Abstract

Poly(ether ketone sulfone)s with functionalized benzotriazole side chains are simply designed and successfully obtained by the copolycondensation of 4,4-difluorodiphenylsulfone, 4,4’-dihydroxydiphenylamine and a benzotriazole-based difluoro compound. The resulting polymers are identified by Fourier transform infrared spectroscopy and nuclear magnetic resonance, and the results are consistent with the proposed polymer structures. Owing to the intermolecular hydrogen bonding, the phosphoric acid (PA)-doped polymer membranes show encouraging mechanical properties. Taking advantage of the flexible movement of the benzotriazole in the side chains, the resulting membranes exhibit promising proton conductivities and fuel cell performance, which makes them a strong potential material for applications in high-temperature proton exchange membrane fuel cells.

Similar content being viewed by others

Introduction

The increasing severity in pollution and power consumption associated with traditional fossil fuels have led to an ever-increasing demand for many new environment-friendly power sources to replace traditional fossil fuels. Recently, proton exchange membrane fuel cells (PEMFCs) have drawn significant attention as encouraging energy conversion devices, owing to their high energy density and low pollution [1,2,3,4]. Among the types of PEMFCs reported, many efforts have recently been focused on developing various high-temperature proton exchange membrane fuel cells (HT-PEMFCs), which are functional up to 120–200 °C [5]. HT-PEMFCs possess several advantages, including improved fuel efficiency, low pollutant emission, easier water management, higher tolerance to carbon monoxide poisoning, and enhanced electrode kinetics [6,7,8]. The proton exchange membrane (PEM), with its remarkable thermal behaviors, excellent oxidative stability, excellent proton conductivity, and mechanical properties, is the core component in HT-PEMFCs, which can effectively separate fuels and oxygen gas while transporting protons by its ion exchange abilities [9]. DuPont’s Nafion is a famous commercial PEM that shows extraordinarily high proton conductivity and mechanical stability due to its special chemical structure. Despite considerable progress in the development of PEMs, their wider use is limited for some reasons, including high methanol permeability, high production cost, and low proton conductivity under high-temperature conditions, resulting in dehydration [10,11,12]. Accordingly, the development of alternative PEMs with good mechanical, thermal and chemical performance, as well as high proton conductivities at high temperatures, can be considered a promising and attractive challenge.

In recent years, several amphoteric N-heterocycles, such as pyrazole, imidazole, triazole, and tetrazole, acting as both proton donors and acceptors [13,14,15,16], have been shown to be excellent proton carriers in PEMFCs. Recently, we synthesized a benzotriazole-based polymer (PESB) using a traditional C–N coupling reaction [9]. The PA-doped PESB membrane exhibited a high proton conductivity, up to 0.073 S cm−1 at 160 °C, with a maximum peak power density of 427 mW cm−2 and an open cell voltage of 0.91 V at 160 °C. On the one hand, a large number of benzotriazole groups should be introduced into the polymer main chain, which will greatly increase the production cost of the polymer. On the other hand, the membrane’s low proton transport efficiency is due to the limited movement ability of the benzotriazole groups in the polymer main chains. To reduce the production costs of the resulting polymer membranes and promote the movement ability of the benzotriazole groups, in this work, we introduced a small number of benzotriazole groups into the polymer side chains. It was expected that the presence of the benzotriazole groups in the PESB side chains would result in efficient proton transportation in membranes, leading to the higher proton conductivities and remarkable fuel cell performances that are essential requirements for high-temperature PEMFCs.

Experimental

The main materials, measurements, synthetic routes of the monomer and polymers, membrane preparation (Table S1), physical properties of the resulting membranes, and fuel cell testing methods are described in Supporting Information.

