Abstract

Ten analogues of a teicoplanin pseudoaglycon derivative have been synthesized with the aim of optimizing the in vitro activity of the compound against VanA type vancomycin resistant enterococci (VRE) isolated from hospitalized patients. Teicoplanin, vancomycin, and oritavancin were used as reference antibiotics for the antibacterial evaluations. One of the new derivatives exhibited far superior activity than the original compound. The in vitro MICs measured were comparable to that of oritavancin against the investigated VRE strains.

Similar content being viewed by others

Introduction

When resistance to the first beta lactam – penicillin - started to emerge, vancomycin was the first glycopeptide antibiotic used for the treatment of Gram-positive bacterial infections with clinical success. A few decades later the usage of vancomycin heavily increased, which definitely contributed to the development of vancomycin resistance by enterococci, followed by the vanA gene mediated teicoplanin resistance in the 1990s [1]. By the 21st century, antibiotic resistance has become one of the most challenging problems in public healthcare. The demand for new antibacterial drugs including glycopeptide antibiotics stimulated the development of semisynthetic derivatives which have better pharmacokinetic profiles or higher activity against resistant pathogens than those on the market. This resulted in the successful launch of oritavancin, a chloroeremomycin derivative which is known to have exceptionally high activity along with concentration dependent bactericidal effect against a wide range of glycopeptide resistant enterococci, including VanA strains [2].

For many years, our group has been working on the synthesis of new glycopeptides using different parent antibiotics as starting compounds, focusing on N-terminal modifications by a wide range of chemical reactions [3, 4]. So far, the most potent derivatives appear to be those of teicoplanin [5, 6]. Teicoplanin (Fig. 1) is a mixture of six major (A2–1–5 and A3–1, which lacks the N-acyl-glucosamine moiety) and minor components, and is used in such form, however the exact composition suitable for clinical use is more or less strictly stated in pharmacopoeias e. g. Ph. Eur. 9.0. For the sake of synthetic simplicity, we have mainly synthesized lipophilic derivatives of the teicoplanin pseudoaglycon [5,6,7], that proved to be highly active even against multiresistant Gram-positive strains.

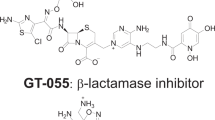

Recently we have reported on the in vitro antibacterial activity of teicoplanin pseudoaglycon derivatives bearing various N-terminal side chain moieties against a collection of vancomycin resistant enterococci [7]. One of the compounds (1, Fig. 2), a triazole derivative, showed significantly lower MIC values compared to the others, although many of the strains were not susceptible to either of the compounds.

In the SAR studies of teicoplanin derivatives, highly vancomycin or teicoplanin resistant enterococci seem to have not been widely investigated. Practically, hardly any of the publications describing the classical modifications of teicoplanin (e.g. deglycosylation [8], N-alkylation [9], ester, and amide formation [10, 11], a combination of these [12], N-acylation [13], synthesis of thioureas [14], etc.) mention activities against teicoplanin resistant strains, which might be due to the less common occurrence of VanA type enterococci at that time. Importantly, however, after the synthesis and in vivo evaluation of several of those compounds, a general finding of the Lepetit Group was, that derivatives on which the N-acyl-d-glucosamine moiety is present are likely to have superior pharmacokinetics.

In a later publication by Malabarba et al., the role of the N-acetyl-d-glucosamine moiety in the antibacterial activity was carefully investigated [15]. Using reductive reaction conditions, they have managed to selectively remove the N-acetyl-glucosamine, which is not possible by the traditional acid hydrolysis methods. In that paper, several teicoplanin resistant Enterococcus faecalis and Enterococcus faecium strains were used for the antibacterial evaluations. The main finding was, that the selective removal of the N-acetyl-glucosamine resulted in more active compounds against VRE, thus, the presence of this sugar is unfavorable for anti-VRE activity. This might still not clearly answer, whether the classical, gradual acidic deglycosylation (i.e. the removal of N-acyl-β-d-glucosamine, α-d-mannose, and the N-acetyl-β-d-glucosamine, in that order) of a certain derivative yields compounds with better or weaker in vitro activity against VRE.

The transformation of the terminal carboxyl function of teicoplanin-like antibiotics into different amides with basic character is known to frequently enhance the antibacterial activity and in vivo efficacy [11]. The improvement is usually more observable against staphylococci, but the susceptibility of resistant enterococci to such amide derivatives is also likely to increase, as it was demonstrated in the case of the structurally related antibiotic A-40926 [16].

