Abstract

We investigated synthetic biomacromolecules to control molecular interactions. Multifunctional glycopolymers for molecular recognition were prepared via living radical polymerization and post-click chemistry with orthogonal Huisgen and thiol-epoxy reactions. The synthesis of the polymer backbone and the subsequent side-chain introduction successfully proceeded in high yield. The multifunctional glycopolymers had a tri-block structure: the first and third blocks contained mannose, and the second block contained either a positively or negatively charged group or a neutral hydrophilic group. The molecular recognition of the glycopolymers toward lectin was evaluated via fluorescence quenching measurements. Because of the electrostatic interaction, the binding constant varied in the following order: positively charged glycopolymer (PT110) > negatively charged glycopolymer (NT110). The effect of the electrostatic interactions was modest compared with the effect of the carbohydrate–lectin binding. These results suggested that the carbohydrate–lectin interaction was an important factor in the molecular recognition of glycopolymers. This study provides guidelines for the preparation of multifunctional polymers, such as biomaterials.

Similar content being viewed by others

Introduction

Molecular recognition between biomacromolecules plays an important role in living systems. Carbohydrate–protein and protein–protein interactions are representative interactions that are formed through several interactions, including hydrogen bonding, hydrophobic, and electrostatic interactions [1, 2]. Although each interaction is weak, these interactions become strong when combined in a living system [3]. Therefore, the design of multifunctional polymers that effectively exert these various interactions is required to develop polymers with efficient molecular recognition.

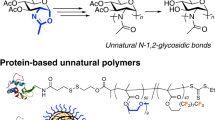

Facile methods for the synthesis of multifunctional polymers have been reported [4,5,6]. Post-click chemistry is a promising method in which functional groups are modified in a preprepared polymer backbone [7,8,9,10,11]. The advantage of this method is that a library of multifunctional polymers can be prepared from a single precursor. The Haddleton group and the Vokin group have reported the modification of polymers with two click reactions [10, 11]. The orthogonal reaction is crucial and is a universal method for the synthesis of multifunctional polymers. For precise molecular recognition, a specific functional group arrangement in a polymer is essential [12, 13]. In recent years, living polymerization has enabled the preparation of synthetic polymers with specific multiblock structures that achieve the required arrangement of functional groups [14,15,16,17]. Using a multiblock structure as the precursor for post-click chemistry, multifunctional polymers with a controlled arrangement of functional groups can be obtained.

Glycopolymers [18,19,20,21,22] are synthetic polymers with pendant carbohydrates that can exhibit strong molecular recognition with sugar recognition proteins (lectins) via the cluster glycoside effect [23]. Previously, we prepared tri-block glycopolymers with carbohydrate units at both ends by reversible addition–fragmentation chain transfer (RAFT) polymerization. The molecular recognition of the glycopolymer was controlled by the spatial arrangement of carbohydrates [24]. However, in the tri-block glycopolymer, an inactive monomer (triethylene glycol) block was used between the carbohydrate blocks, and the effect of interactions, other than in the sugar-binding sites, was not taken into consideration. Lectin has not only sugar recognition sites but also other groups, including charged and hydrophobic groups [1]. As mentioned above, various interactions are involved in biomolecular recognition, and electrostatic interactions are also important factors. In the general glycopolymer design, emphasis has been placed only on the carbohydrate–lectin interaction. Introducing other factors, such as electrostatic and hydrophobic interactions, may be useful for the further functionalization of glycopolymers. For example, when electrostatic interactions are present, in addition to carbohydrate interactions, glycopolymers are predicted to exhibit stronger or more specific molecular recognition for lectin.

In the present study, we report the preparation of multifunctional glycopolymers containing either a positively or negatively charged group or a neutral hydrophilic group in the 2nd block of the tri-block structure and the influence of the electrical charge on the glycopolymer–lectin interaction. The block polymer backbone was prepared using RAFT polymerization [14, 15, 25, 26]. Mannose and electrically charged groups were conjugated via two post-click chemistry reactions with orthogonal Huisgen [27, 28] and thiol-epoxy [29,30,31] reactions. The glycopolymer–lectin interaction was determined via fluorescence quenching measurements [32, 33], and concanavalin A (ConA; mannose recognition protein) [34] was used as the target lectin.

