Abstract

We describe a novel strategy for synthesizing the CD bicyclic ether substructure of the fused polycyclic ether natural product brevenal. This product arises from a three-step sequence beginning with (1) regio- and diastereoselective iodoetherification of an acyclic diene-diol, followed by (2) alkene metathesis with an epoxyalkene synthon, concluding with (3) palladium-catalyzed cycloisomerization. Despite the modest yield and long reaction period for the cycloisomerization step, these studies provide valuable insights into the nature of byproducts generated and the mechanisms by which they form. This work demonstrates a portion of a larger synthetic strategy for constructing the pentacyclic core of brevenal from an acyclic precursor.

Similar content being viewed by others

Introduction

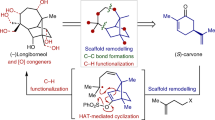

Brevenal (1, Fig. 1) is a fused polycyclic ether natural product produced by Karenia brevis, a dinoflagellate indigenous to the Gulf of Mexico [1, 2]. Remarkably, the same marine organism also produces a host of structurally related but substantially larger compounds known as brevetoxins, or “red tide toxins” [3]. Brevenal binds to the same sodium ion channels as brevetoxins, while exerting no toxic effects [4, 5]. Thus, brevenal tempers the neurotoxic effects of brevetoxin, making it a potential remedy for those exposed to brevetoxins. Brevenal may have additional beneficial applications for treating the symptoms of cystic fibrosis [6]. The literature describes several syntheses of brevenal [7,8,9], in which the seven-membered ring ethers arise from well-developed methods, namely oxidative lactonizations of 1,6-diols [10], dehydrative cyclizations of hydroxyacids and hydroxyacetals [11], intramolecular allylations of γ-alkoxyallylstannanes with α-acetoxy ethers [12], ring-closing metathesis [13] and olefinic ester cyclizations [14].

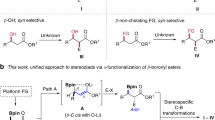

Our recent approach to the synthesis of brevenal has featured a sequence of stereo- and regioselective oxacyclizations of hydroxyalkenes [15, 16]. Prior to our research in this area, these transformations were not well-developed for preparing six- and seven-membered cyclic ethers, especially from structurally complex substrates. We have envisioned that stereoselective intramolecular addition of the C18-hydroxyl onto the alkene terminus (C23) of an epoxyalkene 2 will form the oxepane D ring of brevenal, with the expected product 3 bearing a side-chain corresponding to the chiral tertiary alcohol at C26 of the E ring of brevenal (Fig. 2).

In this Article, we describe the synthesis of the brevenal CD substructure by this strategy, building on our recently reported cycloisomerizations of model compounds 4 and 6 (Fig. 3) [17]. For these transformations:

-

the best results have required dual catalysis with palladium and a Brønsted acid, such as diphenylphosphinic acid, to promote epoxide opening;

-

the acetate ester of 4 suppresses a significant side-reaction occurring with the corresponding allylic alcohol, arising from palladium-catalyzed hydride migration;

-

the epoxyalkene of 4 is chemoselectively activated in preference to the allylic acetate;

-

the stereochemistry of the newly formed carbon-oxygen bond in the pyran 5 arises from the chirality of the epoxide and also the trans- or cis-geometry of the alkene; and

-

the bicyclic trimethylol phosphite ligand (8) [18, 19] increases the rate of cycloisomerization of the epoxyalkene substrate 6 leading to the oxepane 7, relative to triisopropyl phosphite (P(O-i-Pr)3).

Although the stereochemical assignment of the major diastereomer of 7 is not yet confirmed, the chirality depicted at the starred center of 7 is consistent with our results from other (R,R)-epoxy-trans-alkene substrates [17].

Results

Synthesis of epoxyalkene substrate 21

To test the proposed conversion of epoxyalkene 2 into the D-ring of 3 (Fig. 2), we prepared a substrate with stereochemistry identical to the allylic acetate and epoxyalkene of 4 (Fig. 3), tethered to a tetrahydropyranyl alcohol with relative stereochemistry matching C18 and C19 in the C-ring of brevenal. Our synthesis began with enzyme-catalyzed resolution [20] of the known racemic alcohol 9 [21] to provide the allylic acetate 10 with high enantioselectivity (Scheme 1). We then constructed the C-ring from the primary alcohol of 11, beginning with Stahl oxidation [22] and alpha-methylenation [23] of aldehyde 12 to introduce the 1,1-disubstituted alkene of enal 13. Addition of the Grignard reagent 14 [24] to the enal 13 was compatible with the acetate ester, but afforded a mixture of allylic alcohol diastereomers. However, Stahl oxidation [25] to the enone 15 followed by Corey-Bakshi-Shibata reduction [26] set the chiral center of the allylic alcohol 16 with high diastereoselectivity. Iodine-promoted cycloetherification of diene-diol 17 produced the desired pyranyl alcohol 18, structurally corresponding to our precedents for stereoinduction from the chiral allylic alcohol in the tether [15, 16]. Moreover, the six-membered ring of 18 formed without competition from oxacyclization of the secondary alcohol with the monosubstituted alkene [27].

Preparation of tetrahydropyranyl alcohol 18. Conditions: (a) Candida antarctica lipase (CAL-B, 4% by mass), isopropenyl acetate (1.7 equiv), K3PO4 (1.07 equiv), toluene, 20 °C, 3.25 h: (R)-9, 50% yield, 96:4 er; 10, 49% yield, 97:3 er); (b) acetyl chloride (30 mol%), methanol, 0–20 °C, 20 min, 98% yield; (c) Cu(MeCN)4OTf (5 mol%), 2,2′-bipyridine (bpy, 5 mol%), 2,2,6,6-tetramethylpiperidinyloxyl (TEMPO, 5 mol%), N-methylimidazole (NMI, 10 mol%), acetonitrile, air, 20 °C, 12 h, 75% yield; (d) N,N-dimethylmethyleneiminium iodide (2.1 equiv), triethylamine (3.1 equiv), dichloromethane, 20 °C, 2 h, 62% yield; (e) tetrahydrofuran, −78 °C, 15 min, satd. aq. NH4Cl quench, 68% yield (+21% recovered 13); (f) Cu(MeCN)4OTf (15 mol%), 4,4′-dimethoxy-2,2′-bipyridine (MeObpy, 10 mol%), 9-azabicyclo[3.3.1]nonane N-oxyl (ABNO, 2 mol%), NMI (20 mol%), acetonitrile, air, 20 °C, 48 h, 88% yield; (g) (R)-2-methyl-CBS-oxazaborolidine (1.1 equiv), borane-THF (1.06 equiv), tetrahydrofuran, −40 °C, 1.5 h, 56% yield, 96:4 dr; (h) acetyl chloride (2.6 equiv), methanol, 0 °C, 10 min; (i) iodine (3.4 equiv), sodium bicarbonate (7.8 equiv), tetrahydrofuran, 0–20 °C, 1.5 h, 93% yield (2 steps).

