Abstract

Different kinds of flame retardant and toughened glass fiber (GF)-reinforced polycarbonate composites were fabricated through melt extrusion blending and injection molding. Methacrylate-butadiene-styrene (MBS), styrene-maleic anhydride (SMA), ethylene methylacrylate (EMA), and silicon acrylate rubber (SiR) were used as toughness modifiers. Two kinds of aryl phosphorus, namely, triphenyl phosphate (TPP) and resorcinol bis(diphenyl phosphate) (RDP), and oligomeric siloxane-containing potassium dodecyl diphenylsulfone sulfonate (SiKSS) were adopted as flame retardants (FRs). The V-notched Izod impact test revealed that SiR could significantly improve the toughness of GF-reinforced polycarbonate composites. The flame retardancy of FR PC/GF/SiR composites was investigated by the UL-94 vertical burning test. The FR PC/GF/SiR composites showed good flame retardancy with a V0 rating when 9 wt% TPP, 6 wt% TPP/RDP, or 0.2 wt% SiKSS was added. The effect of the FRs on the mechanical properties, rheological properties and heat deflection temperature of PC/GF/SiR composites was also investigated.

Similar content being viewed by others

Introduction

Polycarbonate (PC) possesses a series of excellent advantages, including good electrical insulation, optical transparency, heat resistance, and impact strength. It has become a desirable engineering plastic in various areas, such as electrical and electronic applications, optical equipment, and the construction and aerospace industries. To replace conventional high-density metals in load-bearing applications, fiber-reinforced PC composites with high specific strength and stiffness have drawn extensive attention from researchers and engineers [1].

Unlike continuous fiber composites, short fiber-reinforced polymer composites can be easily and rapidly manufactured with low cost and intricate shapes. To strengthen PC, short carbon fibers [1, 2], glass fibers [3,4,5], basalt fibers [6], and pineapple leaf fibers [7] have been employed. However, the admirable toughness or impact strength of PC would generally be sacrificed by the relatively brittle fibers. On the other hand, virgin PC (V2 rating in the UL94 vertical flame test) and fiber-reinforced PC composites cannot satisfy the requirements of fire safety in electronic applications and construction. To our knowledge, there are few references reporting improvements in the toughness and flammability of fiber-reinforced PC composites, let alone considering these two factors simultaneously.

To reduce notch sensitivity and improve processability, PC is often blended with elastomers such as styrene–ethylene–butylene–styrene block copolymer (SEBS) [8], styrene–ethylene–butylene–styrene grafted maleic anhydride (SEBS-g-MA) [9], core–shell rubbers [10], methacrylate-butadiene-styrene (MBS) [11], styrene-maleic anhydride (SMA) [12], and epoxidized ethylene propylene diene rubber (eEPDM) [13].

Although inorganic fibers have good flame retardancy, flame retarding of fiber-reinforced PC composites is difficult to reach due to the “candlewick effect” [5, 14, 15]. Therefore, incorporating flame retardants (FRs) into PC is necessary to reduce its combustibility. Broadly developed halogen-based FRs efficiently enhance the flame retardancy of PC. However, due to their negative effect on the environment and public health, the use of halogen-containing FRs has been gradually limited [15, 16]. As an alternative to halogen-based FRs, halogen-free FRs have attracted much attention, including phosphorus-based FRs [17, 18], nitrogen-based FRs [19], silicon-based FRs [20], sulfur-based FRs [21,22,23], boron-based FRs [24], and their hybrids [15]. The most popular FRs, such as triphenyl phosphate (TPP) and resorcinol bis(diphenyl phosphate (RDP), not only have a stabilizing effect but also delay the degradation process, where an alcoholysis reaction with the alcohol products from the decomposed PC occurs during thermal degradation [25].