Experimental section

Materials

Glycidyl methacrylate (95.0%), tert-butyl acrylate (98.0%), thioacetic acid (95.0%), α-thioglycerol (95%), pyridinium p-toluenesulfonate (PPTS, 98%), and lithium hydroxide anhydrous (LiOH, 98.0%) were purchased from Tokyo Chemical Industry (Tokyo, Japan). Triethylamine (99.0%), 2,2’-azobis isobutyronitrile (AIBN, 95%), acetic acid (99.7%), and trifluoroacetic acid (98.0%) were purchased from Fujifilm Wako Pure Chemical Corporation (Osaka, Japan). Magnesium sulfate (MgSO4, 95.0%) was purchased from Kanto Chemical (Tokyo, Japan). Tetrabutylammonium fluoride (TBAF) trihydrate (97.0%), 4-cyano-4-(phenylcarbonothioylthio)pentanoic acid (CPADB, 97%), 2-(Boc-amino)ethanethiol (97%), and copper(I) bromide (CuBr, 99.999%) were purchased from Sigma Aldrich (St. Louis, USA). Triethylene glycol monoethyl ether monomethacrylate (TEGMA) was purchased from Polyscience, Inc (Warrington, USA). Concanavalin A-fluorescein isothiocyanate (ConA-FITC) was purchased from Cosmo Bio (Tokyo, Japan). Peanut agglutinin-fluorescein isothiocyanate (PNA-FITC) was purchased from Seikagaku Bio Business (Tokyo, Japan). Rabbit blood was purchased from Nippon Bio-test Laboratories Inc (Saitama, Japan). Tris[(1-benzyl-1H-1,2,3-triazol-4-yl)methyl]amine (TBTA), trimethylsilyl propargyl methacrylate (TMS-PrMA), and mannose azide were synthesized according to previously reported methods [24, 28].

General method

1H NMR spectra were recorded on a JEOL-ECP400 spectrometer (JEOL, Tokyo, Japan) using CDCl3, (CD3)2CO, d6-DMSO, or D2O as a solvent. Size exclusion chromatography (SEC) with organic solvent was performed on a HLC-8320 GPC equipped with a TSKgel Super AW guard column and TSKgel Super AW 4000 columns (TOSOH, Tokyo, Japan). The SEC analyses were performed by injecting 20 μL of polymer solution (2 mg/mL) in DMF buffer with 10 mM LiBr. All samples for SEC were previously filtered through a 0.45 μm filter. The buffer solution was also used as the eluent at a flow rate of 0.5 mL/min. Dynamic light scattering (DLS) was performed on a ZETASIZER NANO-ZS (Malvern, Worcestershire, UK). The DLS analyses were performed using a 1 mL disposable cell of polymer solution (1.0 mg/mL) in 10 mM PBS(+) buffer. All samples for DLS were previously filtered through a 0.45 μm filter. Fluorescent quenching measurements were performed on a JASCO FP-6500 (JASCO, Tokyo, Japan). Fluorescent quenching measurement analyses were performed using a 1 mL disposable cell of ConA-FITC solution (0.033 mM) in 10 mM PBS(+) buffer and polymer solution (0.1 mM carbohydrate concentration) in 10 mM PBS(+) buffer.

Synthesis

Three kinds of glycopolymers were synthesized: a tri-block positively charged glycopolymer composed of glycopolymer-b-poly(TEGMA-stat-GMA(NH3+))-b-glycopolymer (PT110), a tri-block negatively charged glycopolymer composed of glycopolymer-b-poly(TEGMA-stat-GMA(COO-))-b-glycopolymer (NT110), and a tri-block uncharged hydroxy glycopolymer composed of glycopolymer-b-poly(TEGMA-stat-GMA(OH))-b-glycopolymer (HT110).

