Abstract

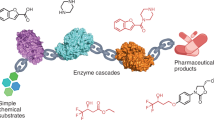

The Cu-catalyzed azide-alkyne cycloaddition (CuAAC) reaction is a cornerstone method for the ligation of biomolecules. However, undesired Cu-mediated oxidation and Cu-contamination in bioconjugates limits biomedical utility. Here, we report a generic CuAAC flow platform for the rapid, robust, and broad-spectrum formation of discrete triazole bioconjugates. This process leverages an engineering problem to chemical advantage: solvent-mediated Cu pipe erosion generates ppm levels of Cu in situ under laminar flow conditions. This is sufficient to catalyze the CuAAC reaction of small molecule alkynes and azides, fluorophores, marketed drug molecules, peptides, DNA, and therapeutic oligonucleotides. This flow approach, not replicated in batch, operates at ambient temperature and pressure, requires short residence times, avoids oxidation of sensitive functional groups, and produces products with very low ppm Cu contamination.

Similar content being viewed by others

Introduction

The Cu-catalyzed azide-alkyne cycloaddition (CuAAC) reaction (Scheme 1a) is a method of widespread utility throughout medicinal chemistry, chemical biology, and the material sciences1,2,3,4,5,6. The pervasiveness of this methodology can be attributed to the rapid, chemo- and regiospecific generation of 1,2,3-triazole products and bioconjugates.

A significant limitation of the CuAAC reaction conducted under batch conditions is the need for a Cu catalyst; this can be problematic in a number of applications5,6. Cu-mediated oxidative damage of sensitive functional groups can result in product mixtures, which may complicate purification or lead to issues with bioassays due to the need for deconvolution of data or unknown pharmacology (Fig. 1b). In biomolecule tagging CuAAC modification of azide/alkyne biomolecules requires (super)stoichiometric loadings of Cu catalyst due to the presence of a number of Cu-chelating sites (e.g., N/S sites of peptides7, N7 of purines in nucleic acids8), which can result in catalyst inhibition and the need for higher concentrations of Cu in the reaction (Fig. 1b)6. In addition, oxidative damage of biomolecules is a significant issue associated with current CuAAC-based bioconjugation strategies, severely limiting development9,10,11. These issues have inspired the development of a series of alternative Cu-free click approaches such as strain-promoted azide-alkyne cycloadditions (SPAAC)12 and inverse electron demand Diels-Alder (IEDDA) approaches using tetrazines13. Despite their moderate to fast kinetics14, these processes have their own issues; for example, lacking the chemo- and regiospecificity afforded by the CuAAC reaction due to the reactive (electrophilic) nature of the requisite cyclic alkynes/alkenes15,16,17,18,19,20,21, which are susceptible to side reactions with nucleophilic residues (e.g., thiol residues in glutathione). Furthermore, the installation of these large lipophilic groups has a significant impact on the overall physicochemical properties of the bioconjugate (Fig. 1c)22.

Azide-alkyne cycloaddition strategies. a The archetypical CuAAC reaction; b Examples of oxidatively labile and ligating functional groups found in biomolecules; c The SPAAC reaction and and the formation of regioisomeric triazole products; d The flow-assisted CuAAC reaction (this work). CuAAC Cu-catalyzed azide-alkyne cycloaddition, Nuc nucleophile, SPAAC strain-promoted azide-alkyne cycloaddition

Whilst efforts have been made to overcome the oxidation and Cu contamination issues of the CuAAC reaction by the development of bespoke ligands, conducting these reactions under anaerobic conditions, the addition of oxidation inhibitors, and Cu scavengers, these issues extend from the requirement for high [Cu] to overcome slow catalytic turnover as a result of the numerous Lewis-basic groups typically found in proteins and nucleic acids23.

Here we describe the development of a rapid flow-assisted CuAAC reaction that overcomes these problems (Fig. 1d). Our operationally simple strategy couples solvent-induced erosion of a copper tube with the formation of a highly active CuAAC catalyst under laminar flow conditions. This enables the facile formation (tR ca. 1–10 min) of discrete ligation products and bioconjugates not possible using conventional batch conditions. Significantly, the level of Cu present in products is well below the reported mammalian cellular toxicity thresholds (e.g., <20 μM for DNA)5,11,24 with no associated oxidative damage observed on a series of representative labile biomolecules, including peptides and DNA strands.

