Abstract

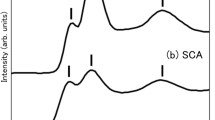

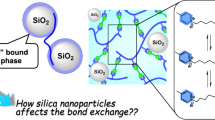

The mechanical properties of rubber nanocomposites are believed to relate to the chain dynamics at the filler interface. Here, we tackle this hypothesis by combining traditional rheological measurements with our published results obtained by a modern technique of interfacial sensitive spectroscopy (Macromolecules 51:2180–2186, 2018). The complex shear modulus (G*) for silica (SiO2) nanoparticles filled with uncross-linked styrene-butadiene rubber (SBR) was studied as a function of the strain amplitude and temperature. In the case of the composite with a higher SiO2 fraction, G* remarkably decreased with increasing strain amplitude, known as the Payne effect. This phenomenon has been explained by the breakage of the filler network formed in the composite. Postulating that the G* difference between strain amplitudes of 0.1 and 20% (ΔG*) is a signature of the extent of how the filler network is broken, ΔG* was plotted against temperature. The decrement of ΔG* with increasing temperature changed at ~340 K. This temperature coincided with the temperature at which the chains in direct contact with the filler surface start to structurally relax. This coincidence was also observed for the SiO2-filled uncross-linked polyisoprene composite. Our results make it clear that the aforementioned hypothesis is likely for SiO2-filled uncross-linked rubber composites.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Cassagnau P. Melt rheology of organoclay and fumed silica nanocomposites. Polymer. 2008;49:2183–96.

Paul DR, Robeson LM. Polymer nanotechnology: nanocomposites. Polymer. 2008;49:3187–204.

Zou H, Wu S, Shen J. Polymer/silica nanocomposites: preparation, characterization, properties, and applications. Chem Rev. 2008;108:3893–957.

Watanabe R, Hagihara H, Sato H. Structure-property relationships of polypropylene-based nanocomposites obtained by dispersing mesoporous silica into hydroxyl-functionalized polypropylene. Part 2: matrix-filler interactions and pore filling of mesoporous silica characterized by evolved gas analysis. Polym J. 2018;50:1067–77.

Watanabe R, Hagihara H, Sato H. Structure-property relationships of polypropylene-based nanocomposites obtained by dispersing mesoporous silica into hydroxyl-functionalized polypropylene. Part 1: toughness, stiffness and transparency. Polym J. 2018;50:1057–65.

Hashimoto T, Amino N, Nishitsuji S, Takenaka M. Hierarchically self-organized filler particles in polymers: cascade evolution of dissipative structures to ordered structures. Polym J. 2019;51:109–30.

Shinohara Y, Kishimoto H, Masui T, Hattori S, Yamaguchi N, Amemiya Y. Microscopic structural response of nanoparticles in styrene–butadiene rubber under cyclic uniaxial elongation. Polym J. 2019;51:161–71.

Fukunaga Y, Fujii Y, Inada S, Tsumura Y, Asada M, Naito M, Torikai N. Dispersion state of carbon black in polystyrene produced with different dispersion media and its effects on composite rheological properties. Polym J. 2019;51:275–81.

Smallwood HM. Limiting law of the reinforcement of rubber. J Appl Phys. 1944;15:758–66.

Guth E. Theory of filler reinforcement. J Appl Phys. 1945;16:20–5.

Heinrich G, Kluppel M, Vilgis TA. Reinforcement of elastomers. Curr Opin Solid State Mater Sci. 2002;6:195–203.

Gusev AA. Micromechanical mechanism of reinforcement and losses in filled rubbers. Macromolecules. 2006;39:5960–2.

Long D, Sotta P. Stress relaxation of large amplitudes and long timescales in soft thermoplastic and filled elastomers. Rheol Acta. 2007;46:1029–44.

Long D, Lequeux F. Heterogeneous dynamics at the glass transition in van der Waals liquids, in the bulk and in thin films. Eur Polym J E. 2001;4:371–87.

Maier PG, Goritz D. Molecular interpretation of the Payne effect. Kautsch Gummi Kunst. 1996;49:18–21.

Sternstein SS, Zhu AJ. Reinforcement mechanism of nanofilled polymer melts as elucidated by nonlinear viscoelastic behavior. Macromolecules. 2002;35:7262–73.

Cassagnau P, Mélis F. Non-linear viscoelastic behavior and modulus recovery in silica filled polymers. Polymer. 2003;44:6607–15.

Zhu AJ, Sternstein SS. Nonlinear viscoelasticity of nanofilled polymers: Interfaces, chain statistics and properties recovery kinetics. Compos Sci Technol. 2003;63:1113–26.

Sternstein SS, Ramorino G, Jiang B, Zhu AJ. Reinforcement and nonlinear viscoelasticity of polymer melts containing mixtures of nanofillers. Rubber Chem Technol. 2005;78:258–70.

Chen Q, Gong SS, Moll J, Zhao D, Kumar SK, Colby RH. Mechanical reinforcement of polymer nanocomposites from percolation of a nanoparticle network. ACS Macro Lett. 2015;4:398–402.

Fukao K, Miyamoto Y. Glass transitions and dynamics in thin polymer films: Dielectric relaxation of thin films of polystyrene. Phys Rev E. 2000;61:1743–54.

