Abstract

The intercalation strategy has become crucial for 2D layered materials to achieve desirable properties, however, the intercalated guests are often limited to metal ions or small molecules. Here, we develop a simple, mild and efficient polymer-direct-intercalation strategy that different polymers (polyethyleneimine and polyethylene glycol) can directly intercalate into the MoS2 interlayers, forming MoS2-polymer composites and interlayer-expanded MoS2/carbon heteroaerogels after carbonization. The polymer-direct-intercalation behavior has been investigated by substantial characterizations and molecular dynamic calculations. The resulting composite heteroaerogels possess 3D conductive MoS2/C frameworks, expanded MoS2 interlayers (0.98 nm), high MoS2 contents (up to 74%) and high Mo valence (+6), beneficial to fast and stable charge transport and enhanced pseudocapacitive energy storage. Consequently, the typical MoS2/N-doped carbon heteroaerogels exhibit outstanding supercapacitor performance, such as ultrahigh capacitance, remarkable rate capability and excellent cycling stability. This study offers a new intercalation strategy which may be generally applicable to 2D materials for promising energy applications.

Similar content being viewed by others

Introduction

To meet ever-increasing energy demands, the exploration of advanced electrode materials has been triggered for developing state-of-the-art energy storage devices. Among various energy storage devices, supercapacitors are promising due to ultrahigh power output and ultralong operating lifetime1. There are two different working mechanisms in supercapacitors, including electrochemical double layer capacitive (EDLC) energy storage2,3 and pseudocapacitive (PC) energy storage4. The first mechanism is realized through physically adsorbing opposing electrolyte charges in two electrodes, featuring high power and long cycling life, while the latter relates to fast and reversible redox reactions occurring over electrodes, significantly elevating the capacitance and meanwhile maintaining high rate capability. The mechanisms are largely determined by the electrode materials employed and play a decisive role in the performance of supercapacitors. When the two mechanisms work together in a supercapacitor, a high comprehensive performance is expected due to their synergistic effect. However, supercapacitors are still suffering from low energy densities, which is an obstacle for their practical applications. Current efforts mainly focus on the development of high-capacitance supercapacitors with simultaneous high power. To achieve high specific capacitance, electrode materials should be designed with high porosity, good electrical conductivity, and especially, feasible redox reactions for efficient PC energy storage.

Recently, MoS2 nanosheets, an analogue of graphene with a two-dimensional layered nanostructure, have attracted tremendous attention for supercapacitors due to their unique structural and electronic properties5,6,7. Specifically, MoS2 nanosheets are stacked by S–Mo–S monolayers via weak van der Waals forces along the c axis, which allows easy intercalation of foreign ions (H+, K+, NH4+) for interlayer charge storage8. In addition, the central Mo ions hold a range of oxidation states from +2 to +6, exhibiting great potential in high-capacitance PC storage9. However, the performance of MoS2-based supercapacitors is still limited by the poor electrical conductivity and few accessible active sites of MoS2. Considerable efforts have been made to either improve the conductivity of MoS2 by integrating conductive carbon materials (graphene10,11,12,13, carbon nanotubes14,15,16,17, and conducting polymers18,19,20), or expose more active sites of MoS2 nanosheets through intercalation using small molecules or ions. In particular, further strategies combining the above mentioned two solutions to simultaneously increase conductivity and extended interlayer of MoS2 have also been developed for the preparation of MoS2/carbon composites21,22. Conventionally, the synthesis strategies can be categorized as “top-down” and “bottom-up” by employing polymers as both carbon sources and intercalation agents, as depicted in Fig. 1a, b. The “top-down” strategy involves the first exfoliation of existing MoS2 by intercalation of small molecules or ions, followed by the mixing and restacking of MoS2 monolayers and polymers, which often accompanies with the formation of highly unstable and flammable intermediates15,23,24,25,26,27. The “bottom-up” strategy was realized through the in situ nucleation and growth of MoS2 monolayers on polymer molecules (polyaniline, polyvinyl pyrrolidone, polyethylene oxide, etc.), which requires precise control of polymer-mediated crystal growth in thermodynamics and dynamics to avoid the formation of bulk MoS2 and phase separation between MoS2 and polymers28,29,30,31,32,33,34,35. Despite great progress, it is noted that the conventional strategies are often associated with complicated approaches such as extra intercalation manipulation or harsh growth conditions. In addition, the resulting MoS2/carbon composites are usually in the form of powders, especially when the MoS2 active material is in high content (over 50%) in the composites, which may lead to a high contacting resistance as well as an unstable and ineffective ion diffusion pathway caused by the aggregation of MoS2. Therefore, it is highly desirable to develop a new, simple, and efficient strategy for constructing MoS2/carbon composites with architectures/nanostructures that are favorable for high-performance supercapacitors.

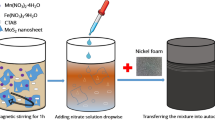

Comparison of different strategies and the polymer direct intercalation. a–c The schematic illustrations show the conventional synthetic strategies to realize interlayer-expended MoS2 (a, b) and the polymer-direct-intercalation (PDI) strategy for the synthesis of a MoS2/NC heteroaerogel (c) to prepare interlayer-expended MoS2/carbon composites. d The schematic illustration for the synthetic procedure of the MoS2/NC heteroaerogel. e–g Optical photographs of the as-synthesized pre-intercalated MoS2 nanosheets (e), the MoS2-PEI (PEI, Mw = 600) composite after freeze-drying (f), and the MoS2/NC heteroaerogel after carbonization (g). Insets of (e–g) show the corresponding SEM images with scale bars of 100 nm

In this work, we propose a novel polymer-direct-intercalation (PDI) strategy to construct three-dimensional (3D) MoS2/N-doped carbon (MoS2/NC) composite heteroaerogels assembled by layered MoS2/carbon heteronanosheets for ultrahigh-capacitance supercapacitors. The strategy, which is simple, mild, and efficient, is realized at room temperature by direct intercalation of polymer molecules into the interlayers of prepared MoS2 nanosheets (Fig. 1c), followed by carbonization treatment. The resulting MoS2/NC heteroaerogels possess a 3D conductive N-doped MoS2/C framework, an overlapped MoS2/C-layered hetero-interface and expanded interlayers of MoS2 nanosheets, conducive not only to fast and stable charge transfer/diffusion, but also enhanced ion intercalation pseudocapacitance. Moreover, when employed as electrodes for supercapacitors, the MoS2/NC heteroaerogel with a high content of MoS2 (up to 74%) and a high valence (+6) of central Mo ions can deliver an ultrahigh specific capacitance of 4144 F g−1 at 1 A g−1, remarkable rate capability (2483 F g−1 at a drastically increased current density of 10 A g−1), and excellent cycling stability with a capacitance loss of ~8% after 8000 cycles at 10 A g−1.

