Abstract

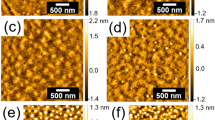

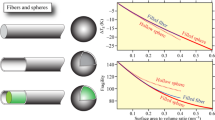

The correlation between mechanical properties and the structural changes of a block copolymer having spherical microdomains in uniaxial stretching was examined by atomic force microscopy observations and two-dimensional small-angle X-ray scattering measurements. For this purpose, coated layers composed of di- and tri-block copolymer blends were prepared by solution coating at different drying temperatures. It was revealed that the bcc lattice underwent affine deformation up to a certain stretching ratio (λ), irrespective of the drying temperature, and that the upper limit of λ for the affine deformation is approximately the same as the stretching ratio at which the stress–strain curve rises dramatically. It was also found that the packing regularity of spheres in the uniaxial stretching direction is enhanced with stretching after a plateau region where the regularity does not change. The behavior of the packing regularity as a function of the stretching ratio strongly depends on the drying temperature. We could correlate the fracture of the block copolymer film having spherical microdomains with the completion of the stretching-induced ordering of spheres in the stretching direction.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Alexandridis P, Lindman B. Amphiphilic block copolymers-self-assembly and application. New York: Elsevier; 2000.

Scheirs J, Priddy DB. Modern styrenic polymers: polystyrenes and styrenic copolymers. John Wiley & Sons Ltd; 2003. https://doi.org/10.1002/0470867213.

Maloshchuk YS, Yevstigneyeva YV, Voyutskii SS. Influence of plasticizers on the autohesion of styrene-butadiene-styrene block copolymers. Polym Sci USSR. 1977;19:2680–5.

Clair DJS. Rubber-styrene block copolymer in adhesives. Rubber Chem Technol. 1981;55:208–18.

Morishita Y, Hamada K, Kunimune T, Ishiura K. Pressure-sensitive adhesive for optical films. US Patent US8236417. 2012.

Morishita Y. Applications of acrylic thermoplastic elastomer. J Soc Rubber Sci Technol Jpn. 2013;86:321–6.

Yamamura K, Fujii S, Nakamura Y, Fujiwara K, Hikasa S, Urahama Y. Influence of diblock addition on tack in a polyacrylic triblock copolymer/tackifier system measured using a probe tack test. J Appl Polym Sci. 2013;129:1008–18.

Nakamura Y, Adachi M, Ito K, Kato Y, Fujii S, Sasaki M, et al. Effects of compatibility between tackifier and polymer on adhesion property and phase structure: tackifier-added polystyrene-based triblock/diblock copolymer blend system. J Appl Polym Sci. 2013;120:2251–60.

Ono T. Acrylic thermoplastic elastomer “KURARITY™”. J Adhes Soc Jpn. 2016;52:342–7.

Doi T, Takagi H, Shimizu N, Igarashi N, Sakurai S. Effects of drying temperature in solution coating process on microphase-separated structures in coated layers of pressure-sensitive adhesive composed of di- and triblock copolymer blends as revealed by small-angle X-ray scattering. Polymer. 2019;170:211–21.

Sakurai S, Aida S, Okamoto S, Sakurai K, Nomura S. Mechanism of thermally induced morphological reorganization and lamellar orientation from the herringbone structure in cross-linked polystyrene-block-polybutadiene-block-polystyrene triblock copolymers. Macromolecules. 2003;36:1930–9.

Fujimura M, Hashimoto T, Kawai H. Structural change accompanied by plastic-to-rubber transition of SBS block copolymers. Rubber Chem Technol. 1978;51:215–24.

Sakurai S, Sakamoto J, Shibayama M, Nomura S. Effects of microdomain structures on the molecular orientation of poly(styrene-block-butadiene-block-styrene) triblock copolymer. Macromolecules. 1993;26:3351–6.

Sakamoto J, Sakurai S, Doi K, Nomura S. Molecular orientation of poly(styrene-block-butadiene-block-styrene) triblock copolymer with polystyrene cylindrical microdomains. Polymer. 1993;34:4837–40.

