Abstract

Although alkaline zinc-manganese dioxide batteries have dominated the primary battery applications, it is challenging to make them rechargeable. Here we report a high-performance rechargeable zinc-manganese dioxide system with an aqueous mild-acidic zinc triflate electrolyte. We demonstrate that the tunnel structured manganese dioxide polymorphs undergo a phase transition to layered zinc-buserite on first discharging, thus allowing subsequent intercalation of zinc cations in the latter structure. Based on this electrode mechanism, we formulate an aqueous zinc/manganese triflate electrolyte that enables the formation of a protective porous manganese oxide layer. The cathode exhibits a high reversible capacity of 225 mAh g−1 and long-term cyclability with 94% capacity retention over 2000 cycles. Remarkably, the pouch zinc-manganese dioxide battery delivers a total energy density of 75.2 Wh kg−1. As a result of the superior battery performance, the high safety of aqueous electrolyte, the facile cell assembly and the cost benefit of the source materials, this zinc-manganese dioxide system is believed to be promising for large-scale energy storage applications.

Similar content being viewed by others

Introduction

There is ever increasing demand of advanced battery technologies with high safety and low cost for applications in portable electronics, electrified vehicles, and renewable energy storage1,2,3,4,5,6,7. Although lithium-ion batteries have gained great improvement in energy/power density and life span, the safety issues associated with flammable organic electrolytes and the growing concerns of the price and availability of Li resources impede their large-scale deployment. Battery chemistries based on electrochemical intercalation/storage of Na+, K+, Mg2+, and Zn2+ in aqueous electrolytes have been considered as promising alternatives, because of high safety, materials abundance, and environmental friendliness8,9,10,11,12,13,14,15,16,17,18,19. Rechargeable Zn-ion batteries (ZIBs) are particularly attractive as zinc features higher water compatibility and stability than alkaline metals, allows multivalent charge transport carriers, and can be produced and recycled with mature industrial process20,21,22,23,24,25.

Zinc-manganese dioxide (Zn-MnO2) batteries have dominated the primary battery market because of low cost, high safety, and easy manufacturing26,27,28. It is highly intriguing to develop rechargeable Zn-MnO2 batteries. Nevertheless, previous attempts are plagued by poor cycling performance due to the formation of irreversible discharged species (e.g., Mn(OH)2 and ZnO at cathode and anode, respectively) in alkaline electrolytes29,30,31. Although alkaline Zn-MnO2 batteries (Fig. 1a) were shown rechargeable for extended cycles, the delivered capacity is limited at shallow depth of discharge (~ 10%)32. Recently, the rechargeability of aqueous Zn-MnO2 batteries has been improved by using mild acidic electrolyte (e.g., aqueous ZnSO4 solution)33−37. However, the reaction mechanism of MnO2 polymorphs remains elusive and controversial. For example, electrochemical Zn-insertion in α-MnO2 is shown to undergo phase transition from tunneled structure to spinel ZnMn2O4 33, layered Zn-buserite36, or birnessite38, most of which collapse upon cycling. A different mechanism was referred to the conversion reaction between α-MnO2 and MnOOH35. For γ-MnO2, complex mutiple-phase transformation was proposed on discharge, involving spinel-type ZnMn2O4, tunnel-type γ-Zn x MnO2, and layered-type L-Zn x MnO2 34. Additionally, the Zn-insertion properties in aqueous ZnSO4 electrolyte are found to vary among polymorphs: α-MnO2 featuring (2 × 2) + (1 × 1) tunnel structure39 and γ-MnO2 with (1 × 2) + (1 × 1) tunnels exhibit high capacity (150‒300 mAh g−1)34, 36, whereas the most stable (1 × 1) tunneled β-MnO2 phase40, 41 hardly incorporates Zn2+ ions33 due to narrow tunnels42. Furthermore, in the widely investigated ZnSO4 electrolyte, MnO2 generally suffers from capacity loss due to the dissolution of Mn2+ from Mn3+ disproportionation34, 35. Pre-addition of Mn2+ salt is proposed to improve capacity retention35 but the underneath mechanism remains unclear. Our previous study indicates that the use of zinc salt with bulky anion (e.g., CF3SO3 −) benefits reactivity and stability of Zn anode and spinel ZnMn2O4 cathode24. Therefore, elucidating the electrode reactions of MnO2 and exploiting compatible electrolyte are desirable in developing rechargeable aqueous Zn-MnO2 batteries.

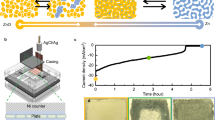

Zn-MnO2 battery chemistry. Schematic illustration of a the primary alkaline Zn-MnO2 battery using KOH electrolyte and b the rechargeable Zn-MnO2 cell using CF3SO3 −-based electrolyte. c Comparison of the cycling performance of Zn-MnO2 cells with electrolytes of 45wt.% KOH (at 0.32 C), 3 M ZnSO4, 3 M Zn(CF3SO3)2, and 3 M Zn(CF3SO3)2 with 0.1 M Mn(CF3SO3)2 additive at 0.65 C. nC equals the rate to charge/discharge the thereotical capacity (308 mAh g−1) of MnO2 in 1/n hours

Herein, we report high-performance rechargeable aqueous Zn-MnO2 cells based on MnO2 cathode, Zn anode, and Zn(CF3SO3)2 electrolyte with Mn(CF3SO3)2 additive. For the widely investigated α-, β-, and γ-MnO2 polymorphs, we elucidate a common electrode reaction mechanism, by combining electrochemical measurements, X-ray diffraction analysis (XRD), elemental analysis, transmission electron microscopy (TEM), and synchrotron X-ray absorption spectroscopy (XAS). Interestingly, in the exemplified β-MnO2 that has been previously demonstrated unfavorable for Zn intercalation, a layer-type phase (i.e., Zn-buserite B-Zn x MnO2·nH2O) is generated during the initial discharge, followed by reversible insertion/extraction of Zn2+ ions in the layered structure (Fig. 1b). Up to ~ 0.5 Zn per molecular MnO2 is accommodated on discharging, along with disproportionated Mn dissolution and capacity fade. We significantly improve the cycling stability of Zn-MnO2 cell by employing concentrated Zn(CF3SO3)2 electrolyte and Mn(CF3SO3)2 additive (Fig. 1c). The pre-added Mn(CF3SO3)2 is found to suppress Mn2+ dissolution and result in the formation of a uniform porous MnO x nanosheet layer on the cathode surface, which helps to maintain the electrode integrity. Remarkably, β-MnO2 exhibits high reversible capacity, high rate capability, and stable cyclability. We further demonstate a soft-packed Zn-MnO2 full cell that delivers a reversible capacity of 1550 mAh with a total energy density of 75.2 Wh kg−1 after 50 cycles.

