Abstract

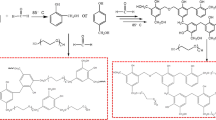

A novel diglycidyl ether (BCNDGE) derived from cashew nut shell liquid (CNSL) was synthesized and used as a building block to formulate an epoxy resin. BCNDGE was synthesized by a two-step epoxidation reaction of a bio-based bisphenol starting from CNSL. Epoxy resins were prepared with BCNDGE and commercial bisphenol A diglycidyl ether (BPADGE) with an acid anhydride hardener. The curing behaviors and chemical structures of the epoxy polymers were confirmed by Fourier transform infrared spectroscopy. All cured epoxys were self-standing films regardless of the BCNDGE content. The gel contents of the epoxy films prepared with BCNDGE and BPADGE were over 90%, indicating that the curing reaction proceeded effectively. The thermal stability of the BCNDGE and BCNDGE/BPADGE films was greater than that of the epoxy prepared with commercial BPADGE, indicating that the long alkyl side chains of BCNDGE inhibited the attack from the reactive species formed during pyrolysis. The glass-transition temperatures of the BCNDGE/BPADGE films decreased with increasing BCNDGE content. These results demonstrate that the inclusion of BCNDGE enhanced the flexible nature of the polymer segments by acting as a plasticizer. Hence, BCNDGE is a promising novel diglycidyl ether candidate with high biomass content to act as an alternative to petroleum-based chemicals for epoxy resins.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Kawai K. New multifunctional epoxy resins. J Netw Polym Jpn. 2012;33:354–60.

Ochi M. Structure and properties of functional epoxy resins. J Adhes Soc Jpn. 2003;39:432–7.

Liu T, Hao C, Zhang S, Yang X, Wang L, Han J, et al. A self-healable high glass transition temperature bioepoxy material based on vitrimer chemistry. Macromolecules. 2018;51:5577–85.

Fache M, Auvergne R, Boutevin B, Caillol S. New vanillin-derived diepoxy monomers for the synthesis of biobased thermosets. Eur Polym J. 2015;67:527–38.

Savonnet E, Grau E, Grelier S, Defoort B, Cramail H. Divanillin-based epoxy precursors as DGEBA Substitutes for Biobased Epoxy Thermosets. ACS Sustain Chem Eng. 2018;6:11008–17.

Shibata M, Ohkita T. Fully biobased epoxy resin systems composed of a vanillin-derived epoxy resin and renewable phenolic hardeners. Eur Polym J. 2017;92:165–73.

Dai J, Peng Y, Teng N, Liu Y, Liu C, Shen X, et al. High-performing and fire-resistant biobased epoxy resin from renewable sources. ACS Sustain Chem Eng. 2018;6:7589–99.

Francois C, Pourchet S, Boni G, Rautiainen S, Samec J, Fournier L, et al. Design and synthesis of biobased epoxy thermosets from biorenewable resources. C R Chim. 2017;20:1006–16.

Miao JT, Yuan L, Guan Q, Liang G, Gu A. Biobased heat resistant epoxy resin with extremely high biomass content from 2,5-furandicarboxylic acid and eugenol. ACS Sustain Chem Eng. 2017;5:7003–11.

Kruijff GHM, Goschler T, Beiser N, Stenglein A, Turk OM, Waldvogel SR. Sustainable access to biobased biphenol epoxy resins by electrochemical dehydrogenative dimerization of eugenol. Green Chem. 2019;21:4815–23.

Tian Y, Wang Q, Shen L, Cui Z, Kou L, Cheng J, et al. A renewable resveratrol-based epoxy resin with high Tg, excellent mechanical properties and low flammability. Chem Eng J. 2020;383:123124

Voirin C, Caillol S, Sadavarte NV, Tawade BV, Boutevin B, Wadgaonkar PP. Functionalization of cardanol: towards biobased polymers and additives. Polym Chem. 2014;5:3142–62.

Gedam PH, Sampathkumaran PS. Cashew nut shell liquid: extraction, chemistry and applications. Prog Org Coat. 1986;14:115–57.

Gandhi T, Patel M, Dholakiya BK. Studies on effect of various solvents on extraction of cashew nut shell liquid (CNSL) and isolation of major phenolic constituents from extracted CNSL. J Nat Prod Plant Resour. 2012;2:135–42.