Results and discussion

Characterization of the BTAPEKS

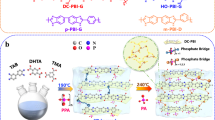

Different molar percentages of the benzotriazole-based difluoro compound (BTADF) were used for the construction of the benzotriazole functionalized poly(ether ketone sulfone)s (BTAPEKS) by its condensation polymerization with 4,4-difluorodiphenylsulfone and 4,4’-dihydroxydiphenylamine, and the polycondensation proceeded smoothly with high yields (Scheme 1, Figs. S1, S2 and Scheme S1, S2, S3). The molecular weights of the linear BTAPEKS polymers were measured by gel permeation chromatography using DMF as an eluent. The Mn and Mw values are shown in Table S3. The Mn values were 101,000–148,000, and the Mw values were 246,000–312,000. The chemical structures of the BTAPEKS polymers were identified by Fourier transform infrared spectroscopy and nuclear magnetic resonance (NMR). The 1H NMR spectra of BTAPEKS polymers in DMSO-d6 are shown in Fig. 1. The aromatic proton signal intensity of the benzotriazole increased with the content of BTADF, and the value of “n” was calculated according to integration of the signal peak area. BTAPEKS-20/40/60, the number corresponding to the in-feed ratio of the molar percentage of BTADF, were found to have actual incorporations of 22/36/63 from the 1H NMR, close to the actual in-feed ratio. Figure 2 displays the FT-IR spectra of BTAPEKS, with a characteristic peak at approximately 1590 cm−1, attributed to the C=C unit of the benzene ring [17]. The absorption band of C=O appeared near 1657 cm−1. The characteristic peak of NH appeared at approximately 3385 cm−1. The results of these spectra confirmed the successful synthesis of the polymer BTAPEKS.

Phosphoric acid uptake of the BTAPEKS membranes

At room temperature, the BTAPEKS membranes were steeped in 85% concentrated PA solution for 5 days (Fig. 3). PA could be absorbed by the BTA groups in the polymer side chains (i.e., H2PO4-H and -N atoms in benzotriazole). With increases in the content of BTADF, the Wdoping of BTAPEKS membranes increased. PA uptakes of the BTAPEKS-20, BTAPEKS-40, and BTAPEKS-60 membranes reached their maximum uptakes in 85% PA after 5 days (Table 1). The Wdoping value of BTAPEKS-20 was 97%, while the value of BTAPEKS-60 reached as high as 178%. Doped PA played a dual role in the PA-doped BTAPEKS membranes [18]. One part of the doped PA was adsorbed onto the polymer backbone by acid-base interactions. The other part existed in the free form of the polymer, and those free-form PA groups could form a hydrogen bond network to transfer protons. Compared to our previous work [9], the PA uptake of BTAPEKS was lower than that of PESB membranes due to the lower benzotriazole content in the polymer chains, whereas in this work, we expected that PA-doped BTAPEKS membranes would result in high proton conductivities benefiting from the flexible movement of the benzotriazole in the side polymer chains.

Thermal properties

The thermal behavior of the BTAPEKS polymers was tested by thermogravimetric analysis (TGA) (Fig. 4), and all polymers with different contents of benzotriazole groups exhibited high decomposition temperatures (Td,5% up to ~450 °C). Compared to the pristine BTAPEKS polymers, the PA-BTAPEKS membranes showed an earlier mass loss at ~160 °C, due to dehydration of the doped PA molecules in the membranes. Due to the easier decomposition of the benzotriazole side chains, BTAPEKS-60 started to decompose faster than BTAPEKS-20/40. Compared with the previous work on PESB and m-PBI materials (Fig. S3) [9], the PA-doped materials showed a loss at ~160 °C due to the existence of PA and some distilled water, and the side chain of BTAPEKS started to decompose at ~300 °C (Fig. 4 and S3). PESB and m-PBI with benzotriazole or benzimidazole in the backbone—the introduction of aromatic compounds would improve the polymers’ thermal performances—showed better relative thermal stabilities. However, at 240 °C, well above fuel cell operating temperatures, BTAPEKS-60 178% materials showed a very slight decay with time in air (Fig. S4). Taken together, the testing results demonstrated that the BTAPEKS membranes showed excellent thermal stabilities in nitrogen and air, and could be considered promising high-temperature PEMs.

