Abstract

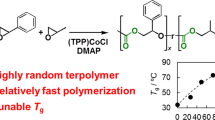

Phosgene is an important carbonyl source for industrial production of polycarbonates (PCs) and polyurethanes (PUs). However, since it is highly toxic, alternative compounds and/or new phosgenation reactions have been explored for safety reasons. Given this background, we found a novel photochemical reaction enabling the synthesis of phosgene from chloroform. Subsequently, we developed new phosgenation reactions and reaction systems, and the key objective was “safe application” to organic synthesis. This focus review reports our recent use of in situ photo-on-demand phosgenations of alcohols and amines in synthesizing PC, PU, and their precursors, such as chloroformates, carbonate esters, and diisocyanates, in batch reaction systems, which are preferable for laboratory or small-scale industrial syntheses. We believe that the present reactions have advantages over conventional phosgenation reactions, especially in terms of safety and environmental impacts, and are expected to make positive contributions to practical organic syntheses in both academia and industry.

Similar content being viewed by others

Introduction

Phosgene has the chemical formula COCl2, is an important C1 building block in organic synthesis and is used as a raw material for the syntheses of polycarbonates (PCs) and polyurethanes (PUs) [1,2,3,4,5,6,7,8,9,10]. However, its laboratory use is often restricted due to its extremely high toxicity [11]. Industrially, it is used in large quantities worldwide with strict legal controls of (1) the storage and transport of phosgene; (2) the use of large quantities of toxic substances (gases) as raw materials; and (3) the disposal of waste, including chlorinated byproducts. The global market for phosgene has grown continuously with the increased production of PCs and diisocyanates such as toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI), which are precursors in the production of PUs [4,5,6,7,8,9,10], along with the production of pharmaceuticals, pesticides, and dyes. Phosgene is generally manufactured on-site and on-demand, where and when it is needed, and only in the quantities needed. Currently, in large-scale industrial processes, it is produced from carbon monoxide (CO) and chlorine (Cl2) gas at 50–150 °C with a carbon catalyst [Fig. 1, reaction (a)] [12, 13]. This method of production has remained essentially unchanged since approximately 1920 and is now an established method for phosgene production [2]. However, the method has clear associated safety risks due to the high toxicity of CO and the toxicity/corrosiveness of Cl2, and their intense exothermic reaction requires temperature control. Furthermore, given global climate change and the consequent strong demand and need for carbon neutrality, innovative phosgene production methods have attracted social attention [14].

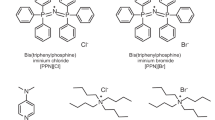

To reduce the safety risk, in situ production of phosgene via decomposition of triphosgene (BTC), which is a solid at room temperature and soluble in organic solvents, with organic bases [Fig. 1, reaction (b)] is mainly used for relatively small-scale chemical syntheses in both academia and industry [15,16,17]. However, Cotarca and coworkers recently reported on the risks of BTC, which also has high toxicity and easily reaches toxic concentrations due to its high vapor pressure, and warned against unrestricted use [18]. Furthermore, the use of organic bases in BTC phosgenation reactions produces the hydrochloride salt in solution owing to the presence of HCl generated from the reaction of phosgene and the substrate. This can lead to mechanical system issues, such as difficulty in stirring the batch tanks and clogging the flow systems. Furthermore, the hydrochloride salt generated in the reaction must be removed through an additional purification process. Although alterations to conventional phosgene syntheses and alternative nonphosgene methods have been studied [19, 20], they have only marginally replaced the current methods due to their higher costs and higher environmental impacts.

