Abstract

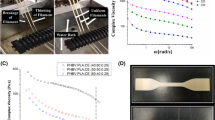

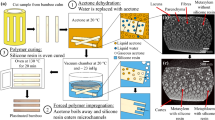

Additive manufacturing enables the creation of lighter, stronger parts and systems. To improve the 3-dimensional (3D) printed quality of bio-based composites, in this study, bamboo fibers were chemically modified via a two-step reaction. In the first step, NCO groups (of a diisocyanate) were grafted onto the surface of fibers, which were subsequently reacted with a polyol. The chemical modification was confirmed by spectroscopic analysis; the hydrophobicity, density, and thermal degradation of the fibers were also evaluated. Afterward, 3D-printed objects were produced using these fibers. First, the printability of these composites was assessed by analyzing their melting flow index (MFI) and glass transition temperature (Tg) values. Next, the enhancement of the 3D printing quality was confirmed by analyzing the morphology of the 3D-printed specimens. The advantage of using treated fibers was reflected in the improved mechanical performance of the obtained 3D specimens.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Jyothish Kumar L, Pandey PM, Wimpenny DI. 3D printing and additive manufacturing technologies. 3D Print. Addit Manuf Technol. (2018).

Bhuvanesh Kumar M, Sathiya P. Methods and materials for additive manufacturing: a critical review on advancements and challenges. Thin-Walled Struct. 2020;159:107228.

Daminabo SC, Goel S, Grammatikos SA, Nezhad HY, Thakur VK. Fused deposition modeling-based additive manufacturing (3D printing): techniques for polymer material systems. Mater Today Chem 2020;16:100248.

Singh S, Singh G, Prakash C, Ramakrishna S, Lamberti L, Pruncu CI. 3D printed biodegradable composites: an insight into mechanical properties of PLA/chitosan scaffold. Polym Test 2020;89:106722.

Khosravani MR, Zolfagharian A, Jennings M, Reinicke T. Structural performance of 3D-printed composites under various loads and environmental conditions. Polym Test 2020;91:106770.

Nadagouda MN, Ginn M, Rastogi V. A review of 3D printing techniques for environmental applications. Curr Opin Chem Eng 2020;28:173–8.

Karakurt I, Lin L. 3D printing technologies: techniques, materials, and post-processing. Curr Opin Chem Eng 2020;28:134–43.

Kalsoom U, Nesterenko PN, Paull B. Recent developments in 3D printable composite materials. RSC Adv. 2016;6:60355–71.

Balla VK, Kate KH, Satyavolu J, Singh P, Tadimeti JGD. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos Part B Eng. 2019;174:106956.

Mazzanti V, Malagutti L, Mollica F. FDM 3D printing of polymers containing natural fillers: a review of their mechanical properties. Polym (Basel). 2019;11:1094.

Hodzic A, Shanks R. Natural Fibre Composites: materials, processes and properties. Woodhead Publishing Limited, Oxford; 2013.

Goh GD, Yap YL, Agarwala S, Yeong WY. Recent progress in additive manufacturing of fiber reinforced polymer composite. Adv Mater Technol. 2019;4:1800271.

Stokke DD, Wu Q, Han G. Introduction to wood and natural fiber composites. John Wiley & Sons, Ltd, Sussex; 2014.

Bahari SA, Krause A. Utilizing Malaysian bamboo for use in thermoplastic composites. J Clean Prod 2016;110:16–24.

Rocky BP, Thompson AJ. Production of natural bamboo fibers: experimental approaches to different processes and analyses. J Text Inst 2018;109:1381–91.

Trujillo E, Moesen M, Osorio L, Van Vuure AW, Ivens J, Verpoest I. Bamboo fibres for reinforcement in composite materials: strength Weibull analysis. Compos Part A Appl Sci Manuf. 2014;61:115–25.

Kaur N, Saxena S, Gaur H, Goyal P. A review on bamboo fiber composites and its applications. 2017 Int Conf Infocom Technol Unmanned Syst Trends Futur Dir ICTUS 2017. 2018;2018:843–9.

Liu D, Song J, Anderson DP, Chang PR, Hua Y. Bamboo fiber and its reinforced composites: structure and properties. Cellulose. 2012;19:1449–80.

Gama N, Barros‐Timmons A, Ferreira A, Evtuguin D. Surface treatment of eucalyptus wood for improved HDPE composites properties. J Appl Polym Sci 2019;137:48619.

Lu T, Jiang M, Jiang Z, Hui D, Wang Z, Zhou Z. Effect of surface modification of bamboo cellulose fibers on mechanical properties of cellulose/epoxy composites. Compos Part B Eng. 2013;51:28–34.

Han Z, Fina A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: a review. Prog Polym Sci 2011;36:914–44.

Lee S-Y, Chun S-J, Doh G-H, Kang I-A, Lee S, Paik K-H. Influence of chemical modification and filler loading on fundamental properties of bamboo fibers reinforced polypropylene composites. J Compos Mater 2009;43:1639–57.

Wang D, Bai T, Cheng W, Xu C, Wang G, Cheng H, et al. Surface modification of bamboo fibers to enhance the interfacial adhesion of epoxy resin-based composites prepared by resin transfer molding. Polymers (Basel) 2019;11:1–16.

Lacerda PSS, Gama N, Freire CSR, Silvestre AJD, Barros-Timmons A. Grafting poly(Methyl Methacrylate) (PMMA) from cork via atom transfer radical polymerization (ATRP) towards Higher Quality of Three-Dimensional (3D) Printed PMMA/Cork-g-PMMA materials. Polym (Basel). 2020;12:1867.