Results

Synthesis of the MoS2/N-doped carbon heteroaerogel

Figure 1d shows the typical preparation procedure of the MoS2/NC composite aerogel by polymer (polyethyleneimine, PEI, Mw = 600, 1800, 10,000, 70,000) direct intercalation. First, pre-intercalated MoS2 nanosheets with interlayer distance of ~10.0 Å were synthesized hydrothermally with the assistance of ammonium and then were mixed with PEI at room temperature for intercalation. It is noted that the pre-intercalated MoS2 nanosheets are in the form of powder and can be produced in a large amount. The pre-intercalated MoS2 nanosheets are intertwined and stacked into a 3D network (scanning electron microscope (SEM) image, inset in Fig. 1e) with a relatively high specific surface area of ~99.99 m2 g−1 (Supplementary Fig. 1a). The pre-intercalated MoS2 nanosheets were detected to possess a negative charge surface (zeta potential −30.4 mV, Supplementary Fig. 2) in neutral aqueous solution. Therefore, PEI was preferentially selected as the intercalator owing to the strong electrostatic interaction between its positively charged NH2+ groups and negatively charged MoS2 nanosheets. As a result, PEI molecules readily adsorbed on the surface of MoS2 nanosheets and inserted into the interlayers of MoS2 nanosheets assisted with the ultrasonic treatment. With intercalation, an aerogel-like 3D MoS2-PEI (PEI, Mw = 600) composite instead of powder was formed after freeze-drying due to the linkage of PEI molecules between MoS2 nanosheets, showing a cylinder-like shape with a diameter of ~2.5 cm and a height of ~3 cm (Fig. 1f). The coating of PEI on MoS2 nanosheets was clearly visible (inset of Fig. 1f). Finally, the MoS2/NC heteroaerogel with the expended MoS2 interlayers was obtained through in situ transformation of the MoS2-PEI composite at 800 °C. The shape of the MoS2/NC heteroaerogel was well preserved compared with its MoS2-PEI precursor, despite slight volume shrinkage (Fig. 1g). The tap density of the MoS2/NC heteroaerogel was calculated to be approximately 0.1263 g cm−3, which makes the aerogel stand freely on a Fatsia japonica flower36. Furthermore, thanks to a variety of stacked pores, the MoS2/NC heteroaerogel exhibits a 3D porous architecture (inset of Fig. 1g) and possesses a specific surface area of ~120.4 m2 g−1 (Supplementary Fig. 1b), slightly higher than that of the pure MoS2 due possibly to more exposed interlayer surface through the intercalation and the contribution of the carbon component.

Structure and composition of the MoS2/N-doped carbon heteroaerogel

A high-resolution transmission electron microscopy (HRTEM) image of the MoS2/NC heteroaerogel in Fig. 2a shows that MoS2 nanosheets are in few layers, showing a tangled and distorted morphology with an expanded interlayer distance of ~0.98 nm, which confirms a graphene-like carbon monolayer inserting into MoS2 interlayers30. The possible mechanism forming graphene-like carbon monolayers in the MoS2 interlayers after carbonization is discussed (Supplementary Note 1). In addition, a thin carbon layer is also observed on the surface of MoS2 nanosheets induced by the adsorption and subsequent in situ carbonization of PEI on MoS2 nanosheets, indicating the formation of an interconnected network of graphitized carbon throughout the heteroaerogel. It is also found that the crystal lattices in (002) plane of MoS2 nanosheets also are distorted to some extent, caused by the introducing foreign atoms (N, C) onto the surface or into interlayers of MoS2 nanosheets, as shown in Fig. 2b. Figure 2c shows the TEM image of pristine MoS2 nanosheets obtained after thermal treatment. Differently, the MoS2 nanosheets show a clean surface, consisting of orderly arranged thin monolayers with a normal displacing of ~0.62 nm for (002) plane10,37. In addition, a regular atomic arrangement in (002) plane with the lattice distance of 0.25 nm, corresponding to the (101) plane of MoS230 (Fig. 2d). The results above indicate that the graphitized carbon stably exists both in the interlayers and on the surface of MoS2 nanosheets through the direct intercalation of PEI. We further employed energy dispersive X-ray spectrometry (EDS) to analyze the chemical composition of the MoS2/NC heteroaerogel. EDS data reveals that Mo, S, C, and N elements coexist and distribute uniformly throughout the whole heteroaerogel (Supplementary Figs. 3, 2e), further verifying the successful formation of the MoS2/NC heteroaerogel. The above results demonstrate that the direct intercalation strategy is effective, which enables not only the adsorption of PEI molecules onto MoS2 nanosheets, but also the intercalation into the interlayers of MoS2 nanosheets. The PEI molecules on the surface of MoS2 nanosheets in the MoS2–polymer composites serve as an interconnected polymer chain network to stabilize the shape and structure of the aerogel-like MoS2–polymer composites. After carbonization, these interconnected PEI molecules converted in situ to graphitized carbon layers on the surface of MoS2 and interconnected carbon networks, accompanying with the formation of the MoS2/NC heteroaerogels.

Characterization of the MoS2/NC heteroaerogel and MoS2 nanosheets. a–d TEM images of the MoS2/NC heteroaerogel derived from the intercalation of PEI (Mw = 600) (a, b) and the annealed MoS2 nanosheets (c, d). Insets of (b, d) show the corresponding SAED patterns. e SEM-EDS mapping images of the MoS2/NC heteroaerogel. f XRD patterns of the MoS2 nanosheets and MoS2-PEI composite obtained after freeze-drying. g XRD patterns of MoS2/NC heteroaerogel obtained after thermal treatments. Scale bars: a, c 5 nm; b, d 1 nm; e 1 µm