Synthesis of poly[(TMS-PrMA)n-b-(TEGMA-stat-GMA)m-b-(TMS-PrMA)k] (T110)

The block polymer backbone was prepared via a three-step RAFT polymerization (Scheme 2). TMS-PrMA (25 eq, 4.0 mmol, 786.0 mg), CPADB (1 eq, 0.16 mmol, 44.7 mg), and AIBN (0.1 eq, 0.016 mmol, 2.7 mg) were dissolved in 2 mL of toluene, and the solution was degassed by freeze-pump-thaw cycles (3 times). The tube was sealed with a gas burner, and the reaction occurred in an oil bath at 60 °C for 15 h. The conversion was evaluated by 1H NMR. The solution was diluted with 2 mL of acetone and precipitated in a mixture of 30 mL of MeOH, 3 mL of water, and 0.1 mL of 1 M HClaq. The product was separated by centrifugation for 20 min (3 times) and obtained by drying under vacuum (yield: 606.1 mg, 73%) (poly(TMS-PrMA)n: 1st polymer).

The 1st polymer (1 eq, 0.05 mmol, 288.3 mg), TEGMA (68 eq, 3.4 mmol, 837.4 mg), GMA (17 eq, 0.9 mmol, 120.8 mg), and AIBN (0.1 eq, 0.005 mmol, 0.8 mg) were dissolved in 6.25 mL of dioxane, and the 1st polymer was used as the macro-RAFT reagent. Reaction and analysis were carried out under the same conditions as the 1st polymerization. The di-block polymer was purified by dialysis against DMSO (MWCO: 3500). The solution was changed from DMSO to acetone, and the product was obtained by drying under vacuum (yield: 842.2 mg, 94%) (poly[(TMS-PrMA)n-b-(TEGMA-stat-GMA)m]: 2nd polymer). The 2nd polymer (1 eq, 0.047 mmol, 842.2 mg), TMS-PrMA (53 eq, 2.5 mmol, 485.4 mg), and AIBN (0.1 eq, 0.005 mmol, 0.8 mg) were dissolved in 5.9 mL of dioxane, and the 2nd polymer was used as the macro-RAFT reagent. Reaction, analysis, and purification were carried out under the same conditions as the 2nd polymerization (yield: 1046.4 mg, 95%) (poly[(TMS-PrMA)n-b-(TEGMA-stat-GMA)m-b-(TMS-PrMA)k]: 3rd polymer (T110)).

Thiol-epoxy reaction of T110 with thiol compounds [31]

To a vial fitted with a magnetic stir bar, dehydrated THF, T110 (1 eq, 0.029 M epoxy moiety), thiol compound (9 eq, 0.26 M), and LiOH (0.8 eq, 0.023 M) were sequentially added, and the mixture was stirred at 25 °C [for 24 (2 and 3) or 36 h (1)]. 2,2-Dimethyl-1,3-dioxane-4-methanethiol was synthesized following Scheme S2 in the supporting information. Then, the reaction mixtures were neutralized with HCl (pH 4). The solutions were purified by dialysis against pure water and changed from pure water to acetone (MWCO: 3500). The products were obtained after removing the solvent under high vacuum overnight. The polymers containing thiol compounds 1–3 were called P1–P3, respectively (Schemes S4–2).

Deprotection of the TMS groups from the polymer backbones

P1–P3 (1 eq, 0.28 M TMS moiety), TBAF (1.5 eq, 0.42 M), and CH3COOH (1.5 eq, 0.42 M) were dissolved in dehydrated THF. The solutions were stirred at room temperature for 5 h. The reaction mixtures were purified by dialysis against DMSO, HClaq at pH 4, and pure water (MWCO: 3500). The products were obtained by freeze-drying. The deprotected compounds P1–P3 were called P4–P6, respectively (Scheme S5).

Mannose introduction via the Huisgen reaction

P4–P6 (1 eq, 0.14 M alkyne moiety), mannose azide [35] (9 eq, 0.21 M), and TBTA (0.9 eq, 0.021 M) were dissolved in dehydrated DMF. The solutions were bubbled with N2 for 30 min. Triethylamine (0.54 eq) was added to the solutions, and the solutions were further bubbled with N2 for 15 min. CuBr was added to the solutions, and the solutions were reacted in a glove box for 3 days. The reaction mixtures were purified by dialysis against DMSO, HClaq at pH 4, and pure water (MWCO: 3500). The products were obtained by freeze-drying. P4–P6 containing mannose were called P7–P9, respectively (Scheme S6).