We completed the substrate synthesis by cross-metathesis of compound 18 with the chiral non-racemic (S,R)-epoxyalkene synthon 19 [17] to provide the substrate 21 (Scheme 2). The best results for the cross-metathesis step arose from adding Hoveyda-Grubbs catalyst 20 and solvent to a mixture of alkenes 18 and 19, then concentrating the reaction solution at slightly elevated temperature on a rotary evaporator to remove the ethylene byproduct from the reaction headspace, and repeating this process two more times.

Palladium-catalyzed cycloisomerization of epoxyalkene substrate 21

We expected that the tetrahydropyran ring tethered to the epoxyalkene of 21 would limit degrees of freedom relative to the simple substrate 6 initially studied for oxepane synthesis. This might be advantageous if the two separated chiral networks at C18-C19 and C22-C26 readily adopted a conformation with the C18 alcohol in proximity to C23 on the reactive face of the proposed palladium π-allyl reactive intermediate, but could be disastrous for our synthetic plan if such a conformation was disfavored. Initial experiments were not promising: compound 21 did not initially react under palladium catalysis at room temperature in CDCl3, and upon gently heating the reaction mixture, we observed the dienyl diol 23 as the only new product (Table 1, entry 1), without any indication of oxepane formation. Upon repeating this experiment with the trimethylol phosphite ligand 8 in place of P(O-i-Pr)3 (entry 2), several new species appeared after 18 h at room temperature, including bisacetate 24, presumably incorporating the acetate lost in the elimination process leading to dienyl diol 23. Although most of the substrate 21 was still present, the 1H NMR spectrum showed one additional minor product, later determined to be bicyclic polyether 22. Compound 22 gradually increased in quantity over six days (entry 3) in proportion to the slow consumption of epoxyalkene 21 and progressive accumulation of byproducts 23 and 24. After 21 days (entry 4), epoxyalkene 21 was no longer visible in the 1H NMR spectrum of the reaction mixture. Compounds 22, 23, and 24 were isolated by preparative thin layer chromatography (entry 5), enabling complete structural assignments by extensive NMR characterization.

Discussion

Structure characterization

We relied extensively on NMR methods to unambiguously assign the bicyclic product 22. In particular, 1H–1H COSY and 1D-TOCSY analyses showed two large, independent spin systems (Fig. 4), establishing connectivity for much of the six-membered ring, as well as linking the seven-membered ring with the side chain alkene. NOESY correlations confirmed the 1,3-syn relationship of Hg and Hi of the oxepane, in addition to identifying the tertiary alcohol hydrogen as Ho. The coupling constant between Hf and Hg was approximately 1.3–1.5 Hz, indicating that the major conformation in solution did not orient these hydrogens anti to each other. Instead, the small coupling constant suggested a dihedral angle close to ~ 90°. The nOe correlation between Hf and Hg, in addition to the deshielding of Hf (5.02 ppm) was consistent with a conformation that placed Hf in a pseudo-equatorial orientation. 13C–1H HMBC spectroscopy linked the independent spin systems, notably:

-

three-bond coupling for CH–Hi, supporting ring-closing to the oxepane;

-

another three-bond coupling for CA–Hf, verifying the location of the acetate; and

-

several two-bond and three-bond correlations of CL with Hd, He, Hm, and particularly CL–Ho, confirming the presence and location of the tertiary alcohol.

The dienyl diol 23 was isolated as an inseparable mixture of (E,E) and (Z,E)-diene isomers (68:32 ratio). The isomers were distinguishable by 1D-TOCSY spectroscopy, so that 1H–1H COSY and NOESY assignments were made for each 1,3-diene isomer within this mixture (Fig. 5).

Mechanism

Although the formation of the bicyclic product 22 from epoxyalkene 21 required an extremely long reaction time and proceeded with modest yield, the generation of byproducts 23 and 24 is consistent with our overall mechanistic hypothesis (Fig. 6). Structure 25 represents a Pd-ligand complex with the trimethylol phosphite (8) and triphenylphosphine ligands, although the relative stoichiometry of the phosphite and phosphine ligands in the reactive catalyst is unknown. We propose that Pd η3-π-allyl intermediate 26 forms upon protonation of the epoxide of 21, with addition of Pd-ligand complex 25 onto the face anti- to the epoxide oxygen. Intramolecular addition of the alcohol nucleophile then occurs onto the π-allyl ligand on the face anti- to Pd, to produce the observed diastereomer 22.

The 1,3-diene byproduct 23 involves the loss of the allylic acetate, in a process analogous to the palladium-catalyzed beta-eliminations of 2-ene-1,4-diol-derived dicarbonates to form 1,3-dienes [28,29,30]. This literature transformation and our observed formation of the diene byproduct 23 requires formal oxidation to Pd(II), which presumably is reduced to Pd(0) by excess phosphite ligand, maintaining a catalytic cycle for this transformation [28]. The beta-elimination to form the diene byproduct 23 also provides a source of acetate, which may add to the Pd π-allyl intermediate 26 in competition with the distant secondary alcohol, to produce the diacetate byproduct 24.

The bicyclic trimethylol phosphite ligand 8 is essential for cycloisomerization of 21 to the bicyclic product 22. The reduced cone angle of the bicyclic phosphite 8 (cone angle 101°) [31] with respect to P(O-i-Pr)3 (cone angle 130°) may better enable nucleophilic addition of sterically hindered alcohols, or alcohols separated from the epoxyalkene by longer tethers. The 31P chemical shift of the phosphorus in bicyclic phosphite ligand 8 is −90.1 ppm, whereas in P(O-i-Pr)3 it is −137.5 ppm [31]. As the phosphorus in trimethylol phosphite 8 is more deshielded than in P(O-i-Pr)3, the bicyclic phosphite ligand 8 may increase the electrophilicity of the η3-π-allyl intermediate 26.