Results

Materials synthesis and characterization

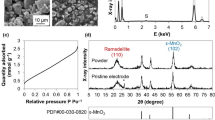

We selected pyrolusite β-MnO2 as a model polymorph, which has been previously demonstrated to exhibit extremely poor electrochemical activity33 and was prepared by a simple hydrothermal route in this study (detailedly described in experimental section). X-ray diffraction patterns (XRD, Supplementary Fig. 1a) reveals high purity of the formed tetragonal phase (JCPDS no. 24-735) with P42/mnm space group. Scanning electron microscope (SEM, Supplementary Fig. 1b) of the sample displays nanorod morphology with average length of 2 μm and width of 100–200 nm. Polymorphs of α-MnO2 and γ-MnO2 nanorods were also synthesized via hydrothermal technique (Supplementary Fig. 2; Supplementary Methods). Commerical β-MnO2 powders with large particle size of ~ 2 μm (Supplementary Fig. 3) were employed for comparison.

Electrode reaction mechanism

Figure 2a shows the cyclic voltammograms (CVs) of β-MnO2 in aqueous 3 M Zn(CF3SO3)2 electrolyte. A sharp peak at around 1.06 V is observed during the first cathodic sweeping. In the following cycles, the CV curves are well repeated with two cathodic peaks located at 1.35 and 1.17 V and an overlapped anodic peak at 1.6/1.65 V. The significant difference in CV profiles between the initial and subsequent cycles suggests phase transition. Figure 2b shows the typical galvanostatic profiles of β-MnO2 at 0.32 C. The first discharge curve displays a flat plateau at around 1.08 V while the second cycle presents two slopping discharge plateaus, in line with the CV results. Notably, the initial discharge capacity reaches 307 mAh g−1, which approaches the theoretical capacity of 308 mAh g−1 (based on MnO2) and corresponds to 0.5 Zn2+ per MnO2. The evolution of CV profiles and discharge plateaus indicates different mechanism of Zn2+ intercalation in MnO2 electrode36, 43, as discussed below.

Electrochemical and structural evolution of β-MnO2 in Zn-MnO2 cell. a Cyclic voltammograms of β-MnO2 electrode at a scan rate of 0.1 mV s−1 from 0.8 to 1.9 V. b Typical charge/discharge curves for the initial two cycles at 0.32 C in 3 M Zn(CF3SO3)2 aqueous electrolyte. The points A–J marked the states where data were collected for XRD analysis. c XRD patterns of β-MnO2 electrode at selected states during the first and second cycles

To probe the structural evolution of β-MnO2 in the discharge/charge process, ex-situ XRD patterns (Fig. 2c) were recorded at the selected states (marked points in Fig. 2b). On first discharging (A → D), the characteristic peaks of β-MnO2 are gradually weakened and new phase arises. Besides the peaks designated to the Zn(CF3SO3)2 salt, new peaks emerge at 6.47, 13.00, 19.58, 26.28, and 32.93°, which could be assigned to reflections from the (001)–(005) crystallographic planes of a layered Zn-buserite phase, respectively. The electrolyte salt is precipitated on the surface of both MnO2 cathode and Zn anode but can be easily removed by immersing and rinsing with water (Supplementary Fig. 4a–c). Notably, the XRD pattern of the rinsed cathode differs from that of previously reported species (e.g., MnOOH35, spinel ZnMn2O4 33, birnessite38, tunneled γ-ZnMnO2 34, and layered L-Zn x MnO2 34) in discharged MnO2 electrodes (Supplementary Fig. 4d). Rietveld refinement of the XRD data of the discharged electrode suggests the formation of Zn-buserite phase (Supplementary Fig. 4e). The exact structural motif of Zn-buserite is not determined yet, but will be further investigated in the future. The Zn-buserite phase, commonly found in layered Mn oxide mineral44,45,46, contains H2O layers in the channels between two MnO6 octohedron slabs (Fig. 1b), featuring a similar structure with Ca-buserite44 (JCPDS No.50-0015). Zn2+ cations reside above and below the Mn vacant sites and are coordinated with three O atoms adjacent to the vacancies and three O atoms from interlayer H2O36, 44,45,46. The presence of H2O in the discharged species was validated using thermal gravimetric analysis (TGA), indicating a composition of ~ 2.28 molecular H2O per formula of Zn-buserite (Supplementary Fig. 5). In the followed charging process (D→F), the intensity of characteristic peaks for the layered phase was gradually weakened upon extraction of Zn ions. This peak attenuation could be explained by the decrease of scattering atom concentration in unit cell and the weakening of Zn–O interaction due to Zn egress. Similar intensity variation of (00l) reflection has been observed on layered intercalation electrodes such as vanadium oxides9, 47. In the second cycle, the signals of layered compound were reversibly strengthened/weakened upon Zn2+ insertion/extraction. The presence of β-MnO2 can be observed in the initial several cycles but is not discernable after 10 cycles (Supplementary Fig. 6). We investigated the structural evolution of α-MnO2 and γ-MnO2 cathodes as well. Interestingly, these two polymorphs undergo phase transformation to layered Zn-buserite upon first discharging and reversible Zn intercalation in the layered structure on subsequent cycling (Supplementary Figs. 7 and 8), resembling the case of β-MnO2. The results suggest common electrode reaction mechanism in tunneled polymorphs of MnO2, which to the best of our knowlege, is first elucidated in mild acidic electrolytes.