Mechanical properties

The mechanical properties of BTAPEKS membranes were tested, and the testing data are shown in Table 2. As seen in Table 2, compared with the PA-doped membranes, the undoped BTAPEKS membranes exhibited better mechanical properties, including higher Young’s modulus and higher tensile strength, which are essential for the high-performance polymer membranes. After doping with PA, the mechanical properties of BTAPEKS membranes declined. For instance, the Young’s modulus of PA-BTAPEKS membranes decreased to 0.18–0.65 GPa, while the tensile strength of PA-BTAPEKS membranes decreased to 6.8–17.3 MPa. The testing data suggested that doping with PA had an important influence on the mechanical properties of BTAPEKS membranes, which was a normal and reasonable phenomenon due to the plasticizing effect of the phosphoric acid [19], which increased the separation of the polymer chains and in turn reduced the intermolecular forces of the polymer. According to our previous work [3], owing to the intermolecular hydrogen bonding (Fig. 5, Supporting Information), the PA-doped BTAPEKS membranes showed improved tensile strength and Young’s modulus, and PA-doped BTAPEKS membranes possessed a comparable level of the mechanical properties to some typical PA-doped PEMs [19,20,21,22,23] used for high-temperature applications in PEMFCs. Compared with the previous work on PESB and m-PBI materials (Table S2) [9], benzotriazole and benzimidazole, as aromatic compounds introduced into the rigid skeleton to improve mechanical properties such as tensile strength and Young’s modulus, were better in the skeleton than in the side chains, due to increased space between polymer chains, and consequently weakened intermolecular forces between polymer backbones and deteriorated the tensile strength of the membrane.

Proton conductivity of the PA-doped BTAPEKS

Proton conductivity of the PA-doped BTAPEKS membranes was successfully tested at high temperatures (from 120 to 180 °C) (Fig. 6). As expected, with the BTADF content and the temperature increasing, the proton conductivities of the PA-doped BTAPEKS membranes steadily increased. At 180 °C, the proton conductivities of PA-doped BTAPEKS-20, BTAPEKS-40, and BTAPEKS-60 were 0.074 S∙cm−1, 0.099 S∙cm−1 and 0.118 S∙cm−1, respectively. Compared with the previous work on PESB and m-PBI materials (Fig. S5) [9], the proton conductivities of BTAPEKS-60 were obviously higher than those of PESB and m-PBI. In the application of PA-doped BTAPEKS membranes, the functional benzotriazole groups acted as a proton transfer media, and the proton conductivity of the polymer membranes was greatly influenced by the movement ability of the benzotriazole in the polymer chains. Compared to our previous work [9], first, a smaller number of benzotriazole groups were introduced to construct the BTAPEKS polymers, which reduced their production costs. Second, BTAPEKS membranes showed encouraging proton conductivities due to the flexible movement of the benzotriazole in the side polymer chains.

Oxidative stability of the BTAPEKS

The oxidative stability of PEMs has a major effect on the lifetime of HT-PEMFCs. During operation of HT-PEMFCs, the degradation of the polymer membrane was due to attacks by hydroxyl (HO∙) or hydroperoxy (HOO∙) ions, which were generated from the incomplete reduction of oxygen [24,25,26]. Fenton’s reagent (3% H2O2 containing 4 ppm FeSO4) was considered the most effective method to test the oxidative stability of the polymer membranes. Herein, we immersed the BTAPEKS membranes into the Fenton’s reagent at 70 °C for 120 h. We evaluated the degradation of the membranes by determining their weight loss, and the test results are shown in Fig. 7. The BTAPEKS membranes with a higher BTADF content displayed a lower weight, which can be explained by the fact that the membrane with higher BTADF content would provide more chances for oxidative radicals to attack the resulting polymer chains. After 120 h of Fenton’s reagent testing, the BTAPEKS membranes remained intact and exhibited a weight loss less than that of m-PBI (65%) [23]. These testing results suggested that the BTAPEKS polymers showed excellent and encouraging oxidative stability.

