Abstract

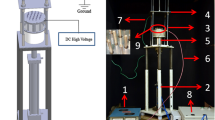

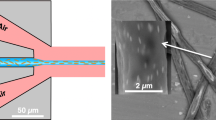

This study focuses on using the multilayer melt electrospinning of polymers in combination with a delamination step to obtain nonwoven webs of ribbon-shaped flat fibers that are ~150 to 200 nm thick. A novel coextrusion system with layer multipliers is used to melt electrospin bicomponent cylindrical microfibers with diameters in the range of ~15–25 μm that have up to 257 alternating layers within each fiber prior to delamination. The diameter of the cylindrical fibers is dependent on the temperature, the flow rate of the polymers, and the die tip-to-collector distance. The fabricated bicomponent layered microfibers are subsequently delaminated using sonication or solvent rinsing to obtain flat nanoribbons whose thicknesses vary from 150 to 200 nm. After delamination, some of the flat nanoribbons are found to roll into cylindrical fibers with diameters ranging from 150 to 250 nm. This bicomponent approach uses a continuous melt extrusion process that can support higher throughputs compared to traditional solution electrospinning and can lead to the fabrication of high surface area nonwoven webs after proper delamination treatments.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Agarwal S, Wendorff JH, Greiner A. Progress in the field of electrospinning for tissue engineering applications. Adv Mater. 2009;21:3343–51.

Kriegel C, Arrechi A, Kit K, McClements DJ, Weiss J. Fabrication, functionalization, and application of electrospun biopolymer nanofibers. Crit Rev Food Sci Nutr. 2008;48:775–97.

Li D, Xia Y. Electrospinning of nanofibers: reinventing the wheel? Adv Mater. 2004;16:1151–70.

Ma Z, Masaya K, Ramakrishna S. Immobilization of Cibacron blue F3GA on electrospun polysulphone ultra-fine fiber surfaces towards developing an affinity membrane for albumin adsorption. J Membr Sci. 2006;282:237–44.

Meng X, Luo N, Cao S, Zhang S, Yang M, Hu X. In-situ growth of titania nanoparticles in electrospun polymer nanofibers at low temperature. Mater Lett. 2009;63:1401–3.

Reneker DH, Yarin AL. Electrospinning jets and polymer nanofibers. Polymer. 2008;49:2387–425.

Tan S, Huang X, Wu B. Some fascinating phenomena in electrospinning processes and applications of electrospun nanofibers. Polym Int. 2007;56:1330–9.

Zhou H, Green TB, Joo YL. The thermal effects on electrospinning of polylactic acid melts. Polymer. 2006;47:7497–505.

Dalton PD, Calvet JL, Mourran A, Klee D, Möller M. Melt electrospinning of poly-(ethylene glycol-block-ϵ-caprolactone). Biotechnol J. 2006;1:998–1006.

Deng R, Liu Y, Ding Y, Xie P, Luo L, Yang W. Melt electrospinning of low-density polyethylene having a low-melt flow index. J Appl Polym Sci. 2009;114:166–75.

Kadomae Y, Maruyama Y, Sugimoto M, Taniguchi T, Koyama K. Relation between tacticity and fiber diameter in melt-electrospinning of polypropylene. Fibers Polym. 2009;10:275–9.

Detta N, Brown TD, Edin FK, Albrecht K, Chiellini F, Chiellini E, et al. Melt electrospinning of polycaprolactone and its blends with poly(ethylene glycol). Polym Int. 2010;59:1558–62.

Dalton PD, Grafahrend D, Klinkhammer K, Klee D, Möller M. Electrospinning of polymer melts: Phenomenological observations. Polymer. 2007;48:6823–33.

Hutmacher DW, Dalton PD. Melt electrospinning. Chem – Asian J. 2011;6:44–56.

Pham QP, Sharma U, Mikos AG. Electrospun poly(ε-caprolactone) microfiber and multilayer nanofiber/microfiber scaffolds: characterization of scaffolds and measurement of cellular infiltration. Biomacromolecules. 2006;7:2796–805.

Zdebiak P, El Fray M.Preparation of fibers from terpoly(ester-ether-ester)s by melt spinning or electrospinning from the solution. Polimery. 2008;53:581–6.

Ogata N, Yamaguchi S, Shimada N, Lu G, Iwata T, Nakane K, et al. Poly(lactide) nanofibers produced by a melt-electrospinning system with a laser melting device. J Appl Polym Sci. 2007;104:1640–5.

Subramanian, C, Ugbolue, SC, Warner, SB & Patra, PK The Melt Electrospinning of Polycaprolactone (PCL) Ultrafine Fibers. MRS Online Proceedings Library Archive 1134, (2008).