Considering the above facts, by synthesizing several analogs of compound 1, we investigated the influence of different degrees of deglycosylation, the modification of the C-terminus or both on the antibacterial activity, including the potency against clinical isolates of VRE. Here, we present the synthesis and the in vitro antibacterial properties of the new derivatives.

Results and discussion

Synthesis

For the modification of the C-terminus 3-(dimethylamino)-1-propylamine was chosen for amide formation, as this moiety seems to enhance the activity rather consistently for teicoplanin and related glycopeptides e.g. dalbavancin, the semisynthetic A-40926 derivative [11, 16]. To slightly increase the lipophilicity, 3-(diethylamino)-1-propylamine was also used for the C-terminal modification (except for teicoplanin A2).

The synthesis began with the preparation of compound 1 by following the procedure we have already published [6]. From this compound, the two amide analogs 2 and 3 were prepared by using 3-(dimethylamino)-1-propylamine and 3-(diethylamino)-1-propylamine, respectively and PyBOP as the peptide coupling reagent (Scheme 1).

Triazole derivatives of the other type of pseudoaglycon (teicoplanin A3–1) and the aglycon (Scheme 2 and Scheme 3) were prepared as follows: deglycosylation reactions were carried out as they are described in the literature [9]. The hydrolysis products were then transformed into the corresponding azido derivatives by the method described earlier [6], and finally the Cu(I)-catalyzed azide-alkyne cycloaddition (CuAAC) gave triazole derivatives 4 and 7 of teicoplanin A3-1 and teicoplanin aglycon, respectively.

Amides 5 and 6 were prepared from derivative 4 by the same method as described for 2 and 3 above. The peptide coupling reaction of the aglycon derivative 7 with the selected amines successfully yielded amides 8 and 9 (Scheme 4).

Finally, the azido derivative from the teicoplanin mixture was prepared by diazotransfer, followed by CuAAC to give the triazole derivative 10 (Scheme 5a). After normal phase flash chromatography and Sephadex LH-20 gel chromatography, we analyzed the composition of our newly obtained teicoplanin mixture by RP-HPLC-ESI-MS (see chromatogram and analysis in supporting information, page S29). The main components (~80%) were found to be the expected triazole derivatives of the A2-2 and A2-3 factors in cca. 2:1 ratio. Smaller amounts of the A2-1, A2-4, and A2-5 factors (cca. 8–10%) and the A3–1 analog (~5%; same as compound 4) were also detected along with small amounts of unidentifiable products.

The amide analog 11 was prepared from compound 10 as described above for the other amide derivatives (Scheme 5b). HPLC-ESI-MS (chromatogram and analysis in supplementary information, page S32) and HSQC NMR (supplementary information S18, S20) indicated that compound 11 is mainly (~80%) a mixture of the A2-2 and A2-3 components in a cca. 5:1 ratio, and contains a small amount of the more apolar components, A2-4 and A2-5 (~8%). The A3-1 analog (same as compound 5, was also detected in the mixture in ~6% quantity). Table 1 summarizes the structures of the new derivatives.

It is expected that minor differences between the lipophilicity of A2 components may cause slight changes in pharmacokinetic parameters. Factor A2-3 is also reported to be somewhat more active in vitro than the most abundant A2-2, on the other hand, the in vivo efficacy in mice seems to be the same, reflecting the essentially similar pharmacokinetics [17]. In our study, not much importance should be ascribed to this, as we have not done in vivo experiments so far. Besides that, most of the derivatives of teicoplanin A2 reported were isolated as a mixture of A2 factors 1–5. (see e.g. refs. 9, 11, 13) Probably, neither the small amounts of the A3-1 component derivatives in our mixtures (10, 11) influence the observed in vitro activities. In relation to this, it should be noted, that according to Ph. Eur. 9.0, the teicoplanin mixtures used in clinical settings are allowed to contain as much as 12% of the more polar A3-1 component.

Antibacterial evaluation

A standard panel of eight Gram-positive bacteria was used as a preliminary test including a vanA positive E. faecalis strain. (Table 2) All tested compounds were active both against the teicoplanin susceptible and resistant bacteria. However, the most prominent activity against the VanA E. faecalis was that of compound 3, which was eight times more active than compound 1. This derivative showed good activity against both teicoplanin resistant Staphylococcus epidermidis strains as well, although compound 2 was superior against these bacteria.

Compound 5 with two carbohydrates (α-d-mannose and N-acetyl-β-d-glucosamine) and a 3-(dimethylamino)-1-propyl side chain also displayed high activity against enterococci, but was less active in the case of MRSA and the coagulase negative staphylococci. The change of the dimethyl substituent to diethyl (compound 6) seemed to increase the activity only against staphylococci. Although the literature indicates, that the derivatives of teicoplanin aglycon usually display similar or better activity than the analogous pseudoaglycon derivatives, compounds 7–9 were generally less active than the corresponding pseudoaglycons (1–3). The same was true for derivatives 10 and 11 with all three formerly present carbohydrates.