Deprotection of the Boc groups [29]

P7 (30.0 mg, 0.013 mmol Boc moiety) was dissolved in 1 mL of trifluoroacetic acid, and the mixture was stirred at room temperature for 1 h and then precipitated into 30 mL of diethyl ether. The precipitated solid was dissolved in 1 mL of pure water, and the solution was neutralized with NaHCO3. The mixture was purified by dialysis against HClaq at pH 4 and pure water (MWCO: 3500). The product was obtained by freeze-drying (yield: 26.7 mg, 91%). The obtained product was called PT110 (Schemes S7–1).

Deprotection of the tert-butyl groups [36]

P8 (30.0 mg, 0.013 mmol tert-butyl moiety) was dissolved in 1 mL of trifluoroacetic acid, and the mixture was stirred at room temperature for 1.5 h and then precipitated into 30 mL of diethyl ether. The precipitated solid was dissolved in 1 mL of pure water, and the solution was neutralized with NaHCO3. The mixture was purified by dialysis against HClaq at pH 4 and pure water (MWCO: 3500). The product was obtained by freeze-drying (yield: 13.3 mg, 45%). The obtained product was called NT110 (Schemes S7–2).

Deprotection of the acetal groups [37]

P9 (30.0 mg, 0.013 mmol acetal moiety) was dissolved in 2 mL of 0.4 M HClaq, and the mixture was stirred at room temperature for 2 h and neutralized with NaHCO3. The mixture was purified by dialysis against HClaq at pH 4 and pure water (MWCO: 3500). The product was obtained by freeze-drying (yield: 13.3 mg, 45%). The obtained product was called HT110 (Scheme S7-3).

Evaluation of the affinity of glycopolymers to lectin

Fluorescence quenching measurements

ConA-FITC was dissolved in phosphate buffered saline PBS (+) (10 mM, pH 7.4) to prepare a 0.033 μM ConA-FITC solution. Each glycopolymer was dissolved in PBS(+) so that the concentration of the sugar side chain was 0.1 M. The prepared ConA-FITC solution (1 mL) was placed in a disposable cell (1 mL) and set in a fluorescence spectrometer. The excitation light at 490 nm was irradiated so that the fluorescence intensity at 517 nm was measured for each carbohydrate concentration. Fluorescent quenching without carbohydrate–protein interactions was measured by the addition of PBS(+), and the quenching effect by PBS(+) was subtracted. Fluorescence measurements with the PNA-FITC solution were performed by the same procedure. The fluorescence intensity changes for each sugar concentration were fitted with the following Langmuir equation to calculate the binding constant of each glycopolymer: [33]

where ΔF, ΔFmax, Ka and C represent the fluorescence intensity change, maximum fluorescence intensity change, binding constant and carbohydrate concentration, respectively.

Results and discussion

Preparation of the reactive polymeric precursor

A tri-block polymer backbone poly[(TMS-PrMA)n-b-(TEGMA-stat-GMA)m-b-(TMS-PrMA)k] was prepared as a multifunctional polymer precursor by a three-step RAFT polymerization (Scheme 2). TMS-PrMA was introduced for the Huisgen reaction, TEGMA for the spacer, and GMA for the thiol-epoxy reaction. Previously, we reported that carbohydrate–ConA recognition was enhanced when carbohydrate blocks were arranged at both ends of a 100-mer tri-block glycopolymer [24]. In the present study, we designed a 100-mer polymer backbone with [n:m:k] = [25:50:25]. The second block was copolymerized with TEGMA:GMA = 4:1 to introduce an electric charge (or neutral hydrophilic group) at a rate of 20%. The conversion rate was determined by the vinyl and reacted side chain 1H NMR peaks in the reaction mixture, and the molecular weights (Mn) and degree of polymerization (D.P.) were determined by the 1H NMR peaks of the terminal RAFT group and the reacted side chain (Fig. 1, Figs. S3-1, S3-2). The Mw/Mn value was determined by SEC. The conversions of the 1st, 2nd (TEGMA), 2nd (GMA), and 3rd blocks were 83%, 54%, 66%, and 55%, respectively (Table 1). To suppress the side reactions of GMA, the 2nd and 3rd blocks were polymerized under dilute solution conditions of 1/10th of the 1st block [31, 38]. Homopolymers of GMA became insoluble gel due to the crosslinking of the epoxy group. Because the conversion rate was low, the target D.P. was obtained by supplying the monomer in excess. The D.P. of the 1st, 2nd (TEGMA), 2nd (GMA), and 3rd blocks were 28, 42, 13, and 27 mer, respectively, which achieved almost the designed composition. SEC analysis revealed that all blocks had narrow molecular distributions (Fig. 2a).