Ellison CJ, Torkelson JM. The distribution of glass-transition temperatures in nanoscopically confined glass formers. Nat Mater. 2003;2:695–700.

Miyazaki T, Nishida K, Kanaya T. Thermal expansion behavior of ultrathin polymer films supported on silicon substrate. Phys Rev E. 2004;69:061803.

Priestley RD, Ellison CJ, Broadbelt LJ, Torkelson JM. Structural relaxation of polymer glasses at surfaces, interfaces and in between. Science. 2005;309:456–9.

Roth CB, McNerny KL, Jager WF, Torkelson JM. Eliminating the enhanced mobility at the free surface of polystyrene: fluorescence studies of the glass transition temperature in thin bilayer films of immiscible polymers. Macromolecules. 2007;40:2568–74.

Tanaka K, Tateishi Y, Okada Y, Nagamura T, Doi M, Morita H. Interfacial mobility of polymers on inorganic solids. J Phys Chem B. 2009;113:4571–7.

Tsuruta H, Fujii Y, Kai N, Kataoka H, Ishizone T, Doi M, Morita H, Tanaka K. Local conformation and relaxation of polystyrene at substrate interface. Macromolecules. 2012;45:4643–9.

Inutsuka M, Horinouchi A, Tanaka K. Aggregation states of polymers at hydrophobic and hydrophilic solid interfaces. ACS Macro Lett. 2015;4:1174–8.

Kawaguchi D, Tateishi Y, Tanaka K. Time-resolved fluorescence analysis for dye-labeled polystyrene in thin films. J Non-Cryst Solids. 2015;407:284–7.

Shimomura S, Inutsuka M, Yamada NL, Tanaka K. Unswollen layer of cross-linked polyisoprene at the solid interface. Polymer. 2016;105:526–31.

Nguyen HK, Inutsuka M, Kawaguchi D, Tanaka K. Depth-resolved local conformation and thermal relaxation of polystyrene near substrate interface. J Chem Phys. 2017;146:203313.

Zuo B, Inutsuka M, Kawaguch D, Wang XP, Tanaka K. Conformational relaxation of poly(styrene-co-butadiene) chains at substrate interface in spin-coated and solvent-cast films. Macromolecules. 2018;51:2180–6.

Sugimoto S, Inutsuka M, Kawaguchi D, Tanaka K. Reorientation kinetics of local conformation of polyisoprene at substrate interface. ACS Macro Lett. 2018;7:85–9.

Nguyen HK, Konomi A, Sugimoto S, Inutsuka M, Kawaguchi D, Tanaka K. Rotational dynamics of a probe in rubbery polymers characterized by time-resolved fluorescence anisotropy measurement. Macromol Chem Phys. 2018;219:1700329.

Yamamoto K, Kawaguchi D, Sasahara K, Inutsuka M, Yamamoto S, Uchida K, Mita K, Ogawa H, Takenaka M, Tanaka K. Aggregation states of poly(4-methylpentene-1) at a solid interface. Polym J. 2019;51:247–55.

Pliskin I, Tokita N. Bound rubber in elastomers—analysis of elastomer-filler interaction and its effect on viscosity and modulus of composite systems. J Appl Polym Sci. 1972;16:473–92.

Dannenberg EM. Bound rubber and carbon black reinforcement. Rubber Chem Technol. 1986;59:512–24.

Takayanagi M, Harima H, Iwata Y. Viscoelastic behavior of polymer blends and its comparison with model experiments. J Soc Mater Sci Jpn. 1963;12:389–94.

Takayanagi M, Uemura S, Minami S. Application of equivalent model method to dynamic rheo-optical properties of crystalline polymer. J Polym Sci Part C. 1964;5:113–22.

Payne AR. A note on the conductivity and modulus of carbon black-loaded rubbers. J Appl Polym Sci. 1965;9:1073–82.

Acknowledgements

This work was partly supported by JSPS KAKENHI for Scientific Research (A) (No. JP15H02183) (KT) and JSPS KAKENHI for Scientific Research (B) (No. JP17H03118) (DK) from the Ministry of Education, Culture, Sports, Science and Technology, Japan. We are also grateful for support from the JST-Mirai Program (JPMJMI18A2) (KT). We also thank Drs Katsuhiko Tsunoda, Takashi Shimizu and Takaaki Igarashi (Bridgestone Corp.) for giving us samples and their fruitful discussion.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Sugimoto, S., Inutsuka, M., Kawaguchi, D. et al. The effect of interfacial dynamics on the bulk mechanical properties of rubber composites. Polym J 52, 217–223 (2020). https://doi.org/10.1038/s41428-019-0254-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0254-8

This article is cited by

-

Conformational relaxation of ethylene-propylene-diene terpolymer at a solid interface

Polymer Journal (2023)

-

Carbon black/silica hybrid filler networking and its synergistic effects on the performance of styrene-butadiene rubber composites

Polymer Journal (2022)

-

Molecular picture of fluoropolymer adsorption on nanocarbon materials

Polymer Journal (2021)

-

Effect of the silica-rubber interface on the mechanical, viscoelastic, and tribological behaviors of filled styrene-butadiene rubber vulcanizates

Polymer Journal (2020)

-

Direct observation of morphological transition for an adsorbed single polymer chain

Scientific Reports (2020)