In light of this, we developed a photo-on-demand synthesis of phosgene from chloroform (CHCl3) [Fig. 1, reaction (c)] [21, 22]. The photochemical oxidation of CHCl3 to COCl2 occurs efficiently upon irradiation with a 20 W low-pressure mercury lamp (LPML), which emits 184.9 and 253.7 nm UV light, with O2 bubbling at room temperature. In the early stage of this study, we synthesized a variety of organic chemicals, including polymers, with the gaseous photooxidation products of CHCl3 by using a gas-transport reaction system (Fig. 2, system [I]) [23, 24]. However, this reaction system had a potential risk of leakage, such as the case of reaction (a) in Fig. 1. To ensure safe use of this reaction, we then developed “in situ” photo-on-demand phosgenation reactions, which required the design and construction of batch and flow reaction systems [25,26,27,28,29,30,31,32,33,34]. We have successfully applied this photo-on-demand phosgenation reaction on a practical scale for most common phosgenation reactions, such as the syntheses of chloroformates [25, 26], carbonate esters [28, 29], PCs [28], isocyanates [30], Vilsmeier reagents [27], acyl chlorides [25], and α-amino acid N-carboxyanhydrides (NCAs) [32] (Fig. 3). This review article highlights the reactions of alcohols and amines used in synthesizing PC, PU, and their precursors, and the examples are limited to those using the batch reaction system. These reactions have the potential to replace the conventional reactions and exhibit superior safety and low energy consumption; additionally, chloroform is a common organic solvent and is readily available as a raw material for a wide variety of reactions conducted on various scales.

Mechanism for the photochemical oxidation of CHCl3

The photochemical oxidation of CHCl3 may proceed through a radical chain mechanism initiated by photolytic cleavage of a C–Cl bond [path (a) in Fig. 4]. The eliminated Cl• reacts with CHCl3 to give Cl3C• and HCl. The resulting Cl3C• initiates a radical chain reaction with O2 to give COCl2 with elimination of a Cl• [path (b) in Fig. 4] [22, 35]. This reaction mechanism was supported by the observation that the yield of the byproduct hexachloroethane (C2Cl6) increased with decreasing oxygen concentrations in the reaction system. It is also known that COCl2 decomposes under UV irradiation to give CO, CO2, and Cl2. The generated Cl2 most likely served as an additional source of Cl•, which accelerated the photochemical oxidation of CHCl3. In general, alcohols such as ethanol are used as stabilizers to inhibit the decomposition of CHCl3 [36] and may serve as radical scavengers to regenerate CHCl3 from the halomethane radicals. However, when the concentration of the halomethane radicals exceeded the threshold alcohol concentrations in both the liquid and vapor phases, the photooxidation of CHCl3 supported phosgenation of the alcohol. This enabled the development of the in situ photo-on-demand phosgenation reactions described in this review article.

Experimental setup of a batch-type photoreaction system

Low-pressure mercury lamps generally exhibit low electric power consumption and generate UV light with wavelengths of 184.9 and 253.7 nm, which match the electronic absorption bands of CHCl3 arising from σ–σ* and/or n–σ* transitions [37]. The lamp (20 W, ø24 mm × 120 mm) exhibited a 254 nm illuminance of 6.2–9.0 mW/cm2 at 5 mm from the lamp and was inserted into the CHCl3 solution in a quartz glass jacket (ø28 mm × 150 mm) fixed in the center of a cylindrical flask (ø42 mm × 170 mm) equipped with an alcohol/water-cooled condenser (Fig. 2, system [II]). The photochemical reactions were conducted in this reaction system while a steady flow of O2 (0.1–0.5 L/min) was bubbled through CHCl3 with or without the substrate for the phosgenation reaction and with stirring of the sample solution at various temperatures. The reactions were demonstrated with a closed system, but the exhausted gas containing unreacted COCl2 and the generated HCl must be trapped with an alcohol trap and an in-line aqueous NaHCO3 trap.

Base-free in situ photo-on-demand synthesis of chloroformate and one-pot syntheses of carbonate esters and carbamates

Chloroformate plays important roles in organic synthesis and is generally prepared from COCl2 and an alcohol (Fig. 5) [38]. In our pioneering study of in situ photo-on-demand phosgenation reactions, we reported that chloroformate was produced in high yield upon photoirradiation of a CHCl3 solution containing an alcohol with O2 bubbling [25, 26]. This approach provided one-pot syntheses of unsymmetric carbonates and carbamates via subsequent addition of alcohols or amines, respectively.

