Abstract

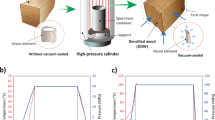

Microstructure-free, strong, binderless, all-wooden nanocomposites (AWNCs) with unidirectional nanofibrils were directly fabricated from lightweight paulownia raw wood (RW) through simultaneous chemomechanical densification and downsizing processes with three main steps: (1) partial delignification, (2) partial dissolution with ionic liquid (IL) or oxidation with the free radical 2,2,6,6-tetramethylpiperidine 1-oxyl (TEMPO) and ammonium persulfate (APS) and (3) hot pressing with cyclic pressurizing-depressurizing conditions. The density of RW was 0.310 g/cm3, while the density of the AWNCs drastically increased to 1.24 g/cm3. Field emission scanning electron microscopy (FE-SEM) demonstrated that the microstructure of RW fibers was directly dismantled into wood nanofibrils during AWNC production. Two-dimensional wide angle X-ray diffraction (2D-WAXS) patterns confirmed the unidirectional structure of the AWNCs. Fourier transform infrared spectroscopy (FTIR) successfully confirmed the effect of all chemical treatments on the specimens. Thermogravimetric analysis (TGA) demonstrated that AWNC-TEMPO and AWNC-APS had the lowest thermal stability. AWNC-TEMPO had the highest flexural (246 ± 15 MPa) and tensile (265 ± 17 MPa) strengths, while RW showed the minimum corresponding values of 38 ± 7 MPa and 18 ± 2.5 MPa, respectively.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Sadatnezhad, SH, Khazaeian, A, Sandberg, D & Tabarsa, T Continuous surface densification of wood: A new concept for large-scale industrial processing. BioResources (2017). https://doi.org/10.15376/biores.12.2.3122-3132

Burnard MD, Kutnar A. Wood, and human stress in the built indoor environment: a review. Wood Sci Technol. 2015;49:969–86.

Qi Y, Jang JH, Hidayat W, Lee AH, Lee SH, Chae HM, et al. Carbonization of reaction wood from Paulownia tomentosa and Pinus densiflora branch woods. Wood Sci Technol. 2016;50:973–87.

Song, J, Chen, C, Zhu, S, Zhu, M, Dai, J, Ray, U, et al. Processing bulk natural wood into a high-performance structural material. Nature (2018). https://doi.org/10.1038/nature25476

Laine K, Segerholm K, Wålinder M, Rautkari L, Hughes M. Wood densification and thermal modification: hardness, set-recovery and micromorphology. Wood Sci Technol. 2016;50:883–94.

Wang Y, Wu Y, Yang F, Yang L, Wang J, Zhou J, et al. A highly transparent compressed wood prepared by cell wall densification. Wood Sci Technol. 2022;56:669–86.

Li, K, Wang, S, Chen, H, Yang, X, Berglund, LA & Zhou, Q. Self-densification of highly mesoporous wood structure into a strong and transparent film. Adv Mater (2020). https://doi.org/10.1002/adma.202003653

Kutnar A, Kamke FA. Influence of temperature and steam environment on set recovery of compressive deformation of wood. Wood Sci Technol 2011 465. 2011;46:953–64.

Soykeabkaew, N, Arimoto, N, Nishino, T & Peijs, T All-cellulose composites by surface selective dissolution of aligned ligno-cellulosic fibres. Compos Sci Technol (2008). https://doi.org/10.1016/j.compscitech.2008.03.023

Nishino T, Matsuda I, Hirao K. All-cellulose composite. Macromolecules. 2004;37:7683–7.

Arévalo R, Peijs T. Binderless all-cellulose fibreboard from microfibrillated lignocellulosic natural fibres. Compos Part A Appl Sci Manuf 2016;83:38–46.

Duchemin BJC, Mathew AP, Oksman K. All-cellulose composites by partial dissolution in the ionic liquid 1-butyl-3-methylimidazolium chloride. Compos Part A Appl Sci Manuf 2009;40:2031–7.

Orelma H, Tanaka A, Vuoriluoto M, Khakalo A, Korpela A. Manufacture of all-wood sawdust-based particle board using ionic liquid-facilitated fusion process. Wood Sci Technol 2021;55:331–49.

Yousefi, H, Faezipour, M, Nishino, T, Shakeri, A & Ebrahimi, G All-cellulose composite and nanocomposite made from partially dissolved micro-and nanofibers of canola straw. Polym J (2011). https://doi.org/10.1038/pj.2011.31

Gindl W, Keckes J. All-cellulose nanocomposite. Polymer. 2005;46:10221–5.

Yousefi H, Nishino T, Faezipour M, Ebrahimi G, Shakeri A, Morimune S. All-cellulose nanocomposite made from nanofibrillated cellulose. Adv Compos Lett 2010;19:190–5.

Mohammadi Amirabad, L, Jonoobi, M, Mousavi, NS, Oksman, K, Kaboorani, A & Yousefi, H. Improved antifungal activity and stability of chitosan nanofibers using cellulose nanocrystal on banknote papers. Carbohydr Polym (2018). https://doi.org/10.1016/j.carbpol.2018.02.041

Yousefi, H, Nishino, T, Faezipour, M, Ebrahimi, G & Shakeri, A. Direct fabrication of all-cellulose nanocomposite from cellulose microfibers using ionic liquid-based nanowelding. Biomacromolecules (2011). https://doi.org/10.1021/bm201147a

Rindler A, Vay O, Hansmann C, Müller U. Dimensional stability of multi-layered wood-based panels: a review. Wood Sci Technol. 2017;51:969–96.