To systematically investigate the PEI direct-intercalation behaviors, X-ray diffraction (XRD) characterization was applied to the pre-intercalated MoS2 nanosheets and MoS2–PEI composite, as well as their corresponding annealed MoS2 nanosheets and carbonized products of the MoS2/NC heteroaerogel (Fig. 2f, g). The pre-intercalated MoS2 and the MoS2–PEI composite show typical XRD diffraction peaks at 33°, 44°, and 59° assigned to the (101), (103), and (110) planes of the hexagonal-phase MoS2 (JCPDS No. 89-5112), respectively. However, the peaks corresponding to (002) plane for the two samples emerge both at lower-angle positions relative to that of the standard MoS2 (JCPDS No. 89-5112), showing increased interlayer distances of 10.0 and 10.8 Å, respectively (Fig. 2f and inset). In addition, (004) peaks corresponding to half distance of MoS2 interlayers also appear for the two samples. The increase in d-spacing of (002) plane for the pre-intercalated MoS2 and MoS2–PEI composite is ascribed to the intercalation of Na+/NH4[+22 and PEI molecules into the MoS2 interlayers, respectively. However, after the thermal treatments, the annealed MoS2 and the MoS2/NC samples obtained from the pre-intercalated MoS2 and MoS2–PEI composite exhibit remarkable difference in final interlayer distance. For the annealed MoS2, the interlayer distance is reduced to 6.2 Å at ~14° (Fig. 2g), corresponding to the standard value of the normal MoS2, which indicates that the inserted NH4+ ions in the layers of pre-intercalated MoS2 were released at a higher temperature over 200 °C38,39. Nevertheless, for the MoS2/NC heteroaerogel, the interlayer distance of MoS2 was reduced to 9.8 Å (Fig. 2g), a value according with that of graphene-inserted MoS2 nanosheets30, confirming the existence of a graphene-like carbon layer in the interlayers of MoS2 induced by the in situ carbonization of PEI. Raman spectroscopy tests also confirmed the formation of the MoS2/NC heteroaerogel, as shown in Supplementary Fig. 4. It can be seen that Raman spectrum of the annealed MoS2 shows two distinct peaks at 376.5 and 402.6 cm−1 ascribed to the typical E12g (the in-plane displacement of Mo and S atoms), and A1g vibration modes (out-of-plane symmetric displacement of S atom along the c axis) of MoS2. However, for the MoS2/NC heteroaerogel, the two peaks shift to 378.1 and 400.2 cm−1, respectively. The blue shift of E12g peak and the red shift of A1g peak are particular signals induced by the carbon insertion40,41. Besides, the other two peaks centered at ~1350.1 and ~1590.9 cm−1 corresponding to the typical D and G bands of graphitized carbons are also observed. The mass ratio of MoS2 and carbon components was measured to be 74:26 based on thermal gravimetric analysis (TGA) method (Supplementary Fig. 5), during which carbon was completely removed and MoS2 was oxidized completely to MoO312,42. The carbon content (26%) in the heteroaerogel is contributed by both the carbon in the interlayers and on the surface of MoS2 nanosheets.

Influence of content of polyethyleneimine intercalator

The influence of some key factors such as content and molecular weight (Mw) of PEI on the direct-intercalation behavior and the structure of resulted MoS2/NC composites was investigated. Supplementary Fig. 6 shows XRD patterns of MoS2–PEI composites after the intercalation of PEI with different mass percentages of 16.7–50 wt%, and their corresponding MoS2/NC composites after carbonization. It is noted that the mass percentage of 44.4 wt% is the typical condition for the direct intercalation of PEI and the preparation of the MoS2/NC heteroaerogel that have been discussed above. In Supplementary Fig. 6a, the (002) peaks with an expanded d-spacing of 10.8 Å are observed in the corresponding XRD patterns of all the four samples of MoS2–PEI composites, indicating the effective intercalation of PEI molecules with the various contents. After annealing treatments, the d-spacings of (002) peaks for all the samples are reduced, yet to different extents (Supplementary Fig. 6b). The MoS2/NC sample derived from a higher PEI content (50 wt%) shows a similar (002) plane d-spacing of 9.8 Å to the typical sample (44.4 wt% PEI), indicating the successful insertion of a graphene layer into MoS2 nanosheets. However, the high PEI content led to the excessive coating of graphitized carbon on the surface of MoS2 nanosheets after carbonization, which may suppress the peak intensity of MoS2, as shown in Supplementary Fig. 6b. For the samples derived from lower PEI contents (33.3 and 16.7 wt%), their corresponding d-spacings of (002) plane are reduced partially or completely to 6.2 Å, the normal d-spacing value of (002) plane of the standard MoS2 nanosheets. The results demonstrate that small amounts of PEI may be prone to be expelled out from the interlayers of MoS2 nanosheets in the MoS2–PEI composites during the carbonization process at high temperatures. Therefore, sufficient PEI is necessary for the preparation of MoS2/NC heteroaerogel with expended interlayers of MoS2 nanosheets via the direct-intercalation strategy. Supplementary Fig. 7 shows XRD patterns of MoS2–PEI composites and their corresponding MoS2/NC composites prepared by using PEI with different molecular weights.

Influence of molecular weight and type of polymer intercalators

Interestingly, it is found that PEI with a wide range of molecular weight from 600 to as high as 70,000, can direct intercalate into the interlayers of MoS2 nanosheets (Supplementary Fig. 7a) and exist stably as graphene layers in the MoS2 interlayers after carbonization (Supplementary Fig. 7b), leading to the formation of the novel MoS2/NC composites. The D, G bands are clearly observed for all the samples, indicating the graphitization of the carbon component in the composites (Supplementary Fig. 8). In contrast, the highest peak intensity ratios, 2.21 and 1.38, of (002)/(101) are obtained for the MoS2-PEI composite and its corresponding MoS2/NC composite derived from the intercalation of PEI (Mw 600), respectively, indicating the best intercalation effect (Supplementary Fig. 7c). Generally speaking, polymers with a higher molecular weight and a longer chain are more difficult to intercalate into interlayers of MoS2 nanosheets. The realization of direct intercalation of PEI may be attributed to the relatively expended interlayer distance (10 Å) of the pre-intercalated MoS2 nanosheets and the electrostatic force between the cationic PEI and the negatively charged MoS2. To extend the scope of the PDI strategy, polyethylene glycol (PEG) which contains oppositely charged –OH groups was employed and systematically investigated with the influence of its content and molecular weight on the direct intercalation behavior and the formation of MoS2/carbon (MoS2/C) composites (Supplementary Figs. 9–12). The results indicate that PEG with different molecular weights of 400–20,000 can also serve as an effective intercalator, resulting in a much larger MoS2 interlayer distance of 15.6 Å for MoS2–PEG composites and a similar interlayer distance of 9.8 Å for the MoS2/C composites after carbonization (Supplementary Fig. 11). The detailed information regarding direct intercalation by PEI and PEG and the finally resulted MoS2/NC and MoS2/C products is summarized in Supplementary Tables 1 and 2.

We noted that the sonication applied in the intercalation process can cause the degradation of polymers, forming lower molecular weight polymers43,44,45 or even small molecules such as oligomers that may intercalate into interlayers of MoS2 and result in interlayer expansion. To confirm the intercalation effect is contributed by polymers rather than oligomers generated during sonication of polymers, systematic experiments and measurements using gel permeation chromatography (GPC) and liquid chromatography-mass spectrometry (LC-MS) were conducted (Supplementary Figs. 13–16 and Supplementary Tables 3, 4).

Molecular dynamics calculations

The intercalation of 2D layered materials by using ions or small molecule (Li+, Na+, NH4+, glucose, etc.) has been well studied13,23,24,25,26,27. However, the direct intercalation by polymers has been rarely reported. To explore the configurations of polymer-intercalated MoS2 molecular layers and understand how polymers diffused into MoS2 interlayers, ab initio molecular dynamics (AIMD) calculations were performed (Supplementary Note 2). Figure 3a, b shows the configurations of PEI-intercalated MoS2 with a interlayer distance of 10.8 Å, where a 3D periodic boundary box of 26.58 × 26.58 × 14 Å3 is adopted. The calculation results reveal that, 5 PEI molecules together with 18 H2O molecules and 17 NH4+ ions arranging in an initial ordered state and a final relaxed state between the two adjacent monolayers of MoS2 nanosheets can both give an interlayer distance of 10.8 Å, agreeing with the experimental value. Similarly, two different configurations with a selected periodic boundary box of 26.58 × 26.58 × 19 Å3 containing 5 PEG molecules, 18 H2O molecules, and 17 NH4+ ions are illustrated for PEG-intercalated MoS2, showing a calculated interlayer distance of 15.6 Å (Supplementary Fig. 17a, b).