In the present study, toughening and flame retarding are simultaneously taken into account for glass fiber-reinforced PC composites. Four impact modifiers (MBS, EMA, SMA, and a silicone acrylate copolymer rubber) and three flame retardants (FRs) (TPP, RDP, and an organic silicon-containing sulfone sulfonate salt) are employed to reduce notch sensitivity and combustibility.

Materials and methods

Materials

Polycarbonate (110) was provided by the CMMT Materials Technology Company (China), and alkali-free short glass fiber (ECS307-3) of 13 μm in diameter and 3 mm in length was supplied by Chongqing Polycomp Company (China). To explore the chemical bond and interfacial interaction between the GF and the resin matrix, as verified in [26, 27], the GF surface was treated with silane coupling agent KH550 consisting of 3-aminopropyltriethoxysilane (APS) provided by Shanghai Yaohua Chemical Plant (China).

Four kinds of impact modifiers were purchased: EMA (1125AC) provided by DuPont Company (USA), MBS (EM500) from LG Chem (Korea), and SMA (SMA703) and silicon acrylate rubber (SiR) (205H) from Guangdong Eversun Company (China). The last of the four types of rubber is based on silicone and poly(n-butyl acrylate) with a styrene-acrylonitrile-maleic anhydride terpolymer shell.

The three FRs are TPP (UN3077) sourced from Lanxess (Germany); RDP supplied by Zhejiang Wansheng Co., Ltd. (China); and an oligomeric siloxane containing potassium dodecyl diphenylsulfone sulfonate (SiKSS) (FR-200N) purchased from Guangdong Eversun Company (China).

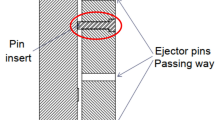

Sample preparation

All materials were sufficiently dried at a suitable temperature. PC, GF, the flame retardant and the toughness modifier were premixed at room temperature according to the predescribed weight percent, and then the mixtures were melt-extruded and repelletized through a SHJ-30 twin-screw extruder (Nanjing Jieya Extrusion Equipment Co., Ltd). The temperature profile was controlled at 250, 260, 270, 280, 290, 280, and 270 °C from the feeder to the extruder’s nozzle. The rotation speed of the twin-screw extruder was 37 rpm. To prepare standard samples for mechanical property measurements, the extruded pellets were redried and shaped into tensile, flexural and Izod impact bars by an XL-680 injection molding machine at temperatures ranging from 270 to 285 °C.

In all formulations, PC was reinforced with 10 wt% GF.

Mechanical tests and characterization

Mechanical tests

Tensile tests and three-point bending tests were carried out on a CMT2404 universal testing machine at room temperature to obtain the tensile/flexural strength and modulus. The tensile samples were of a dumbbell shape and is 165 mm in length, 13.5 mm in width and 3.36 mm in thickness. The flexural specimens were flat and rectangular with a thickness of 3.36 mm and a gauge of 50 mm. The crosshead speeds are 5.0 and 2.0 mm/min for the tension and flexion tests, respectively.

To determine the toughness, an XC-5.5D impact tester was used to perform the Izod impact test on the sample with dimensions of 63.5 × 10.16 × 6.35 mm3 and a V-notch of 2.54 mm in depth.

Melt flow rate (MFR) test

The MFR is tested by a melt flow indexer (MFI-1211) at 265 °C with a preset load of 3.8 kg in 10 min.

Heat deflection temperature (HDT) test

At the HDT, the sample can be deflected to 0.418 mm by a preload of 255 g under a heating rate of 120 °C/h. The device used in this study is an HDT/V-2003 HDT tester.

Morphological analysis

A JSM-6610LV scanning electron microscope (SEM) was employed to observe the morphology of the fractured surface of the impacted sample. In the test, the surface needs to be electrically conductive through coating with a gold layer.

Combustion test

The burning samples were injected in a shape of 130 × 13 × 3.2 mm3 and burned vertically in a UL94 combustion test chamber (British FTT). A calibrated flame is applied to the bottom edge of the vertically supported sample for 10 s, and the after-flame time is noted as t1. When after flaming ceases, the flame is reapplied for an additional 10 s, and the after-flame time is recorded as t2.