The structural evolution of β-MnO2 electrode was further investigated by ex-situ TEM analysis. Figure 3a, b displays the TEM and high-resolution TEM (HRTEM) images at the initial state, where the lattice fringes can be indexed to the (110) plane of β-MnO2. The annular bright field-scanning TEM (ABF-STEM) image (Fig. 3c) clearly shows the atomic arrangement within the tunnel-like framework, as schematically viewed along the [100] direction of the lattice (Fig. 3d). After fully discharging, the one-dimensional nanorod shape is maintained, while the surface of electrode becomes rough with the formation of aggregated nanoparticles (Fig. 3e), which is ascribed to the structural distortion in the phase-conversion process. The observed lattice fringes with interplanar distances of 0.45, 0.64, and 1.29 nm correspond to the (003), (002), and (001) planes of Zn-buserite (Fig. 3f and Supplementary Fig. 9a), respectively, consistent with the XRD analysis.

Microstructural and compositional analysis of MnO2. a TEM image, b HRTEM image, c ABF-STEM image, and d schematic atomic model (viewed from the [100] zone axis) at the initial state. e TEM image, f HRTEM image, g EDS line scanning profiles in TEM, and h XPS spectra of the first fully discharged electrode. Scale bars, 50 nm a, e; 5 nm b, f; and 1 nm c, respectively

To eliminate the impact of precipitated electrolyte salt, the discharged electrode was rinsed with water for elemental dispersive spectroscopy (EDS) and X-ray photoelectron spectroscopy (XPS) analysis. The line scanning profile in TEM (Fig. 3g) and elemental mapping (Supplementary Fig. 9b) in STEM of the discharged electrode reveal the uniform distribution of Zn, Mn and O, whereas S and F from electrolyte are not detectable (Fig. 3g). In XPS spectra, the energy splitting (ΔE) of Mn 3 s doublet peaks is 4.7 and 5.0 eV for pristine and discharged electrodes, respectively, indicating reduced Mn valence after Zn insertion (Fig. 3h). At discharged state, a new Zn 3p peak appears at 92.0 eV, which is lower than that of Zn(CF3SO3)2 (92.7 eV) and could be assigned to the intercalated Zn. These results confirm the presence of Zn2+ ions into the layered manganese oxide host and rule out the possibility of electrode reactions associated with CF3SO3 − anions. Furthermore, the TEM images of β-MnO2 electrode after different cycles (Supplementary Fig. 10) indicate expansion and exfoliation of nanorods, which is attributed to the phase transition, Mn dissolution and repeated Zn2+ intercalation, and would incur capacity loss during cycling.

To gain insight into the variation of Mn oxidation state and electronic structure during the (de)intercalation process, we performed the synchrotron XAS characterization, which has been demonstrated useful to analyze manganese oxides48,49,50,51,52. Figure 4a shows the normalized Mn K-edge XANES (X-ray near edge absorption structure) profiles of β-MnO2 electrode at selected states in the initial two cycles. The nominal Mn valence was plotted vs. excitation energy of reference manganese oxides to establish fitted linear correlation (Fig. 4b). On discharging, the entire edge shifts toward lower energy, indicating a decrease of the average Mn oxidation state. The mean Mn valence at fully discharged state is estimated to be 3.6. During first charging, the edge position slightly shifts back to higher energy, while it remains almost unchanged in the second cycle. The interesting point is that the Mn valence should increase/decrease with Zn2+ intercalation/deintercalation and would approach 3 for the fully discharged electrode, as anticipated from the discharged capacity (Fig. 2b). We postulate that such unexpected observation could be ascribed to the disproportional dissolution of trivalent Mn species (Mn3+ s → Mn4+ s + Mn2+ aq)38, 53. Analysis of Mn by inductively coupled plasma atomic emission spectrometer (ICP-AES) evidences the change of Mn concentration in the electrolyte (Supplementary Fig. 11; Supplementary Note 1). On discharging, the amount of dissolved Mn increases and corresponds to ~ 8.9% of the total manganese at full discharge. The partial dissolution of Mn in electrolyte is a feasible attribution to the noticeable capacity loss on cycling.

XAS characterization of β-MnO2 electrode. a Mn-K edge XANES curves at selected discharge/charge states, with reference to standard MnO, Mn2O3, and Mn3O4. b Fitted linear relationship between the photon energy and oxidation state of Mn element. c The EXAFS spectra. d Schematic depiction of the unit cell of β-MnO2

Figure 4c shows the EXAFS (extended X-ray absorption fine structure) spectra of β-MnO2 electrode at selected Zn (de)intercalation stages. The strongest peak located at 1.5 Å is attributed to the closest oxygen (Mn-O) in the MnO6 octahedra. The peaks at 2.5 and 3.0 Å are assigned to Mn in the edge-sharing (Mn-Mnedge) and corner-sharing (Mn-Mncorner) MnO6 octahedra (Fig. 4d), respectively51, 54. When the elcctrode was fully discharged, the relative intensity of the Mn-Mncorner peak decreased to a much larger extent than that of Mn-O and Mn-Mnedge signals (Supplementary Fig. 12). This result is indicative of the breakage of the corner-shared MnO6 octahedra. Furthermore, the 3.0 Å peak broadens and slightly shifts to larger distance, which is related to the formation of Mn-O-Zn energy-absorbing path between the layered MnO6 octohedron slabs and inserted Zn ions. A comparison of the crystallographic structure between β-MnO2 and Zn-buserite suggests that the co-insertion of Zn2+ and H2O and the dissolution of Mn distort the pyrolusite framework, leaving Mn vacancies in the upper/underlying layers and generating layered Zn-buserite. This tunnel-to-layer phase transition is irreversible, as indicated by the absence of EXAFS spectra recovery on first recharge. Meanwhile, the broadened 3.0 Å peak is not fully recovered after second charging, which can be attritubed to the capacity loss (Fig. 2b). Notably, XAS analysis of α-MnO2 and γ-MnO2 electrodes (Supplementary Fig. 13) reveals similar behavior with that of β-MnO2, again suggesting common electrode reaction mechanism among different tunneled MnO2 polymorphs.