Results

Reaction design

Flow-based technologies offer distinct advantages over batch, such as enhanced mass transfer, which is particularly advantageous for large molecular weight biomolecules where accessibility of functional groups is significantly compromised in the batch regime25,26,27,28,29. Despite these advantages, application of flow-based CuAAC bioconjugation has not been reported due to the need for (i) excess Cu catalyst, which promotes biomolecule degradation, (ii) ionic scavengers, which can result in residual Cu trapped in bioconjugates, (iii) elevated temperatures, which promotes biomolecule degradation, and (iv) organic solvents, which typically limits biocompatibility. This has limited flow CuAAC applications to small molecules and prevented the widespread development of flow-assisted synthesis of discrete bioconjugates30,31,32,33,34,35,36,37,38,39,40,41.

Whilst elemental Cu is an effective catalyst for flow CuAAC, elevated temperature and pressures are required, likely in order to solubilize some Cu in the eluent. However, H2O/organic mixtures are extremely effective and biocompatible solvent mixtures for CuAAC-mediated bioconjugation. In addition, the surface of Cu pipes is typically covered in a protective oxide layer, which are generally poorly soluble in organic solvents but more soluble in H2O. Indeed, erosion of Cu tubes with H2O is a well-studied engineering phenomenon, with Cu leaching a known problem in flow chemistry31.

Based on this, we hypothesized that an aqueous/organic mixture (for example, H2O/MeCN) would offer a blend of sufficient solubility of the (bio)organic components while promoting controlled erosion of surface Cu salts under laminar flow conditions, with in situ Cu(I)/Cu(II) disproportionation providing the mechanistically essential Cu(I) required for the CuAAC reaction. Whilst the level of solubilized Cu was likely to be very low; the increased circulation established under the flow set up would enhance mass transport to provide reaction efficiency not possible in batch26.

This hypothesis was found to be valid. Three benchmark CuAAC reactions, using three alkynes (1a–1c), with known differences in reactivity with benzyl azide (2) were evaluated in a laminar flow system comprising a pump and copper reactor at ambient temperature and pressure (Fig. 2a). The reaction does not proceed in pure MeCN or pure H2O and [Cu] in the eluent (10 mL collected, 1 mL/min under ambient conditions) was extremely low (<20 ppm). However, the addition of small amounts of H2O to the bulk MeCN resulted in the formation of triazole 3a–c, which peaked at 5:1 solvent mixture. Control experiments with an unused Cu reactor (Fig. 2b, red bars) vs. a reactor used for CuAAC reactions (Fig. 2b, blue bars) demonstrated greater erosion in the used reactor, consistent with a more exposed surface due to repeated chemistry; however the solvent composition/erosion trend was comparable, peaking at 1:1 H2O/MeCN. The addition of small percentages of H2O to the carrier solvent (MeCN) enabled the CuAAC reaction of equistoichiometric ynamine 1a and BnN3 (2) effectively at 5:1 MeCN:H2O (tR = 10 min; Fig. 2a). Whilst ynamine 1a exhibits faster batch-reaction kinetics based on a pKa modifying Cu-ligation42, the mixed solvent system was also effective at enabling the CuAAC reaction of more standard alkynes 1b and 1c at the same flow rate. Analysis of the eluent by ICP-MS revealed that [Cu] was ~14 ppm, which is well below the limit required for use in in vivo applications5,11. Importantly, control experiments identified a flow phenomenon. Attempting the CuAAC reaction of alkynes 1a–1c in flask experiments at 14 ppm Cu was unsuccessful for 1b and 1c and only moderately successful for the more reactive ynamine 1a (53% yield after 72 h), whereas the flow system results in quantitative conversion in 10 min (Fig. 2c). Residence times were also shortened significantly to ca. 1 min for more reactive substrates.