Results and discussion

Effect of impact modifiers on the mechanical properties of PC/GF composites

The tensile strength, flexural strength, flexural modulus and impact strength of the 10 wt% GF-reinforced PC composites with and without the addition of the impact modifiers are tested and presented in Table 1; Fig. 1.

Effect of MBS

Comparing the mechanical properties of PC/GF composites with and without MBS revealed that the tensile and bending strengths were slightly decreased by the addition of MBS due to its elastomeric nature. When 6 wt% MBS was mixed into the system, the tensile strength, bending strength and modulus were decreased by 2.3%, 7.98%, and 15.2%, respectively.

The Izod impact strength of the glass fiber-reinforced PC composites increased slightly when the MBS weight percent was 2% but grew significantly when the content became larger. When the MBS amount was 6 wt%, the impact strength increased by 69.6%. MBS is known as a typical core–shell impact modifier containing an elastomeric core of styrene-butadiene rubber and a glassy shell of styrene and methyl methacrylate (MMA) copolymer. Because of the good compatibility between MMA and PC, the rubber phases dispersed in the matrix, and a “sea-island” structure was formed. However, the interfacial adhesion between MMA and PC without chemical bonding is relatively weak. The fracture originated from the interface and caused separation between the dispersed phase and matrix. Therefore, cavities were produced at the interface to resist crack propagation and hence led to improved toughness [28,29,30].

Effect of EMA

With increasing EMA fraction, the tensile strength, the bending strength and modulus were continuously decreased. The addition of 2 and 6 wt% EMA diminished the tensile strength by 13.0% and 29.6% and the bending strength by 13.9% and 22.4%, respectively. EMA elastomers dispersed in matrix and acted as stress concentrators and thus contused the strength. The modulus was also reduced due to the enhanced mobility of the matrix molecules induced by the EMA elastomer.

Blending with EMA can efficiently improve the toughness of fiber-reinforced PC composites, even with a small content. At an EMA content of 2 wt%, the impact strength increased to 81.86 J/m by 39.7%, resulting from the high energy absorption capability of the flexible molecular chains in EMA. Continuously increasing the amount of EMA had little effect on toughness due to the balance between elastomer toughening and matrix continuity disruption caused by rubber coalescence [31].

Effect of SMA

From Table 1; Fig. 1, we can observe that among the impact modifiers tested, only SMA can increase the tensile strength of the GF-reinforced PC composites due to the rigid group in styrene. With a small amount of SMA added, the flexural modulus of the composite was increased because of the high modulus of the rigid group. When the content reached 6 wt%, the modulus was lowered because the excess SMA formed a third phase, which destroyed the matrix continuity and rigidity.

The Izod impact strength increased by a ratio of 18.7% at an SMA content level of 2 wt%. Continuously increasing the amount of SMA mildly affected the toughness, resulting from the tradeoff between the compatibility of SMA and its brittle performance [32].

Effect of SiR

The addition of the elastomer SiR led to a reduction of the tensile and bending strength, which was clearly shown in Fig. 1. The modulus of GF-reinforced PC composites increased slightly at a SiR weight percent of 2% due to the rigid group in styrene. When the amount was over 2 wt%, the modulus immediately decreased.

When the SiR content was 2 wt%, the Izod impact strength of the PC/GF/SiR blend was greatly enhanced from 58.6 to 147.42 J/m, increasing by 151.57%. Then, the impact strength continuously increased and then remained almost unchanged when the SiR content increased to 4 and 6 wt%. The toughening effect of SiR is derived from the silicone-poly(n-butyl acrylate) core with high toughness [33] and the good compatibility between the styrene-acrylonitrile-maleic anhydride shell and PC matrix [34]. However, large-diameter rubber granules would emerge at a high SiR content and then deteriorate the uniform contribution and energy absorbing capability of the additive.