Uozumi M, Matsushita T, Sakamoto N, Yamazaki T, Imaizumi K, Li L, et al. Changes in microphase-separated structures and properties of an elastomeric block copolymer film upon uniaxial stretching as analyzed by conducting simultaneous measurements of two-dimensional small-angle X-ray scattering with stress-strain tests. J Soc Rheol Jpn. 2015;43:77–83.

Kota T, Imaizumi K, Sasaki S, Sakurai S. Spontaneous enhancement of packing regularity of spherical microdomains in the body-centered cubic lattice upon uniaxial stretching of elastomeric triblock copolymers. Polymers. 2011;3:36–50.

Tomita S, Wataoka I, Igarashi N, Shimizu N, Takagi H, Sasaki S, et al. Strain-induced deformation of glassy spherical microdomains in elastomeric triblock copolymer films: time-resolved 2d-SAXS measurements under stretched state. Macromolecules. 2017;50:3404–10.

Tomita S, Lei L, Urushihara Y, Kuwamoto S, Matsushita T, Sakamoto N, et al. Strain-induced deformation of glassy spherical microdomains in elastomeric triblock copolymer films: simultaneous measurements of a stress-strain curve with 2d-SAXS patterns. Macromolecules. 2017;50:677–86.

Grediac M, Pierron F, Avril S, Toussaint E. The virtual fields method for extracting constitutive parameters from full-field measurements: a review. Strain. 2006;42:233–53.

Sasso M, Palmieri G, Chiappini G, Amodio D. Characterization of hyperelastic rubber-like materials by biaxial and uniaxial stretching tests based on optical methods. Polym Test. 2008;27:995–1004.

Uchida M, Tada N. Sequential evaluation of continuous deformation field of semi-crystalline polymers during tensile deformation accompanied by neck propagation. Int J Plast. 2011;27:2085–102.

Uchida M, Tanaka S, Kanagawa T, Tada N. Three-dimensional evaluation of strain field during neck propagation process of semi-crystalline polymer by time-series net DIC. Transac Jpn Soc Mech Eng Part A. 2012;78:1133–45.

Uchida M, Ueno T, Abe T, Kaneko Y. Quantitative evaluation of the development of stress and strain fields using digital image correlation and finite element methods. Adv Exp Mech. 2017;2:76–81.

Ohnogi H, Sasaki S, Sakurai S. Evaluation of grain size by small-angle X-ray scattering for a block copolymer film in which cylindrical microdomains are perpendicularly oriented. Macromol Symp. 2016;366:35–41.

Rasband W. Image J, US National Institutes of Health. Maryland, USA: Bethesda. http://imagej.nih.gov/ij/.

Bayomi RAH, Aoki T, Shimojima T, Takagi H, Shimizu N, Igarashi N, et al. Structural analyses of sphere- and cylinder-forming triblock copolymer thin films near the free surface by atomic force microscopy, X-ray photoelectron spectroscopy, and grazing-incidence small-angle X-ray scattering. Polymer. 2018;147:202–12.

Tomita S, Shimizu N, Igarashi N, Takagi H, Sasaki S, Sakurai S. Coalescence of non-equibrium spheres through thermal annealing in a polystyrene-block-poly(ethylene-co-butylene)-block-polystyrene triblock copolymer film under a uniaxially stretched state. Polym J. 2017;29:519–26.

Hosemann R, Lemm K, Wilke W. The paracrystal as a model for liquid crystals. Mol Cryst. 1967;1:333–62.

Acknowledgements

This study was partially supported by Grant-in-Aid for Scientific Research on Innovative Areas “Materials science on mille-feuille structure (MFS)—Development of next-generation structural materials guided by a new strengthen principle” (No. 19H05127) from the Ministry of Education, Culture, Sports, Science, and Technology of Japan. The SAXS experiments were performed at BL-10C in the Photon Factory, KEK, Japan (under Approval No. 2018G027).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Doi, T., Takagi, H., Shimizu, N. et al. Effects of drying temperature in solution coating process on the structural changes upon uniaxial stretching of sphere-forming block copolymer films. Polym J 52, 421–433 (2020). https://doi.org/10.1038/s41428-019-0287-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0287-z