Post-click chemistry: Huisgen and thiol-epoxy reactions

Carbohydrate ligands and electrically charged groups were introduced into the precursor polymer backbone by two orthogonal post-click chemistry reactions: Huisgen and thiol-epoxy reactions. The synthesis of the glycopolymers was carried out using four reactions in total, including the click reactions and two deprotection reactions (Scheme 1). First, thiol compounds 1–3 with protecting groups (HS-NHBoc, COOtert-butyl, and OHacetal) were introduced using a thiol-epoxy reaction. These protecting groups were selected to be relatively stable under basic conditions. LiOH and dehydrated THF were used as the base catalyst and solvent, respectively. For the preliminary experiment of the thiol-epoxy reaction, poly(TEGMA-stat-GMA) was synthesized and introduced 2-(Boc-amino)ethanethiol to the epoxy group via a thiol-epoxy reaction following the Schemes S4–1. The estimation of the reaction conversion was investigated by 1H NMR with poly(TEGMA-stat-GMA) (Fig. S4-1). The progress of these thiol-epoxy reactions was confirmed by comparing the peak values of the reacted side chain with the propargyl methylene in the 1H NMR spectrum (Fig. 3a), where the conversion of epoxy group to thioether was estimated to be over 85% based on the measurement of 1H NMR. The calculation of the conversion is described in the supporting information (SI, Page 7). There was no dissociation of the protecting groups (TMS group and thiol compounds). Crosslinking between the thiol at the polymer terminal and the epoxy group was not observed, and no side reactions occurred in this reaction. These results indicate that selective modification of thiol compounds is possible in polymer backbones prepared by RAFT polymerization.

The TMS groups were deprotected for the Huisgen reaction and deprotected after the thiol-epoxy reaction to prevent the thiol-yne reaction [39]. The deprotection reactions were confirmed to proceed completely by the disappearance of the peaks at 0.2 ppm in the 1H NMR spectra of the polymers. Then, glycopolymers containing mannose were obtained by reacting the deprotected polymer backbone with mannose azide using the Huisgen reaction. To keep the Huisgen reaction of sugars as high as possible, an excess of azide mannose was added. Progress in the reactions was monitored by the peaks corresponding to the anomeric position of mannose at 5.9–6.0 ppm in the 1H NMR spectra (Fig. 3b), but the reaction progress was not confirmed by FTIR due to the excess amount of azide sugars. Approximately 90% completion of the reactions was confirmed in all glycopolymers from 1H NMR. No side reactions were observed in these Huisgen reactions.

The protecting group for each thiol compound was removed under acidic conditions, as side-chain dissociations were not observed. SEC analysis revealed that the glycopolymers maintained narrow polydispersities, as for their precursor polymer (Fig. 2b, c). From the above, it was shown that the two post-click chemistry reactions achieved the desired orthogonal modification. Through these series of reactions, charged tri-block glycopolymers were obtained (Scheme 2, Table 2); positively charged glycopolymer PT110 (glycopolymer-b-poly(TEGMA-stat-GMA(NH3+))-b-glycopolymer), negatively charged glycopolymer NT110 (glycopolymer-b-poly(TEGMA-stat-GMA(COO–))-b-glycopolymer), and uncharged hydroxy glycopolymer HT110 (glycopolymer-b-poly(TEGMA-stat-GMA(OH))-b-glycopolymer). In this study, we determined that synthesis by these post-click chemistry reactions is an excellent system for multifunctional polymers with electrical charges and carbohydrates.