Scope of the flow platform

The scope of the flow CuAAC process was both broad and reproducible using three different alkyne classes (1a–1c) across a series of azide substrates (3–20; Fig. 3). Triazole products derived from simple azides, azido fluorophores, and azide possessing specific functions for downstream applications, were all isolated in high yield after a single pass. Importantly, ICP-MS analysis of the products again found the residual [Cu] was <20 ppm (see Supporting Information for full details).

We also examined the compatibility of the flow process with regards to established CuAAC chemoselectivity profiles (Fig. 3). Diyne 18, containing aliphatic alkyne and aromatic ynamine sites, underwent sequential CuAAC ligation, firstly with the coumarin azide 19 at the ynamine site followed by ligation with the nucleobase azide 20 at the aliphatic alkyne site; complete chemoselectivity was observed throughout. This demonstrates that established reactivity profiles43 are replicated in the flow format and that our system enhances not only overall reaction kinetics but does so at very low [Cu].

The biomedical utility of the CuAAC reaction lies primarily in the ligation of bio-relevant molecules. We assessed the flow CuAAC process as a method for the ligation of representative alkyne-derivatives of nucleic acids and peptides, which have known susceptibility to form oxidized byproducts in the presence of a Cu catalyst (Fig. 4)8,10. Installation of a fluorinated residue onto a marketed PARP inhibitor44, and a common fluorophore onto a series of peptides and DNA strands containing oxidizable functionality produced triazole products with minimal formation of side-products. These include CuAAC ligations with oligodeoxyribonucleotides (ODNs) and the core ApoliproteinE (ApoE) peptide sequence (27)45, which has demonstrated utility as a delivery vehicle across the blood brain barrier46. Residues with known oxidative susceptibility (27a–e) under conventional CuAAC batch conditions were installed on the N-terminus to report any potential degradation by reactive oxygen species and formed the expected triazole products (1 mL/min; tR = 8 min), with trace Cu contamination and no associated degradation.

Bioconjugation

Finally, we explored applying our flow-based CuAAC ligation approach to prepare therapeutic bioconjugates. Phosphoramidate morpholino oligonucleotides (PMOs) are a class of oligonucleotides with established therapeutic importance47,48,49. An essential requirement for in vivo efficacy of this class of biologics is the need conjugate a cell penetrating peptide sequence onto one of the termini to enable effective delivery to the central nervous system. The bioconjugate triazole 28 was prepared from precursors derived from a PMO azide with known in vivo efficacy as a splice-switching oligonucleotide for the treatment of Spinal Muscular Atrophy (SMA) and a peptide fragment derived from a portion of the ApoE protein50. Under flow conditions, the ApoE-PMO bioconjugate (28) was formed in 60% yield after 15 passes (1 mL/min; total tR = 30 min). No reaction was observed after 24 h under equivalent batch conditions, with only only 26% yield of 28 obtained in batch after 48 h using 100 equiv Cu.

Discussion

In summary, we have developed a rapid and operationally simple flow-based platform for the CuAAC reaction that operates at ambient temperature and pressure. Solvent-induced erosion of a Cu pipe provides catalytically competent Cu to promote the CuAAC reaction of a range of both small molecules and biomolecules without oxidative damage to labile functional groups and with trace Cu contamination. We have demonstrated the dependency of the system on the composition of the medium and that the observed effect is unique to the flow conditions with comparable isolated experiments of low efficiency. We expect that these findings will significantly increase the utility of flow-assisted CuAAC across a series of academic and industrial applications.

Methods

General methods

See Supplementary Methods for further details supporting experiments, Supplementary Tables 1–11 for additional data, and Supplementary Figures 1–125 for spectra.

General procedure for the flow CuAAC process

Alkyne (0.2 mmol) and azide (0.2 mmol) were dissolved in 10 mL of MeCN/H2O (5/1). The CuAAC reactions were carried out in a commercial chemical flow reactor equipped with a 10 mL copper reactor (easy-Scholar from Vapourtec). The reaction mixture was flowed through a copper tube (diameter = 1 mm, volume = 10 mL, surface area = 400 cm2) at a flow rate of 1 mL/min at rt (25 °C, tR = 10 min). The reaction mixture was then collected and concentrated in vacuo to afford the crude product. Where necessary, purification was achieved by flash silica column chromatography (for small molecule products) or preparative HPLC (for peptide/DNA-based products).

