Abstract

In this work, a benzoxazine bridged by a flexible polysulfide rubber chain (BLP) was conveniently prepared through the ring-opening addition of thiol-capped liquid polysulfide rubber (LP-3) and bisphenol-A/aniline-based benzoxazine (B-a). The structure and composition of BLP were investigated by nuclear magnetic resonance (NMR) and Fourier transform infrared (FT-IR) spectra, and the structure and properties of polymerized BLP (PBLP) were characterized by FT-IR, differential scanning calorimetry (DSC), dynamic mechanical analysis (DMA), and thermogravimetric analysis (TGA). BLP was a highly viscous fluid at room temperature with a low curing temperature. After curing, most of the polysulfide chains were incorporated into the crosslinked PBLP through covalent bond linkages. PBLP presented excellent flexibility, outstanding thermal stability, and an extremely high char yield. The glass transition temperature (Tg) of PBLP was 80 °C, the 5% weight-loss temperature (T5%) was 270 °C, and the char yield at 800 °C was 33%.

Similar content being viewed by others

Introduction

In recent years, benzoxazine, a fast-developing thermosetting resin, has mainly been synthesized from phenols, primary amines, and formaldehyde [1,2,3,4,5]. As a promising member of the thermosetting resin family, polybenzoxazine is increasingly catching attention from both industry and academia because of its attractive properties, including an extremely high modulus, a high glass transition temperature above its curing temperature, a high char yield, and a low water uptake and dielectric constant (despite containing abundant polar groups), as well as the lack of volatiles released during curing and near-zero shrinkage after curing [6,7,8,9,10]. These characteristics make benzoxazines suitable candidates for high-performance composites, adhesives, flame-retardant materials, and insulation materials.

However, the brittleness of polybenzoxazine limits its application to some extent, and great efforts have been made to improve the toughness of polybenzoxazine. One of the most common and effective strategies is to incorporate a flexible chain into the benzoxazine monomer. For instance, Baranek et al. [11] reported a series of bifunctional benzoxazines bridged by alkyl chains of different lengths to bisphenols, butylamine, and formaldehyde. Allen et al. [12] synthesized different alkyl-chain-bridged benzoxazines from phenol, aliphatic diamines, and formaldehyde. It was found that the introduction of an alkyl chain made it possible to prepare a flexible polybenzoxazine film, and the elongation at break can reach up to 9.7%. Liu et al. [13] prepared a bifunctional benzoxazine containing a siloxane bridge, and this polybenzoxazine can effectively toughen other polybenzoxazines through copolymerization. To date, most of the known benzoxazines bridged by flexible chains have been obtained from bisphenols or diamines with flexible bridges through the Mannich condensation, which greatly restricts the diversity of flexible chain-bridged benzoxazines due to the limited reactants.

To enrich the number of sources of benzoxazines, we made an effort to prepare polysulfide rubber chain-bridged benzoxazine (BLP) by simply reacting a thiol-capped liquid polysulfide rubber (LP-3) and a commercial bisphenol-A/aniline-based benzoxazine (B-a) through the ring-opening addition of the thiol and benzoxazine [14]. In this work, the reaction between LP-3 and B-a was monitored, and the properties of the resulting thermoset were characterized.

Experimental procedures

Measurements

Fourier transform infrared (FT-IR) spectroscopy was performed on a TENSOR-27 FT-IR spectrometer (BRUKER, Germany) at room temperature in the range of 4000–400 cm−1. FT-IR spectra were obtained by casting a thin film on a KBr plate for the liquid samples or using the KBr pellet technique for the solid samples.

Nuclear magnetic resonance (NMR) spectra were recorded on an AVANCE 400 MHz NMR spectrometer (BRUKER, Germany) using deuterated dimethyl sulfoxide (DMSO-d6) or deuterated chloroform (CDCl3) as the solvent and tetramethylsilane (TMS) as the internal reference.

Differential scanning calorimetry (DSC) was performed on an SII EXSTAR6000-DSC6220 instrument (SEIKO, Japan) in a N2 flow of 50 mL min−1 at a heating rate of 10 °C min−1.