Conclusion

We have developed an effective synthetic route for the epoxyalkene-containing substrate 21, leading to the CD substructure of brevenal 22. As the cycloisomerization step forming the seven-membered ring of product 22 proceeded in modest yield, we do not currently have sufficient material to attempt subsequent steps. Nonetheless, knowing the identity of byproducts has suggested some avenues for improving selectivity in favor of oxepane formation. As the bicyclic product 22 contains a side-chain with the oxygen substituents necessary for cycloetherification to the E ring of brevenal, we foresee melding an optimized version of this approach with our previously disclosed synthetic strategy for the ABC substructure [15]. Our long-term goal is a sequential oxacyclization synthesis of the pentacyclic core of brevenal from an acyclic precursor.

Experimental procedure

General methods

Proton and carbon NMR spectra were recorded on INOVA-400 (400 MHz), VNMRS 400 (400 MHz), INOVA-600 (600 MHz), or a BRUKER 600 (600 MHz) instrument equipped with cryogen probe. NMR spectra were taken in solutions of deuterated chloroform (CDCl3) with the residual chloroform (7.27 ppm for 1H NMR and 77.23 ppm for 13C NMR) taken as the internal standard, and were reported in parts per million (ppm). All diastereomer and trans:cis ratios were determined by NMR integration of isolated peaks with an uncertainty of ± 2%. Abbreviations for signal coupling are as follows: s, singlet; d, doublet; t, triplet; q, quartet; dd, doublet of doublet; ddd, doublet of doublet of doublet; dt, doublet of triplet; dq, doublet of quartet; tt, triplet of triplet; tdd, triplet of doublet of doublet; m, multiplet. IR spectra were collected on a Nicolet iS10 from Thermo Scientific and reported in units of cm−1. Mass spectra (high resolution ESI and APCI) were recorded on a Thermo LTQ (linear quadrupole ion trap) FTMS (Fourier transform mass spectrometer) based on ion cyclotron resonance mass spectrometry (ICR-MS). Optical rotations were measured using a Perkin-Elmer 341 polarimeter (concentration in g/100 mL). Thin layer chromatography (TLC) was performed on pre-coated glass-backed plates purchased from Whatman (silica gel 60F254; 0.25 mm thickness). Preparative TLC was conducted with pre-coated glass-backed plates purchased from Analtech (20 × 20 cm, Silica gel GF UV254, 1.0 mm thickness). Flash column chromatography utilized silica gel 60 (230–400 mesh ASTM) from Silicycle. All reactions were carried out with anhydrous solvents in oven dried or flame dried and argon-charged glassware unless otherwise specified. All anhydrous solvents were dried with 4 Å molecular sieves purchased from Sigma-Aldrich and tested for trace water content with Coulometric KF titrator from Denver instruments. All reagents, catalysts, and solvents used in extraction procedures and chromatography were used as received from commercial suppliers without prior purification.

Allylic acetate 10

To a solution of the known allylic alcohol 9 [21] (17.3 g, 70.8 mmol) in toluene (175 mL) was added K3PO4 (16.9 g, 76 mmol), isopropenyl acetate (12 mL, 120 mmol) and Candida antarctica lipase (CAL-B resin, 733 mg). The mixture was stirred at rt for 3.25 h, whereupon an NMR aliquot showed ~ 50% conversion to the acetate. The reaction mixture was filtered through a pad of Celite with diethyl ether (Et2O). The solution was concentrated by rotary evaporation and chromatographed eluting with 5/95 ethyl acetate (EtOAc)/hexanes–20/80 EtOAc/hexanes–EtOAc to give the (S)-acetate 10 as a clear oil (9.87 g, 34.5 mmol, 49% yield, er 97:3 by analysis of the Mosher esters following acetate hydrolysis), and (R)-alcohol 9 as a yellow oil (8.62 g, 35.3 mmol, 50% yield, er 96:4 by analysis of the Mosher esters). The spectra and optical rotation of 10 matched the literature values [32]. HRMS (NSI) calculated for C15H31O3Si+ [M+H]+ 287.20370, found 287.20405; IR (CH2Cl2): 2951, 2930, 2858, 1741, 1472, 1371, 1238, 1099, 835, 775 cm−1; [α]\({{\,}_{\mathrm{D}}^{20}}\) −2.6 (c 1.3, CH2Cl2); 1H NMR (600 MHz, CDCl3): δ 5.78 (ddd, J = 17.3, 10.6, 6.4 Hz, 1H), 5.25–5.22 (m, 2H), 5.17 (dt, J = 10.5, 1.2 Hz, 1H), 3.61 (t, J = 6.4 Hz, 2H), 2.07 (s, 3H), 1.70–1.57 (m, 2H), 1.56–1.50 (m, 2H), 1.43–1.33 (m, 2H), 0.90 (s, 9H), 0.05 (s, 6H); 13C NMR (151 MHz, CDCl3): δ 170.56, 136.76, 116.80, 75.02, 63.10, 34.17, 32.72, 26.17, 21.66, 21.46, 18.56, −5.07.

For Mosher ester analysis [33], a small portion of 10 was hydrolyzed with K2CO3 in methanol, then concentrated and filtered through a small plug of silica gel to give the (S)-alcohol 9. Mosher ester derivatives were prepared by dissolving the alcohol in dry CDCl3 (1.2 mL), adding d5-pyridine (12 drops, from a freshly opened ampule) to this solution, then partitioning the mixture between two new NMR tubes, sparged with argon. To each tube was added one drop (as dispensed from a short Pasteur pipette using thumb pressure) of one enantiomer of α-methoxy-α-(trifluoromethyl)phenylacetyl chloride (MTPA-Cl). The NMR tubes were inverted several times to mix and then allowed to stand for 24 h before NMR analysis (Fig. 7).

Primary alcohol 11

To a cooled (0 °C) solution of crude silyl ether 10 (7.91 g, 27.6 mmol) in methanol (MeOH, 100 mL) was added acetyl chloride (AcCl, 0.6 mL, 8.4 mmol). After 20 min the starting material was consumed (TLC analysis), and the reaction mixture was quenched with satd. aq. NaHCO3 (20 mL). The solution was concentrated in vacuo to remove the methanol. The aqueous layer was then extracted with Et2O (5 × 50 mL). The combined organics were washed with brine (50 mL), dried over MgSO4 and concentrated by rotary evaporation to give a yellow oil. Flash chromatography eluting with 50/50 Et2O/hexanes–75/25 Et2O/hexanes–Et2O delivered primary alcohol 11 as a yellow oil (4.67 g, 27.2 mmol, 98% yield). HRMS (NSI) calculated for C9H17O3+ [M+H]+ 173.11722 found 173.11714; IR (CH2Cl2): 3412, 3088, 2939, 2865, 1736, 1647, 1373, 1240, 1021 cm−1; [α]\({{\,}_{\mathrm{D}}^{20}}\) −8.3 (c 1.00, CH2Cl2); 1H NMR (600 MHz, CDCl3): δ 5.78 (ddd, J = 17.2, 10.6, 6.5 Hz, 1H), 5.27–5.23 (m, 2H), 5.18 (dt, J = 10.5, 1.2 Hz, 1H), 3.65 (t, J = 6.5 Hz, 2H), 2.07 (s, 3 H), 1.72–1.56 (m, 4H), 1.46–1.38 (m, 2H), 1.29 (s, 1H); 13C NMR (151 MHz, CDCl3): δ 170.61, 136.64, 116.96, 74.88, 62.93, 34.17, 32.63, 21.58, 21.47.