Data availability

All data generated or analyzed during this study are included in this published article (and its supplementary information files). These data are also available from the author upon request.

References

Kolb, H. C., Finn, M. G. & Sharpless, K. B. Click chemistry: diverse chemical function from a few good reactions. Angew. Chem. Int. Ed. 40, 2004–2021 (2001).

Hein, J. E. & Fokin, V. V. Copper-catalyzed azide–alkyne cycloaddition (CuAAC) and beyond: new reactivity of copper(I) acetylides. Chem. Soc. Rev. 39, 1302–1315 (2010).

Meldal, M. & Tornøe, C. W. Cu-catalyzed azide−alkyne cycloaddition. Chem. Rev. 108, 2952–3015 (2008).

Moses, J. E. & Moorhouse, A. D. The growing applications of click chemistry. Chem. Soc. Rev. 36, 1249–1262 (2007).

Sletten, E. M. & Bertozzi, C. R. Bioorthogonal chemistry: fishing for selectivity in a sea of functionality. Angew. Chem. Int. Ed. 48, 6974–6998 (2009).

McKay, C. S. & Finn, M. G. Click chemistry in complex mixtures: bioorthogonal bioconjugation. J. Chem. Biol. 21, 1075–1101 (2014).

Saito, F., Noda, H. & Bode, J. W. Critical evaluation and rate constants of chemoselective ligation reactions for stoichiometric conjugations in water. ACS Chem. Biol. 10, 1026–1033 (2015).

Gierlich, J., Burley, G. A., Gramlich, P. M. E., Hammond, D. M. & Carell, T. Click chemistry as a reliable method for the high-density postsynthetic functionalization of alkyne-modified DNA. Org. Lett. 8, 3639–3642 (2006).

Hong, V., Presolski, S. I., Ma, C. & Finn, M. G. Analysis and optimization of copper‐catalyzed azide–alkyne cycloaddition for bioconjugation. Angew. Chem. Int. Ed. 48, 9879–9883 (2009).

Li, S. et al. Extent of the oxidative side reactions to peptides and proteins during the CuAAC reaction. Bioconjugate Chem. 27, 2315–2322 (2016).

Abel, G. R. Jr., Calabrese, Z. A., Ayco, J., Hein, J. E. & Ye, T. Measuring and suppressing the oxidative damage to DNA during Cu(I)-catalyzed azide–alkyne cycloaddition. Bioconjugate Chem. 27, 698–704 (2016).

Dommerholt, J., Rutjes, F. P. J. T. & van Delft, F. L. Strain-promoted 1,3-dipolar cycloaddition of cycloalkynes and organic azides. Top. Curr. Chem. 374, 16 (2016).

Knall, A.-C. & Slugovc, C. Inverse electron demand diels–alder (iEDDA)-initiated conjugation: a (high) potential click chemistry scheme. Chem. Soc. Rev. 42, 5131–5142 (2013).

Lang, K. & Chin, J. W. Bioorthogonal reactions for labeling proteins. ACS Chem. Biol. 9, 16–20 (2014).

Baskin, J. M. et al. Copper-free click chemistry for dynamic in vivo imaging. Proc. Natl Acad. Sci. USA 104, 16793–16797 (2007).

Li, X., Fang, T. & Boons, G.-J. Preparation of well-defined antibody–drug conjugates through glycan remodeling and strain-promoted azide–alkyne cycloadditions. Angew. Chem. Int. Ed. 53, 7179–7182 (2014).

Blackman, M. L., Royzen, M. & Fox, J. M. Tetrazine ligation: fast bioconjugation based on inverse-electron-demand diels-alder reactivity. J. Am. Chem. Soc. 130, 13518–13519 (2008).

Taylor, M. T., Blackman, M. L., Dmitrenko, O. & Fox, J. M. Design and synthesis of highly reactive dienophiles for the tetrazine–trans-cyclooctene ligation. J. Am. Chem. Soc. 133, 9646–9649 (2011).