Electrical charge and hydrodynamic diameter of glycopolymers

The zeta potential and hydrodynamic diameter of the glycopolymers were confirmed by DLS measurements (Fig. 4). The zeta potentials of PT110, NT110, and HT110 were +44.0, –23.8, and –1.6 mV, respectively, and they existed in the charged state as designed in water. Furthermore, the sizes of all polymers were less than 10 nm, indicating that the polymers existed in the monomeric state.

Evaluation of the molecular recognition of the glycopolymers with lectin

The molecular recognition of the glycopolymer-ConA was determined via fluorescence quenching measurements. The fluorescence intensity changes ΔF (F0−Fn) with changing sugar concentrations were fitted with the Langmuir adsorption isothermal model to calculate the binding constant (Ka). Figure 5 shows the ΔF and Ka values of the glycopolymers. The Ka values of PT110, NT110, and HT110 were 2.9 × 106, 1.9 × 106, and 8.5 × 105 [M−1], respectively. The Ka values were in the order PT110 >NT110 >HT110 with slight changes. Carbohydrate–lectin and electrostatic interactions contributed to the overall interaction. PT110 and NT110 exhibited a strong interaction with ConA (Ka on the order of 106 M−1). Previously, we reported that approximately 100-mer glycopolymers exceeded the distance between the sugar-binding sites in ConA (6.5 nm), and the Ka values were 106 [M−1] order and five times larger than for short glycopolymers [24]. The strong binding of PT110 and NT110 was due to the bivalent binding of the glycopolymers to ConA.

Because ConA has a negative net charge [40], the positively charged glycopolymer (PT110) and the negatively charged glycopolymer (NT110) were expected to show a stronger and weaker interaction, respectively. However, the effect of the electrostatic interaction was modest compared with the effect of the carbohydrate–ConA bivalent binding. Theoretically, electrostatic interactions are stronger than hydrogen bonding interactions [41]. However, the contribution of the electrostatic interaction was considered to be limited because both positive and negative charges exist on the surface of ConA, and thus, these interactions are offset. Therefore, interaction by the carbohydrate groups is essential for molecular recognition, and the influence of the electrostatic interaction in lectin is small. In addition, the Ka value of HT110 was weaker than expected, which might be because of the shrinking polymer conformation based on the DLS measurement.

Furthermore, we also measured the molecular recognition of the glycopolymers toward peanut agglutinin (PNA; galactose recognition protein). In this case, the fluorescence intensity did not change (Fig. 6), showing the specificity of the sugar recognition. Although the electrical charge of PNA was negative, no observable interaction was found. These results suggest that carbohydrate binding is the most important factor in the molecular recognition of glycopolymers.

Conclusion

In summary, tri-block glycopolymers with multifunctional groups were prepared by orthogonal post-click chemistry, and glycopolymers with terminal mannose groups and electrical charges were successfully synthesized. The molecular recognition of the glycopolymers toward lectin was evaluated via fluorescence quenching measurements. The Ka values varied slightly in the order PT110 > NT110 because of electrostatic interactions. The effect of the electrostatic interaction was modest compared with the effect of carbohydrate–ConA bivalent binding. These results suggest that the carbohydrate interaction is dominant in glycopolymer–lectin recognition and that the influence of electrostatic interactions is small. Many functional groups, such as hydrophobic, fluorescent, and crosslinking groups, can be introduced using this method. This study provides guidelines for the preparation of multifunctional polymers, such as biomaterials.

References

Sites WE. Protein-protein interactions: interface structure, binding thermodynamics, and mutational analysis. Chem Rev 1997;97:1233–50.

Kiessling LL. Chemistry-driven glycoscience. Bioorg Med Chem 2018;26:5229–38.

Fasting C, Schalley CA, Weber M, Seitz O, Hecht S, Koksch B, et al. Multivalency as a chemical organization and action principle. Angew Chem Int Ed 2012;51:10472–98.

Blasco E, Sims MB, Goldmann AS, Sumerlin BS, Barner-Kowollik C. 50th Anniversary perspective: polymer functionalization. Macromolecules 2017;50:5215–52.