Thermogravimetric analysis (TGA) was carried out on a STA449F3 instrument (NETZSCH, Germany) at a heating rate of 10 °C min−1 in a N2 flow of 20 mL min−1.

Dynamic mechanical analysis (DMA) was performed on a Q800 instrument (TA, America) in the double-cantilever mode at a frequency of 1 Hz and a heating rate of 5 °C min−1 in air. The dimensions of the sample were 60 mm × 12 mm × 2.5 mm.

Materials

Bisphenol/aniline-based benzoxazine (B-a, industrial grade) was purchased from Chengdu Coryes Polymer Science and Technology Co., Ltd. (Chengdu, China). Thiol-capped liquid polysulfide rubber (LP-3, industrial grade) with an average molecular weight of 1000 was provided by Toray (Japan). THF was obtained from Beijing Chemical Works (Beijing, China). All these materials were used without further purification.

Synthesis and cure of polysulfide rubber chain-bridged benzoxazine (BLP)

Into a 100 mL round bottom glass flask equipped with a mechanical stirrer, 20 mmol B-a was added and heated at 120 °C. After degassing, 10 mmol LP-3 was added, and the mixture was stirred for 1 h under vacuum. The resultant was poured into a preheated stainless-steel mold treated with a silicone-based mold-release agent and was cured according to the procedure of 140 °C for 2 h, 160 °C for 2 h, and 180 °C for 6 h.

The polybenzoxazine film was prepared by sandwiching BLP between two Teflon sheets with a spacer of approximately 0.4 mm and curing according to the above procedure.

Results and discussion

Synthesis and characterization of BLP

The toughness of polybenzoxazine can be significantly improved by the incorporation of a flexible chain in the benzoxazine monomer. Generally, benzoxazines containing flexible chains are prepared from phenols and/or amines through the Mannich condensation. As a result, the diversity of this kind of benzoxazine is limited because of the lack of related raw materials. In this work, utilizing the ring-opening addition between a thiol and benzoxazine [14], we tried to obtain polysulfide rubber chain-bridged benzoxazine (BLP) by simply mixing thiol-capped liquid polysulfide rubber (LP-3) and commercial bisphenol-A/aniline-based benzoxazine (B-a) with a molar ratio of 1:2. The synthetic route of BLP is shown in Scheme 1.

The structure and composition of BLP were characterized by FT-IR and 1H NMR. Figure 1 shows the FT-IR spectra of B-a, LP-3, and BLP. Clearly, the characteristic band of thiols at 2560 cm−1 was not found in the spectrum of BLP. Meanwhile, the characteristic signal of phenolic hydroxyls at 3400 cm−1 was significantly enhanced and the characteristic signal of benzoxazine at 946 cm−1 greatly weakened. These changes indicated the ring-opening addition between LP-3 and B-a.

Figure 2 presents 1H NMR spectra of B-a, LP-3, and BLP. Consistent with the results from FT-IR spectroscopy, the phenolic hydroxyl signal at 9.5–9.2 ppm in the 1H NMR spectrum of BLP obviously strengthened after LP-3 and B-a mixing, indicating the ring-opening of benzoxazine. The results from FT-IR and 1H NMR spectroscopy suggested that the thiol of LP-3 might have completely reacted with B-a.

In fact, the thiol conversion was approximately 70%, as calculated from the peak areas of N–CH2–O and –CH3. This result was reasonable because an earlier report had uncovered the reversible nature of the ring-opening addition between a thiol and benzoxazine with a maximum equilibrium conversion of 80% [14]. As the thiol signal was inherently weak in FT-IR, the remaining thiol in BLP may have been beyond the detection limit, which led to the disappearance of the thiol signal in the FT-IR spectrum of BLP. As a result, BLP may be a mixture of bifunctional benzoxazine BLP2, monofunctional benzoxazine BLP1, and the unreacted B-a and LP-3, as shown in Scheme 2.