When CHCl3 solutions containing 20 mmol of a primary alkyl alcohol (n = 0, 1, 2, 3, or 6) in the above photochemical reaction system were exposed to UV light at 30 °C, the corresponding chloroformates were obtained as the major products in 7–93% yields. (Fig. 5a). Formates and carbonate esters were also obtained as minor products with ~5% yields. The chloroformate yield clearly decreased with decreasing alcohol chain length because the alkyl alcohols with shorter chain lengths evaporated more easily, which slowed the photochemical conversion of CHCl3 to COCl2 in the gas phase. In support of this proposed mechanism, the reaction was decelerated dramatically when the reaction temperature was raised to 50 °C, which may have vaporized both the alcohol and COCl2 in the CHCl3. Longer irradiation times also tended to decrease the product yields, most likely due to photodecomposition of the products. With the concentration of alcohol, the temperature, and the irradiation time optimized, triethylene glycol monomethyl ether (TEGM) was converted to the corresponding chloroformate in 89% yield. Although aryl alcohols, which are generally less nucleophilic than alkyl alcohols, showed no notable reaction, aryl-substituted aliphatic alcohols such as benzyl alcohol and 9-fluorenylmethanol provided the corresponding chloroformates.

This reaction enables the preparation of CHCl3 solutions containing chloroformates, and thus, these solutions are available for one-pot syntheses of unsymmetric carbonate esters and carbamates (Figs. 5b and 5c). An as-prepared CHCl3 solution of n-hexyl chloroformate was stirred at 30–70 °C for 1–3 h to remove the HCl, and the unreacted COCl2 dissolved in the sample solution. Since the carbonyl carbon in chloroformate is less electrophilicity than that of COCl2, the second substitution reaction with an alkyl alcohol to form the carbonate ester occurs slowly when the sample solution is heated. For example, when 1.5 equiv. of 1-hexanol was added into a CHCl3 solution containing chloroformate, and the sample solution was stirred for 15 h at 90 °C to evaporate the CHCl3 solvent from the system, the corresponding symmetric carbonate was obtained in 95% yield (isolated amount and yield: 1.29 g and 56%, respectively). With a similar procedure, benzyl alcohol and TEGM provided unsymmetrical carbonates in 87% and 50% yields, respectively. 2-Propanol, a secondary alcohol, did not react without a base, but the corresponding unsymmetrical carbonate was obtained in 60% yield upon addition of pyridine. (–)-Menthol, with a boiling point higher than that of 2-propanol, underwent the reaction without a base and at a higher temperature to give the corresponding carbonate in 54% yield. Although phenol, an aryl alcohol which is less nucleophilic than alkyl alcohols, did not react with chloroformate even at elevated temperatures, it underwent the reaction after triethyl amine (TEA) was added and provided the asymmetric hexyl phenyl carbonate in 56% yield. With similar one-pot procedures, biobased nonionic amphiphiles were synthesized from CHCl3 solutions of TEGM. The TEGM underwent an initial photochemical conversion in CHCl3 to form the corresponding chloroformate, and subsequent addition of citronellol or geraniol to the sample solution and heating provided the corresponding amphiphilic carbonates in 69% and 70% yields, respectively.

The introduction of N-protecting groups to amines is an important application of chloroformates [39]. One-pot syntheses of carbamates were also achieved upon addition of an amine to the prepared CHCl3 solution of chloroformate (Fig. 5c). For example, the photochemical conversion of 1-hexanol to the corresponding chloroformate in CHCl3 and a subsequent reaction with aniline under reflux generated the carbamate in 70% yield based on the alcohol (isolated amount and yield: 1.13 g and 48%, respectively) with the elimination of HCl. With a similar procedure, an amphiphilic carbamate was also synthesized from TEGM in 56% yield. Cbz- and Fmoc-protection of cyclohexylamine were then achieved with this one-pot procedure.

Base-promoted in situ photo-on-demand syntheses of carbonate esters and polycarbonates

COCl2 and chloroformates undergo faster condensation reactions with alcohols in the presence of a base, which serves as a catalyst as well as an HCl scavenger. Since organic bases such as TEA and pyridine absorb UV light [40, 41], difficulties were anticipated for in situ photo-on-demand syntheses of carbonate esters with CHCl3 solutions containing a mixture of alcohol and organic base, both of which inhibit the photooxidation of CHCl3. In fact, the amount of COCl2 generated by photooxidation of CHCl3 (30 mL, 0.37 mol) decreased to 46% when 0.03 mol (8%) of pyridine was added. However, the reactions occurred with aryl alcohols and haloalkyl alcohols to give the corresponding carbonate esters (Fig. 6). This reaction provides convenient in situ photo-on-demand syntheses of carbonate esters in high yields on a gram scale [28].