Campaner P, D’Amico D, Longo L, Stifani C, Tarzia A. Cardanol-based novolac resins as curing agents of epoxy resins. J Appl Polym Sci. 2009;114:3585–91.

Cardona F, Kin-Tak AL, Fedrigo J. Novel phenolic resins with improved mechanical and toughness properties. J Appl Polym Sci. 2012;123:2131–9.

Kumar RP. Cathodic electrodeposition of self-curable polyepoxide resins based on cardanol. J Coat Technol Res. 2011;8:563–75.

Yadav R, Awasthi P, Srivastava D. Studies on synthesis of modified epoxidized novolac resin from renewable resource material for application in surface coating. J Appl Polym Sci. 2009;114:1471–84.

Kanehashi S, Yokoyama K, Masuda R, Kidesaki T, Nagai K, Miyakoshi T. Preparation and characterization of cardanol-based epoxy resin for coating at room temperature curing. J Appl Polym Sci. 2013;130:2468–78.

Gopalakrishnan S, Fernando TL. Influence of polyols on properties of bio-based polyurethanes. Bull Mater Sci. 2012;35:243–51.

Mythili CV, Retna AM, Gopalakrishnan S. Physical, mechanical, and thermal properties of polyurethanes based on hydroxyalkylated cardanol–formaldehyde resins. J Appl Polym Sci. 2005;98:284–8.

Sultania M, Rai JSP, Srivastava D. Modeling and simulation of curing kinetics for the cardanol-based vinyl ester resin by means of non-isothermal DSC measurements. Mater Chem Phys. 2012;132:180–6.

Sultania M, Rai JSP, Srivastava D. Studies on the synthesis and curing of epoxidized novolac vinyl ester resin from renewable resource material. Eur Polym J. 2010;46:2019–32.

Lochab B, Varma IK, Bijwe J. Cardanol-based bisbenzoxazines. J Therm Anal Calorim. 2012;107:661–8.

Rao BS, Palanisamy A. A new thermo set system based on cardanol benzoxazine and hydroxy benzoxazoline with lower cure temperature. Prog Org Coat. 2012;74:427–34.

Lubi MC, Thachil ET. Cashew nut shell liquid (CNSL) — a versatile monomer for polymer synthesis. Des Monomers Polym. 2000;3:123–53.

Amorati R, Pedulli GF, Valgimigli L, Attanasi OA, Filippone P, Fiorucci C, et al. Absolute rate constants for the reaction of peroxyl radicals with cardanol derivatives. J Chem Soc Perkin Trans 2. 2001;11:2142–6.

Yokoyama Y, Yasui T, Takeda A, Kanehashi S, Ogino K. Synthesis of bisphenol compounds from non-edible cashew nut shell liquid. Tetrahedron Lett. 2023;118:154384.

Tsuda S, Oyama T, Takahashi A, Okabe Y, Kagawa H, Yamada S, et al. Application of biomass-derived lignophenol to epoxy resins. Kobunshi Ronbunshu. 2010;67:497–505.

Ogura I. Design technologies of high performance epoxy resins. J Netw Polym Jpn. 2010;31:113–24.

Yanga X, Guoa Y, Luob X, Zhenga N, Maa T, Tana J, et al. Self-healing, recoverable epoxy elastomers and their composites with desirable thermal conductivities by incorporating BN fillers via in-situ polymerization. Compos Sci Technol. 2018;164:59–64.

Arita K. Fundamental study on development of high heat resistant epoxy resins. J Netw Polym Jpn. 2015;36:255–64.

Uchiya Y, Kobayash T. Composition analysis of cured epoxy resin by pyrolysis GC-MS. J Netw Polym Jpn. 2006;27:35–42.

ARITA K. Molecular design for advanced high heat resistance epoxy resins. J Jpn Inst Electron Packag. 2013;16:352–8.

Acknowledgements

We thank members of the Smart-Core-Facility Promotion Organization of Tokyo University of Agriculture and Technology, Japan for technical assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yokoyama, Y., Yasui, T., Takeda, A. et al. Novel bio-based flexible bisphenol epoxy resin derived from cashew nut shell liquid. Polym J 55, 859–867 (2023). https://doi.org/10.1038/s41428-023-00782-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00782-9