Six of the compounds (3, 5, 7, 9, 10, and 11) were selected for evaluation against clinical isolates of VanA type VRE listed in Table 3 (19 E. faecium and 1 E. faecalis). All 20 strains tested were susceptible to the new derivatives. In most cases, the teicoplanin derivatives shows equal, sometimes better in vitro activity, than oritavancin. The notable superiority of oritavancin was observed in five cases (entries 14, 15, 17, 18, and 19), however, with the exception of one strain (entry 17) the MIC values for compound 3 remained under the current MIC breakpoint for teicoplanin. Compounds 5, 7, 9, 10, and 11 had less consistent activity. By comparing the number of MIC values obtained above the breakpoint of teicoplanin and vancomycin, the most promising candidate besides compound 3 seems to be 11, which is a little unexpected considering the lower activity of this compound seen in the preliminary tests (Table 2.). The other derivatives were essentially similar in activity against VRE with compound 5 having been slightly more active than the rest.

Conclusions

Using systematic structural modifications, we could obtain new derivatives of 1 that proved to have enhanced in vitro activity against VanA enterococci. The MIC values of the new derivatives, especially compound 3, are comparable to, or in some cases even lower than that of oritavancin against the tested VRE strains.

Although, in the aforementioned study of the Lepetit group [15] it was concluded, that the presence of the N-acetyl-β-d-glucosamine is detrimental to anti-VRE activity, in all of our highly active compounds, N-acetyl-glucosamine is present. Moreover, on the most active compound 3, the only carbohydrate moiety is the N-acetyl-d-glucosamine.

Previous findings have clearly demonstrated the influence of the carbohydrate residues of teicoplanin derivatives on pharmacokinetics. Especially the presence of the N-acyl-glucosamine on amino acid four is reported to be beneficial [9, 11,12,13]. Thus, the in vivo potency is likely to be altered by the presence vs. absence of sugars on the aglycon, regardless of the in vitro activities observed. Therefore, the reasonable in vitro activity of the fully glycosylated compound 11 besides pseudoaglycon 3 against VRE presents a good opportunity to compare the pharmacokinetic differences in the future and decide which would be the better candidate for further modifications.

Experimental methods

General information

3-(dimethylamino)-1-propylamine and 3-(diethylamino)-1-propylamine were purchased from Tokyo Chemical Industry Co., Ltd. Triflyl azide was prepared as described elsewhere [5]. The vancomycin hydrochloride standard used for the antibacterial evaluations was a gift from TEVA Pharmaceutical Industries Ltd. (Debrecen, Hungary) and teicoplanin was purchased from Shaanxi Sciphar Biotechnology Co., Ltd (Xi’an, Shaanxi, China). Oritavancin was purchased from Xi’an Kerui Biotechnology Co., Ltd. (Xi’an, Shaanxi, China) and checked by MALDI-TOF MS, 1D, and 2D NMR experiments. Teicoplanin for synthetic purposes was purchased from Xi’an Sgonek Biological Technology Co., Ltd. (Weiyang Qu, Xian Shi, Shaanxi Sheng, China). The antibacterial evaluations were carried out as it was described in our previous publication [7].

TLC was performed on Kieselgel 60 F254 (Merck) with detection either by immersing into ammonium molybdate-sulfuric acid solution followed by heating or by using Pauly’s reagent for detection. Flash column chromatography was performed using Silica gel 60 (Merck 0.040–0.063 mm). The 1H NMR (400 MHz), 13C NMR (100 MHz), and 2D NMR spectra were recorded with a Bruker DRX-400 spectrometer at 298 K. Chemical shifts are referenced to Me4Si (0.00 ppm for 1H) and to the solvent signals (DMSO-d6: 2.50 ppm for 1H, 39.51 ppm for 13C). MALDI-TOF MS analysis of the compounds was carried out in the positive reflectron mode using a BIFLEX III mass spectrometer (Bruker, Bremen, Germany) equipped with delayed-ion extraction. 2,5-Dihydroxybenzoic acid (DHB) was used as matrix and CF3COONa as cationizing agent in DMF.

