Abstract

A highly efficient and environmentally friendly graft polymerization method of methyl methacrylate (MMA) onto cotton was performed using an alkyl zinc initiator in an emulsion system. Using this method, a high-molecular weight (Mw > 106) polymer was grafted onto a cotton fiber with a high graft yield at ambient temperature. The grafted cotton fiber was characterized by Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD) and thermogravimetric analysis (TGA). The surface morphologies of the unmodified and grafted cotton were analyzed by scanning electron microscopy (SEM). Furthermore, the grafted cotton produced by this novel method that involved modifying the surface of the cotton improved its compatibility with a number of organic solvents.

Similar content being viewed by others

Introduction

Recently, due to environmental crises, the demand for replacing synthetic materials with natural resources has increased. Cellulose is an organic raw material that has received widespread attention, and cotton, which is composed of 95% cellulose, is a commonly used, natural, and inexpensive material. Due to its comfort and breathability, cotton is extensively used in the manufacture of personal care items, bedding products, clothing, and underwear. However, cotton also suffers from various inherent properties includiflammability, low abrasion durability, and poor interfacial compatibility with other matrices. With the development of new technology, the benefits of cotton are no longer limited to its softness and warmth. Nevertheless, novel methods must be developed to further enhance the functional diversity of cotton materials. To expand the number of applications of cotton, its structure and properties can be modified by introducing polymer chains with various functional groups onto the cellulose backbone.

Among the many methods for modifying cotton, graft polymerization can modify the cellulose structure, tailor its properties, and increase the functionality of cotton without compromising the intrinsic properties of cellulose. Grafting functional monomers onto cotton has been extensively studied to improve various aspects. The flammability of cotton is a critical issue that has been specifically considered for various applications. By grafting phosphorus-, nitrogen-, and sulfur-containing monomers [1], a binary mixture of acrylonitrile and 4-vinyl pyridine [2] can improve the flame retardant property of cotton. It is generally believed in the clothing industry that increased water vapor permeability signifies higher comfort of the fabric. Recently, due to potential industrial applications, superhydrophobic cotton surfaces have been generated by grafting polystyrene [3] and octadecylamine [4]. By grafting nonfluorinated methacrylate [5], waterproof, windproof and breathable cotton fabrics have been prepared. The textile industry has stringent requirements for the mechanical properties of cotton including abrasion resistance and tensile properties. The physical and mechanical properties of cotton can be greatly improved via graft modification with glycidyl methacrylate [6]. In addition, antimicrobial properties can be imparted to the grafted cotton by bonding with L-cysteine [7] and graft acrylamide [8], and monochlorotriazine-β-CD [9] can improve the dyeability of cotton. The grafting of vinyl monomers on cotton has been studied in detail. As the most widely used monomer, methyl methacrylate (MMA) has been used by many researchers for grafting onto cellulose. Detailed studies of MMA grafting to cellulose using various initiators, such as UV light [10, 11], ionizing conditions [10], azobisisobutyronitrile (AIBN), ammonium persulfate (APS) [12, 13], Fe2+ ion and N-bromosuccinimide (NBS) [14], have been reported [15]. However, the currently used grafting methods often have many disadvantages, such as low grafting efficiency, high energy consumption, short grafted polymer chains, and poor recyclability of the organic solvents used in the grafting process, which leads to environmental pollution. In most cases, the reaction has been performed at 60 °C or higher using ordinary radical initiators [3, 16]. Therefore the development of a grafting method that is efficient, convenient, and does not require the use of an organic solvent is important.

Previously, we reported a novel organic zinc complex (diethyl(1,10-phenanthroline N1,N10)zinc, (Phen-DEZ)) and investigated its initiation behavior [17,18,19]. As a highly reactive initiator, Phen-DEZ rapidly initiated homopolymerization and graft polymerization at room temperature without additional heating or other stimulation. However, this novel initiator has not been studied for the efficient initiation of graft polymerization in an emulsion system. In emulsion systems, polymers with high molecular weights can be obtained. Therefore, graft modification of cotton in an emulsion system could enable uniform grafting of long polymer chains onto the cotton surface and improve the compatibility of the modified cotton with other synthetic polymers. To the best of our knowledge, no studies have focused on grafting MMA onto cotton in an emulsion system using Phen-DEZ as an initiator. In this study, the graft polymerization of MMA onto cotton was performed under various conditions, and FTIR, XRD, TG and SEM analyses were performed on the original and grafted cotton.