Devaraj, N. K., Upadhyay, R., Haun, J. B., Hilderbrand, S. A. & Weissleder, R. Fast and sensitive pretargeted labeling of cancer cells through a tetrazine/trans‐cyclooctene cycloaddition. Angew. Chem. Int. Ed. 48, 7013–7016 (2009).

Devaraj, N. K., Weissleder, R. & Hilderbrand, S. A. Tetrazine-based cycloadditions: application to pretargeted live cell imaging. Bioconjugate Chem. 19, 2297–2299 (2008).

Murrey, H. E. et al. Systematic evaluation of bioorthogonal reactions in live cells with clickable HaloTag Ligands: Implications for Intracellular Imaging. J. Am. Chem. Soc. 137, 11461–11475 (2015).

Row, R. D. & Prescher, J. A. Constructing new bioorthogonal reagents and reactions. Acc. Chem. Res. 51, 1073–1081 (2018).

Kumar, A., Li, K. & Cai, C. Anaerobic conditions to reduce oxidation of proteins and to accelerate the copper-catalyzed “click” reaction with a water-soluble bis(triazole) ligand. Chem. Commun. 47, 3186–3188 (2011).

Egorova, K. S. & Ananikov, V. P. Which metals are green for catalysis? comparison of the toxicities of Ni, Cu, Fe, Pd, Pt, Rh, and Au salts. Angew. Chem. Int. Ed. 55, 12150–12162 (2016).

Plutschack, M. B., Pieber, B., Gilmore, K. & Seeberger, P. H. The Hitchhiker’s guide to flow chemistry. Chem. Rev. 117, 11796–11893 (2017).

Noël T., Su Y., Hessel V. in Organometallic Flow Chemistry, (eds Noël T.) Vol. 57. (Switzerland, Springer, 2015).

Barnes, J. C. et al. Iterative exponential growth of stereo- and sequence-controlled polymers. Nat. Chem. 7, 810–815 (2015).

Leibfarth, F. A., Johnson, J. A. & Jamison, T. F. Scalable synthesis of sequence-defined, unimolecular macromolecules by flow-IEG. Proc. Natl Acad. Sci. USA 112, 10617–10622 (2015).

Mijalis, A. J. et al. A fully automated flow-based approach for accelerated peptide synthesis. Nat. Chem. Biol. 13, 464–466 (2017).

Bogdan, A. R. & Sach, N. W. The use of copper flow reactor technology for the continuous synthesis of 1,4-disubstituted 1,2,3-triazoles. Adv. Synth. Catal. 351, 849–854 (2009).

Fuchs, M., Goessler, W., Pilger, C. & Kappe, C. O. Mechanistic insights into copper(I)-catalyzed azide-alkyne cycloadditions using continuous flow conditions. Adv. Synth. Catal. 352, 323–328 (2010).

Razzaq, T. & Kappe, C. O. Continuous flow organic synthesis under high-temperature/pressure conditions. Chem. Asian J. 5, 1274–1289 (2010).

Bogdan, A. R. & James, K. Efficient access to new chemical space through flow—construction of druglike macrocycles through copper-surface-catalyzed azide–alkyne cycloaddition reactions. Chem. Eur. J. 16, 14506–14512 (2010).

Smith, C. J., Nikbin, N., Ley, S. V., Lange, H. & Baxendale, I. R. A fully automated, multistep flow synthesis of 5-amino-4-cyano-1,2,3-triazoles. Org. Biomol. Chem. 9, 1938–1947 (2011).

Carlos Varas, A., Noël, T., Wang, Q. & Hessel, V. Copper(I)-catalyzed azide–alkyne cycloadditions in microflow: catalyst activity, high-t operation, and an integrated continuous copper scavenging unit. ChemSusChem 5, 1703–1707 (2012).

Ötvös, S., Mándity, I. M., Kiss, L. & Fülöp, F. Alkyne–azide cycloadditions with copper powder in a high-pressure continuous-flow reactor: high-temperature conditions versus the role of additives. Chem. Asian J. 8, 800–808 (2013).

Ötvös, S., Georgiádes, A., Mándity, I. M., Kiss, L. & Fülöp, F. Efficient continuous-flow synthesis of novel 1,2,3-triazole-substituted β-aminocyclohexanecarboxylic acid derivatives with gram-scale production. Beilstein J. Org. Chem. 9, 1508–1516 (2013).

