaHS-Mg/Al(2/1) was about half the expected value (Fig. 2i), which is attributable to an incomplete anion exchange from Cl− to HS− (see Supplementary Discussion and Supplementary Fig. 21 for discussion on chemical formula of NaHS-Mg/Al(2/1)).

It is widely known that NaHS and Na2S also release odor characteristic to H2S and we confirmed that these simple salts release H2S under air (Supplementary Fig. 12). H2S has rather high pKa so that even simple salts can participate in CO2-stimulated protonation equilibrium. However, these salts are deliquescent and strongly basic (pH ≥ 12). In contrast, NaHS-Mg/Al(2/1) is non-deliquescent, insoluble in water, and nearly neutral (pH ≈ 8), even when wet with water (Supplementary Fig. 12). Moreover, LDHs offer fine control of H2S release by tuning of their chemical compositions. Mg/Al-type LDH, known as hydrotalcite, is toxic-heavy-metal-free, biocompatible, and practically utilized as an antacid drug23. These features of LDHs are advantageous for medical applications.

We note a fundamental importance of LDH in gas release. Our previous study15 revealed that interlayer CO32− of LDH is dynamically exchanging with aerial CO2, although CO32− of a simple salt (13C-labeled Na2CO3) did not exchange. The result implies that interlayer anions in LDH is activated to CO2-stimulus due to 2D structure and high affinity of LDH to CO2 (while contact of interlayer anions and aerial components is appropriately regulated). The concept is generally applicable and will guide a design of controlled release of various types of gases.

Controlled release of H2S from LDHs

To reduce the interaction between NaHS-Mg/Al(2/1) and air for longer H2S release, assembled materials with LDHs wrapped with porous tapes were prepared. About 1.1 mg of NaHS-Mg/Al(2/1), which was synthesized under the optimum conditions using 40 mg LDH and 36.6 mg NaHS∙nH2O (Fig. 2i), was sandwiched between the membrane filters and further between the porous tapes (Fig. 3a and see Supplementary Fig. 13 for details). As a result, the H2S release profile was significantly improved compared to that of the bare (i.e., noncovered) material (Fig. 3b). In addition, this patch-like assembly was effective in holding the LDH powder.

a Photograph and illustration of H2S release patches. One patch contains 1.1 mg of LDH. b–i Influences of various factor for H2S release profiles#; b patch numbers (release from noncovered sample is also shown for comparison), c flow rate of air, d humidity in air, e type of carrier gases, f humidity in N2, g CO2 concentration in dry N2, h effect of temperature and humidity, and i aging effect. #Unless noted, H2S release from two patches was tested under the standard flow condition. ##Release from four patches was halved. See Supplementary Figs. 1 and 2 for experimental set-up.

The H2S release profiles of the patch-like assembly were investigated under various conditions to probe the mechanisms and controllability of H2S release. The H2S concentration was almost proportional to the number of patches (Fig. 3b), which indicates ease of control of the gas concentration. The flow rate also affects the measured concentration: the H2S concentration was inversely proportional to the flow rate of air (Fig. 3c). This means that the quantity of H2S released from LDHs was almost constant. The RH in air did not affect so much on the concentration of H2S (under practical range; 10~87%RH), although the concentration reduced for several times under fully dry air (Fig. 3d). H2S release was not observed under dry N2 and O2 (Fig. 3e), but addition of humidity to N2 induced H2S release (Fig. 3f) due to the presence of equilibrium between interlayer HS− and H2O (i.e., [HS−]LDH + H2O → H2S↑ + [OH−]LDH). Addition of CO2 into dry N2 also caused H2S release (Fig. 3g) and it is clear that the gas release from LDHs is strongly dependent on CO2 concentration. However, CO2 concentration in air is almost constant (~400 p.p.m.), which is in contrast to RH that can change dramatically from moment to moment. In this process, the proton source must be interlayer H2O and the overall reaction is expressed as 2[HS−]LDH + CO2 + [H2O]LDH → 2H2S↑ + [CO32−]LDH. The activity of H2S release was gradually quenched when exposed to dry O2 beforehand, which is attributable to HS− oxidation (Supplementary Fig. 14). The H2S concentration was slightly increased when heated to 36 °C (Fig. 3h), presumably due to accelerated diffusion of gas molecules and anions within the interlayer. LDHs preserved in a sealed pack for six months demonstrated a rather flat and elongated H2S release (Fig. 3i). Mechanism of the aging effect could be homogenized distribution of HS− within the interlayer. In fact, the aging effect can be accelerated by thermal treatment (e.g., 60 °C for several days) (see Supplementary Discussion and Supplementary Fig. 15 and 23 for discussion on the aging effect).