Figure 2 shows the impact fracture surface morphology of PC/GF/SiR blends observed by SEM.

From Fig. 2, brittle crack propagation can be observed in the flat fracture surface of the PC/10GF composite without adding SiR. After incorporating SiR, the crack was impeded and then branched by the rubbery phase in the matrix, resulting in a scaly fracture morphology. The microvoid regions formed by debonding SiR particles with hemi-spherical bumps, indicating good adhesion between styrene-acrylonitrile-maleic anhydride and the matrix. Therefore, more energy was absorbed in the impact, and the composite was toughened by SiR.

From the above description, one can clearly find that among the impact modifiers tested, SiR was the most efficient additive to improve the toughness of GF-reinforced PC composites, and the optimum dosage was 2 wt% for an excellent comprehensive mechanics performance. Therefore, this formulation was the focus in the following research.

Effect of flame retardants on the combustion performance of PC/GF/SiR composites

Glass fibers have high ignition points and are categorized as nonflammable materials. However, due to the “candlewick” effect, the combustion capability of polymers is promoted [5]. Therefore, flame retardancy in glass fiber-reinforced polymers is difficult to achieve and needs to be improved by adding FRs. A UL94 combustion test was performed to study the flame resistance of PC/GF/SiR composites blended with four additives.

Effect of TPP

The aromatic phosphate TPP is one of most widely used FRs and exhibits fairly good fire retarding performance for polyesters and their blends [35]. TPP was expected to improve the retardancy of the GF-reinforced and SiR-toughened PC composites. The combustion test results for five PC/GF/SiR/TPP specimens are collected in Table 2.

From the above table, the total after-flame time (t1 plus t2 for the 5 specimens) was continuously reduced with increasing TPP content. The flame retarding effect was small when 3 wt% TPP was added. When the weight percent of TPP reached 6%, the after-flame times t1 and t2 obviously decreased, but the UL 94 rating of V1 remained. When the TPP content was 9 and 12 wt%, the flame resistance was improved enormously, and a V0 rating was achieved.

TPP mainly causes flame inhibition in the gaseous phase, delivering PO radicals that replace the hydrogen and hydroxide radicals and thus reduce combustion efficiency. On the other hand, due to the high volatility of TPP, a considerable amount of inflammable gas is produced, diluting the flammable gas or oxygen content around the comburent [5, 34].

Effect of compounded TPP/RDP

Due to the low melt temperature of TPP at approximately 50 °C, it is easily bonded to the wall of the feed port or even blocks the inlet during the injection molding process. Additionally, the high volatility of TPP makes it easy to vaporize in the forming process, which decreases its content in polymers and the FR function. Therefore, a compound of TPP and RDP is employed to obtain a good burning resistance at both low and high temperatures by virtue of the dominant condensed-phase barrier effect of RDP. The mixture ratio between TPP and RDP was set as 2:1 in the present study because of the difficulty in blending liquid RDP. The UL94 vertical burning results of the PC/GF/SiR/TPP/RDP system are presented in Table 3.

Comparing Tables 2 with 3 revealed that the mixed aryl phosphates quickly declined the total after-flame time and had better flame retardancy than TPP by itself. When the total content of TPP and RDP was 6 wt%, a UL 94 rating of V0 was achieved as opposed to the V1 rating when 6 wt% TPP was added. The addition of more TPP/RDP would improve inflammability.

Sticky metaphosphoric decomposition products originating from RDP at high temperature were present on the composite surface, which can insulate the composite matrix from oxygen and heat, repress the volatilization of the inflammable gas, and realize condensed-phase flame resistance. Additionally, the phosphate group promoted dehydration charring on the surface, which can absorb the combustion heat and dilute or prevent inflammable gas. Therefore, the synergistic effect of the gas-phase flame retardancy of TPP at low temperature and the condensed-phase flame retardancy of RDP at high temperature obviously shortened the extinguishing time of the residual flames [36].