Aldehyde 12

To a solution of primary alcohol 11 (4.69 g, 27.2 mmol) in acetonitrile (MeCN, 150 mL) was added Stahl 1° alcohol oxidation solution (7 mL of a MeCN solution containing 0.2 M in TEMPO, 0.2 M in bpy, and 0.4 M in NMI) followed by Cu(MeCN)4OTf (512 mg, 1.4 mmol). The resulting red solution was stirred vigorously while open to air for 12 h whereupon it turned green, indicating completion. The mixture was concentrated by rotary evaporation, the resulting oil was filtered through a plug of silica gel with Et2O and the eluant concentrated to give the aldehyde 12 as an orange oil (3.50 g, 20.6 mmol, 75% yield). HRMS (NSI) calculated for C9H15O3+ [M+H]+ 171.10157, found 171.10153; IR (CH2Cl2): 3087, 2940, 2725, 1732, 1646, 1372, 1237, 1020 cm−1; [α]\({{\,}_{\mathrm{D}}^{20}}\) −7.1 (c 1.13, CH2Cl2); 1H NMR (600 MHz, CDCl3): δ 9.77 (t, J = 1.5 Hz, 1H), 5.78 (ddd, J = 17.2, 10.7, 6.4 Hz, 1H), 5.28–5.23 (m, 2H), 5.19 (dt, J = 10.5, 1.1 Hz, 1H), 2.48 (tdd, J = 6.7, 3.1, 1.5 Hz, 2H), 2.08 (s, 3H), 1.72–1.62 (m, 4H); 13C NMR (151 MHz, CDCl3): δ 202.06, 170.50, 136.24, 117.26, 74.40, 43.64, 33.64, 21.41, 17.81.

Enal 13

To a solution of aldehyde 12 (3.33 g, 19.6 mmol) in CH2Cl2 (70 mL) at room temperature was added Et3N (8.5 mL, 61 mmol) followed by N,N-dimethylmethyleneiminium iodide (7.51 g, 40.6 mmol). The reaction was stirred for 2 h whereupon the starting aldehyde was consumed (TLC analysis). The mixture was quenched with satd. aq. NaHCO3 (50 mL), and the aqueous layer was extracted with CH2Cl2 (3 × 50 mL). The combined organic layers were dried over Na2SO4 and concentrated by rotary evaporation. Flash chromatography eluting with 25/75 Et2O/Hexanes gave the enal 13 as a pale yellow oil (2.20 g, 12.1 mmol, 62% yield). HRMS (NSI) calculated for C10H15O3+ [M+H]+ 183.10157, found 183.10144; IR (CH2Cl2): 3088, 2933, 2821, 2702, 1735, 1688, 1647, 1629, 1431, 1372, 1236, 1022, 958 cm−1; [α]\({{\,}_{\mathrm{D}}^{20}}\) −1.7 (c 1.14, CH2Cl2); 1H NMR (600 MHz, CDCl3): δ 9.55 (s, 1H), 6.29 (t, J = 1.4 Hz, 1H), 6.04 (s, 1H), 5.78 (ddd, J = 17.1, 10.6, 6.4 Hz, 1H), 5.26 (d, J = 17.2 Hz, 1H), 5.24 (q, J = 6.5 Hz, 1H), 5.20 (d, J = 10.6 Hz, 1H), 2.37–2.23 (m, 2H), 2.08 (s, 3H), 1.86–1.74 (m, 2H); 13C NMR (151 MHz, CDCl3): δ 194.55, 170.48, 149.45, 136.15, 134.58, 117.39, 74.20, 32.20, 23.82, 21.41.

Preparation of Grignard reagent 14

To an oven dried 100 mL round bottomed flask equipped with a new stir bar was added Mg turnings (788 mg, 32.4 mmol). (Note: Mg turnings should be shiny, without black MgO on the surface; it is advisable to clean them with conc. HCl prior to use). The flask was purged with argon (× 3) whereupon tetrahydrofuran (THF, 30 mL) was added, followed by 1 M diisobutylaluminum hydride (DIBAL) in hexanes (0.15 mL, 0.15 mmol) (Note: DIBAL serves both to dry the THF and to activate the Mg surface) [34]. The reaction mixture was stirred at rt for 20 min whereupon 1,2-dibromoethane was added (0.05 mL), followed by the dropwise addition of (3-bromopropoxy)-tert-butyldimethylsilane (3.2 mL, 13.8 mmol) over 25 min, the surface of the flask not exceeding 34 °C as observed by thermal camera (SeekThermalTM Thermal Camera for iPhone). After aging for 2 h, the solution was black. Removal of a small (0.1 mL) aliquot of the solution, quenching it with CD3OD and NMR analysis showed the solution to have been ~ 33% Grignard (the rest of the material being dimerized bromide or elimination products).