Controlled release of NO from LDHs

LDHs involving NO2− were synthesized from Cl−-type LDHs (Mg:Al = 2:1 or 3:1) and NaNO2, yielding NaNO2-Mg/Al(2/1) and NaNO2-Mg/Al(3/1) (183 mg NaNO2 used for 40 mg LDHs; see Supplementary Method, Discussion, and Fig. 22 for optimization of mixing ratio and discussion on chemical formula of the product). Release of HNO2 from NaNO2-Mg/Al(3/1) under air is suggested by visible color change of Griess reagent, which is a NO2− indicator29 (Fig. 4a). The detector tube for NO + NO2 demonstrates a positive response (0.7 p.p.m.) for gases released from 100 mg NaNO2-Mg/Al(3/1) under air (Fig. 4b). It is noteworthy that the detector tube for NO + NO2 (“Tube-A”) was equipped with the strong oxidant (Cr6+ + H2SO4) part at the entry for conversion of NO to NO2 and its response should also involve the contribution of HNO2. Thus, the total concentration, NO + NO2 + HNO2, was 0.7 p.p.m. The concentration of nitrogenous gases released from LDHs was two to three orders of magnitude lower than that of H2S, because H2CO3 formed by CO2 and water can afford fewer protons to NO2− than that to HS− due to lower pKa of HNO2 ( = ~3.0)30. On the other hand, release of nitrogenous gases was much longer, and continued for at least one day, maintaining similar concentration. Besides, NO2 measured by another type of detector tube without the oxidant part (“Tube-B”) was 0.2 p.p.m. NO was measured by combining two detector tubes, as follows. First, NO2 and HNO2 were removed by detector tube “B” for NO2, which contains o-tolidine (aromatic amine) as an indicator. Here, acidic HNO2 was removed by passing through this tube, but did not change color of the tube. In fact, after this treatment, the released gas did not change color of the Griess reagent, indicating complete removal of HNO2 together with NO2. Then, NO was determined as 0.2 p.p.m. by the next detector tube, “A” for NO + NO2. Thus, HNO2 was estimated to be 0.3 p.p.m. by subtracting 0.2 p.p.m. of NO2 and 0.2 p.p.m. of NO from the total 0.7 p.p.m. The release of equal amounts (0.2 p.p.m.) of NO and NO2 indicates that these gases are derived from the disproportionation of HNO2 (eq. 4 in Fig. 1b). Release of nitrogenous gases (NO + NO2 + HNO2) under air flow (100 mL min−1) increased a little with humidity (0.5 p.p.m. at 1.8%RH, 0.7 p.p.m. at 35%RH, 1.1 p.p.m. at 82%RH, and 1.6 p.p.m. at 90%RH), but maintained similar order of concentration under practical RH (i.e., 35~90%RH).

a Color change of Griess reagent showing the presence of HNO2. b–e Concentrations of NO, NO2, and HNO2 released from 100 mg NaNO2-Mg/Al(3/1) (determined by detector tube). See Supplementary Fig. 3 for experimental details. Air (20 °C, 35%RH) or exhaled breath were applied at flow rate of 100 mL min−1. Released gases were passed through FeSO4∙7H2O and Mg(OH)2 loaded in the glass tube. f NO-release profile from 100 mg NaNO2-Mg/Al(3/1) under exhaled-breath flow (50 mL min−1). FeSO4∙7H2O was occasionally replaced with new ones (indicated by blue arrow). See Supplementary Fig. 4 for experimental details. g Tandemly connected NaNO2-Mg/Al(3/1) and FeSO4∙7H2O (in block or alternative manner) for accumulating the concentration of NO under exhaled-breath flow (50 mL min−1). Each vial contains 100 mg NaNO2-Mg/Al(3/1). The NO concentration is monitored after stabilization for 15 min.

Compared with NaNO2-Mg/Al(3/1), release of nitrogenous gases from NaNO2-Mg/Al(2/1) was considerably small in air (~0.1 p.p.m. or less) in the initial 2 h, whereas that of gases was gradually increased to ~1.5 p.p.m. when the sample was further left in air. This delayed release profile resembles the case of NaHS-Mg/Al(2/1), where the anion-exchange reaction was regulated due to the narrow interlayer space.