Experimental

Materials

The cotton (gossypium herbaceum) that was provided by Yuuan Gardens (Tenri, Nara, Japan) was purified by extraction with hot boiling acetone for 5 h. MMA was purchased from Wako Pure Chemical Industry, Ltd., and the stabilizer was removed according to previously published methods [19]. Diethylzinc was supplied by Nippon Aluminum Alkyls, Ltd., and 1,10-phenanthroline, chloroform (CHCl3), methanol, acetone, magnesium sulfate, sodium dodecyl sulfate (SDS), and sodium hydroxide were purchased from Wako Pure Chemical Industry, Ltd. Ultrapure distilled water was obtained using a Milli-Q laboratory system.

Equipment and instrumentation

The FTIR spectra of the modified and unmodified cotton were recorded using a Jasco FT/IR-480 Plus spectrometer from 400 to 4000 cm−1. The surface morphology of the cotton was observed by SEM (Hitachi SU-8020). The molecular weight of the free polymer was determined using size-exclusion chromatography system (SEC, Jasco PU-2080 Plus pump) that was equipped with an RI-2031 Plus Intelligent RI detector. CHCl3 was used as the eluent (40 °C), and X-ray diffraction (XRD) patterns were recorded under ambient conditions with Cu-Kα radiation (X-ray wavelength: 1.5418 Å) in steps of 0.02˚ over a 2θ range of 5–70° using a Rigaku Smartlab diffractometer. The thermal behaviors of the prepared cotton samples were analyzed by TGA (Hitachi, STA 7200 RV) in air at a heating rate of 10 °C /min. The surface morphology of the cotton fiber was examined using field emission (FE)-SEM (Hitachi SU-8020).

Synthesis of Phen-DEZ

The synthesis method for Phen-DEZ was the same as that employed in the literature [17]. A certain amount of DEZ was slowly injected into a mixture of 1,10-phenanthroline and hexane. The reaction was performed at 23 °C for 24 h. The reddish-orange Phen-DEZ solid was collected by filtration and dried in vacuo. All processes were performed under an argon atmosphere.

Preparation of modified cotton fabrics

Grafted cotton was prepared via emulsion polymerization. The cotton (50 mg), SDS (180 mg), and 7.5 mL of water were added to a 50 mL flask and stirred. After the materials were sufficiently blended, the flask was degassed using two freeze-pump-thaw cycles. Then, a defined amount of monomer (2.5 mL) was added to the flask. Continuous stirring of the mixture was performed for 1 h, and 80 mg of Phen-DEZ was added to the stable emulsion system under an Ar flow. Polymerization was performed at room temperature (23 °C) for 24 h. For comparison, graft polymerization in a solution system with toluene as the solvent and a bulk system were also prepared. The cotton (50 mg), Phen-DEZ (80 mg), and 1.5 mL of toluene were added to a 20 mL flask and stirred. The mixture was gently stirred while MMA (2 mL) was slowly added followed by stirring for 24 h. The grafted cotton was extracted to a constant weight with chloroform and vacuum dried. The extract was poured into methanol, and the recovered homo-PMMA was dried and weighed.

The graft yield (Yg) was calculated using the weight increase in the original cotton according to the following equation:

where m0 is the weight of the original cotton sample and m1 is the weight of the cotton after graft polymerization.

Results and discussion

Graft polymerization was performed at room temperature (23 °C) in an emulsion system with a constant emulsifier concentration. Cotton is compatible with water, resulting in full contact with the initiator and monomer during graft polymerization. The initiator gained access to the cotton fabric via the many reactive sites available for graft polymerization. For comparison with the emulsion polymerization method, bulk and solution graft polymerizations were also performed. The monomer to initiator ratio was fixed at 90:1, and the other conditions were identical to those used for emulsion polymerization.

Table 1 shows the changes in the grafting yield and molecular weight of the free PMMA as the monomer to initiator ratios varied. The graft yield with a Phen-DEZ/MMA ratio of 1:500 was 16.7%, and when the ratio increased to 1:180 and 1:90, the graft yields were 69.7 and 89.1%, respectively. However, when the Phen-DEZ/MMA molar ratio was 30:1, the graft yield decreased to 35.3%. Therefore, only a certain initiator concentration increases the grafting yield as the initiator content increases. When the initiator concentration is excessively high, the probability of biradical termination increases, and the graft yield decreases. After measuring the molecular weight of the free polymer, the molecular weight of the homopolymer obtained using this method was very high. For example, under the conditions of Entry 3, the weight average molecular weight (Mw) reached 1.53 × 106 Da (polydispersity index = 1.18). When the molecular weight of the polymer exceeds 1 × 106 Da, this polymer corresponds to an ultra-high molecular weight polymer [20, 21]. In general, that the molecular weight of a grafted polymer is close to that of the free polymer [3, 22]. Therefore, the use of Phen-DEZ as an initiator in an emulsion system can result in higher grafting yields and grafted polymer chains with high molecular weights.