For analytical RP-HPLC a Waters 2695 Separations Module (Waters Corp., Milford, USA) was used. The separations were carried out on a VDSpher PUR 100 C18-M-SE, 5 μm, 150 × 4.6 mm column (Batch# VD173001) at an injection volume of 10 μl, using a flow rate of 1.0 ml min−1 with a Waters 2996 DAD set at 254 nm and a Bruker MicroTOF-Q type Qq-TOF MS instrument (Bruker Daltonik, Bremen, Germany) as detectors. The following system was used for the elutions: solvent A: water: MeCN 9: 1+0.0025%v/v TFA, solvent B: MeCN. Gradient: 20% B from 0 to 20 min, from 20% B to 80% B from 20 to 40 min, 80% B from 40 to 50 min, from 80% B to 20% B from 50 to 51 min. Solvent A: Water: MeCN 9: 1 + 0.0025%v/v TFA, Solvent B: MeCN. The MicroTOF-Q mass spectrometer was equipped with an electrospray ion source. The mass spectrometer was operated in positive ion mode with a capillary voltage of 3.5 kV, an endplate offset of −500 V, nebulizer pressure of 1.8 bar, and N2 as drying gas with a flow rate of 9.0 l min−1 at 200 °C. The mass spectra were recorded by means of a digitizer at a sampling rate of 2 GHz. The mass spectra were calibrated externally using the exact masses of clusters [(NaTFA)n + TFA]− from the solution of sodium trifluoroacetate (NaTFA). The spectra were evaluated with the DataAnalysis 3.4 software from Bruker. Elemental analysis (C, H, N) was performed on an Elementar Vario MicroCube instrument.

Synthesis

Compound 2

Teicoplanin A3-2 derivative 1 [7] (120 mg, 0.075 mmol) was dissolved in dry DMF (1 ml). Then, 19 μl (0.15 mmol, 2.0 equiv.) of 3-(dimethylamino)-1-propylamine was added followed by 21 μl (0.15 mmol, 2.0 equiv.) of triethylamine and 47 mg (0.09 mmol, 1.2 equiv.) of PyBOP®. After stirring the mixture at room temperature for 3 h, additional 19 μl of 3-(dimethylamino)-1-propylamine and 39 mg PyBOP® (1.0 equiv.) were added. The addition of the reagents was repeated another two times over the course of 6 h. After TLC indicated sufficient conversion, 75 ml of ethyl acetate was added, and the precipitate was filtered off, then washed with diethyl ether (75 ml). The residue was dissolved in a mixture of acetonitrile:water=7:3, silica gel was added and the mixture was evaporated in vacuo. The product was purified by flash chromatography using a step gradient starting from acetonitrile to acetonitrile:water = 85:15 (+0.1 v/v% AcOH). The obtained powder was dissolved in MeCN:H2O mixture and the pH was set to ~8 by adding dilute ammonium hydroxide. The mixture was evaporated to dryness then the product was dissolved in an acetonitrile:water = 7:3 mixture and purified on a Sephadex LH-20 column in the same solvent mixture to obtain compound 2 as a white powder. The yield was 45 mg (35%). NMR data and spectra can be found in the supporting information (Table S1). MALDI-TOF m/z 1715.65 [M + Na]+ (calcd. for C84H78Cl2N12NaO23+, 1715.46). Analysis Calculated for C84H78Cl2N12O23 C 59.54, H 4.64, N 9.92 Found: C 59.36, H 4.81, N 9.80

Compound 3

Teicoplanin A3-2 derivative 1 (120 mg, 0.075 mmol) was dissolved in dry DMF (1 ml). Then, 24 μl (0.15 mmol, 2.0 equiv.) of 3-(diethylamino)-1-propylamine was added followed by 21 μl (0.15 mmol, 2.0 equiv.) of triethylamine and 47 mg (0.09 mmol, 1.2 equiv.) of PyBOP®. After stirring the mixture at room temperature for 3 h, additional 24 μl of 3-(diethylamino)-1-propylamine and 39 mg PyBOP® (1.0 equiv.) were added. After 3 h, 75 ml of ethyl acetate was added, and the precipitate was filtered off, then washed with diethyl ether (75 ml). The residue was dissolved in a mixture of acetonitrile:water = 7:3, silica gel was added and the mixture was evaporated in vacuo. The product was purified by flash chromatography using a step gradient starting from acetonitrile to acetonitrile:water = 85:15 (+0.1 v/v % AcOH). The obtained powder was dissolved in MeCN:H2O mixture and the pH was set to ~8 by adding dilute ammonium hydroxide. The mixture was evaporated to dryness then the product was dissolved in an acetonitrile:water = 7:3 mixture and purified on a Sephadex LH-20 column in the same solvent mixture to obtain compound 3 as a white powder. Yield: 45 mg (35%). NMR data and spectra can be found in the supporting information (Table S1). MALDI-TOF m/z 1743.75 [M + Na]+ (calcd. for C86H82Cl2N12NaO23+, 1743.49). Analysis calculated for C86H82Cl2N12O23 C 59.96, H 4.80, N 9.76 found: C 59.77, H 5.01, N 9.58.