Electrochemical performance

To evaluate the electrochemical performance, coin-type Zn-MnO2 cell was assembled in ambient air by using β-MnO2 nanorod cathode, Zn foil anode, filter paper separator, and aqueous Zn(CF3SO3)2 electrolyte. The concentrated 3 M Zn(CF3SO3)2 results in better cyclic stability than diluted electrolyte (e.g., 1 M) (Supplementary Fig. 14), which is ascribed to the decrease of water activity and water-induced side reactions4, 24, 55. As shown in Fig. 1c, the cells based on mild acidic electrolye (3 M ZnSO4, pH ~ 3.4; 3 M Zn(CF3SO3)2, pH ~ 3.6) show much better cycling performance as compared with that employing KOH electolyte. Meanwhile, the cell using Zn(CF3SO3)2 electrolyte delivers much higher initial discharge capacity than that of ZnSO4 (275 vs. 120 mAh g−1) at 0.65 C. However, similar capacity deterioration is observed upon cycling, due to the loss of active mass. To address this issue, we pre-added Mn2+ salts into the electrolyte to accommodate the dissolution equilibrium of Mn2+ from MnO2 electrode. By eliminating the anion effect, we selected Mn(CF3SO3)2 as the electrolyte additive, with concentration from diluted 0.01 M to the saturated 0.1 M. The optimized electrolyte composition was found to be 3 M Zn(CF3SO3)2 + 0.1 M Mn(CF3SO3)2, which results in the highest Coulombic efficiency and ionic conductivity as well as high capacity of 225 mAh g−1 after 100 cycles (Supplementary Figs. 15 and 16).

Figure 5a shows the charge/discharge profiles of Zn-MnO2 cells at different current densities. Discharge capacities of 258, 213, 188, 151, and 115 mAh g−1 were recorded at rates of 0.65, 1.62, 3.25, 6.50, and 16.20 C, respectively. Even at a high rate of 32.50 C, a reversible capacity of 100 mAh g−1 could be obtained. In addition, when the rate shifted back to 0.65 C, the capacity recovered to 246 mAh g−1, showing a strong tolerance to the rapid Zn2+ ions insertion/extraction (Supplementary Fig. 17). The superior rate performance can be further viewed from the Ragone plots (specific energy vs. specific power) by comparing the Zn-MnO2 system to reported α-MnO2 33, δ-MnO2 56, Zn0.25V2O5·nH2O9, Zn1.86Mn2O4 24, todorokite37, KCuFe(CN)6 (CuHCF)21, and Zn3[Fe(CN)6]2 (ZnHCF)57 cathodes for aqueous ZIBs (Fig. 5b). High-specific energy and specific power (254 Wh kg−1 at 197 W kg−1; 110 Wh kg−1 at 5910 W kg−1) can be simultaneously achieved, which is promising for energy storage applications. The Zn-MnO2 cell was galvanostatically discharged/charged at 6.50 C (Fig. 5c) to evaluate the long-term cycling stability. Remarkably, the reversible capacity sustains 135 mAh g−1 with a capacity retention of 94% over 2000 cycles and Coulombic efficiency approaching 100%.

Electrochemical performance of Zn-MnO2 cells in 3 M Zn(CF3SO3)2 electrolyte with 0.1 M Mn(CF3SO3)2 additive. a Discharge/charge profiles at varying C rates. b The Ragone plots of Zn-MnO2 battery and ZIBs with other reported cathode materials. Values are based on the total active mass of both cathode and anode. c Long-cycle performance at rate of 6.5 C. Inset shows the capacity evolution at the initial 19 cycles

We also investigated the Zn-MnO2 cells with 3 M ZnSO4 + 0.1 M MnSO4 and 3 M Zn(CF3SO3)2 + 0.1 M MnSO4 electrolytes, which delivered initial discharge capacity of 110 and 205 mAh g−1, respectively (Supplementary Fig. 18). In SO4 2−-based electrolyte, an increase of capacity was observed within the first several cycles, which was attributed to the activation process that has been similarly found in reported α-/γ-MnO2 cathodes34,35,36. Interestingly, the CF3SO3 −-based electrolyte endows much higher initial discharge capacity (275 mAh g−1 at 0.65 C) and results in capacity stabilization after ~ 10 cycles. The different behaviors could be ascribed to the Zn(CF3SO3)2 solution that not only features higher ionic conductivity (Supplementary Fig. 19) but also enables faster kinetics and higher stability of Zn plating/stripping as compared with sulfate and alkaline electrolytes (Supplementary Fig. 20; Supplementary Note 2). Besides, the bulky CF3SO3 − anion (vs. SO4 2− with double charge) could decrease the number of water molecules surrounding Zn2+ cations and reduce the solvation effect24, thus facilitating Zn2+ ions transportation and charge transfer.

Although the pre-addition of Mn2+ in electrolyte has been demonstrated to enhance the cyclability of MnO2 electrode35, the underneath mechanism remains unclear. To further understand the functions of pre-added Mn2+, we have carried out a series of analytical studies, including electrochemical measurements, XRD, Raman, XPS, XANES, and SEM/TEM. In acidic electrolyte, manganese oxides (MnO x ) such as MnO2 or Mn2O3 can be generated from electrolysis of Mn2+-containing solution32 based on the following reactions:

According to Nernst equation, the required theoretical potentials to form MnO2 and Mn2O3 in Mn(CF3SO3)2 (0.1 M, pH 6.0) solution are 1.35 and 1.26 V (vs. Zn2+/Zn), respectively; the corresponding values are 1.60 and 1.64 V in 3 M Zn(CF3SO3)2 electrolyte containing 0.1 M Mn2+ (pH 3.8). This estimation is consistent with the voltammetry results of three-electrode measurements (Supplementary Fig. 21; Supplementary Note 3), which also reveals that Mn2+ is not reduced within the investigated potential windows. After charging in 3 M Zn(CF3SO3)2 + 0.1 M Mn(CF3SO3)2 electrolyte, brown deposit layer was observed on the electrode. The layer is composed of manganese oxide with Mn oxidation state between + 3 and + 4, and features nanosheet morphology and poor crystallinity, as analyzed by SEM, XRD, Raman, XPS, and XAENS (Supplementary Fig. 22).