For comparison with the emulsion system, we also grafted cotton in a solution system with toluene as the solvent and a bulk polymerization system. Based on a comparison of the data in Table 1 (Entries 3, 5, and 6), the cotton modified in the emulsion system exhibited a higher graft yield. This result is most likely due to water being a good swelling medium for cotton that can interrupt hydrogen bonding and increase the accessibility of the cotton fiber to the grafted monomer [23]. Therefore, emulsion graft polymerization, which is environmentally friendly and efficient, is suitable for cotton surface modification while depositing long polymer chains on the surface. Table 1 shows that when the monomer to initiator ratio is 90:1, the graft yield is the highest among all tested conditions. Therefore, the samples prepared under these conditions were used for subsequent measurements.

Figure 1 shows the FTIR spectra of the pure and modified cotton samples. Figure 1a, b show the same cotton characteristic FTIR peaks [24, 25]. The band at 3000–3500 cm−1 is attributed to the stretching vibration of –OH, and the band at 2900 cm−1 is due to the stretching vibration of C-H. The weak absorption at 2852 cm−1 is associated with the symmetric stretching of -CH2. The bands at 1429 and 1318 cm−1 are assigned to C-H wagging. The bands at 1161 and 1110 cm−1 correspond to C–O–C asymmetric stretching. The band at 1032 cm−1 is characteristic of C–O stretching, and the band at 1058 cm−1 is attributed to asymmetric in-plane ring stretching.

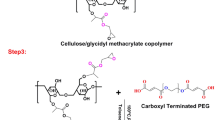

As shown in Fig. 1b, all characteristic absorption peaks of PMMA were observed [26] including the peak at 1732 cm−1 that is due to the C=O stretching vibration of the ester groups of grafted PMMA [27]. The bands at 2994 and 2950 cm−1 correspond to C–H bond stretching vibrations of the –CH3 and –CH2– groups. The distinct band at 753 cm−1 is assigned to the α-methyl group vibration. The bands at 1151 and 1246 cm−1 correspond to the C–O–C stretching vibration. However, all these peaks are absent in the pure cotton samples, indicating that MMA was successfully grafted onto the cotton fabric. The grafting reaction process is considered to be grafting-from. The initiator attached to the cotton surface and formed an active site. Then, the monomer was connected to the cotton one by one and gradually grew to form a polymer brush. The reaction scheme for the graft polymerization process is shown in Scheme 1.

The XRD spectra of the natural (pure) and grafted cotton are shown in Fig. 2. The XRD patterns of the cotton before and after graft modification display diffraction peaks at 2θ = 14.9°, 16.6° and 22.7°, arising from the typical structure of native cotton fibers [23, 28]. The characteristic peak positions of the two curves are identical. However, the peak intensity is significantly reduced by graft modification. Because cellulose is semicrystalline, the hydroxyl groups in the amorphous regions are modified, resulting in a decrease in the crystallinity percentage. The degree of crystallinity of pristine and modified cotton was calculated from the XRD profiles. Based on a comparison of the results, the crystallinity of the grafted cotton decreased from 68.7 to 49.3%. This result indicates that the degree of crystallinity of the cotton fibers change upon graft modification.

The thermal stabilities of the pure cotton and grafted cotton samples were assessed by TGA in air, and the results are shown in Fig. 3. The weight loss during the initial stage was attributed to the loss of water and solvent remaining on the surface and in inner cavities of the cotton fiber. When the temperature increased to >300 °C, both the pure and modified cotton started decomposing. The initial decomposition temperatures and behavior of the two cotton samples were similar. However, when the temperature increased to >480 °C, the unmodified cotton completely decomposed but the grafted cotton still retained approximately 8% of its original weight. This result is most likely due to the amount of grafted PMMA on the cotton surface being relatively large, resulting in a uniform coverage. The grafted PMMA and cotton start to decompose with increasing temperature but the grafted PMMA layer protects the cotton during decomposition. Therefore, when the temperature increased to 500 °C, 8% of the residue remains.