Effect of SiKSS

Since the above-mentioned viscous liquid aromatic phosphates would reduce the hydrolysis stability and heat distortion temperature of PC composites [21, 37], the use of sulfonates and silicon-containing FRs has attracted much attention because of their effectiveness in exerting a flame retarding effect on PC at a very low content and environmentally friendly properties. Therefore, an organic silicone containing potassium dodecyl diphenylsulfone sulfonate (SiKSS) was chosen as an FR in this study, and its flame retardancy is shown in Table 4.

From the table, we can observe that the PC composite containing 0.2 wt% SiKSS has the shortest after-flame time and that its UL94 rating was V0. Then, the residual flame went out slowly as the weight percent of SiKSS increased. When the weight fraction was 0.8%, the UL94 rating remained V0. However, the rating turns into V1 when the content was 1.4 and 2%.

The Fries rearrangement of the para-carbonyl group to the ortho position in the PC composites is catalyzed by SO3 generated from the decomposition of the organic metal salts at flame front temperatures, forming cyclic oligomers with phenol end groups that can crosslink with siloxane. Due to the low surface energy of silicon, it can move to the surface of PC composites and oxidize to silicon dioxide during burning. Therefore, a protective char layer can be formed on the surface, holding back the flammable gases and isolating the heat from the unburned matrix, which improves the high-temperature thermal stability of the composite [38]. When much more SiKSS was added, the flame resistance decreased. This effect may be caused by the decomposition of PC at low temperature promoted by SiKSS and the formation of a char layer on the surface, which promotes earlier ignition and the spread of flame [21].

Effect of flame retardants on the mechanical and rheological properties and heat deflection temperature of PC/GF/SiR composites

Unfortunately, most flame retardants will deteriorate the mechanical properties of a polymer while enhancing its flame retardancy. Therefore, the tensile strength, impact strength, flexural strength and modulus of the FR PC/GF/SiR composites are tested, as well as the MFR and HDT.

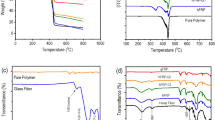

From Fig. 3a, b, showing the tensile and flexural strengths of the FR PC composites, one can clearly see the continuous negative deviation in the strength with increasing aryl phosphate content due to incompatibility between the FRs and polymer. The strengths of the PC composites dramatically declined with the addition of a very low content of SiKSS and then remained unchanged when its content increased. This result is due to the poor compatibility between KSS and PC, resulting in poor interfacial adhesion between KSS and the PC matrix and the cleavage of the macromolecular chains in PC [39].

As Fig. 3c shows, adding relative low-modulus phosphates also decreased the system modulus from 4340 MPa to 3552 and 3469 MPa for 6 wt% TPP and TPP/RDP, respectively. In contrast, the siloxane in SiKSS possessed a higher modulus and enhanced the system modulus to a small degree due to its rigidity.

The Izod impact strength of the blends is depicted in Fig. 3d. It collapsed when TPP or TPP/RDP was added, specifically, from 147.42 J/m to 69.28 and 70.47 J/m when the weight percent was 6%, corresponding to a ratio of 47.0 and 47.8%, respectively. When the composite was compounded with SiKSS, the impact strength decreased first and then recovered, and the smallest value was 100.06 J/m, corresponding to a 32.12% decrease.

The MFR and HDT are two important measures for polymer compounds when gauging their processability and load-carrying capacity at elevated temperatures. Therefore, the MFR and HDT of the FR PC composites were studied, and the measurement results are plotted in Fig. 4.

As Fig. 4a shows, when the composites were blended with aryl phosphates, the MFR vigorously grew and reached 39 g/10 min at a content level of 12%, which is 3.26 times that of the composite without any FR due to the deterioration of the attraction among the molecular chains caused by the low-molecular-weight phosphates. Only a slight growth in MFR can be observed in PC composites with the addition of SiKSS.