When the photoreactions were conducted by adding 3.5 equiv. of pyridine to CHCl3 solutions containing ethanol (EtOH) or 2-propanol (2-PrOH), neither the carbonate ester nor the chloroformate was obtained (data not shown). Both pyridine and alcohol inhibit the oxidative photodecomposition of CHCl3 by absorbing UV light and/or trapping the radical species generated from CHCl3. Although phenol, whose nucleophilicity is lower than those of alkyl alcohols, also showed no reaction in the absence of a base, the phosgenation reaction occurred to give diphenyl carbonate (DPC) in >99% yield (isolated amount: 1.1 g) in the presence of 5 equiv. of pyridine. Phenol is relatively more acidic (pKa = 10.0) than alkyl alcohols (pKa = 15–18) [42], and pyridine forms a weak acid–base complex with phenol with an association constant of K = 33 M–1 in CHCl3 solution at 20 °C. This interaction may decelerate radical trapping and accelerate the nucleophilic additions of phenol to COCl2 and chloroformate. 2-Naphthol, which has a larger π-conjugated structure, and 4-methoxyphenol, which contains an electron-donating methoxy group, have lower and higher pKa values, respectively, (9.51 and 10.05, respectively) than phenol and provided the corresponding carbonate esters in >99% yields [43, 44]. 4-Fluorophenol, with an electron-withdrawing F on the phenol ring, provided the corresponding carbonate esters in 93% yield. Furthermore, 4-nitrophenol and 4-cyanophenol contain electron-withdrawing substituents and were converted to the corresponding carbonate esters in 39% and 62% yields, respectively. Even with pentachlorophenol and pentafluorophenol, which have lower pKa values of 4.96 and 5.53 [45, 46], respectively, the reactions occurred with high yields.

Fluorinated alkyl alcohols, which are relatively acidic and form acid–base complexes, also participated in situ photochemical syntheses of carbonate esters in CHCl3 solutions containing a mixture of the alcohol and a base. For example, 1,1,1,3,3,3-hexafluoro-2-propanol (HFIP), which forms a pyridine complex with K = 58 M−1 in CHCl3 at 20 °C, underwent a reaction in the presence of 2 equiv. of pyridine to produce the corresponding carbonate ester (BHFC) in quantitative yield. 2,2,2-Trifluoroethanol and 2,2,3,3-tetrafluoro-1-propanol, whose pKa values are higher than that of HFIP, were also converted to the corresponding carbonate esters in 98 and 88% yields, respectively. A highly fluorinated alkyl carbonate was then synthesized from 1,1,1,2,2,4,5,5,5-nonafluoro-4-(trifluoromethyl)pentan-3-ol in 61% yield. The reaction also occurred with chlorinated alkyl alcohols. HFIP and 2,2,2-trichloroethanol provided the corresponding carbonate esters in 81 and 90% yields, respectively.

These base-promoted in situ photo-on-demand syntheses of carbonate esters were also available for the syntheses of PCs from diols (Fig. 7). Bisphenol A (BPA) provided a quantitative yield for a conventional PC (isolated amount: 2.7 g) with an average molecular weight of Mw = 52,000, Mn = 23,000, and PDI = 2.26. Bisphenol AF (BPAF), which contains electron-withdrawing trifluoromethyl groups, provided a PC with Mw = 14,000, Mn = 6,400, and PDI = 2.19. The lower molecular weight may be ascribed to the lower nucleophilicity of BPAF relative to that of BPA. 2,2,3,3,4,4-Hexafluoro-1,5-pentanediol, a fluoroalkyl diol, afforded the corresponding PC in 59% yield with Mw = 41,300, Mn = 24,400, and PDI = 1.69. The low solubility of the fluoroalkyl PC in organic solvents reduced the isolated yield.