Mandegari M, Fashandi H. Untapped potentials of acrylonitrile-butadiene-styrene/polyurethane (ABS/PU) blend membrane to purify dye wastewater. J Environ Manag 2017;197:464–75.

de León AS, Domínguez-Calvo A, Molina SI. Materials with enhanced adhesive properties based on acrylonitrile-butadiene-styrene (ABS)/thermoplastic polyurethane (TPU) blends for fused filament fabrication (FFF). Mater Des 2019;182:108044.

Gama N, Godinho B, Barros-Timmons A, Ferreira A. PU/Lignocellulosic Composites Produced from Recycled Raw Materials. J Polym Environ. 1–12, https://doi.org/10.1007/s10924-021-02191-6 (2021).

Nuno Gama BG, Ana Barros-Timmons AF. PU composites based on different types of textile fibers. J Compos Mater https://doi.org/10.1177/00219983211031656 (2021).

Li H, Liang Y, Li P, He C. Conversion of biomass lignin to high-value polyurethane: a review. J Bioresour Bioprod. 2020;5:163–79.

Abushammala H, Mao J. A review of the surface modification of cellulose and nanocellulose using aliphatic and aromatic mono- and di-isocyanates. Molecules. 2019;24:2782.

Siqueira G, Bras J, Dufresne A. New process of chemical grafting of cellulose nanoparticles with a long chain isocyanate. Langmuir. 2010;26:402–11.

He J, Tang Y, Wang S-Y. Differences in morphological characteristics of bamboo fibres and other natural cellulose fibres: studies on Xray diffraction, solid state 13 C-CP/MAS NMR, and second derivative FTIR spectroscopy data. Polym. J. 2007;16:807–18.

Ramesh M, RajeshKumar L, Bhuvaneshwari V. Bamboo fiber compos. Singapore: Springer; 2021. p. 1–13.

Gama N, Ferreira A, Barros-Timmons A. Polyurethane foams: past, present, and future. Mater (Basel). 2018;11:1–35.

Rimdusit S, Damrongsakkul S, Wongmanit P, Saramas D, Tiptipakorn S. Characterization of coconut fiber-filled polyvinyl chloride/acrylonitrile styrene acrylate blends. J Reinf Plast Compos 2011;30:1691–702.

Bourmaud A, Beaugrand J, Shah DU, Placet V, Baley C. Towards the design of high-performance plant fibre composites. Prog Mater Sci 2018;97:347–408.

Zakikhani P, Zahari R, Sultan MTH, Majid DL. Extraction and preparation of bamboo fibre-reinforced composites. Mater Des 2014;63:820–8.

Gama N, Ferreira A, Barros-Timmons A. 3D Printed Thermoplastic Polyurethane Filled with Polyurethane Foams Residues. J Polym Environ 2020;28:1560–70.

Gama N, Ferreira A, Barros-Timmons A. 3D printed cork/polyurethane composite foams. Mater Des 2019;179:107905.

Amaral C, Gama NV, Mohseni F, Amaral JS, Amaral VS, Marques PAAP, et al. Development of structural layers PVC incorporating phase change materials for thermal energy storage. Appl Therm Eng 2020;179:115707.

Gama N, Santos R, Godinho B, Silva R, Ferreira A. Triacetin as a secondary PVC plasticizer. J Polym Environ 2019;27:1294–101.

Gama NV, Santos R, Godinho B, Silva R, Ferreira A. Methyl acetyl ricinoleate as polyvinyl chloride plasticizer. J Polym Environ 2019;27:703–9.

Wang S, Capoen L, D’hooge DR, Cardon L. Can the melt flow index be used to predict the success of fused deposition modelling of commercial poly(lactic acid) filaments into 3D printed materials? Plast Rubber Compos 2018;47:9–16.

Zierdt P, Theumer T, Kulkarni G, Däumlich V, Klehm J, Hirsch U, et al. Sustainable wood-plastic composites from bio-based polyamide 11 and chemically modified beech fibers. Sustain Mater Technol 2015;6:6–14.

Shahinur S, Hasan M, Ahsan Q, Haider J. Effect of chemical treatment on thermal properties of jute fiber used in polymer composites. J Compos Sci 2020;4:132.

Salih AA, Zulkifli R, Azhari CH. Tensile properties and microstructure of single-cellulosic bamboo fiber strips after Alkali treatment. Fibers. 2020;8:26.

Kushwaha PK, Kumar R. Influence of chemical treatments on the mechanical and water absorption properties of bamboo fiber composites. J Reinf Plast Compos 2011;30:73–85.

Magalhães da Silva SP, Antunes T, Costa MEV, Oliveira JM. Cork-like filaments for Additive Manufacturing. Addit Manuf. 2020;34:101229.

Acknowledgements

This work was developed within the scope of the project CICECO-Aveiro Institute of Materials, UIDB/50011/2020 and UIDP/50011/2020, financed by national funds through the Portuguese Foundation for Science and Technology/MCTES. Sandra Magina acknowledges FCT for the PhD grant SFRH/BD/121275/2016. The authors acknowledge Martinho Oliveria for the MF measurements.

Author information

Authors and Affiliations

Contributions

All authors contributed equally to this work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gama, N., Magina, S., Ferreira, A. et al. Chemically modified bamboo fiber/ABS composites for high-quality additive manufacturing. Polym J 53, 1459–1467 (2021). https://doi.org/10.1038/s41428-021-00540-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-021-00540-9