Molecular dynamics calculations. a, b Schematic illustration shows configurations of PEI-intercalated MoS2 with the resulted interlayer distance of 10.8 Å: a an initial ordered state; b the final relaxed state. c–f Illustration of PEI molecule intercalation process with the MoS2 interlayer distance of 10 Å: c 0 ps, d 4 ps, e 6 ps, f 7 ps

We further performed AIMD to simulate the diffusion process of the polymers intercalating into MoS2 interlayers. The simulation was carried out in a periodic boundary box of 23.06 × 40.48 × 13.22 Å3. In the Y direction, about 20 Å vacuum is added to simulate the edge of MoS2. The interlayer distance of MoS2 nanosheets is about 10 Å, which is close to our experiment measurement. As shown in Fig. 3c–f and Supplementary Movie 1, a PEI molecule is initially placed outside near the MoS2 layers (Fig. 3c, 0 ps). Then, the NH2 group in the PEI molecule is attached to the sulfur site on the MoS2 edge (Fig. 3d, 4 ps). From 6 ps on, the molecule starts to intercalate into MoS2 layers (Fig. 3e). Eventually, the PEI molecule fully enters the interlayer (Fig. 3d, 7 ps). Similarly, for the PEG case, due to the interaction of the OH group and the edge of MoS2, the molecule first attaches with edge, then the molecule gradually enters the interlayers of MoS2 (Supplementary Fig. 17c–f and Supplementary Movie 2). The intercalation process of the polymers consists of two steps: the first is the interaction between polymer molecules and the edge of MoS2 which shorten the distance between the polymer and MoS2. And the second, the interaction of the polymer molecule with the MoS2 attracts the molecule entering the interlayer. From our static calculations, the binding energy (BE) of a single molecule of PEG and PEI with MoS2 is about −1.53 and −1.76 eV, respectively.

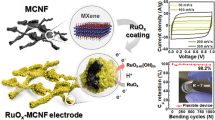

Electrochemical performance. a–c CV curves at 5 mV s−1 (a), galvanostatic charging–discharging curves at 1 A g−1 (b), and specific capacitances at different current densities from 1 to 10 A g−1 (c) of MoS2 nanosheets, and the MoS2/C and MoS2/NC heteroaerogels. d Cycling performance at a current density of 10 A g−1 of the MoS2/NC heteroaerogel. The inset in (d) shows charging–discharging curves of the last 5 cycles. e Nyquist plots of the three electrodes. f Dependence of the peak current density on square root of sweep rate of the MoS2/NC heteroaerogel

It is noted that, the equilibrium interlayer distances induced by the intercalation of PEI and PEG are different (10.8 Å for PEI and 15.6 Å for PEG). We think such difference is attributed to the difference in BE of PEI and PEG to MoS2 surfaces and the different behaviors of the two polymers in the water environment. First, PEI has a higher BE than PEG to MoS2 surfaces with a stronger interaction, leading to a closer distance between PEI and MoS2 layers. Second, the further AIMD simulation indicates that PEI molecules are surrounded by less H2O molecules and have a smaller first solvation shell (2.62 Å) than that of PEG (2.75 Å) in aqueous solution (Supplementary Fig. 18). The average distance between PEI molecules and their solvation shell is slightly smaller, which gives rise to a smaller interlayer distance of MoS2 nanosheets.

Electrochemical performance

The electrochemical performance of the MoS2-based heteroaerogels as electrodes of supercapacitors was measured in a three-electrode cell in the presence of 6.0 M KOH solution. Figure 4a shows representative cyclic voltammetry (CV) curves of the MoS2/NC and MoS2/C heteroaerogels as well as the annealed MoS2 nanosheets at a sweep rate of 5 mV s−1 in the potential range of −0.2 to 0.6 V. The CV curves for all three electrodes display pairs of redox peaks, proving the presence of a reversible Faradic reaction and PC behavior between different valence states of Mo ions (+2 to +6). The peak intensity and curve area for pure MoS2 are pretty low (the inset of Fig. 4a), indicating that the capacitance of pure MoS2 is negligible. With increasing the scanning rate, the curve shapes for MoS2-based heteroaerogels are basically preserved (Supplementary Fig. 19a–c), suggesting fast and stable reversible reactions over the composite electrodes. Figure 4b shows the galvanostatic charge/discharge curves of the three electrodes at 1 A g−1, where several sloping plateaus are observed, in good agreement with the CV results. Obviously, the voltage plateaus for the MoS2/C and MoS2/NC heteroaerogel electrodes, especially the latter, are much more pronounced during both the charging and discharging processes, suggesting a significantly enhanced PC energy storage relative to pure MoS2.

An ultrahigh specific capacitance of 4144 F g−1 is obtained for the MoS2/NC heteroaerogel electrode at a current density 1 A g−1, which is much higher than those of the MoS2/C heteroaerogel (2576 F g−1) and the pure annealed MoS2 (259 F g−1). This value of specific capacitance also far surpasses those of previously reported high-capacitance electrodes based on metal sulfides, phosphides and oxides, such as NiS nanoframes (2112 F g−1 at 1 A g−1)46, MnCo2S4 hollow tubular structures (1203 F g−1 at 2 A g−1)47, NiCo2S4 nanosheets (1231 F g−1 at 2 A g−1)48, Ni2P nanosheets arrays (3496 F g−1 at 2.5 A g−1)49, NiO atomic clusters/graphene (3023 F g−1 at 1 A g−1)50, and amorphous Ni(OH)2 (3262 F g−1 at 5 mV s−1), etc51. The ultrahigh capacitance of the MoS2/NC heteroaerogel should be resulted from its synergistic effect in structure and composition, because the capacitance contributed from the annealed pristine MoS2 (Fig. 4a), N-containing carbon (NC) by direct carbonization of PEI and blank electrode of pristine Ni foam (Supplementary Fig. 20) is almost negligible at the same current density. Moreover, the MoS2/NC heteroaerogel electrode exhibits higher capacitances of 3550, 3150, 2900, 2670, and 2483 F g−1 at current densities of 2, 4, 6, 8, and 10 A g−1 than the other two electrodes, respectively, demonstrating an excellent rate capability (Fig. 4c and Supplementary Fig. 19d–f). The MoS2/NC heteroaerogel electrode also demonstrates remarkable long-term cycling stability. As shown in Fig. 4d, the electrode shows only an ~8% capacitance decrease after an 8000-cycle charge/discharge test at 10 A g−1. The quasi-triangular shape of the discharge/charge curves is still well preserved in the last 5 cycles, indicating the heteroaerogel electrode is stable during the long-term cycling. Such outstanding combined capacitance-rate performances thanks to the PDI strategy which creates efficient pathways for electrons/ions transport and provides more active sites for reversible redox reactions.