Combining the FT-IR and 1H NMR spectroscopy results, there was no doubt that the ring-opening addition between LP-3 and B-a indeed occurred, and the polysulfide rubber chain-bridged benzoxazine can be easily obtained. Even though the prepared BLP still contained unreacted thiol, these remaining thiols can further react with benzoxazine during curing, which is discussed later. Further prolonging the reaction time or increasing the reaction temperature may lead to a higher conversion of thiol, but the risk of gelation through the ring-opening polymerization of benzoxazine is increased.

Curing of BLP

The BLP obtained at room temperature was a highly viscous fluid, as shown in Fig. 3a, indicating its better processability than that of B-a. Figure 3b shows the DSC curves of B-a and BLP. The thermal enthalpy (ΔH) of BLP was 133 J/g, which was significantly lower than that of B-a (264 J/g) because of the dilution effect of the polysulfide rubber chains. Compared with that of B-a, BLP had a substantially lower initial exothermic temperature (Ti = 150 °C) and peak exothermic temperature (Tp = 229 °C). Two factors accounted for the lower curing temperature of BLP. First, the abundant phenolic hydroxyl groups produced from the ring-opening addition of LP-3 and B-a promoted the ring-opening polymerization of benzoxazine. Second, the reaction between the remaining thiols and benzoxazine could also occur at low temperature.

After curing, BLP produced a crosslinked polymer (PBLP). Figure 4 shows the DSC curve of PBLP. No detectable exothermal peak was observed, indicating the complete curing of BLP. The glass transition temperature (Tg) of PBLP was 44 °C, as indicated from the DSC curve.

The FT-IR spectra of BLP, PBLP, and the polymerized B-a (PB-a) are compared in Fig. 5. The characteristic band of benzoxazine at 946 cm−1 for BLP was dramatically weakened after curing, suggesting the ring-opening polymerization of benzoxazine. However, the weak signal at this position persisted in the FT-IR spectrum of PBLP. The residual was attributed to the polysulfide rubber chains because the weak band at 946 cm−1 was also observed in the FT-IR spectrum of LP-3 (Fig. 1). Furthermore, the disappearance of the Ar–O–C band at 1232 cm−1 and the 1,2,4-trisubstituted benzene band at 1500 cm−1 as well as the appearance of the Ar–OH band at 1281 cm−1 and 1,2,4,6-tetrasubstituted benzene at 1485 cm−1 further suggested the ring-opening polymerization of benzoxazine into polybenzoxazine via Mannich bridging [15].

Comparing PBLP with PB-a, the band approximately 1680 cm−1 corresponding to the imine group (–N=CH2) is noteworthy. This band was apparent for PB-a but undetectable for PBLP. The imine group found in polybenzoxazine was related to the specific ring-opening mechanism of benzoxazine, which generated an imine cation intermediate during polymerization [3]. The vitrification during benzoxazine polymerization made the motion of polymer segments difficult and therefore made the reaction of some imine cation intermediates impossible. For BLP, the incorporation of flexible polysulfide rubber chains made the motion of polymer segments significantly easier during polymerization, which facilitated the complete reaction of imine intermediates.