Enone 15

A solution of the aldehyde 13 (846 mg, 4.6 mmol) in THF (20 mL) was cooled to −78 °C. The entire solution of the Grignard reagent 14 (30 mL, as prepared above) was slowly added down the side of the flask via syringe. After 5 min, TLC showed almost complete conversion to the alcohol product. After 15 min, the reaction mixture was quenched at −78 °C with the addition of satd. aq. NH4Cl (10 mL) by syringe. After warming to rt, more satd. aq. NH4Cl (40 mL) was added. The aqueous layer was extracted with Et2O (3 × 50 mL), the combined organics washed with water (10 mL), brine (10 mL), dried over MgSO4 and concentrated by rotary evaporation. Flash chromatography eluting with 1/100 MeOH CH2Cl2 to 3/100 MeOH/CH2Cl2 gave allylic alcohol 16 as an inseparable 1:1 mixture with its diastereomer, as a clear oil (1.12 g, 3.1 mmol, 68% yield). Aldehyde 13 was also recovered (180 mg, 0.98 mmol, 21% yield). The mixture of product 16 and its diastereomer was characterized: HRMS (NSI) calculated for C19H37O4Si+ [M+H]+ 357.24556, found 357.24498; IR (CH2Cl2): 3446, 3084, 2952, 2929, 2885, 2857, 1740, 1645, 1472, 1372, 1239, 1098, 1023, 835, 775 cm−1; [α]\({{\,}_{\mathrm{D}}^{20}}\) −1.3 (c 0.88, CH2Cl2); 1H NMR (600 MHz, CDCl3): δ 5.79 (apparent dddd, J = 17.2, 10.6, 6.5, 0.9 Hz, 1H (0.9 Hz because of two diastereomers), 5.29–5.24 (m, 2H), 5.19 (dq, J = 10.5, 1.2 Hz, 1H), 5.08 (tt, J = 2.2, 1.1 Hz, 1H), 4.86 (quintet, J = 1.4 Hz, 1H), 4.10–4.08 (m, 1H), 3.67 (t, J = 5.8 Hz, 2H), 2.64 (s, 1H), 2.14 (tdd, J = 16.1, 10.6, 5.7 Hz, 1H), 2.08 (apparent d, J = 0.7 Hz, 3H (both diastereomers)), 2.02 (tdd, J = 16.8, 10.7, 6.2 Hz, 1H), 1.89–1.74 (m, 2H), 1.75–1.68 (m, 1H), 1.65–1.54 (m, 3H), 0.91 (s, 9H), 0.07 (s, 6H); 13C NMR (151 MHz, CDCl3): δ 170.60, 170.55, 151.09, 150.98, 136.53, 136.50, 117.17, 117.13, 110.10, 109.94, 75.28, 75.09, 74.78, 74.69, 63.55, 33.11, 33.02, 32.71, 32.69, 29.19, 27.21, 26.93, 26.16, 25.87, 21.47, 18.55, −5.15. To a solution of alcohol 16 and its diastereomer (349 mg, 0.98 mmol) in MeCN (5 mL) was added Stahl 2° alcohol oxidation solution (15 mL of a MeCN solution containing 0.002 M in ABNO, 0.01 M in MeObpy and 0.02 M in NMI) followed by Cu(MeCN)4OTf (68 mg, 0.18 mmol). The reaction was stirred open to air for 2 days, and concentrated by rotary evaporation. The resulting residue was filtered through a plug of SiO2 with Et2O and the eluant concentrated by rotary evaporation to give nearly pure enone 15 (305 mg, 0.86 mmol, 88% yield). HRMS (NSI) calculated for C19H35O4Si+ [M + H]+ 355.22991, found 355.22970; IR (CH2Cl2): 3090, 2953, 2929, 2857, 1737, 1678, 1472, 1372, 1236, 1097, 1021, 836, 776 cm−1; [α]\({{\,}_{\mathrm{D}}^{20}}\) + 1.6 (c 1.13, CH2Cl2); 1H NMR (600 MHz, CDCl3): δ 6.06 (s, 1H), 5.79 (ddd, J = 17.4, 10.8, 6.7 Hz, 1H), 5.76 (t, J = 1.8 Hz, 1H), 5.25 (d, J = 17.3 Hz, 1H), 5.24 (q, J = 6.5 Hz, 1H), 5.19 (d, J = 10.6 Hz, 1H), 3.64 (t, J = 6.1 Hz, 2H), 2.78 (t, J = 7.3 Hz, 2H), 2.36–2.27 (m, 2H), 2.08 (s, 3H), 1.83 (dt, J = 13.7, 6.7 Hz, 2H), 1.79–1.69 (m, 2H), 0.89 (s, 9H), 0.05 (s, 6H); 13C NMR (151 MHz, CDCl3): δ 201.80, 170.53, 148.07, 136.35, 124.53, 117.17, 74.42, 62.37, 34.19, 33.04, 27.69, 26.84, 26.14, 25.86, 21.44, −5.12.

Allylic alcohol 16

To a flask charged with THF (5 mL) was added R-2-methyl-CBS-oxazaborolidine (0.53 mL, 1 M in toluene, 0.53 mmol) followed by BH3•THF (0.51 mL, 1 M in THF, 0.51 mmol). The mixture was stirred at room temperature for 1 h before cooling to −40 °C. A solution of enone 15 (174 mg, 0.48 mmol) in THF (5 mL) was added dropwise. After 1.5 h the reaction was complete (TLC analysis) and was quenched by the addition of MeOH (0.4 mL). Following concentration, the resulting residue was chromatographed to give allylic alcohol 16 (96 mg, 0.27 mmol, 56% yield). 1H NMR (600 MHz, CDCl3): δ 5.80 (ddd, J = 17.2, 10.6, 6.5 Hz, 1H), 5.28 (q, J = 6.6 Hz, 1H), 5.26 (dt, J = 17.3, 1.2 Hz, 1H), 5.19 (dt, J = 10.6, 1.2 Hz, 1H), 5.08 (quintet, J = 1.0 Hz, 1H), 4.86 (q, J = 1.4 Hz, 1H), 4.10 (dd, J = 7.3, 3.2 Hz, 1H), 3.67 (t, J = 5.8 Hz, 2H), 2.67 (d, J = 3.6 Hz, 1H), 2.13 (ddd, J = 15.8, 10.1, 5.8 Hz, 1H), 2.08 (s, 3H), 2.03 (ddd, J = 15.9, 10.5, 5.6 Hz, 1H), 1.88–1.77 (m, 2H), 1.74–1.69 (m, 1H), 1.64–1.56 (m, 3H), 0.91 (s, 9H), 0.08 (s, 6H).

The major allyl alcohol stereocenter was determined to be S by analysis of the corresponding Mosher esters (Fig. 8), which also revealed a dr of 96:4.

