Abstract

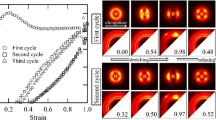

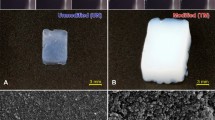

Two different supermolecular structures of β-iPP cast films were used to investigate structural evolution during the simultaneous biaxial stretching process via small-angle X-ray scattering (SAXS), scanning electron microscopy (SEM), and Fourier transform infrared (FTIR) spectroscopy. Based on the mechanical behaviors and porosity variations during the stretching process, it was found that the two samples had different structural evolution modes. During the initial stage of deformation, β-hedrites exhibited violent cavitation behavior in the center region of the hedrites by forming elliptical crazes and expanding, while β-spherulites were more inclined to fragment into blocky crystal structures, which was accompanied by the slippage of these structures. In the later stages of stretching, β-hedrites formed numerous dense regions around the elliptical crazes, which hindered microvoid formation and led to a poor pore size distribution. Conversely, β-spherulites generated abundant microfibrillar structures, and abundant microvoids were formed by directly separating the microfibrils, forming a membrane with a superior pore size distribution.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Arora P, Zhang ZJ. Battery separators. Chem Rev. 2004;104:4419–62.

Lopez J, Mackanic DG, Cui Y, Bao Z. Designing polymers for advanced battery chemistries. Nat Rev Mater. 2019;4:312–30.

Kalnaus S, Wang Y, Li J, Kumar A, Turner JA. Temperature and strain rate dependent behavior of polymer separator for Li-ion batteries. Extrem Mech Lett. 2018;20:73–80.

Deimede V, Elmasides C. Separators for Lithium-Ion Batteries: a Review on the Production Processes and Recent Developments. Energy Technol. 2015;3:453–68.

Huang X. Separator technologies for lithium-ion batteries. J Solid State Electr. 2010;15:649–62.

Costa CM, Lizundia E, Lanceros-Méndez S. Polymers for advanced lithium-ion batteries: state of the art and future needs on polymers for the different battery components. Prog Energy Combust Sci. 2020;79:100846.

Costa CM, Lee Y-H, Kim J-H, Lee S-Y, Lanceros-Méndez S. Recent advances on separator membranes for lithium-ion battery applications: From porous membranes to solid electrolytes. Energy Storage Mater. 2019;22:346–75.

Wu G-G, Chen W-B, Ding C, Xu L-Y, Liu Z-Y, Yang W, et al. Pore formation mechanism of oriented β polypropylene cast films during stretching and optimization of stretching methods: In-situ SAXS and WAXD studies. Polymer. 2019;163:86–95.

Zhang C, Liu G, Song Y, Zhao Y, Wang D. Structural evolution of β – iPP during uniaxial stretching studied by in–situ WAXS and SAXS. Polymer. 2014;55:6915–23.

Lin Y, Meng L, Wu L, Li X, Chen X, Zhang Q, et al. A semi-quantitative deformation model for pore formation in isotactic polypropylene microporous membrane. Polymer. 2015;80:214–27.

Luo B, Li Z, Zhang J, Wang X. Formation of anisotropic microporous isotactic polypropylene (iPP) membrane via thermally induced phase separation. Desalination. 2008;233:19–31.

Zhao C, He J, Li J, Tong J, Xiong J. Preparation and properties of UHMWPE microporous membrane for lithium ion battery diaphragm. IOP Conference Series: Materials Science and Engineering. 2018;324:012089.

Shi G-y, Chu F, Zhou G-e, Han Z-w. Plastic deformation and solid-phase transformation in β-phase polypropylene. Die Makromol Chem. 1989;190:907–13.

Chu F, Yamaoka T, Kimura Y. Crystal transformation and micropore formation during uniaxial drawing of β-form polypropylene film. Polymer. 1995;36:2523–30.

Wu T, Xiang M, Cao Y, Kang J, Yang F. Pore formation mechanism of β nucleated polypropylene stretched membranes. RSC Adv. 2014;4:36689–701.

Ding L, Xu R, Pu L, Yang F, Wu T, Xiang M. Pore formation and evolution mechanism during biaxial stretching of β-iPP used for lithium-ion batteries separator. Mater Design. 2019;179:107880.

Offord GT, Armstrong SR, Freeman BD, Baer E, Hiltner A, Swinnea JS, et al. Porosity enhancement in β nucleated isotactic polypropylene stretched films by thermal annealing. Polymer. 2013;54:2577–89.

Fischer S, Diesner T, Rieger B, Marti O. Simulating and evaluating small-angle X-ray scattering of micro-voids in polypropylene during mechanical deformation. J Appl Crystallogr. 2010;43:603–10.

Varga J. β-Modification of isotactic polypropylene: preparation, structure, processing, properties, and application. J Macromol Sci, Part B. 2007;41:1121–71.

Jones AT, Aizlewood JM, Beckett DR. Crystalline Forms of Isotactic Polypropylene. Makromol Chem. 1964;75:134–58.