Yang C, Flynn JP, Niu J. Facile synthesis of sequence-regulated synthetic polymers using orthogonal SuFEx and CuAAC click reactions. Angew Chem Int Ed 2018;57:16194–9.

Martin L, Gody G, Perrier S. Preparation of complex multiblock copolymers via aqueous RAFT polymerization at room temperature. Polym Chem 2015;6:4875–86.

Malkoch M, Thibault RJ, Drockenmuller E, Messerschmidt M, Voit B, Russell TP, et al. Orthogonal approaches to the simultaneous and cascade functionalization of macromolecules using click chemistry. J Am Chem Soc 2005;127:14942–9.

Gauthier MA, Gibson MI, Klok HA. Synthesis of functional polymers by post-polymerization modification. Angew Chem Int Ed 2009;48:48–58.

Fukuda T, Tsuji S, Miura Y. Glycopolymer preparation via post-polymerization modification using N-succinimidylmonomers. Polym J. (in press). https://doi.org/10.1038/s41428-019-0170-y).

Zhang Q, Anastasaki A, Li G-Z, Haddleton AJ, Wilson P, Haddleton DM. Multiblock sequence-controlled glycopolymers via Cu(0)-LRP following efficient thiol–halogen, thiol–epoxy and CuAAC reactions. Polym Chem 2014;5:3876–83.

Oakdale JS, Kwisnek L, Fokin VV. Selective and orthogonal post-polymerization modification using sulfur(VI) fluoride exchange (SuFEx) and copper-catalyzed azide-alkyne cycloaddition (CuAAC) reactions. Macromolecules 2016;49:4473–9.

Pasparakis G, Krasnogor N, Cronin L, Davis BG, Alexander C. Controlled polymer synthesis—from biomimicry towards synthetic biology. Chem Soc Rev 2010;39:286–300.

Matsuura K, Hibino M, Yamada Y, Kobayashi K. Construction of glyco-clusters by self-organization of site-specifically glycosylated oligonucleotides and their cooperative amplification of lectin-recognition. J Am Chem Soc 2001;123:357–8.

Gody G, Maschmeyer T, Zetterlund PB, Perrier S. Rapid and quantitative one-pot synthesis of sequence-controlled polymers by radical polymerization. Nat Commun 2013;4:1–10.

Perrier S. 50th anniversary perspective: RAFT polymerization-a user guide. Macromolecules 2017;50:7433–47.

Ouchi M, Sawamoto M. 50th anniversary perspective: metal-catalyzed living radical polymerization: discovery and perspective. Macromolecules 2017;50:2603–14.

Engelis NG, Anastasaki A, Nurumbetov G, Truong NP, Nikolaou VP, Shegiwal A, et al. Sequence-controlled methacrylic multiblock copolymers via sulfur-free RAFT emulsion polymerization. Nat Chem 2016;9:171–8.

Miura Y, Hoshino Y, Seto H. Glycopolymer nanobiotechnology. Chem Rev 2016;116:1673–92.

Miura Y, Yasuda K, Yamamoto K, Koike M, Nishida Y, Kobayashi K. Inhibition of alzheimer amyloid aggregation with sulfated glycopolymers. Biomacromolecules 2007;8:2129–34.

Gestwicki JE, Cairo CW, Strong LE, Oetjen KA, Kiessling LL. Influencing receptor-ligand binding mechanisms with multivalent ligand architecture. J Am Chem Soc 2002;124:14922–33.

Ting SRS, Chen G, Stenzel MH. Synthesis of glycopolymers and their multivalent recognitions with lectins. Polym Chem 2010;1:1392–412.

Nagao M, Fujiwara Y, Matsubara T, Hoshino Y, Sato T, Miura Y. Design of glycopolymers carrying sialyl oligosaccharides for controlling the interaction with the influenza virus. Biomacromolecules 2017;18:4385–92.

Pieters RJ. Maximising multivalency effects in protein-carbohydrate interactions. Org Biomol Chem 2009;7:2013–25.

Jono K, Nagao M, Oh T, Sonoda S, Hoshino Y, Miura Y. Controlling the lectin recognition of glycopolymers via distance arrangement of sugar blocks. Chem Commun 2018;54:82–5.