Exhaled breath (4.0% CO2, nearly saturated humidity, 100 mL min−1) was applied to 100 mg NaNO2-Mg/Al(3/1) for promoting protonation of interlayer NO2− (eq. 3 in Fig. 1b) and NO, NO2, and HNO2 measured by detector tubes were 1.0, 1.1, and 5.9 p.p.m., respectively (Fig. 4c). HNO2 can be reduced to NO using Fe2+ (eq. 5 in Fig. 1b)17, and insertion of the FeSO4∙7H2O column into the flow line successfully increased NO concentration to 6.6 p.p.m. (Fig. 4d). NO2 was decreased to 0.55 p.p.m., presumably due to partial reduction to NO and/or adsorption on FeSO4∙7H2O. The total amount of nitrogenous gases (NO + NO2 + HNO2) was ~7.0 p.p.m., which means that the unreacted HNO2 was negligible. The remaining NO2 could be removed down to 0.02 p.p.m. (only twice of the atmospheric level) using Mg(OH)2, a selective adsorbent for acidic gases (Fig. 4e)31,32.

Release of NO from NaNO2-Mg/Al(3/1) under exhaled breath continued over 2 weeks, as monitored by an electrochemical NO sensor, and its half-life of release was ~6 days (Fig. 4f and see Supplementary Fig. 16 for enlarged image). The NO concentration did not increase in proportion to the quantity of materials (block connection in Fig. 4g). On the other hand, when NaNO2-Mg/Al(3/1) and FeSO4∙7H2O were alternatively connected (Fig. 4g), the NO concentration could be increased in proportion to the quantity of the materials. This is because HNO2 generation reached saturation under chemical equilibrium (eq. 3 in Fig. 1b) in case of block connection, whereas HNO2 was converted to neutral NO in each step without disturbing HNO2 generation in the next step in case of the alternative connection.

The IR spectra of the as-prepared NaNO2-Mg/Al(3/1) showed an intense absorption band of NO2− at 1227 cm−1 (Supplementary Fig. 16). After the LDH was exposed to exhaled breath for 2 weeks, the NO2− signal was reduced, yet the CO32− signal at 1360 cm−1 increased. This result indicates the dominant role of the CO2-triggered anion-exchange reaction for HNO2 release. XRD analyses also supported these results (Supplementary Fig. 16).

Battery-free respirator for inhaled NO

The potential utility of the gas release system was demonstrated by creating a portable and battery-free respirator that can supply therapeutically useful quantity of NO into inhaled air. NO becomes a selective and fast-acting pulmonary vasodilator upon inhalation, and inhaled NO is a well-established method for treating respiratory distress such as persistent pulmonary hypertension of the newborn33,34,35,36. However, current inhaled NO is an advanced medical treatment since it requires a high-pressure gas cylinder, expensive medical instrument, and trained operator for controlling/monitoring the purity and dose of NO35,36. The typical concentration of NO used for treatment of respiratory distress is 5–20 p.p.m.33,34,35,36 and the respiratory volume of newborns and infants is ~0.5–2.5 L min−1. Although the NO-release systems described in Fig. 4b–g, which are based on spatially isolated LDH and a reducing agent, provided NO over two weeks, limited quantity of NO (~1 p.p.m. NO, 100 mL min−1) could be obtained from 100 mg NaNO2-Mg/Al(3/1) under air. Thus, it will require gram scale of materials to satisfy the criteria (5–20 p.p.m., 0.5–2.5 L min−1) of inhaled NO. In contrast, the results of Fig. 4g suggest that a spontaneous conversion of HNO2 into NO is effective for NO accumulation (as a result of forwarding eq. 3 in Fig. 1b). Thus, we attempted to mix NaNO2-Mg/Al(3/1) (100 mg) and FeSO4∙7H2O (1.0 g) in powder form, and found that injection of wet air (saturated humidity, 100 mL min−1) to the mixture led to release of highly concentrated NO (up to 650 p.p.m.) [CAUTION!!]. It is noted that preparation of wet air (with saturated humidity) is much easier than preparing air with other fixed humidity (e.g., 10%RH). After dilution with ambient air (4.0 L min−1), 5–16 p.p.m. NO was obtained for about 1 h (Fig. 5a). The use of Mg(OH)2 effectively reduced the concentration of contaminated NO2 to 0.03–0.075 p.p.m., which is much lower than the permissible limit of concentration determined by the U.S. Environmental Protection Agency (=1 p.p.m.)37. It is noteworthy that mixing of NaNO2 and FeSO4∙7H2O caused a burst release of NO [CAUTION!!] due to rapid reaction of NO2− and Fe2+ (Supplementary Fig. 17e).

a Concentration of NO released from the mixture of NO2−-incorporated LDH and 10 equivalent (in weight) of FeSO4∙7H2O under 4.1 L min−1 air. See Supplementary Fig. 5 for experimental set-up. b Photograph of NaNO2-Mg/Al(3/1) and FeSO4∙7H2O mixture before and after ending of NO release. c Prototype portable and battery-free respirator for inhaled NO.