In post-mortem analysis of Zn-MnO2 cell using 3 M Zn(CF3SO3)2 + 0.1 M Mn(CF3SO3)2 electrolyte, we also observed an interconnected porous MnO x layer on the cathode surface after charging (Fig. 6a, b). The cross-sectional SEM image and elemental mapping images (Fig. 6c) evidence the presence of a uniform layer with thickness around 10 μm. TEM imaging and selected area electron diffraction (SAED) analysis reveal porous nanosheet microstructure and amorphous character of the deposited layer (Fig. 6d), which would facilitate mass diffusion. In contrast, the integrity of β-MnO2 electrode was seriously destroyed with the formation of cracks in 3 M Zn(CF3SO3)2 electrolyte without Mn(CF3SO3)2 additive (Fig. 6e). The electrode pulverization would break the electronic conducting network and increase electrode polarization, further aggravating the capacity decay. Electrochemical impedance spectroscopy (EIS) was performed in a three-electrode cell, using the dismantled cathode after ten cycles as the working electrode, platinum plate as the counter electrode, and saturated calomel electrode (SCE) as the reference electrode. The cycled electrode in Mn2+-added electrolyte displays two depressed semicircles in high frequency area and one line in low frequency region (Fig. 6f). Fitting the EIS data (Supplementary Table 1) gives a series resistance (R s, 4.5 Ω), an interface resistance (R i, 6.0 Ω) between electrolyte and deposited layer, a charge-transfer resistance (R ct, 25 Ω) and a Warburg diffusion impedance (Z w, 124.7 Ω). In comparison, the cell without electrolyte additive shows higher R s (8.0 Ω), R ct (350 Ω), and Z w (1200 Ω), in the absence of the apparent interface component (Fig. 6g).

Function of pre-added Mn2+ in electrolyte. a, b, c, e SEM, d TEM images, and f, g three-electrode-cell EIS analysis of re-obtained cathodes after ten cycles in 3 M Zn(CF3SO3)2 electrolyte a–d, f with and e, g without 0.1 M Mn(CF3SO3)2 additive. Insets of c, d show elemental mapping and SAED pattern, respectively. Insets of f, g show the equivalent circuit to fit the EIS data, where R s, R i, R ct, CPE, and Z w represent series resistance, interface resistance between electrolyte and deposited layer, charge-transfer resistance, constant-phase element, and Warburg diffusion process, respectively. Scale bars, 5 μm a, e; 1 μm b; 10 μm c; 100 nm d; and 5 1/nm (inset of d), respectively

Based on the above results, we propose three merits of the Mn2+ electrolyte additive for the Zn-MnO2 battery: (1) accommodating and compensating Mn2+ dissolution from the electrode, (2) improving initial Coulombic efficiency and ionic conductivity of the electrolyte and (3) generating a uniform porous nanostructured MnO x film on the cathode surface, which helps to maintain the electrode integrity and favor charge transfer. Note that the generated MnO x layer itself contributes to nearly 2.4% of the capacity delivered by the active material (Supplementary Fig. 23). The Zn(CF3SO3)2 + Mn(CF3SO3)2 electrolyte is also applicable to improve the cycling stability of nanostructured α-MnO2 and γ-MnO2 cathodes (Supplementary Fig. 24a, b). Furthermore, commercial β-MnO2 powders with irregular shape and micrometer particle size (Supplementary Fig. 3) also exhibit considerable capacity (132 mAh g−1 at 0.65 C) and cyclability (200 cycles) in this electrolyte (Supplementary Fig. 24c, d).

The Zn anode was also investigated to understand the high-performing Zn-MnO2 cell chemistry (Supplementary Figs. 25–28). Post-mortem analysis of cycled Zn in three-electrode cell with 3 M Zn(CF3SO3)2 + 0.1 M Mn(CF3SO3)2 electrolyte reveals a dense and dendrite-free surface morphology after 280 h of repeated Zn plating/stripping (Supplementary Fig. 25). In a Zn-MnO2 full cell, neither dendritic morphology nor formation of byproducts such as ZnO or Zn(OH)2 was evidenced after rate test (Supplementary Fig. 26), favoring the cyclic stability of Zn-MnO2 batteries. In contrast, in 3 M ZnSO4 + 0.1 M MnSO4 electrolyte, Zn plate with lots of cracks formed on the zinc surface, while ZnO nanorods were observed in KOH electrolyte, which would deter the cyclability of Zn (Supplementary Figs. 25 and 27). Furthermore, the EDS analysis indicates that there is no detectable Mn in Zn anode (Supplementary Fig. 28).

Discussion

The exceptional performance of Zn-MnO2 coin-type batteries has motivated us to further assess soft-packed full cells, which were facilely assembled in ambient air negating complicated procedures or extra protection (Supplementary Methods). Figure 7a schematically shows the battery configuration consisting of six anode—separator—cathode stacks. A typical assembled pouch-type cell lightens a “Zn-Mn”—shape indicator containing 44 LEDs (Fig. 7b). A stable discharge capacity of 1550 mAh can be obtained after 50 repeated cycles with an average potential of 1.35 V (Fig. 7c). The full cell delivers an energy density of 158.5 Wh kg−1 based on the total weight of the active materials (including both cathode and anode). This value far exceeds that of other aqueous Li-ion batteries (50–90 Wh kg−1)3, 4, 58 and aqueous Na-ion batteries (~ 33 Wh kg−1)8, 16, 59. Remarkably, a total energy density of 75.2 Wh kg−1 is obtained according to the mass of whole battery mass, much higher than that of commercial Pb-acid (~ 30 Wh kg−1) and Ni-Cd technologies (~ 50 Wh kg−1)26. We note that the higher price of anhydrous Zn(CF3SO3)2 salt relative to ZnSO4 and KOH would inevitably increase the practical cost of this aqueous Zn-MnO2 battery system, even though Zn(CF3SO3)2 merely serves as charge carrier and is not consumed during battery operation. Fortunately, considering the abundant, cheap precursors (i.e., triflic acid and ZnCO3)60 and the direct usage of hydrate-form salt in aqueous solution, the cost of Zn(CF3SO3)2 electrolyte could be expected to drop with the development of synthetic technique and market demand.