Chiefari J, Chong YK, Ercole F, Krstina J, Jeffery J, Le TPT, et al. Living free-radical polymerization by reversible addition-fragmentation chain transfer: the RAFT process. Macromolecules 1998;31:5559–62.

Hill MR, Carmean RN, Sumerlin BS. Expanding the scope of RAFT polymerization: recent advances and new horizons. Macromolecules 2015;48:5459–69.

Worrell BT, Malik JA, Fokin VV. Direct evidence of a dinuclear copper intermediate in Cu(I)-catalyzed azide-alkyne cycloadditions. Science 2013;340:457–60.

Brassard CJ, Zhang X, Brewer CR, Liu P, Clark RJ, Zhu L. Cu(II)-Catalyzed oxidative formation of 5,5′-bistriazoles. J Org Chem. 2016;81:12091–105.

Gadwal I, Stuparu MC, Khan A. Homopolymer bifunctionalization through sequential thiol–epoxy and esterification reactions: an optimization, quantification, and structural elucidation study. Polym Chem 2015;6:1393–404.

Stuparu MC, Khan A. Thiol-epoxy “Click” chemistry: application in preparation and postpolymerization modification of polymers. J Polym Sci A. 2016;54:3057–70.

Muzammil EM, Khan A, Stuparu MC. Post-polymerization modification reactions of poly(glycidyl methacrylate)s. RSC Adv 2017;7:55874–84.

Hasegawa T, Kondoh S, Matsuura K, Kobayashi K. Rigid helical poly(glycosyl phenyl isocyanide)s: synthesis, conformational analysis, and recognition by lectins. Macromolecules 1999;32:6595–603.

Miura Y, Koketsu D, Kobayashi K. Synthesis and properties of a well-defined glycopolymer via living radical polymerization. Polym Adv Technol 2007;18:647–51.

Derewenda Z, Yariv J, Helliwell JR, Kalb AJ, Dodson EJ, Papiz MZ, et al. The structure of the saccharide-binding site of concanavalin A. EMBO J 1989;8:2189–93.

Tanaka T, Nagai H, Noguchi M, Kobayashi A, Shoda S. One-step conversion of unprotected sugars to β-glycosyl azides using 2-chloroimidazolinium salt in aqueous solution. Chem Commun 2009;0:3378–9.

Tachihara T, Ishizaki S, Kurobayashi Y, Tamura H, Ikemoto Y, Onuma A, et al. Synthesis and odour evaluation of stereoisomers of N-alkyl-pyrrolidine derivatives, characteristic roast odour of seafood. Flavour Fragr J 2003;18:305–8.

Bibak N, Hajdu J. A new approach to the synthesis of lysophosphatidylcholines and related derivatives. Tetrahedron Lett 2003;44:5875–7.

Gritter RJ, Wallece TJ. The free radical chemistry of epoxides: a radical rearrangement and displacement. J Org Chem 1961;26:282–3.

Lowe AB, Hoyle CE, Bowman CN. Thiol-yne click chemistry: a powerful and versatile methodology for materials synthesis. J Mater Chem 2010;20:4745–50.

Espinosa EP, Perrigault M, Ward JE, Shumway SE, Allam B. Microalgal cell surface carbohydrates as recognition sites for particle sorting in suspension-feeding bivalves. Biol Bull 2010;218:75–86.

Hoeben FJ, Jonkheijm P, Meijer EW, Schenning AP. About supramolecular assemblies of π-conjugated systems. Chem Rev. 2005;105:1491–546.

Acknowledgements

This work was supported by the Japan Agency for Medical Research and Development (JP17fk0108127), Grant-in-Aid for Scientific Research (B) (JP19H02766), Grant-in-Aid for Scientific Research on Innovative Areas (JP18H04420), Grant-in-Aid for Challenging Research (Exploratory) (JP19K22971), and Takeda Science Foundation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Oh, T., Jono, K., Kimoto, Y. et al. Preparation of multifunctional glycopolymers using double orthogonal reactions and the effect of electrostatic groups on the glycopolymer–lectin interaction. Polym J 51, 1299–1308 (2019). https://doi.org/10.1038/s41428-019-0244-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0244-x