Electrochemical reactions kinetics analysis

As can also be seen in the Nyquist plots, the contact resistance (Rs) and charge transfer resistance (Rct) of the MoS2/NC heteroaerogel electrode are both the lowest among the three electrodes (Fig. 4e and the inset), suggesting the excellent conductivity and compatible electrode–electrolyte interface. The Nyquist plots demonstrated a conspicuously decreased Rct for the MoS2-based heteroaerogels, compared with the pure MoS2. The enhanced capability of charge transfer should be ascribed to the graphitized carbon inserting into MoS2 interlayers and coating on the surfaces of MoS2 nanosheets, which ensures the effective electron transfer between nanosheets in the composite heteroaerogels during capacitive process.

Kinetics analysis of the MoS2/NC heteroaerogel electrode was conducted based on their CV curves shown in Supplementary Fig. 19a. From the plots of peak current density (Ip) versus square root of sweep rate (ν1/2) from 2 to 40 mV s−1 for both cathodic and anodic peaks (Fig. 4f), the current follows well a power-law relationship with the sweep rate (Ip = aνb). A b-value of 0.5 indicates that the current is controlled by semi-infinite linear diffusion, whereas a value of 1 indicates that the current is surface-controlled. Specifically, the b-value was calculated to be ~0.58 and ~0.51 from the cathodic peak and anodic peak, respectively. The result indicates that the electrode kinetics under the conditions investigated was both diffusion- and surface-controlled, demonstrating a combined PC energy storage contributed from battery-like ion intercalation reactions and fast surface redox reactions. Since the b-values are closer to 0.5, the diffusion-controlled ion intercalation effect may be predominant in the whole PC energy storage process, which is facilitated by interlayer distance expansion of the MoS2/NC heteroaerogel that allows efficient ion diffusion into/from the interlayers.

X-ray photoelectron spectroscopy analyses

In order to probe the interfacial interactions between MoS2 and carbon-based (C or NC) components, X-ray photoelectron spectroscopy (XPS) examination was conducted for the MoS2-based heteroaerogels and the annealed pristine MoS2. A survey XPS spectrum of the MoS2/NC heteroaerogel provides direct evidence of the presence of C, N, Mo, and S in the heteroaerogel (Supplementary Fig. 21). The C 1s spectrum of MoS2/NC heteroaerogel exhibits a strong and sharp peak of C–C (284.6 eV) with the weak peaks of C–N (285.5 eV) and C=N (287.0 eV), implying that the graphite carbon is the majority species (Fig. 5a). The two prominent peaks of S 2p1/2 at 163.2 eV and S 2p3/2 at 162.2 eV in the core-level S 2p XPS spectrum are assigned to the S2− in MoS2 of the heteroaerogel (Supplementary Fig. 22), similar to those of the pristine MoS2 (Supplementary Fig. 23a). The high-resolution Mo 3d XPS of the MoS2/NC heteroaerogel reveals that the BEs of Mo 3d3/2 at 232.4 eV and Mo 3d5/2 at 229.5 eV are related to the Mo4+ ion in the pristine MoS2 (Fig. 5b). Notably, compared with pure MoS2 (Supplementary Fig. 23b) a new peak at 236.2 eV and a deconvoluted peak at 233.0 eV emerge in the XPS spectrum of Mo 3d for the MoS2/NC heteroaerogel, corresponding to Mo6+ 3d5/2 and 3d3/2 respectively (Fig. 5b). The deconvolution of N 1s energy level signals for the MoS2/NC heteroaerogel reveals the peaks at 398.3, 400.5, and 401.4 eV, which are assigned to pyridinic, pyrrolic, and graphitic N (Fig. 5c), respectively. Although the N 1s and Mo 3p spectra are partially overlapped, a distinct N 1s peak can still be observed at 401.7 eV, assigned to the coordination interactions between the MoS2 nanosheets and the N species in the carbon52,53. Accordingly, the valence increase of Mo ions is considered as a result of electron transfer from NC component to MoS2 via interfacial chemical bonds, i.e., Mo–N bonds between the two components, as evidenced by the Mo 3p + N1s XPS spectrum in Fig. 5c. For the MoS2/C heteroaerogel, in addition to typical C–C bonds as the majority, C–O and C=O bonds derived from PEG intercalator is found existing in the heteroaerogel (Fig. 5d). Interestingly, Mo6+ ions are also present, which may be induced by similar electron transfer from Mo to O atoms via interfacial Mo–O bonds between MoS2 and carbon components in the composite (Fig. 5e, f)54. The strong interactions between MoS2 and carbon-based components via the Mo–N or Mo–O bonds can distort the intrinsic Mo–S bonds of MoS2, thus leading to a disordered crystal lattice arrangement, as mirrored in Fig. 2b. The above results demonstrate that MoS2 nanosheets in the two composites are chemically bonded with the carbon-based components via Mo–N or Mo–O bonds, with increased valence of central Mo ions and efficient across-nanosheet electron transfer pathways through the interfacial bonds.

Discussion

Taking all into account, we think the superior PC performance of the MoS2-based heteroaerogels, especially the MoS2/NC heteroaerogel, is ascribed to their intriguing structural/composition advantages induced by the PDI behavior. First, the 3D heteroaerogels made of the stably stacked MoS2 framework and interconnected graphitized carbon network, derived from PEI adsorption on the surface of MoS2 nanosheets, offer stable ions diffusion channels and fast electron transport between MoS2 nanosheets (Fig. 6a), compared with that of pure MoS2 powder (Fig. 6b). Second, expanded interlayers of MoS2 nanosheets by the insertion of a graphene-like carbon monolayer derived from PDI expose more accessible active sites for redox reactions and create new pathways for ion/electron transport (Fig. 6c, d), which makes each monolayer of MoS2 electrochemically active. For pure MoS2, with unexpanded intrinsic interlayers and poor conductivity, electron transfer along the pathways within (002) plane illustrated in Fig. 6e may be very inefficient. In particular, for the MoS2/NC heteroaerogel, electron transfer through metallic bond-like interfacial Mo–N bonds within the heteroaerogel is more efficient than that via covalent bond-like Mo–O bonds within the MoS2/C heteroaerogel (Fig. 6c, d)55. As a consequence, the MoS2/NC heteroaerogel electrode demonstrates unprecedent PC energy storage performance.