Electrochemical performance of pouch-type Zn-MnO2 battery. a Schematic illustration of the cell configuration with anode—separator—cathode stacks. b A digital photo of the soft-package battery powering a series of LED lights. c Cycling performance in the voltage range of 0.8–1.9 V at constant current of 0.72 A

In conclusion, we demonstrate a high-performing rechargeable Zn-MnO2 battery system based on zinc anode, β-MnO2 cathode, and mild acidic aqueous electrolyte. We elucidate the Zn-insertion mechanism and structural evolution of MnO2 cathode by combining electrochemical investigations, XRD, TEM, ICP, and XANES/EXAFS analysis. A phase transition from tunneled to layered structure (Zn-buserite) occurs during the first discharge of MnO2, followed by reversible Zn2+ (de)intercalation in the H2O-containing Zn-buserite framework. Unlike previous reports, this electrode mechanism is common in polymorphs of α-MnO2, γ-MnO2, and β-MnO2. The phase tranformation, Mn dissolution and electode pulverization incur capacity fade of MnO2. By formulating an aqueous 3 M Zn(CF3SO3)2 + 0.1 M Mn(CF3SO3)2 electrolyte, the Mn2+ dissolution can be effectively accommodated and the electrode integrity can be maintained because of the in-situ generated amorphous MnO x layer. As a result, Zn-MnO2 cell exhibits high capacity (225 mAh g−1 at 0.65 C), high rate capability (100 mAh g−1 at 32.50 C) and long-term cycling stability (94% capacity retention after 2000 cycles at 6.50 C). Furthermore, the assembled soft-packed Zn-MnO2 battery can deliver a high reversible capacity of 1550 mAh with a total energy density of 75.2 Wh kg−1, among the highest value achieved in aqueous battery technologies. The present Zn-MnO2 system holds great promise for potential applications in large-scale energy storage, in view of the remarkable electrochemical performance and other advantages such as low materials cost, easy manufacturing, high safety, and environmental friendliness.

Methods

Synthesis

β-MnO2 nanorods were synthesized by a hydrothermal method. In a typical synthesis, 30 ml KMnO4 (0.1 M) and 30 ml MnSO4·H2O (0.6 M) were mixed under continuous stirring for 30 min at room temperature. The mixture was loaded into a 100 ml Teflon-lined autoclave and maintained at 140 °C for 12 h. The obtained product was centrifuged, washed thoroughly using water and absolute ethyl alcohol, and dried at 80 °C for 10 h. Bulk β-MnO2 powders was purchased from Alfa Aesar. α-MnO2 and γ-MnO2 nanorods were synthesized via hydrothermal technique following previously reported procedures61.

Characterization

Powder XRD patterns were collected on a Rigaku X-ray diffractometer (MiniFlex600) with Cu Kα radiation. SEM images were obtained on Field-emission JEOL JSM-7500F microscope. TEM and HRTEM images were taken on Philips Tecnai G2 F20. ABF-STEM was performed on Titan Cubed Themis G2 300 (FEI) at an acceleration voltage of 200 kV. The XAS data were collected on BL14W1 beamline of Shanghai Synchrotron Radiation Facility and analyzed with software of Ifeffit Athena62. ICP-AES measurements were conducted on a PerkinElmer Optima 8300. XPS was tested on a Perkin Elmer PHI 1600 ESCA system. Raman spectra were obtained on confocal Thermo-Fisher Scientific DXR microscope using 532 nm excitation. TGA was measured by a Netzsch STA 449 F3 Jupiter analyzer.

Electrochemical test

Electrochemical performance was tested using CR2032 coin-type cells. The working electrode was fabricated by blending MnO2 powder, Super P carbon and polyvinylidene fluoride in a weight ratio of 8:1:1 using N-methyl-2-pyrrolidone as solvent. The obtained slurry was pasted onto a Ti foil and vacuum-dried at 100 °C for 12 h. The loading mass of active material was ~ 2 mg cm−2. Filter paper and zinc foil were employed as the separator and anode, respectively. A 3 M Zn(CF3SO3)2 with/without 0.1 M Mn(CF3SO3)2 aqueous solution was used as the electrolyte. The assembled cells were galvanostatically cycled between 0.8 and 1.9 V using the LAND-CT2001A battery-testing instrument. Calculation of specific capacities was based on the mass of initial MnO2. CVs were measured on a Parstat 263 A electrochemical workstation (AMETEK). EIS was performed on a Parstat 2273 electrochemical workstation (AMETEK). The AC perturbation signal was ± 10 mV and the frequency ranged from 100 kHz to 100 mHz. The electrochemical behaviors of Mn2+ additive in electrolyte were characterized using three-electrode cells (Ti foil as working electrode, platinum plate or Zn foil as counter electrode, and SCE as reference electrode).

Data availability

The authors declare that all the relevant data are available within the paper and its Supplementary Information file or from the corresponding author upon reasonable request.

References

Armand, M. & Tarascon, J. M. Building better batteries. Nature 451, 652–657 (2008).

Choi, J. W. & Aurbach, D. Promise and reality of post-lithium-ion batteries with high energy densities. Nat. Rev. Mater. 1, 16013 (2016).

Li, W., Dahn, J. R. & Wainwright, D. S. Rechargeable lithium batteries with aqueous electrolytes. Science 264, 1115–1118 (1994).

Suo, L. et al. “Water-in-salt” electrolyte enables high-voltage aqueous lithium-ion chemistries. Science 350, 938–943 (2015).