The RH required to initiate NO release from the mixture was more than 60% (Supplementary Figs. 6 and 17a) and the NO concentration could be adjusted by manipulating the RH (Supplementary Fig. 17b). Moreover, we found that wet N2 is also applicable (Supplementary Fig. 17c). NO release under wet N2 indicates that it is not governed by CO2-triggered anion exchange and a plausible mechanism is that the direct anion exchange between NO2− and SO42− occurred in the mixed solids in a similar way as that reported for the anion exchange of LDHs in KBr powder38 (Supplementary Fig. 18a). Accordingly, self-reactive Fe(NO2)2 was formed outside LDHs, and then NO2− was reduced to NO by Fe2+. This hypothesis is supported by powder XRD patterns of post-release mixtures of NaNO2-Mg/Al(3/1) and FeSO4∙7H2O, showing typical XRD patterns of SO42−-type LDH (Supplementary Fig. 18b)39.

As shown in Fig. 5a, the concentration of NO release can be controlled by adjusting the amount of NaNO2-Mg/Al(3/1). Moreover, the duration of NO release is elongated using NaNO2-Mg/Al(2/1). After the release of NO, the mixture changed its color from aqua-blue to brown, implying the oxidation of Fe2+ to Fe3+ (Fig. 5b). The NO generation was further confirmed by other methods, including gas-phase IR spectroscopy and chemiluminescence (Supplementary Figs. 7, 8, 19, and 20). Moreover, NO2−-incorporated LDHs were stable at RT as long as they were kept isolated from air (Supplementary Fig. 17d).

Finally, we constructed a completely hand-operated (i.e., battery-free), disposable, and maintenance-free apparatus that can supply NO into the respirator (Fig. 5c). Wet air flow (~100 mL min−1) was delivered to the mixture of NaNO2-Mg/Al(3/1) and FeSO4∙7H2O using a hand pump and humidifier (wet cotton). After passing through Mg(OH)2, purified NO was mixed into the main air stream of the respirator. The NO concentration measured by the electrochemical sensor at the respirator was consistent with the result shown in Fig. 5a. Besides the merits described before, following are the notable technical features of our gas delivery system: (i) low risk of overdose (as far as LDH amount is adequate) and (ii) visibility of gas generation (through Fe3+ formation). In addition, if gas is released under N2 flow, the obtained gas can be stored for a while without being oxidized.

In conclusion, solid materials that release p.p.m.-level H2S and NO in response to aerial components (CO2 and H2O) are developed based on anion-exchange properties of LDHs at the solid–gas and solid–solid interfaces. The concentration and duration of gas release are controllable by adjusting various factors (composition of materials, diffusion of gas molecules and anions, and chemical equilibrium). Not only protic gases (i.e., H2S and HNO2) but also nonprotic gases (i.e., NO and NO2) can be released by combining anion-exchange and redox reactions. The concept is generally applicable and will guide a design of controlled release of various types of gases using a CO2- and H2O-affinitive confined interlayer space as a reaction vessel. A CO2-stimulus is safe, free of cost, ubiquitous and nearly constant in concentration (~400 p.p.m.) on earth; hence, LDH-based gas-release materials is advantageous for operation under ambient air and will expand opportunities of utilizing functional gases in society, including application of physiologically active gases in developing countries and outside hospital.

Reporting summary

Further information on experimental design is available in the Nature Research Reporting Summary linked to this paper.

Data availability

The data that support the finding of this study are available from the corresponding authors upon reasonable request.

References

Chu, S., Cui, Y. & Liu, N. The path towards sustainable energy. Nat. Mater. 16, 16–22 (2017).

Kumar, K. V., Preuss, K., Titirici, M.-M. & Rodríguez-Reinoso, F. Nanoporous materials for the onboard storage of natural gas. Chem. Rev. 117, 1796–1825 (2017).