Compound 4

Teicoplanin complex (1.5 g, 0.798 mmol) was dissolved in 90% aqueous TFA (15 ml) and the reaction mixture was stirred at room temperature. After 2 h, diethyl ether was added (150 ml) and the precipitate was filtered. The solid residue was washed with an additional 100 ml of diethyl ether and dried. The compound was purified by flash chromatography using a step gradient starting from acetonitrile:water = 9:1 to acetonitrile:water 75:25 (+0,1 v/v% AcOH). The yield of teicoplanin A3-1 [8] was 990 mg (78%). This material was dissolved in pyridine (40 ml), and Et3N was added (1.24 mmol, 2.0 equiv., 174 μl) followed by freshly prepared triflyl azide (1.46 mmol, 2.35 equiv.) in dry pyridine (4 ml). Then an aqueous solution of 15 mg of copper(II)-sulfate pentahydrate (2 ml) was added and the reaction mixture was stirred for 16 h at room temperature. After the addition of 300 ml ethyl acetate, a solid precipitated, which was filtered off and washed with 200 ml of ether, yielding 1.0 g of crude azido teicoplanin A3-1. This material was dissolved in a mixture of acetonitrile:water = 7:3, silica gel was added, then the mixture was evaporated. The compound was purified by flash chromatography using a step gradient starting from 100% acetonitrile to acetonitrile:water 88:12 (+0,1 v/v% AcOH). The yield was 540 mg. 150 mg (0.094 mmol) of this compound was dissolved in a tert-butanol:water = 1:1 mixture (2 ml). Then, 21 μl (0.118 mmol, 1.25 equiv.) of 1-(prop-2-yn-1-yloxy)naphthalene was added followed by ca. 3 mg (~15 mol%) of CuSO4×5H2O in 200 μl of water and 17 mg (0.096 mmol, 1 equiv.) of l-ascorbic acid. The mixture was stirred overnight at room temperature. After the addition of silica gel, solvents were evaporated, and the product was purified by flash chromatography using a step gradient starting from acetonitrile to acetonitrile:water = 87:13 yielding 55 mg (14% for three steps) of the desired compound. NMR data and spectra can be found in the supporting information (Table S1). MALDI-TOF m/z 1793.60 [M + Na]+ (calcd. for C85H76Cl2N10NaO29+, 1793.40). Analysis calculated for C85H76Cl2N10O29 C 57.60, H 4.32, N 7.90 found: C 57.35, H 4.58, N 7.72.

Compound 5

Compound 4 (130 mg, 0.073 mmol) was dissolved in dry DMF (1 ml). Then, 19 μl (0.15 mmol, 2.0 equiv.) of 3-(dimethylamino)-1-propylamine was added followed by 21 μl (0.15 mmol, 2.0 equiv.) of triethylamine and 47 mg (0.09 mmol, 1.2 equiv.) of PyBOP®. After stirring the mixture at room temperature for 3 h, additional 19 μl of 3-(dimethylamino)-1-propylamine and 39 mg PyBOP® (1.0 equiv.) were added. After 3 h, 75 ml of ethyl acetate was added, and the precipitate was filtered off, then washed with diethyl ether (75 ml). The residue was dissolved in a mixture of acetonitrile:water = 7:3, silica gel was added and the mixture was evaporated in vacuo. The product was purified by flash chromatography using a step gradient starting from acetonitrile to acetonitrile:water = 78:22 (+0,1 v/v % AcOH) yielding 41 mg (30%) of the desired compound. NMR data and spectra can be found in the supporting information (Table S1). MALDI-TOF m/z 1877.82 [M + Na]+ (calcd. for C90H88Cl2N12NaO28+, 1877.51). Analysis Calculated for C90H88Cl2N12O28 C 58.22, H 4.78, N 9.05 Found: C 58.04, H 5.03, N 8.87.