In situ syntheses of isocyanates, blocked isocyanates, and polyurethanes with photo-oxidized CHCl3

Isocyanates contain –N = C = O groups and are typically synthesized industrially from amines and COCl2 [4,5,6,7,8,9,10]. Alternatively, to avoid the direct use of COCl2 in laboratory-scale experiments and small-scale industrial production, BTC is used in synthesizing isocyanates [2, 15]. We recently reported that the following two reactions involving in situ photochemical oxidation of CHCl3 to COCl2 allowed selective syntheses of N-substituted ureas and isocyanates from amines: [30] (I) UV photoirradiation of a CHCl3 solution containing an amine and an organic base with O2 bubbling at 20–40 °C provided the N-substituted urea. (II) A two-step reaction involving photochemical oxidation of CHCl3 at low temperature and subsequent sequential injections of an amine and organic base into the sample solution provided the isocyanate. Processes (I) and (II) proceed with relative concentrations of [COCl2] < [amine] and [COCl2] > [amine], respectively, to provide the 1:2 and 1:1 reactions.

The amount of the COCl2 generated in a 20 mL CHCl3 solution was estimated to be 18.5 mmol after exposure to UV light from a 20 W LPML at 0 °C for 1 h while bubbling O2 at a flow rate of 0.1 L/min. Based on this result, several diisocyanates that are conventionally used to manufacture PUs industrially were synthesized with [COCl2]>[amine] concentration ratios (Fig. 8). Toluene diisocyanate (TDI), methylenediphenyl diisocyanate (MDI), benzene diisocyanate (BDI), and naphthalene diisocyanate (NDI), which are aromatic diisocyanates, were synthesized in 80%, 90%, 47%, and 67% yields, respectively, from the corresponding diamines (5 mmol). Hexamethylene diisocyanate (HDI) and pentamethylene diisocyanate (PDI), which are alkyl diisocyanates, were synthesized in 96% and 83% yields, respectively. Cyclic diisocyanates, such as m-xylylene diisocyanate (XDI), 1,4-bis(isocyanatomethyl)cyclohexane (H6XDI), isophorone diisocyanate (IPDI), and norbornanediisocyanate (NBDI), were obtained in 63%, 58%, 42%, and 65% yields, respectively.

By preparing the diisocyanates in CHCl3 solution, one-pot syntheses of biscarbamates, which serve as blocked isocyanates, were achieved (Fig. 9). When EtOH or HFIP was added to a CHCl3 solution containing MDI, which was prepared with the two-step procedures described above without and with added pyridine, the corresponding biscarbamates were obtained in 78 and 71% yield, respectively. HDI, which is less reactive than MDI, also reacted with HFIP to give the corresponding biscarbamate with a lower yield of 37%. Fluorinated HDI (8FHDI), which is more reactive and unstable in air, was then prepared from a CHCl3 solution containing the HCl salt of 2,2,3,3,4,4,5,5-octafluorohexane-1,6-diamine (8FHDA·2HCl). The one-pot synthesis proceeded after addition of HFIP to the sample solution and afforded the corresponding biscarbamate in 37% yield.

One-pot syntheses of polyurethanes (PU) were achieved by adding diols instead of monoalcohols to the diisocyanate CHCl3 solutions. When an equimolar amounts of 1,6-hexanediol (HD) relative to the diamines were added to CHCl3 solutions containing MDI or 8FHDI, the corresponding PUs [poly(MDI-HD) or poly(8FHDI-HD)] were obtained in 50% and 91% yields (isolated amounts: 0.92 and 0.81 g, respectively) with average molecular weights of Mw = 4100, Mn = 2200, PDI = 1.86 and Mw = 4000, Mn = 2400, PDI = 1.67, respectively. Their relatively low average molecular weights may have originated from the poor solubility of the formed PUs. Then, polypropylene glycol (PPG) with an average molecular weight of 400 increased the solubility of the PU and provided poly(MDI-PPG) and poly(8FHDI-PPG) in 89 and 86% yields (isolated amounts: 2.91 and 1.18 g, respectively) with Mw = 6200, Mn = 3600, PDI = 1.72, and Mw = 8800, Mn = 3400, PDI = 2.59, respectively. The average molecular weight of the PU formed in this one-pot synthesis can be controlled by estimating the amount of the diisocyanate formed in the sample solution via spectroscopic and/or HPLC analyses.