Schematic illustration of different electron transport pathways. a, b Electron transport pathways between MoS2 nanosheets in the MoS2-based heteroaerogels (a) and pure MoS2 powder (b). c, d Electron transport pathways across MoS2 monolayers in the MoS2/NC heteroaerogel (c) and MoS2/C heteroaerogel (d). e Electron transport pathways within MoS2 monolayers in pure MoS2 powder

In summary, the PDI strategy has been proposed for the preparation of interlayer-expanded MoS2 nanosheets and MoS2/carbon heteroaerogels for ultrahigh-capacitance supercapacitors. The strategy is facile, mild, and efficient, which is applicable to differently charged polymers with a wide range of molecular weight. The direct intercalation behavior of polymers has been investigated systematically by substantial characterizations and molecular dynamic calculations. The resulting MoS2/carbon heteroaerogels exhibited outstanding supercapacitor performance such as ultrahigh capacitance, remarkable rate capability, and excellent cycling stability. The superior performance is attributed to the structural and composition advantages of the unique MoS2/carbon heteroaerogels with a 3D conductive MoS2/C framework, expanded interlayers of MoS2 nanosheets, interoverlapped MoS2/C layered heterointerface as well as a high content of MoS2 (up to 74%) and a high valence (+6) of central Mo ions, which are conducive to not only fast and stable charge transfer/diffusion, but also enhanced ions intercalation pseudocapacitance. The novel PDI strategy may be generally applicable to other 2D layered materials. This study may offer an opportunity for the development of 2D materials-based composites with desirable structure and property for promising energy applications.

Methods

Synthesis of pre-intercalated pristine MoS2 nanosheets

All the reagents mentioned in the experiment were purchased from Aladdin Biological Technology Co., LTD (China) and used without further purification. The pre-intercalated MoS2 nanosheets were synthesized through a simple hydrothermal method. In a typical procedure, sodium molybdate (Na2MoO4, 0.3 g) and thioacetamide (TAA, C2H5NS, 0.6 g) were dissolved in DI water (20 mL) mixed with ethylene glycol (10 mL) under continuous stirring for 30 min to form a homogeneous solution. Then, the mixture was transferred into a 100 mL Teflon-lined stainless-steel autoclave, and hydrothermally treated at 220 °C for 24 h. After naturally cooled to room temperature, the resulting black precipitate of pre-intercalated MoS2 was collected by filtration and washed with distilled water for several times to remove the residue of reactants. Finally, the obtained MoS2 black product was calcined at 300 °C in the flowing argon for 2 h at a heating rate of 2 °C min−1 and marked as the annealed pristine MoS2.

Synthesis of MoS2/NC and MoS2/C heteroaerogels

In a typical synthesis of MoS2/NC heteroaerogel, 1.6 g PEI (Mw = 600, Aladdin) and 2.0 g MoS2 with a mass ratio of 44 wt% were mixed in a certain amount of water under sonication for 1 h to form a suspension, followed by freeze-drying treatment, resulting in a MoS2–PEI composite. Then, the obtained MoS2–PEI composite was annealed at 800 °C for 6 h with argon flow, leading to a black product of the MoS2/NC heteroaerogel. For the synthesis of MoS2/C heteroaerogel, typically, the polymer of PEG (Mw = 400) was employed instead of PEI under otherwise the same conditions. The final composite heteroaerogels prepared by using PEI (Mw = 600) and PEG (Mw = 400) were regarded as the standard samples and were denoted as MoS2/NC and MoS2/C, respectively. The mass percentage of polymers employed for direct intercalation was 44 wt% if not specified.

Characterizations

The crystal structure of the samples was characterized by XRD using a D/max2550VB3+/PC X-ray diffractometer with Cu Kα radiation (λ = 0.15418 nm) at 40 kV, 100 mA. The 2θ degree range used in the measurements was from 5° to 80°. The morphology was observed using a SEM (Hitachi S4800, 3 kV) equipped with an EDS analysis system and a HRTEM (JEM 2011, 200 kV). XPS investigation was conducted in a PHI-5000C ESCA system (PerkinElmer) with Mg Kα radiation (ℏν = 1253.6 eV). The XPS spectra were measured with a constant analyzer pass energy of 46.95 eV. All BEs were referred to the C 1s peak (284.6 eV) arising from surface hydrocarbons (or adventitious hydrocarbon). Raman spectra were recorded by using a spectrophotometer (inVia, Renishaw, Germany) with a 514 nm laser. Thermogravimetric analysis (NETZSCH STA409PC) was carried out from 25 to 700 °C at a heating rate of 10 °C min−1 under flowing air. A zeta potential instrument (zetasizer Nano Z) was used for determining the surface charge of the MoS2/NC heteroaerogel samples. The specific surface area was measured by the multipoint Brunauere–Emmette–Teller (BET) method at 77.3 K with a Quantachrome NOVA-4200e system. Molecular weight distribution of polymers was studied with GPC using a system from Agilent Technologies 1100. Samples were dissolved in H2O. For the measurement, 20 μL of sample was injected. The chromatography was performed at 40 °C using 0.1 mol/L NaNO3 as eluent with a flow rate of 0.5 mL/min. Mass spectra were measured on a LC-MS Varian 310 instrument.

Fabrication and electrochemical test of supercapacitors

All the electrochemical measurements were conducted on a standard three-electrode setup in an electrochemical cell by using a CHI 660E electrochemical workstation (CH Instruments, Inc., Shanghai) in an aqueous KOH electrolyte (6.0 M), where a Pt wire and a saturated Ag/AgCl electrode (filled with saturated KCl with a potential of 0.197 V versus SHE) serve as the counter electrode and the reference electrode, respectively. The working electrode was prepared by mixing active materials, conductive carbon black (Super-P), and polymer binder (polytetrafluoroethylene, PTFE) in a weight ratio of 8:1:1. The mixture was pressed onto a Ni foam that was first treated with a 5% HCl solution, and then was dried at 100 °C for 24 h under vacuum to remove the solvent. The working area of the electrode was set as 1 × 1 cm2 and the mass loading of the electrode materials was controlled to be around 2.5 mg. In addition, before each electrochemical test, the electrode was immersed into the electrolyte for 4–5 h.

Cyclic voltammograms (CV), galvanostatic charge/discharge (GCD), and electrochemical impedance spectroscopy (EIS), measurements were performed by using a CHI 660E workstation at ambient temperature. The CVs were recorded from −0.2 to 0.6 V at scan rates of 5–80 mV s−1. The GCD measurements were performed at the current densities of 1–40 A g−1 with cutoff voltage of 0–0.37 V. EIS was recorded by applying the open-circuit potential with an amplitude of 5 mV over the frequency range from 100 kHz to 0.01 Hz. All potential values for electrochemical measurements were calibrated to the Ag/AgCl reference electrode. Cyclic stability was characterized using galvanostatic charge–discharge measurements over 8000 cycles at a charge–discharge rate of 10 A g−1. The specific capacitances of the electrodes are calculated using the following equation56:

where C (F g−1) is the specific capacitance, im = I/m (A g−1) is the current density, where I represents the current and m represents the active mass of the electrode. \(\mathop {\smallint }\nolimits^ Vdt\) represents the integral current area and V represents the potential with initial and final values of Vi and Vf respectively.