Figure 4b, which shows the heat deflection temperatures, reveals that both TPP and TPP/RDP mixtures had inferior effects on the PC/GF/SiR composites because of the poor heat resistance of this type of FR. With the addition of 6 wt% aryl phosphates, namely, TPP and TPP/RDP, the HDT of the composites sharply decreased by a factor of 41.63% and 42.78% from 130.2 to 76.0 °C and 74.5 °C, respectively. However, adding SiKSS caused the system to maintain a relatively high HDT of approximately 120 °C due to its superior ability to bear a given load at elevated temperatures.

In summary, the PC/GF/SiR composite blended with 0.2 wt% SiKSS possessed the best flame resistance and a larger modulus, impact strength and HDT than the PC/GF/SiR composites compounded with 6 wt% aryl phosphates.

Conclusions

The present investigation focused on improvements in both the toughness and flame resistance of GF-reinforced PC composites. The raw materials were melt-extruded and then shaped by injection into test samples. Four elastomers, namely, MBS, SMA, EMA, and SiR, were expected to increase the V-notched Izod impact strength of the composite. PC/GF composites can be efficiently toughened by blending with only 2 wt% SiR, although the addition of SiR reduced the tensile and bending strength more than the addition of MBS and SMA at the same content. The impact strength of the PC/GF/2SiR composite was 3.59 times that of the PC/GF composite due to the highly tough core of silicone-poly(n-butyl acrylate) and the good compatibility between PC and the styrene-acrylonitrile-maleic anhydride shell.

Then, the PC/GF/SiR blend was designed to possess higher inflammability through compounding with three FRs: TPP, a TPP/RDP mixture and SiKSS. Only a small amount (0.2 wt%) of SiKSS made the composite pass a V0 rating in the UL-94 vertical burning test, whereas an aryl phosphorus content of more than 6 wt% was required to achieve the same rating. A protective char layer consisting of silicon-dioxide was formed on the surface during the burning process. It efficiently held back the flammable gases and isolated the heat, thus improving the flame retardancy.

The mechanical properties, MFR and HDT of the FR PC/GF/SiR composites were also considered in the present investigation. The PC/GF/SiR/0.2SiKSS composite with a V0 rating had a greater impact strength, flexural modulus and HDT than the PC/GF/SiR/9TPP and PC/GF/SiR/6TPP/3RDP blends. Regarding the tensile and bending strengths, the same level can be found in PC/GF/SiR/0.2SiKSS and PC/GF/SiR/9TPP, whereas larger values were observed in PC/GF/SiR/6TPP/3RDP. In these three systems, the addition of SiKSS led to the smallest MFR but a higher HDT than PC/GF/SiR composites without any FR. Therefore, it can be generally concluded that SiR and SiKSS blending could be used to improve the toughness and flame retardancy of GF-reinforced PC composites while sacrificing certain levels of tensile and bending strengths.

References

Ozkan C, Karsli NG, Aytac A, Deniz V. Short carbon fiber reinforced polycarbonate composites: effects of different sizing materials. Compos Part B. 2014;62:230–35.

Danyadi L, Gulyas J, Pukanszky B. Coupling of carbon fibers to polycarbonate: surface chemistry and adhesion. Compos Interface. 2003;10:61–76.

Tanimoto Y, Inami T, Yamaguchi M, Nishiyama N, Kasai K. Preparation, mechanical, and in vitro properties of glass fiber-reinforced polycarbonate composites for orthodontic application. J Biomed Mater Res Part B. 2015;103B:743–50.

Biswas KK, Ikueda M, Somiya S. Study on creep behavior of glass fiber reinforced polycarbonate. Adv Compos Mater. 2001;10:265–73.

Wang W, Zhao G, Wu X, Li X, Wang C. Investigation on phosphorus halogen-free flame-retardancy systems in short glass fiber-reinforced PC/ABS composites under rapid thermal cycle molding process condition. Polym Compos. 2015;36:1653–63.