The surface of pure cotton and cotton-g-PMMA was examined by SEM (Fig. 4). As shown in Fig. 4a, pure cotton exhibits a texture with striations and nanogrooves [29]. In comparison to the images of the grafted cotton, the texture of the cotton disappears after surface modification when the surface is covered with a rough polymer film. This significant morphological change indicates that MMA was grafted onto the cotton by the Phen-DEZ initiator.

Because the cotton used in the experiment is a fiber, a uniform and flat sample is difficult to prepare. Therefore, the cotton before and after modification cannot be used to measure the contact angle. To study the surface properties of the cotton fiber after modification, two cotton balls (raw cotton and grafted cotton) were added to a bottle of water and a mixture of pure water and MMA monomer, shaken, and allowed to stand until the layers separated. The significant differences in wettability are shown in Fig. 5 and Fig. 6. As shown in Fig. 5, the pure cotton is immersed in water, and the grafted cotton floated on the surface of the water. Furthermore, as shown in Fig. 6, the unmodified cotton sinks to the water layer at the bottom of the bottle, indicating the hydrophilicity of the cotton fiber. The grafted cotton is completely immersed in the MMA solution because the grafted cotton surface is covered with a layer of PMMA, making its dispersion in MMA more favorable. Based on these results, surface graft modification changed the surface properties of cotton, improving its compatibility with polymers.

Conclusion

A highly efficient, green, and nonpolluting method for the surface modification of cotton has been developed. MMA was grafted onto cotton fibers using Phen-DEZ as an initiator in an emulsion system at ambient temperature. This method is an environmentally friendly process for the surface modification of cotton. FTIR, XRD, TG, and SEM measurements confirmed that the graft polymerization was successful. By comparing the compatibility of the grafted and unmodified cotton samples in water and MMA solvent, the modified cotton exhibited an affinity for the MMA solvent. The hydrophilicity of the modified cotton decreased, and the grafted polymer chains on the cotton increased its compatibility with polymeric materials.

References

Verma SK, Kaur I. Gamma-induced polymerization and grafting of a novel phosphorus, nitrogen, and sulfur-containing monomer on cotton fabric to impart flame retardancy. J Appl Polym Sci. 2012;125:1506–12.

Kaur I, Bhati P, Sharma B. Antibacterial, flame retardant, and physico-chemical properties of cotton fabric graft copolymerized with a binary mixture of acrylonitrile and 4-vinylpyridine. J Appl Polym Sci. 2014;131:40415/1–40415/14.

Li Y, Li Q, Zhang C, Cai P, Bai N, Xu X. Intelligent self-healing superhydrophobic modification of cotton fabrics via surface-initiated ARGET ATRP of styrene. Chem Eng J. 2017;323:134–42.

Yu Y, Wang Q, Yuan J, Fan X, Wang P, Cui L. Hydrophobic modification of cotton fabric with octadecylamine via laccase/TEMPO mediated grafting. Carbohyd Polym. 2016;137:549–55.

Wu J, Li J, Wang Z, Yu M, Jiang H, Li L, et al. Designing breathable superhydrophobic cotton fabrics. RSC Adv. 2015;5:27752–8.

Effenberger F, Schweizer M, Mohamed WS. Elucidation of the nanoparticle effect on the grafting of vinyl monomers onto cotton fabric. J Appl Polym Sci. 2009;113:492–501.

Nogueira F, Vaz J, Mouro C, Piskin E, Gouveia I. Covalent modification of cellulosic-based textiles: A new strategy to obtain antimicrobial properties. Biotechnol Bioproc E. 2014;19:526–33.

Maulik SR, Das D, Bhattacharya SC. Modification of cotton fabric with acrylamide in the presence of K2S2O8 for improving dyeability of natural dyes. J Text I. 2011;102:131–9.

Ibrahim NA, E-Zairy WR, Eid BM. Novel approach for improving disperse dyeing and UV-protective function of cotton-containing fabrics using MCT-β-CD. Carbohyd Polym. 2010;79:839–46.

Garnett JL, Ng L, Viengkhou V. Grafting of methyl methacrylate to cellulose and polypropylene with UV and ionizing radiation in the presence of additives including CT complexes. Radiat Phys Chem. 1999;56:387–403.

Vicini S, Princi E, Luciano G, Franceschi E, Pedemonte E, Oldak D, et al. Thermal analysis and characterisation of cellulose oxidised with sodium methaperiodate. Thermochim Acta. 2004;418:123–30.