Cl2-promoted photochemical oxidation of CHCl3 with visible light and application to one-pot organic syntheses

Compared with the conventional phosgenation reactions run with CO/Cl2 or triphosgene, the photo-on-demand phosgenation reactions described above for CHCl3 are safe, convenient, and inexpensive, but the use of the LPML causes unfavorable side reactions arising from photodecomposition of both reagents and products by the high-energy UV-C light. The use of mercury lamps has recently been avoided due to their large environmental impacts and associated health hazards [47]. This background motivated us to develop a novel photo-on-demand photocatalytic reaction using lower-energy visible light, which enables the use of light-emitting diodes (LEDs) and sunlight as light sources instead of LPMLs. We found that bubbling O2 through a CHCl3 solution containing ~2% Cl2 caused photooxidation with the white LED light [31]. For example, when 30 mL of CHCl3 subjected to O2/Cl2 bubbling was exposed to white light from a 9 W LED at 20 °C for 1.5 h, a 12.5% conversion to COCl2 resulted. The added Cl2 may have served as a visible light-responsive initiator for the radical chain reaction of CHCl3 and O2 (Fig. 4) [48].

This photochemical reaction using visible light provided one-pot syntheses of chloroformates, carbonate esters, and isocyanates (Fig. 10). However, it is important to note that the reaction should be performed with a two-step procedure since some of the alkyl alcohols and amines used as reactants react with Cl2. Using this method, hexyl chloroformate was synthesized quantitatively from a CHCl3 solution (50 mL) containing 1-hexanol (30 mmol) without the need for an organic base. Dibutyl carbonate (DBC), DPC, and BHFC were also synthesized in 95, 84, and 70% yields via base-catalyzed condensation reactions. Furthermore, 1-isocyanatohexane, isocyanatobenzene, and (3-isocyanatopropyl)trimethoxysilane were synthesized in >99, 73, and 56% yields, respectively.

Conclusion

We have focused this review on our recent studies of in situ photo-on-demand phosgenation reactions of alcohols and amines, which were used to synthesize PCs, PUs, and their precursors such as chloroformates, carbonate esters, and diisocyanates in batch reactions. Given the current global warming problem, sustainable synthetic methods for polymer production are being actively studied. This photochemical reaction efficiently converts CHCl3 to COCl2, which is extremely reactive toward nucleophiles, and this enables in situ syntheses of many organic chemicals and polymers while reducing energy consumption and waste generation. We believe that the present in situ photo-on-demand phosgenation reaction has advantages over conventional phosgenation reactions, especially in terms of safety and environmental impact. When combined with the flow photo-on-demand phosgenation system reported recently by our group [34], which enables scale-up of chemical processes, our present findings are expected to provide practical polymer syntheses of use in both academia and industry. Our group is currently developing suitable facilities for the safe use of this photo-on-demand phosgenation reaction on a larger scale and is constructing a reaction library describing the syntheses of various organic chemicals, including polymers, for eventual commercial use.

References

Babad H, Zeiler AG. The chemistry of phosgene. Chem Rev. 1973;73:75–91.

Cotarca L, Eckert H. Phosgenations-a handbook. Weinheim: Wiley-VCH; 2003.

Nakata M. An overview on polycarbonate. Kobunshi. 1997;46:558–61.

Liu J, Yee AF. Enhancing plastic yielding in polyestercarbonate glasses by 1,4-cyclohexylene linkage addition. Macromolecules. 1998;31:7865–70.

Saunders JH, Slocombe RJ. The chemistry of the organic isocyanates. Chem Rev. 1948;43:203–2018.

Arnold RG, Nelson JA, Verbanc JJ. Recent advances in isocyanate chemistry. Chem Rev. 1957;57:47–76.

Ozaki S. Recent advances in isocyanate chemistry. Chem Rev. 1972;72:457–96.

Hardy DVN Preparation of aryl carbimides. J Chem Soc. 1934:2011.

Gill JE, MacGillivray R, Munro J Preparation of symmetrical aromatic triamines and triisocyanates. J Chem Soc. 1949:1753–4.

Slocombe RJ, Hardy EE, Saunders JH, Jenkins RL. Phosgene derivatives. The preparation of isocyanates, carbamyl chlorides and cyanuric acid. J Am Chem Soc. 1950;72:1888–91.

Pauluhn J. Phosgene inhalation toxicity: update on mechanisms and mechanism-based treatment strategies. Toxicology. 2021;450:152682.