Iodomethyl-tetrahydropyranyl alcohol 18

To a cooled (0 °C) solution of 16 (96 mg, 0.27 mmol) in MeOH (3 mL) was added acetyl chloride (3–5 drops, ~ 0.05 mL, ~ 0.7 mmol). The reaction mixture was stirred for 10 min and then quenched with solid NaHCO3 (47 mg). Filtration and concentration by rotary evaporation gave the diene diol 17, which was carried on to the next step without further purification. To a 0 °C solution of the diene diol 17 in THF (5 mL) was added NaHCO3 (180 mg, 2.1 mmol) followed by I2 (235 mg, 0.93 mmol). After 1.5 h, the reaction was complete (TLC analysis) and was quenched with satd. aq. Na2S2O3 (2 mL). The aqueous layer was extracted with Et2O (3 × 5 mL) and the combined organics dried over MgSO4 and concentrated to give iodomethyl-tetrahydropyranyl alcohol 18 (93 mg, 0.25 mmol, 93% yield, 2 steps). 1H NMR (600 MHz; CDCl3): δ 5.80 (ddd, J = 17.2, 10.7, 6.4 Hz, 1H), 5.30–5.24 (m, 2H), 5.21 (d, J = 10.5 Hz, 1H), 3.79 (ddd, J = 7.7, 5.9, 4.0 Hz, 1H), 3.61 (ddd, J = 11.6, 6.8, 4.5 Hz, 1H), 3.53 (ddd, J = 11.8, 7.8, 4.0 Hz, 1H), 3.47 (d, J = 10.9 Hz, 1H), 3.40 (d, J = 10.9 Hz, 1H), 2.10 (s, 3H), 1.91 (ddt, J = 12.8, 8.2, 4.3 Hz, 1H), 1.83 (d, J = 6.1 Hz, 1H), 1.80–1.63 (m, 6 H), 1.54–1.47 (m, 1H).

Tetrahydropyranyl alcohol-epoxyalkene substrate 21

To a solution of allylic acetate 18 (93 mg, 0.25 mmol) and (S,R)-epoxyalkene 19 [17] (385 mg, 1.1 mmol) in CDCl3 (5 mL) was added Hoveyda Grubbs II catalyst (20, 10 mg, 0.016 mmol). The mixture was concentrated on a rotary evaporator with water bath temperature at 50 °C for 2 h. 1H NMR analysis of an aliquot of the reaction mixture showed 27% conversion to the desired product 21, with 46% of the epoxyalkene having dimerized. To increase conversion to the cross-metathesis product 21, another portion of catalyst (10 mg) was added with CDCl3 (5 mL). After concentrating on the rotary evaporator for another 2 h, 1H NMR analysis of an aliquot indicated 48% conversion to the desired product 21, and 86% of the epoxyalkene having dimerized. Thus one additional portion of catalyst (10 mg) was added with CDCl3, and the reaction mixture was concentrated on the rotary evaporator for two more hours (6 h total). 1H NMR analysis of an aliquot of the reaction mixture showed 80% conversion to the cross-metathesis product 21, with 89% of epoxyalkene 19 having dimerized. Column chromatography of the resulting oil eluting with 60/40 Et2O/Hexanes gave tetrahydropyranyl alcohol-epoxyalkene 21 as a brown oil (104 mg, 0.15 mmol, 60% yield, E/Z 88:12, dr of E 85:15 (± 2)) containing an additional 10 mg of the starting acetate 18. HRMS (APCI) calculated for C33H46IO6Si+ [M+H]+ 693.21029, found 693.20889; IR (CH2Cl2) 3459, 3070, 3048, 2931, 2858, 1736, 1471, 1428, 1372, 1237, 1112, 1085, 1020, 824, 742, 703 cm–1; [α]\({{\,}_{\mathrm{D}}^{20}}\) −0.8 (c 0.883, CH2Cl2); 1H NMR (600 MHz; CDCl3): δ 7.71–7.65 (m, 4H), 7.46–7.38 (m, 6H), 5.78 (ddd, J = 15.6, 6.5, 0.9 Hz, 1H), 5.53 (ddd, J = 15.6, 6.9, 1.1 Hz, 1H), 5.23 (q, J = 6.0 Hz, 1H), 3.69–3.65 (m, 3H), 3.55–3.46 (m, 2H), 3.42 (d, J = 10.9 Hz, 1H), 3.32 (d, J = 10.9 Hz, 1H), 3.28 (d, J = 6.4 Hz, 1H), 2.03 (s, 3H), 1.93–1.43 (m, 11H), 1.26 (s, 1H), 1.07 (s, 9H);13C NMR (151 MHz, CDCl3): δ 170.49, 135.87, 135.78, 134.21, 133.54, 133.33, 129.98, 129.97, 127.98, 127.94, 127.18, 75.54, 73.60, 68.05, 65.26, 63.26, 63.12, 61.54, 29.57, 27.64, 27.32, 26.98, 22.68, 21.44, 20.08, 19.50, 10.85.

Bicyclic CD substructure 22

Epoxyalkene 21 (15.3 mg, 0.022 mmol) was combined with Pd(PPh3)4 (2.8 mg, 0.0025 mmol), trimethylolpropane phosphite (8, 2.5 mg, 0.016 mmol) and diphenylphosphinic acid (0.9 mg, 0.004 mmol) in CDCl3 (0.7 mL) in a clean NMR tube. The solution was monitored by NMR analysis at several time points. Extensive 2-dimensional NMR analysis after 21 days indicated the presence of the bicyclic product 22. Preparative thin layer chromatography (eluting with Et2O) allowed for isolation of 22 as a colorless film (1.2 mg, 0.0017 mmol, 8% yield), as well as 1,3-diene byproducts 23 (3.5 mg, 0.0055 mmol, 25% yield) and diacetate 24 (4.8 mg, 0.0064 mmol, 29% yield).

Data for 22

HRMS (APCI, negative ion mode) calculated for [M−H]− C33H44IO6Si− 691.19573, found 691.19320; IR (CH2Cl2) 3361, 3312, 2952, 2921, 1737, 1659, 1633, 1468, 1390, 1260, 1088, 1019, 800, 702 cm–1; [α]\({\,}_{\mathrm{D}}^{20}\) −4.0 (c 0.100, CH2Cl2); 1H NMR (600 MHz; CDCl3): δ 7.68–7.65 (m,4H), 7.48–7.45 (m, 2H), 7.43–7.40 (m, 4H), 5.83 (dd, J = 15.7, 1.6 Hz, 1H), 5.74 (dd, J = 15.7, 4.8 Hz, 1H), 5.02 (dt, J = 7.0, 1.3 Hz, 1H), 4.23 (dt, J = 4.8, 1.5 Hz, 1H), 3.81 (dd, J = 11.8, 2.2 Hz, 1H), 3.73 (dd, J = 11.7, 5.0 Hz, 1H), 3.66 (ddd, J = 12.3, 4.5, 1.5 Hz, 1H), 3.58 (d, J = 11.9 Hz, 1H), 3.53 (d, J = 9.7 Hz, 1H), 3.51 (d, J = 9.6 Hz, 2H), 3.38 (td, J = 11.9, 3.3 Hz, 1H), 2.63 (s, 1H), 2.14 (s, 3H), 1.99 (dd, J = 13.3, 5.2 Hz, 1H), 1.87 (td, J = 13.2, 6.4 Hz, 1H), 1.84 (dd, J = 13.1, 4.0 Hz, 1H), 1.75–1.55 (m, 2H), 1.65–1.57 (m, 1H), 1.62–1.58 (m, 1H), 1.54–1.49 (m, 1H), 1.46 (s, 1H), 1.09 (s, 9H); 13C NMR (101 MHz, CDCl3): δ 170.05, 135.56, 135.61, 135.25, 132.86, 132.97, 129.86, 127.8, 127.44, 82.01, 76.97, 76.08, 75.44, 72.86, 70.93, 60.35, 32.84, 30.32, 26.83, 26.76, 25.13, 21.96, 21.35, 19.33, 10.19.