Compound 6

Compound 4 (88 mg, 0.05 mmol) was dissolved in dry DMF (1 ml). Then, 14 μl (0.1 mmol, 2.0 equiv.) of triethylamine was added followed by 78 μl (0.5 mmol, 10 equiv.) of 3-(diethylamino)-1-propylamine and 31 mg (0.06 mmol, 1.2 equiv.) of PyBOP®. After stirring the mixture at room temperature for 1 h, additional 10 mg (0.4 equiv.) of PyBOP® was added. After another hour, 5 mg (0.2 equiv.) of PyBOP® was added and in 60 min the starting material was consumed (checked by TLC). Ethyl acetate (75 ml) was added, and the precipitate was filtered off and washed with ether (75 ml). The residue was dissolved in a mixture of acetonitrile:water = 7:3, silica gel was added and the mixture was evaporated in vacuo. The product was purified by flash chromatography using a step gradient starting from acetonitrile to acetonitrile:water = 78:22 (+0,1 v/v% AcOH) yielding 43 mg (46%) of the desired compound. NMR data and spectra can be found in the supporting information (Table S1). MALDI-TOF m/z 1883.45 [M + H]+ (calcd. for C92H93Cl2N12O28+, 1883.56). Analysis calculated for C92H92Cl2N12O28 C 58.63, H 4.92, N 8.92 found: C 58.48, H 5.20, N 8.76

Compound 7

Teicoplanin complex of 4.00 g (2.13 mmol) was heated in 90% aqueous TFA for 6 h then worked up as it is published in the literature [8], followed by treatment with TfN3 as described earlier [5]. After chromatographic purification, 450 mg (0.367 mmol) of azido teicoplanin aglycon was obtained. This material was dissolved in a tert-butanol:water = 1:1 mixture (6 ml). Then, 83 μl (0.46 mmol, 1.25 equiv.) of 1-(prop-2-yn-1-yloxy)naphthalene was added followed by ca. 14 mg (~15 mol%) of CuSO4 × 5H2O in 200 μl of water and 65 mg (0.096 mmol, 1.0 equiv.) of l-ascorbic acid in 500 μl of water. A few drops of acetonitrile was added to effect homogenity. The mixture was stirred overnight at room temperature. The reaction mixture was concentrated to a small volume and ethyl acetate was added. The precipitate was filtered off and washed with ether. The solid was dissolved in a minimum amount of acetonitrile:water = 7:3 and was loaded on a column containing Sephadex LH-20 in the same solvent mixture. Fractions were checked by TLC (cellulose, eluent = nPrOH:cc.NH4OH:H2O = 7:3:2). Fractions containing the desired compound were pooled and concentrated to a small volume. To this, silica gel was added and the mixture was evaporated to dryness. Flash chromatography was used for further purification using a step gradient starting from acetonitrile to acetonitrile:water 93:7, yielding 255 mg (49% from azido teicoplanin aglycon) of the title compound. NMR data and spectra can be found in the supporting information (Table S1). MALDI-TOF m/z 1428.09 [M + Na]+ (calcd. for C71H53Cl2N9NaO19+, 1428.27). Analysis calculated for C71H53Cl2N9O19 C 60.60, H 3.80, N 8.96 found: C 60.32, H 4.04, N 8.79

Compound 8

Compound 7 (125 mg, 0.09 mmol) was dissolved in DMF (1.5 ml). 2.0 equiv. of Et3N (0.178 mmol, 24.8 μl) was added, then N,N-dimethyl-1,3-propanediamine (3.0 equiv., 0.27 mmol, 34 μl) followed by PyBOP (1.2 equiv., 55 mg). After 2 h, EtOAc was added, the precipitate filtered and washed with diethyl ether. The crude product was dissolved in MeCN:H2O 1:1 mixture and evaporated to dryness after the addition of a small amount of silica gel. The product was purified by flash column chromatography using step gradient elution (MeCN:H2O = 95:5, 92:8, 9:1, 87:13 + 0.1% V/V AcOH) yielding the title compound (58 mg, 44%) as a white powder. NMR data and spectra can be found in the supporting information (Table S1). MALDI-TOF m/z 1512.18 [M + Na]+ (calcd. for C76H65Cl2N11NaO18+, 1512.38). Analysis calculated for C76H65Cl2N11O18 C 61.21, H 4.39, N 10.33 found: C 60.96, H 4.58, N 10.10

Compound 9

Compound 7 (100 mg, 0.071 mmol) was dissolved in DMF (1.3 ml). 2.0 equiv. of Et3N (0.142 mmol, 20 μl) was added, then N,N-diethyl-1,3-propanediamine (3.0 equiv., 0.213 mmol, 34 μl) followed by PyBOP (1.2 equiv., 44 mg). After 2 h, EtOAc was added, the precipitate filtered and washed with diethyl ether. The crude product was dissolved in MeCN:H2O 1:1 mixture and evaporated to dryness after the addition of a small amount of silica gel. The product was purified by flash column chromatography using step gradient elution (MeCN:H2O = 95:5, 92:8, 9:1, 88:12 + 0.1% V/V AcOH) yielding the title compound (39 mg, 36%) as a white powder. NMR data and spectra can be found in the supporting information (Table S1). MALDI-TOF m/z 1540.18 [M + Na]+ (calcd. for C78H69Cl2N11NaO18+, 1540.41). Analysis Calculated for C78H69Cl2N11O18 C 61.66, H 4.58, N 10.14 Found: C 61.40, H 4.86, N 9.82