Data availability

The data that support the findings of this study are available within the paper and its Supplementary Information file, or from the corresponding author on request.

References

Patrice, S. & Yury, G. Materials for electrochemical capacitors. Nat. Mater. 7, 845–854 (2008).

Chhowalla, M. et al. The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nat. Chem. 5, 263–275 (2013).

Feng, J. et al. Metallic few-layered VS2 ultrathin nanosheets: high two-dimensional conductivity for in-plane supercapacitors. J. Am. Chem. Soc. 133, 17832–17838 (2011).

Ma, G. et al. In situ intercalative polymerization of pyrrole in graphene analogue of MoS2 as advanced electrode material in supercapacitor. J. Power Sources 229, 72–78 (2013).

Acerce, M., Voiry, D. & Chhowalla, M. Metallic 1 T phase MoS2 nanosheets as supercapacitor electrode materials. Nat. Nanotechnol. 10, 313–318 (2015).

Rapoport, L., Fleischer, N. & Tenne, R. Applications of WS2 (MoS2) inorganic nanotubes and fullerene-like nanoparticles for solid lubrication and for structural nanocomposites. J. Mater. Chem. 15, 1782–1788 (2005).

Stephenson, T., Li, Z., Olsen, B. & Mitlin, D. Lithium ion battery applications of molybdenum disulfide (MoS2) nanocomposites. Energy Environ. Sci. 7, 209–231 (2014).

Xiao, J. et al. Electrochemically induced high capacity displacement reaction of PEO/MoS2/graphene nanocomposites with lithium. Adv. Funct. Mater. 21, 2840–2846 (2011).

Ji, H. et al. Porous hybrid composites of few-layer MoS2 nanosheets embedded in a carbon matrix with an excellent supercapacitor electrode performance. Small 11, 6480–6490 (2015).

Kong, D. et al. Rational design of MoS2@graphene nanocables: towards high performance electrode materials for lithium ion batteries. Energy Environ. Sci. 7, 3320–3325 (2014).

Qiu, W., Jiao, J., Xia, J., Zhong, H. & Chen, L. Phosphorus-doped graphene-wrapped molybdenum disulfide hollow spheres as anode material for lithium-ion batteries. RSC Adv. 4, 50529–50535 (2014).

Teng, Y. et al. MoS2 nanosheets vertically grown on graphene sheets for lithium-ion battery anodes. ACS Nano 10, 8526–8535 (2016).

Zhao, C. et al. Self-assembly-induced alternately stacked single-layer MoS2 and N-doped graphene: a novel van der waals heterostructure for lithium-ion batteries. ACS Appl. Mater. Interfaces 8, 2372–2379 (2016).

Ding, S., Chen, J. S. & Lou, X. W. Glucose-assisted growth of MoS2 nanosheets on CNT backbone for improved lithium storage properties. Chemistry 17, 13142–13145 (2011).

Chen, W.-X., Ma, L., Xu, Z.-D., Xia, J.-B. & Li, X. Carbon nanotubes coated with tubular MoS2 layers prepared by hydrothermal reaction. Nanotechnology 17, 571–574 (2006).

Shi, Y. et al. Self-assembly of hierarchical MoSx/CNT nanocomposites (2 < x < 3): towards high performance anode materials for lithium ion batteries. Sci. Rep. 3, 2169–2077 (2013).

Wang, S. et al. Solvothermal synthesis of MoS2/carbon nanotube composites with improved electrochemical performance for lithium ion batteries. Nanosci. Nanotechnol. Lett. 4, 378–383 (2012).

Hu, L., Ren, Y., Yang, H. & Xu, Q. Fabrication of 3D hierarchical MoS2/polyaniline and MoS2/C architectures for lithium-ion battery applications. ACS Appl. Mater. Interfaces 6, 14644–14652 (2014).

Yang, L. et al. Hierarchical MoS2/polyaniline nanowires with excellent electrochemical performance for lithium-ion batteries. Adv. Mater. 25, 1180–1184 (2013).

Zhang, C., Wang, Z., Guo, Z. & Lou, X. W. Synthesis of MoS2–C one-dimensional nanostructures with improved lithium storage properties. ACS Appl. Mater. Interfaces 4, 3765–3768 (2012).

Xu, J., Zhang, J., Zhang, W. & Lee, C. S. Interlayer nanoarchitectonics of two-dimensional transition-metal dichalcogenides nanosheets. Adv. Energy Mater. 7, 1700571 (2017).

Rasamani, K. D., Alimohammadi, F. & Sun, Y. Interlayer-expanded MoS2. Mater. Today 20, 83–91 (2017).

Anto Jeffery, A., Nethravathi, C. & Rajamathi, M. Two-dimensional nanosheets and layered hybrids of MoS2 and WS2 through exfoliation of ammoniated MS2 (M = Mo,W). J. Phys. Chem. C 118, 1386–1396 (2014).

Li, Y. et al. Enhancing sodium-ion battery performance with interlayer-expanded MoS2–PEO nanocomposites. Nano Energy 15, 453–461 (2015).

Liang, Y. et al. Interlayer-expanded molybdenum disulfide nanocomposites for electrochemical magnesium storage. Nano Lett. 15, 2194–2202 (2015).

Somoano, R. B., Hadek, V. & Rembaum, A. Alkali metal intercalates of molybdenum disulfide. J. Chem. Phys. 58, 697–701 (1973).

Zheng, J. et al. High yield exfoliation of two-dimensional chalcogenides using sodium naphthalenide. Nat. Commun. 5, 2995–3003 (2014).

Chang, K. et al. Graphene-like MoS2/amorphous carbon composites with high capacity and excellent stability as anode materials for lithium ion batteries. J. Mater. Chem. C 21, 6251–6259 (2011).

Gao, M. R., Chan, M. K. & Sun, Y. Edge-terminated molybdenum disulfide with a 9.4 Å interlayer spacing for electrochemical hydrogen production. Nat. Commun. 6, 7493–7500 (2015).

Jiang, H. et al. 2D monolayer MoS2-carbon interoverlapped superstructure: engineering ideal atomic interface for lithium ion storage. Adv. Mater. 27, 3687–3695 (2015).

Liu, N. et al. Microwave-assisted reactant-protecting strategy toward efficient MoS2 electrocatalysts in hydrogen evolution reaction. ACS Appl. Mater. Interfaces 7, 23741–23749 (2015).

Liu, Q. et al. Gram-scale aqueous synthesis of stable few-layered 1 T-MoS2: applications for visible-light-driven photocatalytic hydrogen evolution. Small 11, 5556–5564 (2015).

Wang, X., Guan, Z., Li, Y., Wang, Z. & Chen, L. Guest–host interactions and their impacts on structure and performance of nano-MoS2. Nanoscale 7, 637–641 (2015).