Nishioka N, Kosai K. Homogeneous graft copolymerization of vinyl monomers onto cellulose in a dimethyl sulfoxide-paraformaldehyde solvent system. I. Acrylonitrile and methyl methacrylate. Polym J. 1981;13:1125–33.

Nishioka N, Matsumoto K, Kosai K. Homogeneous graft copolymerization of vinyl monomers onto cellulose in a dimethyl sulfoxide-paraformaldehyde solvent system. II. Characterization of graft copolymers. Polym J. 1983;15:153–8.

Zahran MK. Graft copolymerization of methyl methacrylate and other vinyl monomers onto cotton fabric using ferrous cellulose thiocarbonate-N-bromosuccinimide redox initiation system. J Appl Polym Sci. 1996;62:49–57.

Zahran MK, Mahmoud RI. Peroxydiphosphate-metal ion-cellulose thiocarbonate redox system-induced graft copolymerization of vinyl monomers onto cotton fabric. J Appl Polym Sci. 2003;87:1879–89.

Klimov VV, Bryuzgin EV, Le MD, Zelenova EA, Nguyen TH, Navrotskii AV, et al. An investigation of the hydrophobic property stability of grafted polymeric coatings on a cellulose material surface. Polym Sci Ser D Glues Seal Mater. 2016;9:364–7.

Zhao C, Okada H, Sugimoto R. Polymerization of styrene in aqueous system using a diethylzinc and 1, 10-phenanthroline complex. Polymer. 2018;154:211–7.

Zhao C, Okada H, Sugimoto R. Diethyl(1, 10-phenanthroline-N1, N10) zinc initiated grafting of styrene on polypropylene/ polyethylene. Bull Chem Soc Jpn. 2018;91:1576–8.

Zhao C, Okada H, Sugimoto R. Surface modification of polypropylene with poly(methyl methacrylate) initiated by a diethylzinc and 1, 10-phenanthroline complex. React Funct Polym. 2018;132:127–32.

Kitayama Y, Okubo M. A synthetic route to ultra-high molecular weight polystyrene (>106) with narrow molecular weight distribution by emulsifier-free, emulsion organotellurium-mediated living radical polymerization (emulsion TERP). Polym Chem. 2016;7:2573–80.

Okamoto S, Ito S, Ando K, Mouri M, Ikeda A, Hasegawa H, et al. Gelation of photonic microdomain structures formed in semi-dilute solutions of ultra-high-molecular-weight polystyrene-b-polybutadiene with various polybutadiene contents. Mater Sci Eng. 2010;14:012008/1–012008/14.

Matyjaszewski K, Dong H, Jakubowski W, Pietrasik J, Kusumo A. Grafting from surfaces for “everyone”: ARGET ATRP in the presence of air. Langmuir. 2007;23:4528–31.

Parikh DV, Thibodeaux DP, Condon B. X-raycrystallinity of bleached and crosslinked cottons. Text Res J. 2007;77:612–6.

Jiang B, Chen Z, Sun Y, Yang H, Zhang H, Dou H, et al. Fabrication of superhydrophobic cotton fabrics using crosslinking polymerization method. Appl Surf Sci. 2018;441:554–63.

Lin J, Zheng C, Ye WJ, Wang HQ, Feng DY, Li QY, et al. A facile dip-coating approach to prepare SiO2/fluoropolymer coating for superhydrophobic and superoleophobic fabrics with self-cleaning property. J Appl Polym Sci. 2015;132:41458/1–41458/9.

Duan G, Zhang C, Li A, Yang X, Lu L, Wang X. Preparation and characterization of mesoporous zirconia made by using a poly(methyl methacrylate) template. Nanoscale Res Lett. 2008;3:118–22.

Dokolas P, Qiao GG, Solomon DH. Graft copolymerization studies. III. Methyl methacrylate onto polypropylene and polyethylene terephthalate. J Appl Polym Sci. 2002;83:898–915.

Palama IE, D’Amone S, Arcadio V, Caschera D, Toro RG, Gigli G, et al. Underwater Wenzel and Cassie oleophobic behavior. J Mater Chem A. 2015;3:3854–61.

Cortese B, Caschera D, Padeletti G, Ingo GM, Gigli G. A brief review of surface-functionalized cotton fabrics. Surf Innov. 2013;1:140–56.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, C., Okada, H. & Sugimoto, R. Chemical modification of cotton by methyl methacrylate via emulsion polymerization. Polym J 51, 1023–1028 (2019). https://doi.org/10.1038/s41428-019-0225-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0225-0