Bai H, Wang Y, Zhang Z, Han L, Li Y, Liu L, et al. Influence of Annealing on Microstructure and Mechanical Properties of Isotactic Polypropylene with β-Phase Nucleating Agent. Macromolecules. 2009;42:6647–55.

Olley RH, Bassett DC. An improved permanganic etchant for polyolefines. Polymer. 1982;23:1707–10.

Xiong B, Kang J, Chen R, Men Y. Initiation of cavitation upon drawing of pre-oriented polypropylene film: in situ SAXS and WAXD studies. Polymer. 2017;128:57–64.

Nitta K-h, Sawada T, Yoshida S, Kawamura T. Three dimensional molecular orientation of isotactic polypropylene films under biaxial deformation at higher temperatures. Polymer. 2015;74:30–37.

Lu X, Li X. Preparation of polyvinylidene fluoride membrane via a thermally induced phase separation using a mixed diluent. J Appl Polym Sci. 2009;114:1213–9.

Li X, Wu H, Huang T, Shi Y, Wang Y, Xiang F, et al. β/α Transformation of β-polypropylene during tensile deformation: effect of crystalline morphology. Colloid Polym Sci. 2010;288:1539–49.

Vaughan AS. The Morphology of Semicrystalline Polymers. Sci Prog. 1992;76:1–65.

Humbert S, Lame O, Chenal J-M, Rochas C, Vigier G. Small strain behavior of polyethylene: in situ SAXS measurements. J Polym Sci, Part B: Polym Phys. 2010;48:1535–42.

Hay IL, Keller A. Polymer deformation in terms of spherulites. Kolloid-Z Z für Polym. 1965;204:43–74.

Bao R-Y, Ding Z-T, Liu Z-Y, Yang W, Xie B-H, Yang M-B. Deformation-induced structure evolution of oriented β-polypropylene during uniaxial stretching. Polymer. 2013;54:1259–68.

Kawai T, Soeno S, Kuroda S-i, Koido S, Nemoto T, Tamada M. Deformation induced void formation and growth in β nucleated isotactic polypropylene. Polymer. 2019;178:121523.

Cai Z, Zhang Y, Li J, Xue F, Shang Y, He X, et al. Real time synchrotron SAXS and WAXS investigations on temperature related deformation and transitions of β-iPP with uniaxial stretching. Polymer. 2012;53:1593–601.

Lezak E, Bartczak Z. Plastic deformation behavior of β phase isotactic polypropylene in plane-strain compression at elevated temperatures. J Polym Sci, Part B: Polym Phys. 2008;46:92–108.

Lezak E, Bartczak Z, Galeski A. Plastic deformation behavior of β-phase isotactic polypropylene in plane-strain compression at room temperature. Polymer. 2006;47:8562–74.

Chang B, Schneider K, Xiang F, Vogel R, Roth S, Heinrich G. Critical Strains for Lamellae Deformation and Cavitation during Uniaxial Stretching of Annealed Isotactic Polypropylene. Macromolecules. 2018;51:6276–90.

Zhang X, Schneider K, Liu G, Chen J, Brüning K, Wang D, et al. Deformation-mediated superstructures and cavitation of poly (l-lactide): In-situ small-angle X-ray scattering study. Polymer. 2012;53:648–56.

Hubert L, David L, Séguéla R, Vigier G. Small-angle X-ray scattering investigation of the deformation processes in the amorphous phase of high density polyethylene. Polym Int. 2004;53:582–5.

Huy TA, Adhikari R, Lüpke T, Henning S, Michler GH. Molecular deformation mechanisms of isotactic polypropylene in α- and β-crystal forms by FTIR spectroscopy. J Polym Sci, Part B: Polym Phys. 2004;42:4478–88.

Pawlak A, Galeski A, Rozanski A. Cavitation during deformation of semicrystalline polymers. Prog Polym Sci. 2014;39:921–58.

Lu Y, Men Y. Cavitation‐Induced Stress Whitening in Semi‐Crystalline Polymers. Macromol Mater Eng. 2018;303:1800203.

Galeski A, Rozanski A. Cavitation during Drawing of Crystalline Polymers. Macromol Symposia. 2010;298:1–9.

Nitta KH, Takayanagi M. Direct observation of the deformation of isolated huge spherulites in isotactic polypropylene. J Mater Sci. 2003;38:4889–94.

Zhang D, Ding L, Yang F, Lan F, Cao Y, Xiang M. Effect of annealing on the microvoid formation and evolution during biaxial stretching of β nucleated isotactic polypropylene. Polym-Plast Technol Mater. 2020;59:1595–607.

Acknowledgements

We would like to express our sincere thanks to the Natural Science Foundation of China for financial support (51721091).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, D., Ding, L., Yang, F. et al. Structural evolution of β-iPP with different supermolecular structures during the simultaneous biaxial stretching process. Polym J 53, 331–344 (2021). https://doi.org/10.1038/s41428-020-00430-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-020-00430-6

This article is cited by

-

Comparison of the Structural Evolution of β Polypropylene during the Sequential and Simultaneous Biaxial Stretching Process

Chinese Journal of Polymer Science (2021)