Xie, J. et al. Controllable disorder engineering in oxygen-incorporated MoS2 ultrathin nanosheets for efficient hydrogen evolution. J. Am. Chem. Soc. 135, 17881–17888 (2013).

Zhao, X., Hu, C. & Cao, M. Three-dimensional MoS2 hierarchical nanoarchitectures anchored into a carbon layer as graphene analogues with improved lithium ion storage performance. Chem. Asian J. 8, 2701–2707 (2013).

Bi, H., Chen, I. W., Lin, T. & Huang, F. A new tubular graphene form of a tetrahedrally connected cellular structure. Adv. Mater. 27, 5943–5949 (2015).

Wang, P. P., Sun, H., Ji, Y., Li, W. & Wang, X. Three-dimensional assembly of single-layered MoS2. Adv. Mater. 26, 964–969 (2014).

Tang, Y. J. et al. Molybdenum disulfide/nitrogen-doped reduced graphene oxide nanocomposite with enlarged interlayer spacing for electrocatalytic hydrogen evolution. Adv. Energy Mater. 6, 1600116 (2016).

Xu, Y. et al. Monolayer MoS2 with S vacancies from interlayer spacing expanded counterparts for highly efficient electrochemical hydrogen production. J. Mater. Chem. A 4, 16524–16530 (2016).

Chen, J., Xia, Y. & Yang, J. Graphene/surfactant-assisted synthesis of edge-terminated molybdenum disulfide with enlarged interlayer spacing. Mater. Lett. 210, 248–251 (2018).

Wang, Z. et al. CTAB-assisted synthesis of single-layer MoS2–graphene composites as anode materials of Li-ion batteries. J. Mater. Chem. A 1, 2202–2210 (2013).

Xu, X. et al. A nanosheets-on-channel architecture constructed from MoS2 and CMK-3 for high-capacity and long-cycle-life lithium storage. Adv. Energy Mater. 4, 1400902 (2014).

Watanabe, T. et al. Determination of primary bond scissions by mass spectrometric analysis of ultrasonic degradation products of poly(ethylene oxide-block-propylene oxide) copolymers. J. Mass Spectrom. 45, 799–805 (2010).

Vijayalakshmi, S. P. & Madras, G. Effect of initial molecular weight and solvents on the ultrasonic degradation of poly(ethylene oxide). Polym. Degrad. Stab. 90, 116–122 (2005).

Taghizadeh, M. T. & Asadpour, T. Effect of molecular weight on the ultrasonic degradation of poly(vinyl-pyrrolidone). Ultrason. Sonochem. 16, 280–286 (2009).

Yu, X. Y., Yu, L., Wu, H. B. & Lou, X. W. Formation of nickel sulfide nanoframes from metal–organic frameworks with enhanced pseudocapacitive and electrocatalytic properties. Angew. Chem. 54, 5331–5335 (2015).

Chen, Y. M., Li, Z. & Lou, X. W. General formation of MxCo(3−x)S4 (M = Ni, Mn, Zn) hollow tubular structures for hybrid supercapacitors. Angew. Chem. 54, 10521–10524 (2015).

Shen, L. et al. NiCo2S4 nanosheets grown on nitrogen-doped carbon foams as an advanced electrode for supercapacitors. Adv. Energy Mater. 5, 1400977 (2015).

Zhou, K. et al. Ultrahigh-performance pseudocapacitor electrodes based on transition metal phosphide nanosheets array via phosphorization: a general and effective approach. Adv. Funct. Mater. 25, 7530–7538 (2015).

Jeong, H. M. et al. Rescaling of metal oxide nanocrystals for energy storage having high capacitance and energy density with robust cycle life. Proc. Natl. Acad. Sci. USA 112, 7914–7919 (2015).

Jiang, W. et al. Ternary hybrids of amorphous nickel hydroxide-carbon nanotube-conducting polymer for supercapacitors with high energy density, excellent rate capability, and long cycle life. Adv. Funct. Mater. 25, 1063–1073 (2015).

Ren, W., Zhang, H., Guan, C. & Cheng, C. Ultrathin MoS2 nanosheets@metal organic framework-derived n-doped carbon nanowall arrays as sodium ion battery anode with superior cycling life and rate capability. Adv. Funct. Mater. 27, 1702116 (2017).

Shan, T. T. et al. Combining nitrogen-doped graphene sheets and MoS2: a unique film–foam–film structure for enhanced lithium storage. Angew. Chem. 55, 12783–12788 (2016).

Mahmood, Q. et al. Transition from diffusion-controlled intercalation into extrinsically pseudocapacitive charge storage of MoS2 by nanoscale heterostructuring. Adv. Energy Mater. 6, 1501115 (2016).

Zhong, Y. et al. Transition metal carbides and nitrides in energy storage and conversion. Adv. Sci. 3, 1500286 (2016).

Mai, L. Q. et al. Synergistic interaction between redox-active electrolyte and binder-free functionalized carbon for ultrahigh supercapacitor performance. Nat. Commun. 4, 2923–2930 (2013).

Acknowledgements

This work was financially supported by National Natural Science Foundation (21273161), Natural Science Foundation of Shanghai (17ZR1447800), the Program for Professor of Special Appointment (Eastern Scholar) at Shanghai Institutions of Higher Learning, Hundred Youth Talent Plan of Tongji University, and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Contributions

N.F. and J.Y. conceived the ideas. R.M. investigated the polymers. N.F. and R.M. carried out intercalation experiments. N.F., R.M., L.Z., and Y.F. synthesized and characterized the structure and composition of materials. N.F. and C.P. assembled the cells and conducted the measurements. N.F., R.M., L.Z., J.H., G.L., B.C., and J.Y. prepared the figures, analyzed the electrochemical data, and proposed the mechanism. N.F. and J.Y. co-wrote the manuscript. All the authors discussed the results and commented on the manuscript at all stages.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Journal peer review information: Nature Communications thanks Jun Xu and the other anonymous reviewers for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Feng, N., Meng, R., Zu, L. et al. A polymer-direct-intercalation strategy for MoS2/carbon-derived heteroaerogels with ultrahigh pseudocapacitance. Nat Commun 10, 1372 (2019). https://doi.org/10.1038/s41467-019-09384-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-019-09384-7

This article is cited by

-

Recent advances on liquid intercalation and exfoliation of transition metal dichalcogenides: From fundamentals to applications

Nano Research (2024)

-

Vertical-Aligned and Ordered-Active Architecture of Heterostructured Fibers for High Electrochemical Capacitance

Advanced Fiber Materials (2024)

-

CuCo-MOF/MoS2 as a High-Performance Electrocatalyst for Oxygen Evolution Reaction

Electrocatalysis (2023)

-

Organic/inorganic hybrids for intelligent sensing and wearable clean energy applications

Advanced Composites and Hybrid Materials (2023)

-

Enhanced high energy and power density hybrid asymmetric supercapacitor based on 2D layered MoS2/g-C3N4 electrode materials

Journal of Materials Science: Materials in Electronics (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.