Jang KS. Mechanics and rheology of basalt fiber-reinforced polycarbonate composites. Polymer. 2018;147:133–41.

Threepopnatkul P, Kaerkitcha N, Athipongarporn N. Effect of surface treatment on performance of pineapple leaf fiber–polycarbonate composites. Compos Part B. 2009;40:628–32.

Garhwal A, Maiti SN. Influence of styrene–ethylene–butylene–styrene (SEBS) copolymer on the short-term static mechanical and fracture performance of polycarbonate (PC)/SEBS blends. Polym Bull. 2016;73:1719–40.

Garhwal A, Maiti SN. Fabrication of super tough polycarbonate /styrene-ethylene -butylene-styrene grafted maleic anhydride (SEBS-g-MA) blends: morphological, short term static mechanical and fracture performance interpretation. Polymer. https://doi.org/10.1080/03602559.2018.1466167.

Cho K, Yang JH, Yoon S, Hwang M, Nair S. V. Toughening of polycarbonate: effect of particle size and rubber phase contents of the core-shell impact modifier. J Appl Polym Sci. 2005;95:748–55.

Falk JC, Narducy KW, Cohen MS, Brunner R. Transparent notch width sensitivity improvers for polycarbonate. Polym Eng Sci. 1980;20:763–8.

Hansen MG, Bland DG. Impact strength and melt viscosity of bisphenol-A polycarbonate and styrene-maleic-anhydride copolymer blends. Polym Eng Sci. 1985;25:896–902.

Wang XH, Wang ZG, Jiang W, Liu CH, Yang HD, Zhang HX, Jiang BZ. Toughened blend of polycarbonate and epoxidized ethylene propylene diene rubber. Polymer. 1997;38:6251–3.

Xiao Xiong, Hu Shuang, Zhai Jinguo, Chen Tao, Mai Yongyi. Thermal properties and combustion behaviors of flame-retarded glass fiber-reinforced polyamide 6 with piperazine pyrophosphate and aluminum hypophosphite. J Therm Anal Calorim. 2016;125:175–85.

Wen W, Guo J, Zhao X, Li X, Yang H, Chen JK. Synthesis of an efficient S/N-based flame retardant and its application in polycarbonate. Polymers. 2018;10:441.

Wu N, Lang S. Flame retardancy and toughness modification of flame retardant polycarbonate/acrylonitrile-butadiene-styrene/AHP composites. Polym Degrad Stabil. 2016;123:26–35.

Liu C, Yao Q. Design and synthesis of efficient phosphorus flame retardant for polycarbonate. Ind Eng Chem Res. 2017;56:8789–96.

Zhang WC, Li XM, Guo XY, Yang RJ. Mechanical and thermal properties and flame retardancy of phosphorus-containing polyhedral oligomeric silsesquioxane (DOPO-POSS)/polycarbonate composites. Polym Degrad Stabil. 2010;95:2541–6.

Gao M, Yang S. A novel intumescent flame-retardant epoxy resins system. J Appl Polym Sci. 2010;115:2346–51.

Yuan DD, Yin HQ, Cai XF. Synergistic effects between silicon-containing flame retardant and potassium-4-(phenylsulfonyl) benzenesulfonate (KSS) on flame retardancy and thermal degradation of PC. J Therm Anal Calorim. 2013;114:19–25.

Li ZQ, Yang RJ. Flame retardancy, thermal and mechanical properties of sulfonate-containing polyhedral oligomeric silsesquioxane (S-POSS)/polycarbonate composites. Polym Degrad Stabil. 2015;116:81–7.

Guo JW, Wang YQ, Feng LJ, Zhong X, Yang CF, Liu S, Cui YD. Performance of a novel sulfonate flame retardant based on adamantane for polycarbonate. Polymer. 2013;37:437–41.

Smith GN, Hallett JE, Joseph P, Tretsiakova-McNally S, Zhang T, Blum FD, Eastoe J. Structural studies of thermally stable, combustion-resistant polymer composites. Polym J. 2017;49:711–9.