Lin, M. C. et al. An ultrafast rechargeable aluminium-ion battery. Nature 520, 325–328 (2015).

Ponrouch, A., Frontera, C., Barde, F. & Palacin, M. R. Towards a calcium-based rechargeable battery. Nat. Mater. 15, 169 (2015).

Hassoun, J., Lee, K. S., Sun, Y. K. & Scrosati, B. An advanced lithium ion battery based on high performance electrode materials. J. Am. Chem. Soc. 133, 3139–3143 (2011).

Kim, H. et al. Aqueous rechargeable Li and Na ion batteries. Chem. Rev. 114, 11788–11827 (2014).

Kundu, D. et al. A high-capacity and long-life aqueous rechargeable zinc battery using a metal oxide intercalation cathode. Nat. Energy 1, 16119 (2016).

Pasta, M. et al. Full open-framework batteries for stationary energy storage. Nat. Commun. 5, 3007 (2014).

Pasta, M., Wessells, C. D., Huggins, R. A. & Cui, Y. A high-rate and long cycle life aqueous electrolyte battery for grid-scale energy storage. Nat. Commun. 3, 1149 (2012).

Lu, Y., Goodenough, J. B. & Kim, Y. Aqueous cathode for next-generation alkali-ion batteries. J. Am. Chem. Soc. 133, 5756–5759 (2011).

Wang, Y. et al. Ti-substituted tunnel-type Na0.44MnO2 oxide as a negative electrode for aqueous sodium-ion batteries. Nat. Commun. 6, 6401 (2015).

Yabuuchi, N., Kubota, K., Dahbi, M. & Komaba, S. Research development on sodium-ion batteries. Chem. Rev. 114, 11636–11682 (2014).

Su, D., McDonagh, A., Qiao, S. Z. & Wang, G. High-capacity aqueous potassium-ion batteries for large-scale energy storage. Adv. Mater. 29, 1604007 (2017).

Shan, X. et al. Bivalence Mn5O8 with hydroxylated interphase for high-voltage aqueous sodium-ion storage. Nat. Commun. 7, 13370 (2016).

Häupler, B. et al. Aqueous zinc-organic polymer battery with a high rate performance and long lifetime. NPG Asia Mater. 8, e283 (2016).

Sun, X. et al. Investigation of the mechanism of Mg insertion in birnessite in nonaqueous and aqueous rechargeable mg-ion batteries. Chem. Mater. 28, 534–542 (2016).

Bucur, C. B., Gregory, T., Oliver, A. G. & Muldoon, J. Confession of a magnesium battery. J. Phys. Chem. Lett. 6, 3578–3591 (2015).

González, M. A. et al. Layered double hydroxides as a suitable substrate to improve the efficiency of Zn anode in neutral pH Zn-ion batteries. Electrochem. Commun. 68, 1–4 (2016).

Trócoli, R. & La Mantia, F. An aqueous zinc-ion battery based on copper hexacyanoferrate. ChemSusChem. 8, 481–485 (2015).

Tahil, W. The zinc air battery and the zinc economy: A virutuous circle. Available at: www.meridian-int-res.com/Projects/The_Zinc_Air_Solution.pdf (Meridian International Research, 2007).

Chamoun, M. et al. Hyper-dendritic nanoporous zinc foam anodes. NPG Asia Mater 7, e178 (2015).

Zhang, N. et al. Cation-deficient spinel ZnMn2O4 cathode in Zn(CF3SO3)2 electrolyte for rechargeable aqueous Zn-ion battery. J. Am. Chem. Soc. 138, 12894–12901 (2016).

Cheng, Y. et al. Highly reversible zinc-ion intercalation into chevrel phase Mo6S8 nanocubes and applications for advanced zinc-ion batteries. ACS Appl. Mater. Interfaces 8, 13673–13677 (2016).

Linden, D. & Reddy, T. Handbook of Batteries 3rd edn (McGraw-Hill, 2002).

Winter, M. & Brodd, R. J. What are batteries, fuel cells, and supercapacitors? Chem. Rev. 104, 4245–4270 (2004).

Cheng, F. Y., Chen, J., Gou, X. L. & Shen, P. W. High-power alkaline Zn–MnO2 batteries using γ-MnO2 nanowires/nanotubes and electrolytic zinc powder. Adv. Mater. 17, 2753–2756 (2005).

Kannan, A. M. et al. Characterization of the bismuth-modified manganese dioxide cathodes in rechargeable alkaline cells. J. Electrochem. Soc. 149, A483 (2002).

McLarnon, F. R. & Cairns, E. J. The secondary alkaline zinc electrode. J. Electrochem. Soc. 138, 645–656 (1991).

Shen, Y. & Kordesch, K. The mechanism of capacity fade of rechargeable alkaline manganese dioxide zinc cells. J. Power Sources 87, 162–166 (2000).

Gibson, A. J. et al. Dynamic electrodeposition of manganese dioxide: Temporal variation in the electrodeposition mechanism. J. Electrochem. Soc. 163, H305–H312 (2016).

Xu, C., Li, B., Du, H. & Kang, F. Energetic zinc ion chemistry: The rechargeable zinc ion battery. Angew. Chem. Int. Ed. 51, 933–935 (2012).

Alfaruqi, M. H. et al. Electrochemically induced structural transformation in a γ-MnO2 cathode of a high capacity zinc-ion battery system. Chem. Mater. 27, 3609–3620 (2015).

Pan, H. et al. Reversible aqueous zinc/manganese oxide energy storage from conversion reactions. Nat. Energy 1, 16039 (2016).

Lee, B. et al. Elucidating the intercalation mechanism of zinc ions into small alpha-MnO2 for rechargeable zinc batteries. Chem. Commun. 51, 9265–9268 (2015).

Lee, J. et al. Todorokite-type MnO2 as a zinc-ion intercalating material. Electrochim. Acta 112, 138–143 (2013).

Lee, B. et al. Electrochemically-induced reversible transition from the tunneled to layered polymorphs of manganese dioxide. Sci. Rep. 4, 6066 (2014).