Rossi GE, Winfield JM, Mitchell CJ, Meyer N, Jones DH, Carr RH, et al. Phosgene formation via carbon monoxide and dichlorine reaction over an activated carbon catalyst: reaction kinetics and mass balance relationships. Appl Catal A-Gen. 2020;602:117688.

Rossi GE, Winfield JM, Meyer N, Jones DH, Carr RH, Lennon D. Phosgene synthesis catalysis: the influence of small quantities of bromine in the chlorine feedstream. Ind Eng Chem Res. 2021;60:3363–73.

Voßnacker P, Wüst A, Keilhack T, Müller C, Steinhauer S, Beckers H, et al. Novel synthetic pathway for the production of phosgene. Sci Adv. 2021;7:eabj5186.

Eckert H, Forster B. Triphosgene, a crystalline phosgene substitute. Angew Chem Int Ed Engl. 1987;26:894–5.

Yasukouchi H, Nishiyama A, Mitsuda M. Safe and efficient phosgenation reactions in a continuous flow reactor. Org Process Res Dev. 2018;22:247–51.

Ganiu MO, Nepal B, Van Houten JP, Kartika R. A decade review of triphosgene and its applications in organic reactions. Tetrahedron. 2020;76:131553–76.

Cotarca L, Geller T, Répási J. Bis(trichloromethyl)carbonate (BTC, Triphosgene): a safer alternative to phosgene? Org Process Res Dev. 2017;21:1439–46.

Fukuoka S, Fukawa I, Adachi T, Fujita H, Sugiyama N, Sawa T. Industrialization and expansion of green sustainable chemical process: a review of non-phosgene polycarbonate from CO2. Org Process Res Dev. 2019;23:145–69.

Maisonneuve L, Lamarzelle O, Rix E, Grau E, Cramail H. Isocyanate-free routes to polyurethanes and poly(hydroxy Urethane)s. Chem Rev. 2015;115:12407–39.

Tsuda A A reaction mixture obtained by photo-irradiation of halogenated hydrocarbon and its use as a source of halogen or carbonyl halide. Japanese Patent. JP2013181028 A. 2013.

Kuwahara Y, Zhang AL, Soma H, Tsuda A. Photochemical molecular storage of Cl2, HCl, and COCl2: synthesis of organochlorine compounds, salts, ureas, and polycarbonate with photodecomposed chloroform. Org Lett. 2012;14:3376–9.

Kawakami K, Tsuda A. Brominated methanes as photo-responsive molecular storage of elemental Br2. Chem Asian J. 2012;7:2240–52.

Zhang A, Kuwahara Y, Hotta Y, Tsuda A. Organic syntheses with photochemically generated chemicals from tetrachloroethylene. Asian J Org Chem. 2013;2:572–8.

Tsuda A Preparation of halogenated carboxylate esters by irradiating light to halocarbons and alcohols in the presence of oxygen. WIPO Patent. WO2015/156245 A1. 2015.

Liang F, Yanai M, Suzuki Y, Tsuda A. Photo-on-demand synthesis of chloroformates with a chloroform solution containing an alcohol and its one-pot conversion to carbonates and carbamates. Org Lett. 2020;22:3566–9.

Liang F, Eda K, Okazoe T, Wada A, Mori N, Konishi K, et al. Photo-on-demand synthesis of Vilsmeier reagents with chloroform and their applications to one-pot organic syntheses. J Org Chem. 2021;86:6504–17.

Hashimoto Y, Hosokawa S, Liang F, Suzuki Y, Dai N, Tana G, et al. Photo-on-demand base-catalyzed phosgenation reactions with chloroform: synthesis of arylcarbonate and halocarbonate esters. J Org Chem. 2021;86:9811–9.

Hatsumura S, Hashimoto Y, Hosokawa S, Nagao A, Eda K, Harada H, et al. Reactivity and product selectivity of fluoroalkyl carbonates in substitution reactions with primary alcohols and amines. J Org Chem. 2022;87:11572–82.

Muranaka R, Liu Y, Okada I, Okazoe T, Tsuda A. Photo-on-demand phosgenation reactions with chloroform for selective syntheses of N-substituted ureas and isocyanates. ACS Omega. 2022;7:5584–94.