Martin C, Lligadas G, Ronda JC, Galia M, Cadiz V. Synthesis of novel boron-containing epoxy-novolac resins and properties of cured products. J Polym Sci Part A. 2006;44:6332–44.

JangBN WilkieCA. The effects of triphenylphosphate and recorcinolbis(diphenylphosphate) on the thermal degradation of polycarbonate in air. Thermochim Acta. 2005;433:1–12.

Park SJ, Jin JS. Effect of silane coupling agent on interphase and performance of glass fibers/unsaturated polyester composites. J Colloid Interface Sci. 2001;242:174–9.

Shokoohi S, Arefazar A, Khosrokhavar R. Silane coupling agents in polymer-based reinforced composites: a review. J Reinf Plast Comp. 2008;27:473–85.

Tanrattanakul V, Baer E, Hiltner A, Hu R, Dimonie ZV, EL-Aasser MS, Sperling LH, Mylonakis SG. Toughening polycarbonate with core–shell structured latex particles. J Appl Polym Sci. 1996;62:2005–13.

Chang FC, Wu JS, Chu LH. Fracture and impact properties of polycarbonates and MBS elastomer‐modified polycarbonates. J Appl Polym Sci. 1992;44:491–504.

Wang HL, Tan HS, Li JY, Yu YZ. Phase morphology and dynamic mechanical behavior for MIS toughened polyvinyl chloride. J Appl Polym Sci. 2013;129:3466–72.

Bagotia N, Singh BP, Choudhary V, Sharma DK. Excellent impact strength of ethylene-methyl acrylate copolymer toughened polycarbonate. RSC Adv. 2015;5:87589.

Stretz HA, Cassidy PE, Paul DR. Blends of bisphenol A polycarbonate and rubber-toughened styrene–maleic anhydride copolymers. J Appl Polym Sci. 1999;74:1508–15.

Yanagase A, Ito M. Silicone-based impact modifiers for poly(vinyl chloride),engineering resins, and blends. J Polym Sci Part A. 2004;42:1112–19.

Wildes GS, Harada T, Keskkula H, Paul DR, Janarthanan V, Padwa AR. Synthesis and characterization of an amine-functional SAN for the compatibilization of PC/ABS blends. Polymer. 1999;40:3069–82.

Fu SQ, Guo JW, Zhu DY, Yang Z, Yang CF, Xian JX, Li X. Novel halogen-free flame retardants based on adamantane for polycarbonate. RSC Adv. 2015;5:67054.

Pawlowski KH, Schartel B. Flame retardancy mechanisms of triphenyl phosphate, resorcinolbis(diphenyl phosphate) and bisphenol A bis(diphenyl phosphate) in polycarbon-ate/acrylonitrile–butadiene–styrene blends. Polym Int. 2007;56:1404–14.

Tang Z, Li Y, Zhang YJ, Jiang P. Oligomeric siloxane containing triphenylphosphonium phosphate as a novelflame retardant for polycarbonate. Polym Degrad Stabil. 2012;97:638–44.

Ni P, Fang Y, Qian L, Qiu Y. Flame-retardant behavior of a phosphorus/silicon compound on polycarbonate. J Appl Polym Sci. 2018;135:45815.

Zhu DY, Guo JW, Xian JX, Fu SQ. Novel sulfonate-containing halogen-free flame-retardants: effect of ternary and quaternary sulfonates centered on adamantane on the properties of polycarbonate composites. RSC Adv. 2017;7:39270.

Acknowledgements

This project is supported by the National Natural Science Foundation of China (Grant No. 51705291, 51675307) and the Jiangsu Province Science Foundation for Youths, China (BK20160371).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lin, J., Li, J., Li, X. et al. Flame retardancy and toughening modification of glass fiber-reinforced polycarbonate composites. Polym J 51, 657–665 (2019). https://doi.org/10.1038/s41428-019-0181-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0181-8