Yuan, Y. et al. The influence of large cations on the electrochemical properties of tunnel-structured metal oxides. Nat. Commun. 7, 13374 (2016).

Jiao, F. & Bruce, P. G. Mesoporous crystalline β-MnO2–a reversible positive electrode for rechargeable lithium batteries. Adv. Mater. 19, 657–660 (2007).

Tompsett, D. A., Parker, S. C. & Islam, M. S. Rutile (β-)MnO2 surfaces and vacancy formation for high electrochemical and catalytic performance. J. Am. Chem. Soc. 136, 1418–1426 (2014).

Wei, C. et al. Preparation and characterization of manganese dioxides with nano-sized tunnel structures for zinc ion storage. J. Phys. Chem. Solids 73, 1487–1491 (2012).

Yamada, A. et al. Room-temperature miscibility gap in LixFePO4. Nat. Mater. 5, 357–360 (2006).

Luo, J. et al. Double-aging method for preparation of stabilized Na−buserite and transformations to todorokites incorporated with various metals. Inorg. Chem. 38, 6106–6113 (1999).

Post, J. E. Manganese oxide minerals: Crystal structures and economic and environmental significance. Proc. Natl Acad. Sci. 96, 3447–3454 (1999).

Golden, D. C., Chen, C. C. & Dixon, J. B. Transformation of birnessite to buserite, todorokite, and manganite under mild hydrothermal treatment. Clays Clay Miner 35, 271–280 (1987).

Tepavcevic, S. et al. Nanostructured bilayered vanadium oxide electrodes for rechargeable sodium-ion batteries. ACS Nano 6, 530–538 (2012).

Hu, Y. Y. et al. Origin of additional capacities in metal oxide lithium-ion battery electrodes. Nat. Mater. 12, 1130–1136 (2013).

Lu, J. et al. Effectively suppressing dissolution of manganese from spinel lithium manganate via a nanoscale surface-doping approach. Nat. Commun. 5, 5693 (2014).

Kim, C. et al. Direct observation of reversible magnesium ion intercalation into a spinel oxide host. Adv. Mater. 27, 3377–3384 (2015).

Zhang, R. et al. α-MnO2 as a cathode material for rechargeable Mg batteries. Electrochem. Commun. 23, 110–113 (2012).

Li, C. et al. Phase and composition controllable synthesis of cobalt manganese spinel nanoparticles towards efficient oxygen electrocatalysis. Nat. Commun. 6, 7345 (2015).

Thackeray, M. M. et al. Structural fatigue in spinel electrodes in high voltage (4 V) Li / LixMn2O4 cells. Electrochem. Solid-State Lett. 1, 7–9 (1998).

Nam, K. W., Kim, M. G. & Kim, K. B. In situ Mn K-edge x-ray absorption spectroscopy studies of electrodeposited manganese oxide films for electrochemical capacitors. J. Phys. Chem. C 111, 749–758 (2007).

Alfaruqi, M. H. et al. A layered δ-MnO2 nanoflake cathode with high zinc-storage capacities for eco-friendly battery applications. Electrochem. Commun. 60, 121–125 (2015).

Ramanujapuram, A. et al. Degradation and stabilization of lithium cobalt oxide in aqueous electrolytes. Energy Environ. Sci. 9, 1841–1848 (2016).

Zhang, L., Chen, L., Zhou, X. & Liu, Z. Towards high-voltage aqueous metal-ion batteries beyond 1.5 V: The zinc/zinc hexacyanoferrate system. Adv. Energy Mater. 5, 1400930 (2015).

Luo, J. Y., Cui, W. J., He, P. & Xia, Y. Y. Raising the cycling stability of aqueous lithium-ion batteries by eliminating oxygen in the electrolyte. Nat. Chem. 2, 760–765 (2010).

Li, Z. et al. Towards high power high energy aqueous sodium-ion batteries: The NaTi2(PO4)3/Na0.44MnO2 system. Adv. Energy Mater 3, 290–294 (2013).

Chandak, H., Sarode, P. & Bahekar, S. Zn(OTf)2-mediated expeditious and solvent-free synthesis of propargylamines via C–H activation of phenylacetylene. Synlett 27, 2209–2212 (2016).

Cheng, F. et al. Facile controlled synthesis of MnO2 nanostructures of novel shapes and their application in batteries. Inorg. Chem. 45, 2038–2044 (2006).

Yu, H. et al. The XAFS beamline of SSRF. Nucl. Sci. Tech. 26, 050102 (2015).

Acknowledgements

This work was supported by MOST (2016YFA0202500 and 2017YFA0206702), NSFC (21231005, 21473235, and 11227902) and MOE (B12015, ACET-13-0296, and IRT13R30).

Author information

Authors and Affiliations

Contributions

N.Z., J.L., and L.W. conducted the synthesis. N.Z. carried out the characterization and the electrochemical measurements. N.Z., F.C., and J.C. co-wrote the manuscript. N.Z., F.C., and X.L. analyzed the results of synchrotron X-ray absorption spectroscopy. All authors discussed the data and commented on the manuscript. F.C. and J.C. directed the research.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, N., Cheng, F., Liu, J. et al. Rechargeable aqueous zinc-manganese dioxide batteries with high energy and power densities. Nat Commun 8, 405 (2017). https://doi.org/10.1038/s41467-017-00467-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-017-00467-x

This article is cited by

-

Inkjet-printed flexible planar Zn-MnO2 battery on paper substrate

Scientific Reports (2024)

-

An extended substrate screening strategy enabling a low lattice mismatch for highly reversible zinc anodes

Nature Communications (2024)

-

The photocatalytic oxidation of As(III) on birnessite

npj Clean Water (2024)

-

Development of a Qualitative Tool for Sustainability Assessment and Application of the Tool to Benchmark Electronic Smart Labels

Circular Economy and Sustainability (2024)

-

ZnO Additive Boosts Charging Speed and Cycling Stability of Electrolytic Zn–Mn Batteries

Nano-Micro Letters (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.