Götz, M. et al. Renewable power-to-gas: a technological and economic review. Renew. Energy 85, 1371–1390 (2016).

Yu, L., Hu, P. & Chen, Y. Gas-generating nanoplatforms: material chemistry, mulitifunctionality, and gas therapy. Adv. Mater. 30, 1801964 (2018).

Yang, T., Zelikin, A. N. & Chandrawati, R. Progress and promise of nitric oxide-releasing platforms. Adv. Sci. 5, 1701043 (2018).

Pinto, M. L., Rocha, J., Gomes, J. R. B. & Pires, J. Slow release of NO by microporous titanosilicate ETS-4. J. Am. Chem. Soc. 133, 6396–6402 (2011).

Wheatley, P. S. et al. NO-releasing zeolites and their antithrombotic properties. J. Am. Chem. Soc. 128, 502–509 (2006).

Bloch, E. D. et al. Gradual release of strongly bound nitric oxide from Fe2(NO)2(dobdc). J. Am. Chem. Soc. 137, 3466–3469 (2015).

Horcajada, P. et al. Metal-organic frameworks in biomedicine. Chem. Rev. 112, 1232–1268 (2012).

Kajimura, M., Fukuda, R., Bateman, R. M., Yamamoto, T. & Suematsu, M. Interactions of multiple gas-transducing systems: hallmarks and uncertainties of CO, NO, and H2S gas biology. Antioxid. Redox Signal. 13, 157–192 (2010).

Wallace, J. L. Hydrogen sulfide-releasing anti-inflammatory drugs. Trends Pharmacol. Sci. 28, 501–505 (2007).

Napoli, C. & Ignarro, L. J. Nitric oxide-releasing drugs. Annu. Rev. Pharmacol. Toxicol. 43, 97–123 (2003).

Duan, X. & Evans, D. G. (eds) Layered Double Hydroxide (Springer, Heidelberg, 2006).

Iyi, N., Ebina, Y. & Sasaki, T. Water-swellable MgAl-LDH (layered double hydroxide) hybrids: synthesis, characterization, and film preparation. Langmuir 24, 5591–5598 (2008).

Ishihara, S. et al. Dynamic breathing of CO2 by hydrotalcite. J. Am. Chem. Soc. 135, 18040–18043 (2013).

Sahoo, P. et al. Rapid exchange between atmospheric CO2 and carbonate anion intercalated within magnesium rich layered double hydroxide. ACS Appl. Mater. Interfaces 6, 18352–18359 (2014).

Cotton, F. A. & Wilkinson, G. Advanced Inorganic Chemistry 4th edn. (John Wiley & Sons, Inc., New York, 1980).

Frost, M. C., Reynolds, M. M. & Meyerhoff, M. E. Polymers incorporating nitric oxide releasing/generating substances for improved biocompatibility of blood-contacting medical devices. Biomaterials 26, 1685–1693 (2005).

Neufeld, M. J., Harding, J. L. & Reynolds, M. M. Immobilization of metal-organic framework copper (II) benzene-1,3,5-tricarboxylate (CuBTC) onto cotton fabric as a nitric oxide release catalyst. ACS Appl. Mater. Interfaces 7, 26742–26750 (2015).

Russell, S. E., Carballo, J. M. G., Orellana-Tavra, C., Fairen-Jimenez, D. & Morris, R. E. A comparison of copper and acid site zeolites for the production of nitric oxide for biomedical applications. Dalton Trans. 46, 3915–3920 (2017).

Doyle, R. A., Russell, S. E. & Morris, R. E. Nitric oxide production from nitrite by a series of zeolites produced via the ADOR route. Micropor. Mesopor. Mater. 280, 367–371 (2019).

Qin, Y. et al. Portable nitric oxide (NO) generator based on electrochemical reduction of nitrite for potential applications in inhaled NO therapy and cardiopulmonary bypass surgery. Mol. Pharmaceutics 14, 3762–3771 (2017).

Choy, J.-H., Choi, S.-J., Oh, J.-M. & Park, T. Clay minerals and layered double hydroxides for novel biological applications. Appl. Clay Sci. 36, 122–132 (2007).

Ma, S. et al. Highly efficient iodine capture by layered double hydroxides intercalated with polysulfides. Chem. Mater. 26, 7114–7123 (2014).

Iyi, N., Matsumoto, T., Kaneko, Y. & Kitamura, K. A novel synthetic route to layered double hydroxides using hexamethylenetetramine. Chem. Lett. 33, 1122–1123 (2004).