Table 2 provides correlation analysis of NMR data for bicyclic compound 22, including HMQC (1H–13C; 1J), COSY (1H–1H; 2J,3J,4J), HMBC (1H–13C; 2J,3J) and NOESY experiments.

Data for 23

HRMS (NSI) calculated for C31H42IO3Si+ [M–OH]+ 617.19424, found 617.19670; IR (CH2Cl2): 3423, 3071, 3048, 2929, 2857, 1735 (weak), 1691, 1671, 1472, 1428, 1112, 1085, 823, 741, 702 cm−1; 1H NMR (600 MHz, CDCl3): δ 7.69–7.64 (m, 4H), 7.47–7.43 (m, 2H), 7.42–7.38 (m, 4H), 6.64 (ddd, J = 15.4, 11.1, 1.1 Hz, 1H, (Z,E)), 6.27 (dd, J = 15.4, 10.4 Hz, 1H, (E,E)), 6.07 (dd, J = 15.2, 10.4 Hz, 1H, (E,E)), 6.00 (t, J = 10.9 Hz, 1H, (Z,E)), 5.71 (dt, J = 14.8, 7.2 Hz, 1H, (E,E)), 5.67 (d, J = 15.3 Hz, 1H, (Z,E)), 5.57 (d, J = 15.5 Hz,1H, (E,E)), 5.46 (dt, J = 10.7, 7.5 Hz, 1H, (Z,E)), 3.82 (ddd, J = 7.4, 6.5, 3.8 Hz, 1H), 3.66–3.62 (m, 1 H), 3.57–3.54 (m, 1 H), 3.53–3.46 (m, 3H), 3.41 (apparent dd, J = 10.9, 1.1 Hz, 1H), 2.69 (s, 1H, (Z,E)), 2.64 (s, 1H, (E,E)), 2.31–2.08 (m, 2 H), 1.96–1.66 (m, 5H), 1.54–1.47 (m,1H), 1.27 (apparent d, J = 3.2 Hz, 3H), 1.07 (app. d, J = 0.8 Hz, 9H); 13C NMR (151 MHz, CDCl3): δ 137.91, 137.88, 135.90, 135.83, 135.55, 135.47, 134.03, 133.96, 133.33, 133.22, 131.44, 130.40, 130.07, 130.04, 129.32, 128.82, 128.02, 127.99, 127.98, 127.96, 124.40, 124.39, 73.46, 73.20, 71.36, 71.34, 68.04, 61.67, 61.64, 29.92, 29.89, 27.61, 27.57, 27.11, 27.05, 25.69, 24.51, 22.58, 22.48, 20.98, 20.92, 19.56, 10.99, 10.90. (Note: Many double peaks were present in the 13C NMR spectrum due to presence of both E,E and Z,E stereoisomers).

Data for 24

HRMS (NSI) calculated for C35H48IO7Si+ [M–OH]+ 735.22085, found 735.22098; IR (CH2Cl2): 3468, 3071, 3049, 2929, 2857, 1737, 1665, 1428, 1371, 1234, 1085, 1022, 973, 824, 741, 703 cm−1; 1H NMR (600 MHz, CDCl3): δ 7.66–7.62 (m, 4 H), 7.48–7.44 (m, 2H), 7.43–7.38 (m, 4H), 5.80 (ddd, J = 15.7, 6.4, 0.9 Hz, 1H), 5.66 (ddd, J = 15.7, 6.9, 1.2 Hz, 1H), 5.36 (dd, J = 6.4, 1.0 Hz, 1H), 5.23 (q, J = 6.6 Hz, 1H), 3.76 (dt, J = 8.8, 4.6 Hz, 1H), 3.61–3.58 (m, 1H), 3.58 (d, J = 10.1 Hz, 1H), 3.52 (d, J = 11.0 Hz, 1H), 3.51–3.45 (m, 1H), 3.46 (d, J = 10.1 Hz, 1H), 3.35 (d, J = 11.0 Hz, 1H), 2.59 (s, 1H), 2.30 (d, J = 6.0 Hz, 1H), 2.04 (s, 3H), 2.00 (s, 3H), 1.89 (dt, J = 12.7, 6.1 Hz, 1H), 1.80–1.71 (m, 3H), 1.70–1.59 (m, 2H), 1.55–1.48 (m, 2H), 1.12 (s, 3H), 1.08 (s, 9H); 13C NMR (151 MHz, CDCl3): δ 170.45, 170.25, 135.88, 135.81, 133.07, 132.89, 132.84, 130.17, 130.16, 128.07, 128.04, 127.77, 75.97, 75.70, 73.94, 73.80, 67.91, 67.67, 61.49, 29.93, 27.57, 27.51, 27.11, 23.12, 21.53, 21.38, 19.99, 19.47, 11.57.

References

Bourdelais AJ, Jacocks HM, Wright JLC, Bigwarfe PM, Baden DG. A new polyether ladder compound produced by the dinoflagellate Karenia brevis. J Nat Prod. 2005;68:2–6.

Fuwa H, Ebine M, Bourdelais AJ, Baden DG, Sasaki M. Total synthesis, structure revision, and absolute configuration of (-)-brevenal. J Am Chem Soc. 2006;128:16989–99.

Yasumoto T, Murata M. Marine Toxins. Chem Rev. 1993;93:1897–909.

Bourdelais AJ, et al. Brevenal is a natural inhibitor of brevetoxin action in sodium channel receptor binding assays. Cell Mol Neurobiol. 2004;24:553–63.

Gold EP, Jacocks HM, Bourdelais AJ, Baden DG. Brevenal, a brevetoxin antagonist from Karenia brevis, binds to a previously unreported site on mammalian sodium channels. Harmful Algae. 2013;26:12–19.