Compound 10

A solution of fresh TfN3 was prepared using the following amounts: 2 ml pyridine (solvent), 134 μl Tf2O (0.8 mmol, 2.35 equiv.) and 65 mg NaN3 (1.0 mmol). Teicoplanin complex (640 mg, cca. 0.34 mmol) was suspended in 15 ml pyridine. 2.0 equiv. of Et3N (95 μl) was added followed by the TfN3 reagent, and CuSO4 x 5H2O (10 mg) dissolved in 1.0 ml water. The reaction mixture became green and homogenous. After stirring overnight at room temperature, EtOAc was added, the precipitate was filtered and washed with diethyl ether, acetonitrile, then ether again. The crude product was dissolved in MeOH, some silica gel was added and the mixture was evaporated to dryness. The product was purified by flash chromatography, using a step gradient elution starting from 100% MeCN, followed by MeCN: H2O = 9:1, 85:15, 8:2, then 75:25 yielding azido teicoplanin A2 (400 mg, 0.21 mmol) which was dissolved in a mixture of t-BuOH:H2O = 1:1 (3 ml). α-naphthyl propargyl ether (48 mg, 1.25 equiv.) was added. Then, a 100 μl aqueous solution of CuSO4 × 5 H2O (7 mg, ca. 15 mol%) was added followed by 1.0 equiv. of l-ascorbic acid (37 mg) in 100 μl of water. The solution was stirred at room temp. for about 16 h, after which silica gel was added, and the mixture was evaporated to dryness. The product was purified by flash column chromatography using a step gradient starting with 100% MeCN to MeCN:H2O 88:12 (+0.1 v/v % AcOH). After evaporating the solvents, the product was dissolved in DMSO (1.5 ml) and was filtered through a small piece of cotton. To the obtained clear solution EtOAc was added. The precipitated product was filtered off and washed with diethyl ether several times. The yield was 210 mg (48%). NMR data, spectra and HPLC chromatogram can be found in the supporting information. MS (HPLC-ESI-MS) m/z 2088.616 [M + H]+ (component A2-2) (2088.629 calcd. for C101H106Cl2N11+). See supplementary information for further analysis.

Compound 11

Compound 10 (80 mg, 0.038 mmol) was dissolved in a mixture of DMF:DMSO = 1:1 (1 ml) and 2.0 equiv. of Et3N was added (0.076 mmol, 10.6 μl) followed by 2.5 equiv. of N,N-dimethyl-1,3-propanediamine (0.095 mmol, 12.0 μl), then 1.0 equiv. of PyBOP was added (0.038 mmol, 20 mg) and the solution was stirred for 3 h, after which the starting material was consumed (as indicated by TLC). Diethyl ether was added, and the resulting precipitate was filtered off and washed several times with ether. The crude product was dissolved in a small of amount of MeCN:H2O 1:1 mixture, n-butanol was added followed by silica gel. The mixture was evaporated to dryness. Flash chromatography was used for purification (step gradient from MeCN:H2O 95:5 (+0.1 v/v% AcOH) to MeCN:H2O 8:2 (+0.1 v/v% AcOH). The obtained powder was dissolved in MeCN:H2O mixture and the pH was set to ~8 by adding dilute ammonium hydroxide. The mixture was evaporated to dryness then the product was dissolved in an acetonitrile:water = 7:3 mixture and purified on a Sephadex LH-20 column in the same solvent mixture, yielding compound 11 (26 mg, 32%) as a white powder. NMR data, spectra and HPLC-ESI-MS analysis can be found in the supporting information. MS (HPLC-ESI-MS) m/z 2172.738 [M + Na]+ (component A2-2) (2172.735 calcd. for C106H118Cl2N13O33+). See supplementary information for further analysis.

References

Levine D. Vancomycin: a history. Clin Infect Dis. 2006;42(Supplement_1):S5–S12.

Biavasco F, et al. In vitro antibacterial activity of LY333328, a new semisynthetic glycopeptide. Antimicrob Agents Chemother. 1997;41:2165–72.

Sztaricskai F, et al. A new series of glycopeptide antibiotics incorporating a squaric acid Moiety. J Antibiot. 2006;59:564–82.