Zhou F-L, Gong R-H. Manufacturing technologies of polymeric nanofibres and nanofibre yarns. Polym Int. 2008;57:837–45.

Lyons J, Li C, Ko F. Melt-electrospinning part I: processing parameters and geometric properties. Polymer. 2004;45:7597–603.

Lee S, Obendorf SK. Developing protective textile materials as barriers to liquid penetration using melt-electrospinning. J Appl Polym Sci. 2006;102:3430–7.

Dalton PD, Klinkhammer K, Salber J, Klee D, Möller M. Direct in vitro electrospinning with polymer melts. Biomacromolecules. 2006;7:686–90.

Zakaria M, Shibahara K, Nakane K. Melt-electrospun polyethylene nanofiber obtained from polyethylene/polyvinyl butyral blend film. Polymers. 2020;12:457.

Zihang W, Xianan W, Haoyi L, Xiaohui W, Chao X, Mingjun C, et al. Linear two-component melt differential electrospinning crescent-like polypropylene fibers and their morphology control. J Beijing Univ Chem Technol (Nat Sci). 2020;47:61–6.

Li Z, Olah A, Baer E. Micro- and nano-layered processing of new polymeric systems. Prog Polym Sci. 2020;102:101210.

Ponting M, Hiltner A, Baer E. Polymer nanostructures by forced assembly: process, structure, and properties. Macromol Symposia. 2010;294:19–32.

Mueller CD, Nazarenko S, Ebeling T, Schuman TL, Hiltner A, Baer E. Novel structures by microlayer coextrusion—talc-filled PP, PC/SAN, and HDPE/LLDPE. Polym Eng Sci. 1997;37:355–62.

Weber MF, Stover CA, Gilbert LR, Nevitt TJ, Ouderkirk AJ. Giant birefringent optics in multilayer polymer mirrors. Science. 2000;287:2451–6.

Baer, E & Moet, A High performance polymers-Structure, properties, composites, fibers. (Hanser Publishers/Oxford University Press, 1991).

Hopmann, C & Michaeli, W Extrusion Dies for Plastics and Rubber: Design and Engineering Computations. (Carl Hanser Verlag GmbH & Co. KG, 2016). https://doi.org/10.3139/9783446401815.

Kong CS, Jo KJ, Jo NK, Kim HS. Effects of the spin line temperature profile and melt index of poly(propylene) on melt-electrospinning. Polym Eng Sci. 2009;49:391–6.

Gupta P, Elkins C, Long TE, Wilkes GL. Electrospinning of linear homopolymers of poly(methyl methacrylate): exploring relationships between fiber formation, viscosity, molecular weight and concentration in a good solvent. Polymer. 2005;46:4799–810.

McKee MG, Elkins CL, Long TE. Influence of self-complementary hydrogen bonding on solution rheology/electrospinning relationships. Polymer. 2004;45:8705–15.

Shenoy SL, Bates WD, Wnek G. Correlations between electrospinnability and physical gelation. Polymer. 2005;46:8990–9004.

Skoglund P, Fransson Å. Continuous cooling and isothermal crystallization of polycaprolactone. J Appl Polym Sci. 1996;61:2455–65.

Zhuravlev E, Schmelzer JWP, Wunderlich B, Schick C. Kinetics of nucleation and crystallization in poly(ɛ-caprolactone) (PCL). Polymer. 2011;52:1983–97.

Zargarian SSH, Hadadiasl V. A nanofibrous composite scaffold of PCL/hydroxyapatite-chitosan/PVA prepared by electrospinning. Iran Polym J. 2010;19:457–68.

Acknowledgements

This work was supported by funding from the Institute for Critical Technology and Applied Science (ICTAS) at Virginia Tech. We are grateful for the support of Dr. R. Mahajan (ICTAS), 3 M Company, St. Paul, MN, and Westlake Chemical Corporation, TX for providing us with materials, Michael Vaught of the Department of Chemical Engineering, Virginia Tech for assistance in the machine shop. AD would like to acknowledge funding from the Adhesives and Sealants graduate research assistantship from the Macromolecules Innovation Institute (MII) at Virginia Tech. EGJ would like to acknowledge support from 3 M Company, St. Paul, MN. We would also like to acknowledge the valuable comments provided by the late Dr. G.L. Wilkes of the Department of Chemical Engineering at Virginia Tech.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Joseph, E.G., Budhavaram, N., DePolo, W. et al. Nanoribbons fabricated by melt electrospinning. Polym J 53, 493–503 (2021). https://doi.org/10.1038/s41428-020-00446-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-020-00446-y