Iyi, N., Yamada, H. & Sasaki, T. Deintercalation of carbonate ions from carbonate-type layered double hydroxides (LDHs) using acid-alcohol mixed solutions. Appl. Clay Sci. 54, 132–137 (2011).

Ogawa, M. & Saito, F. Easily oxidizable polysulfide anion occluded in the interlayer space of Mg/Al layered double hydroxide. Chem. Lett. 33, 1030–1031 (2004).

Sato, M., Kuwabara, H. & Saito, S. Characterization of anion exchanged hydrotalcite and determination of the site of exchanged SO4 group. Clay Sci. 8, 309–317 (1992).

Hetrick, E. M. & Schoenfisch, M. H. Analytical chemistry of nitric oxide. Annu. Rev. Anal. Chem. 2, 409–433 (2009).

Silva, G., da, Kennedy, E. M. & Dlugogorski, B. Z. Ab initio procedure for aqueous-phase pKa calculation: the acidity of nitrous acid. J. Phys. Chem. A 110, 11371–11376 (2006).

Sada, E., Kumazawa, H. & Butt, M. A. Single and simultaneous absorptions of lean SO2 and NO2 into aqueous slurries of Ca(OH)2 or Mg(OH)2 particles. J. Chem. Eng. Jpn. 12, 111–117 (1979).

Rezaei, F., Rownaghi, A. A., Monjezi, S., Lively, R. P. & Jones, C. W. SOx/NOx removal from fuel gas streams by solid adsorbents: a review of current challenges and future directions. Energy Fuels 29, 5467–5486 (2015).

Rossaint, R. et al. Inhaled nitric oxide for the adult respiratory distress syndrome. N. Eng. J. Med. 328, 399–405 (1993).

Roberts, J. D., Jr. et al. Inhaled nitric oxide and persistent pulmonary hypertension of the newborn. N. Eng. J. Med. 336, 605–610 (1997).

Yu, B., Ichinose, F., Bloch, D. B. & Zapol, W. M. Inhaled nitric oxide. Br. J. Pharmacol. 176, 246–255 (2019).

Yu, B., Muenster, S., Blaesi, A. H., Bloch, D. B. & Zapol, W. M. Producing nitric oxide by pulsed electrical discharge in air for portable inhalation therapy. Sci. Transl. Med. 7, 294ra107 (2015).

Centers for Disease Control and Prevention. 1988 OSHA PEL Project Documentation (Centers for Disease Control and Prevention, Atlanta, GA, 1988).

Iyi, N., Geng, F. & Sasaki, T. Effect of KBr on the FTIR spectra of NO3 −LDHs (layered double hydroxides). Chem. Lett. 38, 808–809 (2009).

Iyi, N., Fujii, K., Okamoto, K. & Sasaki, T. Factors influencing the hydration of layered double hydroxides (LDHs) and the appearance of an intermediate second staging phase. Appl. Clay Sci. 35, 218–227 (2007).

Acknowledgements

This study was partly supported by a collaboration research grant from Sumitomo Seika Chemicals, Co. Ltd and JSPS KAKENHI (Grant Number 18H02016). Mr Daisuke Misho, Mr Noriyuki Hayashizaka, Mr Shunji Oyama, and Mr Shigeki Sakaue (Sumitomo Seika Chemicals, Co. Ltd) are acknowledged for fruitful discussion. Dr Ya Xu (NIMS) is grateful for supporting NO analysis. Ms Kumiko Hara and Ms Reiko Takano are acknowledged for assisting research.

Author information

Authors and Affiliations

Contributions

S.I. and N.I. designed the research, performed experiments, and wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

NIMS and Sumitomo Seika Chemicals, Co. Ltd filed a joint patent on H2S-releasing materials, and NIMS solely filed a patent on NOx-releasing materials and systems.

Additional information

Peer review information Nature Communications would like to thank Alirio Rodrigues and other, anonymous, reviewers for their contributions to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ishihara, S., Iyi, N. Controlled release of H2S and NO gases through CO2-stimulated anion exchange. Nat Commun 11, 453 (2020). https://doi.org/10.1038/s41467-019-14270-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-019-14270-3

This article is cited by

-

Incorporation of tetracarboxylate ions into octacalcium phosphate for the development of next-generation biofriendly materials

Communications Chemistry (2021)

-

Nanocomposite-based dual enzyme system for broad-spectrum scavenging of reactive oxygen species

Scientific Reports (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.