Segal L, Creely JJ, Martin AE, Conrad CM. An empirical method for estimating the degree of crystallinity of native cellulose using the X-Ray Diffractometer. Text Res J 1959;29:786–94.

Kaffashsaie, E, Yousefi, H, Nishino, T, Matsumoto, T, Mashkour, M, Madhoushi, M, et al. Direct conversion of raw wood to TEMPO-oxidized cellulose nanofibers. Carbohydr Polym (2021). https://doi.org/10.1016/j.carbpol.2021.117938

Yan, Y, Dong, Y, Chen, H, Zhang, S & Li, J. Effect of catalysts and sodium hydroxide on glyoxal-treated wood. BioResources (2014). https://doi.org/10.15376/biores.9.3.4540-4551

Nishino T, Arimoto N. All-cellulose composite prepared by selective dissolving of fiber surface. Biomacromolecules. 2007;8:2712–6.

Mashkour M, Tajvidi M, Kimura F, Yousefi H, Kimura T. Strong highly anisotropic magnetocellulose nanocomposite films made by chemical peeling and in situ welding at the interface using an ionic liquid. ACS Appl Mater Interfaces. 2014;6:8165–72.

Khakalo A, Tanaka A, Korpela A, Hauru LKJ, Orelma H. All-Wood Composite Material by Partial Fiber Surface Dissolution with an Ionic Liquid. ACS Sustain Chem Eng 2019;7:3195–202.

Moosavinejad, SM, Madhoushi, M, Vakili, M & Rasouli, D. Evaluation of degradation in chemical compounds of wood in historical buildings using Ft-Ir And Ft-Raman vibrational spectroscopy. Maderas Cienc y Tecnol (2019). https://doi.org/10.4067/S0718-221X2019005000310

Shibata, M, Teramoto, N, Nakamura, T & Saitoh, Y. All-cellulose and all-wood composites by partial dissolution of cotton fabric and wood in ionic liquid. Carbohydr Polym (2013). https://doi.org/10.1016/j.carbpol.2013.07.062

Lin, N, Bruzzese, C & Dufresne, A. TEMPO-oxidized nanocellulose participating as crosslinking aid for alginate-based sponges. ACS Appl Mater Interfaces (2012). https://doi.org/10.1021/am301325r

Isogai A. TEMPO-catalyzed oxidation of polysaccharides. Polym J. 2021;54:387–402.

Pucetaite, M. Archaeological wood from the Swedish warship Vasa studied by infrared microscopy. (Lund university Press, Sweden, pp 16, 2012).

Mascheroni, E, Rampazzo, R, Ortenzi, MA, Piva, G, Bonetti, S & Piergiovanni, L. Comparison of cellulose nanocrystals obtained by sulfuric acid hydrolysis and ammonium persulfate, to be used as coating on flexible food-packaging materials. Cellulose (2016). https://doi.org/10.1007/s10570-015-0853-2

Isogai A, Saito T, Fukuzumi H. TEMPO-oxidized cellulose nanofibers. Nanoscale. 2011;3:71–85.

Filipova, I, Serra, F, Tarrés, Q, Mutjé, P & Delgado-Aguilar, M. Oxidative treatments for cellulose nanofibers production: a comparative study between TEMPO-mediated and ammonium persulfate oxidation. Cellulose (2020). https://doi.org/10.1007/s10570-020-03089-7

Sehaqui H, Allais M, Zhou Q, Berglund LA. Wood cellulose biocomposites with fibrous structures at micro- and nanoscale. Compos Sci Technol 2011;71:382–7.

Yousefi H, Faezipour M, Hedjazi S, Mousavi MM, Azusa Y, Heidari AH. Comparative study of paper and nanopaper properties prepared from bacterial cellulose nanofibers and fibers/ground cellulose nanofibers of canola straw. Ind Crops Prod. 2013;43,:732–7.

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T. Cellulose nanopaper structures of high toughness. Biomacromolecules. 2008;9:1579–85.

Berglund LA, Peijs T. Cellulose biocomposites—from bulk moldings to nanostructured systems. MRS Bull 2010;35:201–7.

Yousefi H, Azad S, Mashkour M, Khazaeian A. Cellulose nanofiber board. Carbohydr Polym 2018;187:133–9.

Robert J. Chapter 12—Mechanical properties of wood-based composite materials. Wood Handb Wood Eng Mater, 2010. p. 556–8.

Yousefi H, Faezipour M, Nishino T, Shakeri A, Ebrahimi G. All-cellulose composite and nanocomposite made from partially dissolved micro-and nanofibers of canola straw. Polym J 2011;43:559–64.

Ghaderi M, Mousavi M, Yousefi H, Labbafi M. All-cellulose nanocomposite film made from bagasse cellulose nanofibers for food packaging application. Carbohydr Polym 2014;104:59–65.

Yousefi H, Mashkour M, Yousefi R. Direct solvent nanowelding of cellulose fibers to make all-cellulose nanocomposite. Cellulose. 2015;22:1189–1200.

Acknowledgements

EK would like to acknowledge the financial support of the Iranian Ministry of Sciences, Research, and Technology. The authors are also grateful for Nano Novin Polymer Co. (Iran) for its kind cooperation within the primary experiments of this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaffashsaei, E., Yousefi, H., Nishino, T. et al. Simultaneous/direct chemomechanical densification and downsizing of weak paulownia wood to produce a strong, unidirectional, all-wooden nanocomposite. Polym J 55, 691–702 (2023). https://doi.org/10.1038/s41428-023-00766-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00766-9