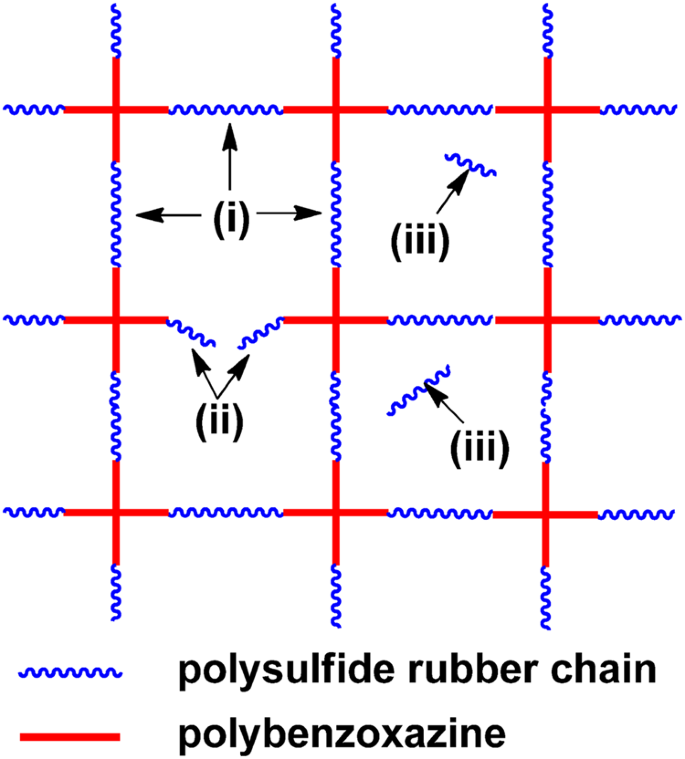

To further detect whether all of the LP-3 was incorporated into the crosslinked network through covalent linkages, 9.50 g PBLP was crushed into small particles and boiled in THF at reflux temperature for 24 h to extract any possible soluble materials. The 1H NMR spectrum of the obtained extract is shown in Fig. 6. The extract showed a similar 1H NMR spectrum to that of LP, implying that some free LP-3 was intermixed in PBLP. Furthermore, weak signals attributed to phenyl were also found in the 1H NMR spectrum, indicating that some products derived from B-a were also soluble. The amount of the extract in PBLP was only 3 wt%, which suggested that most of the LP-3 was incorporated into the crosslinked network by covalent linkages. As a result, there were 3 possible types of polysulfide rubber chains existing in PBLP, including (i) both chain ends linked by covalent bonds, (ii) one chain end linked by a covalent bond, and (iii) a small amount of free LP-3, as shown in Scheme 3.

Properties of PBLP

Figure 7a presents digital photos of a PBLP film with a thickness of 0.4 mm. The PBLP film was red brown, transparent, and extremely flexible. Figure 7b, c shows the DMA curves of PBLP and PB-a, including the storage modulus (E′) and dissipation factor (tan delta). As expected, the introduction of the flexible polysulfide rubber chain led to a significant drop in the Tg and storage modulus. The Tg of PBLP was 80 °C, as indicated by the peak temperature of tan delta. The storage modulus of PBLP at room temperature was 0.9 GPa. Unexpectedly, PBLP showed a higher crosslinking density than that of PB-a based on the lower tan delta peak height of PBLP [16]. Theoretically, the incorporation of long polysulfide rubber chain decreases the crosslinking density. In fact, the flexible polysulfide rubber chain contributed to a more perfect crosslinking network, which was proved by the disappearance of the imine group in PBLP (Fig. 5). The two factors accounted for the increase in the crosslinking density of PBLP.

The thermal stability of PBLP was studied using TGA. Figure 8 shows the TGA and DTG curves of PBLP. It was found that PBLP possessed a good thermal stability with a 5% weight-loss temperature (T5%) of 270 °C. There were two thermal degradation processes, as shown in the DTG curve of PBLP, that corresponded to the degradation of polysulfide rubber chains at 289 °C and polybenzoxazine above 400 °C. Although PBLP contained a high content of polysulfide rubber chains (52 wt%), it showed an extremely high char yield of 33% at 800 °C, which was comparable to that of PB-a (32%).

The thermal properties of PBLP were also compared with those of the typical polybenzoxazines from alkyl chain-bridged benzoxazines (Table 1). The results showed that PBLP had excellent thermal stability and an extremely high char yield, even though it contained the longest flexible chain.

Conclusion

Benzoxazine bridged by a flexible polysulfide rubber chain (BLP) was conveniently prepared through the ring-opening addition of thiol-capped liquid polysulfide rubber (LP-3) and commercial bisphenol-A/aniline-based benzoxazine (B-a). BLP was a highly viscous fluid at room temperature with a low curing temperature. It was found that the thiol of LP-3 cannot react with benzoxazine completely because of the reversibility of the ring-opening addition of a thiol and benzoxazine. However, most of the polysulfide rubber chains were incorporated into the crosslink network by covalent linkages after curing. BLP’s thermoset (PBLP) showed excellent thermal stability (T5% = 270 °C), an extremely high char yield (33% at 800 °C) and outstanding flexibility.