Abraham WM, et al. Airway responses to aerosolized brevetoxins in an animal model of asthma. Am J Respir Crit Care Med. 2005;171:26–34.

Ebine M, Fuwa H, Sasaki M. Total synthesis of (-)-brevenal: a streamlined strategy for practical synthesis of polycyclic ethers. Chem Eur J. 2011;17:13754–61.

Takamura H, et al. Total synthesis of brevenal. Tetrahedron. 2010;66:5329–44.

Zhang YA, Rohanna J, Zhou J, Iyer K, Rainier JD. Total synthesis of brevenal. J Am Chem Soc. 2011;133:3208–16.

Ebine M, Suga Y, Fuwa H, Sasaki M. Highly efficient synthesis of medium-sized lactones via oxidative lactonization: concise total synthesis of isolaurepan. Org Biomol Chem. 2010;8:39–42.

Takamura H, et al. Total synthesis of brevenal. Org Lett. 2009;11:2531–4.

Kadota I, Ohno A, Matsuda K, Yamamoto Y. Convergent synthesis of polycyclic ethers via the intramolecular allylation of α-acetoxy ethers and subsequent ring-closing metathesis. J Am Chem Soc. 2002;124:3562–6.

Crimmins MT, Shamszad M, Mattson AE. A highly convergent approach toward (-)-brevenal. Org Lett. 2010;12:2614–7.

Rainier JD, Allwein SP, Cox JM. C-Glycosides to fused polycyclic ethers. A formal synthesis of (±)-hemibrevetoxin B. J Org Chem. 2001;66:1380–6.

Hurtak JA, McDonald FE. Synthesis of the ABC substructure of brevenal by sequential exo-mode oxacyclizations of acyclic polyene precursors. Org Lett. 2017;19:6036–9.

McDonald FE, Ishida K, Hurtak JA. Stereoselectivity of electrophile-promoted oxacyclizations of 1,4-dihydroxy-5-alkenes to 3-hydroxytetrahydropyrans. Tetrahedron. 2013;69:7746–58.

Setterholm NA, McDonald FE. Stereoselective synthesis of pyrans from epoxyalkenes: dual catalysis with palladium and Brønsted acid. J Org Chem. 2018;83:6259–74.

Takahashi T, Kataoka H, Tsuji J. Palladium-catalyzed stereocontrolled cyclization of 1,3-diene monoepoxides and its application to the synthesis of 11-deoxy-PGE1. J Am Chem Soc. 1983;105:147–9.

Trost BM, Ceschi MA, König B. Palladium-catalyzed additions of alkenyl epoxides to pronucleophiles: a synthesis of the macrolactam aglycone of fluviricin B1. Angew Chem Int Ed Engl. 1997;36:1486–9.

Jana N, Mahapatra T, Nanda S. Chemo-enzymatic asymmetric total synthesis of stagonolide-C. Tetrahedron: Asym. 2009;20:2622–8.

Ascic E, et al. Synthesis of oxacyclic scaffolds via dual ruthenium hydride/Brønsted acid-catalyzed isomerization/cyclization of allylic ethers. Chem - A Eur J. 2014;20:3297–3300.

Hoover JM, Stahl SS. Highly practical copper(I)/TEMPO catalyst system for chemoselective aerobic oxidation of primary alcohols. J Am Chem Soc. 2011;133:16901–10.

Dai X, Davies HML. Formal enantioselective [4+3] cycloaddition by a tandem Diels–Alder reaction/ring expansion. Adv Synth Catal. 2006;348:2449–56.

Molli SD, et al. Structure–activity relationship of a hormones, the mating factors of phytopathogen. Phytophthora Bioorg Med Chem. 2012;20:681–6.

Steves JE, Stahl SS. Copper(I)/ABNO-catalyzed aerobic alcohol oxidation: alleviating steric and electronic constraints of Cu/TEMPO catalyst systems. J Am Chem Soc. 2013;135:15742–5.

Corey EJ, Bakshi RK, Shibata S. Highly enantioselective borane reduction of ketones catalyzed by chiral oxazaborolidines. Mech Synth Implic J Am Chem Soc. 1987;109:5551–3.

Stoltz KL, Alba A-NR, McDonald FE, Wieliczko MB, Bacsa J. Iodoetherification of conformationally restricted dienyl alcohols: unexpected formation of oxocenes by 8-endo-mode oxacyclizations. Heterocycles. 2014;88:1519–26.

Trost BM, Tometzki GB. Umpolung of π-allylpalladium intermediates. A chemoselective reductive elimination of diols. J Org Chem. 1988;53:915–7.

Tsarev VN, Wolters D, Gais H-J. Redox reaction of the Pd0 complex bearing the Trost ligand with meso-cycloalkene-1,4-biscarbonates leading to a Diamidato PdII complex and 1,3-cycloalkadienes: enantioselective desymmetrization versus catalyst deactivation. Chem Eur J. 2010;16:2904–15.

Trost BM, Tometzki GB. A novel palladium-catalyzed deoxygenation of enediols to 1,3-dienes. Synthesis. 1991;1991:1235–44.

Tolman CA. Steric effects of phosphorus ligands in organometallic chemistry and homogeneous catalysis. Chem Rev. 1977;77:313–48.

Enders D, Nguyen D. Synthesis of enantioenriched substituted tetrahydrofurans and tetrahydropyrans via iron-mediated chirality transfer and ring closure. Synthesis. 2000;2000:2092–8.

Su B-N, et al. New chemical constituents of Euphorbia quinquecostata and absolute configuration assignment by a convenient Mosher ester procedure carried out in NMR tubes. J Nat Prod. 2002;65:1278–82.

Tilstam U, Weinmann H. Activation of Mg metal for safe formation of Grignard reagents on plant scale. Org Process Res Dev. 2002;6:906–10.

Acknowledgements

This material is based upon work supported by the National Science Foundation under CHE-1362249. We also acknowledge the use of the Bruker AVANCE III HD 600 MHz NMR spectrometer, supported by NSF grant CHE-1531620.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Dedication This work celebrates the breadth, the quality, and the impact of Prof. Samuel Danishefsky’s contributions to the science of natural products synthesis, and honors his thoughtful mentorship of the corresponding author.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Setterholm, N.A., McDonald, F.E. Sequential exo-mode oxacyclizations for the synthesis of the CD substructure of brevenal. J Antibiot 72, 364–374 (2019). https://doi.org/10.1038/s41429-018-0124-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41429-018-0124-1