Ötvös, S. et al. Continuous-flow azide–alkyne cycloadditions with an effective bimetallic catalyst and a simple scavenger system. RSC Adv. 4, 46666–46674 (2014).

Gürsel, I. V., Aldiansyah, F., Wang, Q., Noël, T. & Hessel, V. Continuous metal scavenging and coupling to one-pot copper-catalyzed azide-alkyne cycloaddition click reaction in flow. Chem. Eng. J. 270, 468–475 (2015).

Chassaing, S., Beénéteau, V. & Pale, P. When CuAAC ‘Click Chemistry’ goes heterogeneous. Catal. Sci. Technol. 6, 923–957 (2016).

Mandoli, A. Recent advances in recoverable systems for the copper-catalyzed azide-alkyne cycloaddition reaction (CuAAC). Molecules 21, 1174 (2016).

Seath, C. P., Burley, G. A. & Watson, A. J. B. Determining the origin of rate-independent chemoselectivity in CuAAC reaction: an alkyne-specific shift in rate-determining step. Angew. Chem. Int. Ed. 56, 3314–3318 (2017).

Hatit, M. Z. C. et al. Chemoselective Sequential Click Ligations Directed by Enhanced Reactivity of an Aromatic Ynamine. Org. Lett. 18, 1694–1697 (2016).

Reiner, T., Earley, S., Turetsky, A. & Weissleder, R. Bioorthogonal small-molecule ligands for PARP1 imaging in living cells. Chembiochem 11, 2374–2377 (2010).

O’Donovan, L. et al. Parallel synthesis of cell-penetrating peptide conjugates of PMO toward exon skipping enhancement in duchenne muscular dystrophy. Nucleic Acid. Ther. 25, 1–10 (2015).

Re, F. et al. Functionalization of liposomes with ApoE-derived peptides at different density affects cellular uptake and drug transport across a blood-brain barrier model. Nanomedicine 7, 551–559 (2011).

Godfrey, C. et al. Delivery is key: lessons learnt from developing splice-switching antisense therapies. EMBO Mol. Med. 9, 545–557 (2017).

Sharma, V. K., Sharmab, R. K. & Singh, S. K. Antisense oligonucleotides: modifications and clinical trials. Med. Chem. Commun. 5, 1454–1471 (2014).

Juliano, R. L. The delivery of therapeutic oligonucleotides. Nucleic Acids Res. 44, 6518–6548 (2016).

Shabanpoor, F. et al. Identification of a peptide for systemic brain delivery of a morpholino oligonucleotide in mouse models of spinal muscular atrophy. Nucleic Acid Ther. 27, 130–143 (2017).

Acknowledgements

We thank Vapourtec for the copper reactors, the EPSRC UK National Mass Spectrometry Facility at Swansea University for analyses, the University of Strathclyde for PhD studentship (M.Z.C.H.), the Leverhulme Trust for a postdoctoral fellowship (L.F.R.; grant no. RPG-2014–001), and the BBSRC for funding (grant nos. BB/R006857/1, BB/N016378/1).

Author information

Authors and Affiliations

Contributions

Conceptualization: G.A.B., A.J.B.W.; data analysis: M.Z.C.H., G.A.B., A.J.B.W.; synthetic chemistry: M.Z.C.H., J.M.T.; preparation of peptide-based materials: M.Z.C.H.; preparation of phosphoramidite building blocks and solid phase ODN synthesis: L.F.R.; project supervision: F.V., G.A.B, A.J.B.W.; writing of the paper: G.A.B, A.J.B.W.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hatit, M.Z.C., Reichenbach, L.F., Tobin, J.M. et al. A flow platform for degradation-free CuAAC bioconjugation. Nat Commun 9, 4021 (2018). https://doi.org/10.1038/s41467-018-06551-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-018-06551-0

This article is cited by

-

Accelerating sulfonyl fluoride synthesis through electrochemical oxidative coupling of thiols and potassium fluoride in flow

Journal of Flow Chemistry (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.