It was concluded that the ring-opening addition of thiols and benzoxazine broadened the origin of polybenzoxazine, and polybenzoxazines with different bridges can be simply obtained from various multifunctional mercaptan compounds and existing multifunctional benzoxazines.

References

Ning X, Ishida H. Phenolic materials via ring-opening polymerization: synthesis and characterization of bisphenol-A based benzoxazines and their polymers. J Polym Sci Part A: Polym Chem. 1994;32:1121–9.

Agag T, Jin L, Ishida H. A new synthetic approach for difficult benzoxazines: preparation and polymerization of 4,4′-diaminodiphenyl sulfone-based benzoxazine monomer. Polymer. 2009;50:5940–4.

Ghosh NN, Kiskan B, Yagci Y. Polybenzoxazines—new high performance thermosetting resins: synthesis and properties. Prog Polym Sci. 2007;32:1344–91.

Takeichi T, Kano T, Agag T. Synthesis and thermal cure of high molecular weight polybenzoxazine precursors and the properties of the thermosets. Polymer. 2005;46:12172–80.

Chen CH, Lin CH, Wong TI, Wang MW, Juang TY. Thermosets derived from diallyl-containing main-chain type benzoxazine polymers. Polymer. 2018;149:286–93.

Takeichi T, Kawauchi T, Agag T. High performance polybenzoxazines as a novel type of phenolic resin. Polym J. 2008;40:1121–31.

Ishida H, Allen DJ. Physical and mechanical characterization of near-zero shrinkage polybenzoxazines. J Polym Sci Part B: Polym Phys. 1996;34:1019–30.

Agag T, Takeichi T. Synthesis and characterization of novel benzoxazine monomers containing allyl groups and their high performance thermosets. Macromolecules. 2003;36:6010–7.

Rimdusit S, Ishida H. Development of new class of electronic packaging materials based on ternary systems of benzoxazine, epoxy, and phenolic resins. Polymer. 2000;41:7941–9.

Su YC, Chang FC. Synthesis and characterization of fluorinated polybenzoxazine material with low dielectric constant. Polymer. 2003;44:7989–96.

Baranek AD, Kendrick LL, Narayanan J, Tyson GE, Wand S, Patton DL. Flexible aliphatic-bridged bisphenol-based polybenzoxazines. Polym Chem. 2012;3:2892–900.

Allen DJ, Ishida H. Physical and mechanical properties of flexible polybenzoxazine resins: effect of aliphatic diamine chain length. J Appl Polym Sci. 2006;101:2798–809.

Liu Y-L, Hsu C-W, Chou C-I. Silicon-containing benzoxazines and their polymers: copolymerization and copolymer properties. J Polym Sci Part A: Polym Chem. 2007;45:1007–15.

Kawaguchi AW, Sudo A, Endo T. Polymerization–depolymerization system based on reversible addition–dissociation reaction of 1,3-benzoxazine with thiol. ACS Macro Lett. 2013;2:1–4.

Ran QC, Zhang DX, Zhu RQ, Gu Y. The structural transformation during polymerization of benzoxazine/FeCl3 and the effect on the thermal stability. Polymer. 2012;53:4119–27.

Ishida H, Allen DJ. Mechanical characterization of copolymers based on benzoxazine and epoxy. Polymer. 1996;37:4487–95.

Acknowledgements

This study was financially supported by the Science and Technology Research Project of Colleges and Universities in Hebei Province (Z2017020) and the Natural Science Foundation of Hebei Province (E2018210079). The authors gratefully thank Professor Huang Wei and Associate Professor Yang Xin of the Institute of Chemistry, Chinese Academy of Sciences for their help.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ren, S., Miao, X. & Song, W. Convenient preparation of flexible polysulfide rubber chain-bridged polybenzoxazine. Polym J 51, 397–403 (2019). https://doi.org/10.1038/s41428-018-0155-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0155-2