Suzuki Y, Liang F, Okazoe T, Okamoto H, Takeuchi Y, Tsuda A. Photo-on-demand phosgenation reactions with chloroform triggered by Cl2 upon irradiation with visible light: syntheses of chloroformates, carbonate esters, and isocyanates. Chem Lett. 2022;51:549–51.

Sugimoto T, Kuwahara T, Liang F, Wang H, Tsuda A. Photo-on-demand synthesis of α-amino acid N-carboxyanhydrides with chloroform. ACS Omega. 2022;7:39250–7.

Akamatsu T, Shele M, Matsune A, Kashiki Y, Liang F, Okazoe T, et al. Photo-on-demand in situ synthesis of N-substituted trichloroacetamides with tetrachloroethylene and their conversions to ureas, carbamates, and polyurethanes. ACS Omega. 2023;8:2669–84.

Liu Y, Okada I, Tsuda A. Flow photo-on-demand phosgenation reactions with chloroform. Org Process Res Dev. 2022;26:3336–44.

Chapman AT. The peroxidation of chloroform. J Am Chem Soc. 1935;57:419–22.

Baskerville C, Hamor WA. The chemistry of anaesthetics, IV: Chloroform. J Ind Eng Chem. 1912;4:571–8.

Russell BR, Edwards LO, Raymonda JW. Vacuum ultraviolet absorption spectra of the chloromethanes. J Am Chem Soc. 1973;95:2129–33.

Saunders JH, Slocombe RJ, Hardy EE. The vapor phase reaction between phosgene and alcohols. J Am Chem Soc. 1951;73:3796–7.

Helgen C, Bochet CG. Photochemical protection of amines with Cbz and Fmoc groups. J Org Chem. 2003;68:2483–6.

Ohkuma S, Sakai I. Detection of aromatic primary amines by a photochemical reaction with pyridine. Bunseki Kagaku (Japanese). 1975;24:385–7.

Prather KA, Lee YT. The photodissociation of pyridine at 193 nm. Isr J Chem. 1994;34:43–53.

Kamps JH, Hoeks T, Kung K, Lens JP, McCloskey PJ, Noordove BAJ, et al. Activated carbonates: enabling the synthesis of differentiated polycarbonate resins via melt transcarbonation. Polym Chem. 2016;7:5294–303.

Bhattacharyya D, Hamrin CE, Northey RP. Oxidation of hazardous organics in a two-phase fluorocarbon-water system. Haz Waste Haz. Mater. 1986;3:405–29.

Slater B, McCormack A, Avdeef A, Comer J. PH-metric logP.4. comparison of partition coefficients determined by HPLC and potentiometric methods to literature values. J Pharm Sci. 1994;83:1280–3.

Schaller KH, Valentin H. The MAK‐collection for occupational health and safety; Wiley-VCH Weinheim. 2012:217–35.

Kütt A, Leito I, Kaljurand I, Sooväli L, Vlasov VM, Yagupolskii LM, et al. A comprehensive self-consistent spectrophotometric acidity scale of neutral brønsted acids in acetonitrile. J Org Chem. 2006;71:2829–38.

Driscoll CT, Mason RP, Chan HM, Jacob DJ, Pirrone N. Mercury as a global pollutant: sources, pathways, and effects. Environ Sci Technol. 2013;47:4967.

Maric D, Burrows JP, Meller R, Moortgat GK. A study of the UV-visible absorption spectrum of molecular chlorine. J Photochem Photobiol A: Chem. 1993;70:205.

Acknowledgements

This research was supported by the Adaptable and Seamless Technology Transfer Program through Target-driven R&D (A-STEP), Seeds development type from Japan Science and Technology Agency (JST). The author is highly grateful to the collaborators on the experiments of photo-on-demand organic syntheses conducted at Kobe University: Prof. Kazuo Eda, Dr. Fengying Liang, Namin Dai, Masaki Yanai, Ryo Muranaka, Yue Liu, Yuka Hashimoto, Yuto Suzuki, Itsuumi Okada, and Yuki Kuwahara.

Funding

Open access funding provided by Kobe University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tsuda, A. In situ photo-on-demand phosgenation reactions with chloroform for syntheses of polycarbonates and polyurethanes. Polym J 55, 903–912 (2023). https://doi.org/10.1038/s41428-023-00800-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00800-w