Sipos A, et al. Synthesis of fluorescent ristocetin aglycon derivatives with remarkable antibacterial and antiviral activities. Eur J Med Chem. 2012;58:361–7.

Pintér G, et al. Diazo transfer−click reaction route to new, lipophilic teicoplanin and ristocetin aglycon derivatives with high antibacterial and anti-influenza virus activity: an aggregation and receptor binding study. J Med Chem. 2009;52:6053–61.

Szűcs Z, et al. Synthesis and biological evaluation of lipophilic teicoplanin pseudoaglycon derivatives containing a substituted triazole function. J Antibiot. 2016;70:152–7.

Szűcs Z, et al. Lipophilic teicoplanin pseudoaglycon derivatives are active against vancomycin- and teicoplanin-resistant enterococci. J Antibiot. 2017;70:664–70.

Malabarba A, et al. Teicoplanin, antibiotics from Actinoplanes teichomyceticus nov. sp. VI. Chemical degradation: physico-chemical and biological properties of acid hydrolysis products. J Antibiot. 1984;37:988–99.

Malabarba A, et al. N 15-alkyl and N 15, N 15-dialkyl derivatives of teicoplanin antibiotics. J Antibiot. 1990;43:1107–21.

Malabarba A, Trani A, Ferrari P, Pallanza R, Cavalleri B. Synthesis and biological activity of some esters of the N-acetylglucosaminyl aglycone and of the aglycone of teicoplanin. J Antibiot. 1987;40:1572–87.

Malabarba A, Ferrari P, Cietto G, Pallanza R, Berti M. Synthesis and biological activity of N 63-carboxypeptides of teicoplanin and teicoplanin aglycone. J Antibiot. 1989;42:1800–16.

Malabarba A, et al. N 63-carboxamides of N 15-alkyl and N 15, N 15-dialkyl derivatives of teicoplanin and deglucoteicoplanin. J Antibiot. 1993;46:668–75.

Malabarba A, Ciabatti R, Scotti R, Goldstein B. Octapeptide derivatives of teicoplanin antibiotics. J Antibiot. 1993;46:661–7.

Trani A, Ferrari P, Pallanza R, Ciabatti R. Thioureas and isothiouronium salts of the aglycone of teicoplanin. I. Synthesis and biological activity. J Antibiot. 1989;42:1268–75.

Malabarba A, et al. Amides of de-acetylglucosaminyl-deoxy teicoplanin active against highly glycopeptide-resistant enterococci. Synthesis and antibacterial activity. J Antibiot. 1994;47:1493–506.

Malabarba A, et al. New Semisynthetic Glycopeptides MDL 63,246 and MDL 63,042, and other amide derivatives of antibiotic A-40,926 active against highly glycopeptide-resistant VanA enterococci. J Antibiot. 1995;48:869–83.

Borghi A, et al. Teichomycins, new antibiotics from Actinoplanes teichomyceticus nov. sp. IV. Separation and characterization of the components of teichomycin (teicoplanin). J Antibiot. 1984;37:615–20.

Acknowledgements

We are thankful for the VRE strains kindly provided by the Department of Medical Microbiology at University of Debrecen. This work was supported by the European Regional Development Fund under the project GINOP-2.3.2-15-2016-00008 and by the European Social Fund under the project EFOP-3.6.3-VEKOP-16-2017-00009.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Szűcs, Z., Ostorházi, E., Kicsák, M. et al. New semisynthetic teicoplanin derivatives have comparable in vitro activity to that of oritavancin against clinical isolates of VRE. J Antibiot 72, 524–534 (2019). https://doi.org/10.1038/s41429-019-0164-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41429-019-0164-1

This article is cited by

-

Synthesis of vancomycin fluorescent probes that retain antimicrobial activity, identify Gram-positive bacteria, and detect Gram-negative outer membrane damage

Communications Biology (2023)

-

Newest perspectives of glycopeptide antibiotics: biosynthetic cascades, novel derivatives, and new appealing antimicrobial applications

World Journal of Microbiology and Biotechnology (2023)

-

Semisynthetic teicoplanin derivatives with dual antimicrobial activity against SARS-CoV-2 and multiresistant bacteria

Scientific Reports (2022)

-

N-Terminal guanidine derivatives of teicoplanin antibiotics strongly active against glycopeptide resistant Enterococcus faecium

The Journal of Antibiotics (2020)

-

Antibiotic repurposing: bis-catechol- and mixed ligand (bis-catechol-mono-hydroxamate)-teicoplanin conjugates are active against multidrug resistant Acinetobacter baumannii

The Journal of Antibiotics (2020)