Fuel cell performance of PA-doped BTAPEKS membranes

Fuel cell performance is the most important factor for the PA-doped BTAPEKS membranes. In this work, PA-doped BTAPEKS membranes with good thermal and mechanical properties, high proton conductivity and good oxidative stability inspired us to investigate their fuel cell performance. The PA-doped BTAPEKS membranes were fabricated into membrane electrode assemblies, and were measured in fuel cells with H2/O2 at 180 °C under anhydrous conditions. Fig. 8 shows the polarization and power density curves of HT-PEMFCs using PA-doped BTAPEKS membranes as the PEMs. As we expected, as the BTADF content increased in the polymer side chains, the maximum power density increased. The maximum power density of PA-doped BTAPEKS-20, PA-doped BTAPEKS-40, and PA-doped BTAPEKS-60 were 240 mW cm−2, 450 mW cm−2 and 562 mW cm−2 at 180 °C, respectively. Compared with our previous work (Fig. S6) [9], BTAPEKS-60 among the membranes showed 562 mW cm−2 at 180 °C, which is higher than PESB and m-PBI with similar PA-doping levels (~180%), and the PEMs containing functionalized benzotriazole groups had higher maximum power density, due to their flexible movement in the side polymer chains. In addition, the open circuit voltages of HT-PEMFCs based on PA-BTAPEKS membranes were found to be above 0.90 V, indicating that the BTAPEKS membranes were highly dense, with considerably low gas permeability, and could prevent H2 and O2 gas crossover. Fuel cell performance evaluations during the long-term operations were performed at high temperatures of 180 °C without external humidification as shown in Fig. S7. The results showed the voltage remained nearly constant throughout the long-term testing, with an average of 0.6 V at 0.4 A/cm2. The phase separation behavior can be seen in Fig. S8; benzotriazole in the side chain made it easier to achieve phase separation, so the phosphoric acid transport channel can be formed after doping with phosphoric acid, which further increased proton conductivity and improved battery performance. The encouraging comprehensive properties of the PA-BTAPEKS membranes indicated that the PA-BTAPEKS membranes can be considered a new promising PEM used in HT-PEMFCs.

Conclusions

In summary, poly(ether ketone sulfone) with functionalized benzotriazole side chains (BTAPEKS) has been successfully synthesized by copolycondensation of 4,4-difluorodiphenylsulfone, 4,4’-dihydroxydiphenylamine and BTADF. Owing to the intermolecular hydrogen bonding, the PA-doped BTAPEKS membranes showed high Young’s modulus and high tensile strength. Taking advantage of the flexible movement of the benzotriazole in the side chains, the BTAPEKS membranes exhibited encouraging proton conductivities and fuel cell performances. The proton conductivities of BTAPEKS-20, BTAPEKS-40, and BTAPEKS-60 were as high as 0.074 S∙cm−1, 0.099 S∙cm−1 and 0.118 S∙cm−1 at 180 °C, respectively. PA-doped BTAPEKS-60 showed a maximum peak power density of 562 mW cm−2, making it one of the most promising materials for application in high-temperature PEMFCs. The testing results suggested that introducing the functional benzotriazole groups into the polymer side chains could be considered an important and encouraging method to promote the PEM properties for HT-PEMFC applications.

References

Martos A, Biasizzo M, Trotta F, Río C, Várez A, Levenfeld B. Synthesis and characterization of sulfonated PEEK-WC-PES copolymers for fuel cell proton exchange membrane application. Eur Polym J. 2014;93:390–402.

Zhang H, Shen PK. Advances in the high performance polymer electrolyte membranes for fuel cells. Chem Soc Rev. 2012;41:2382–94.

Chang G, Shang Z, Yang L. Hydrogen bond cross-linked sulfonated poly(imino ether ether ketone) (PIEEK) for fuel cell membranes. J Power Sources. 2015;282:401–8.

Shin DW, Guiver M, Lee YM. Hydrocarbon-based polymer electrolyte membranes: importance of morphology on ion transport and membrane stability. Chem Rev. 2017;117:4759–805.

Bose S, Kuila T, Nguyen TXH, Kim NH, Lau K, Lee JH. Polymer membranes for high temperature proton exchange membrane fuel cell: recent advances and challenges. Prog Polym Sci. 2011;36:813–43.

Park SJ, Lee DH, Kang YS. High temperature proton exchange membranes based on triazoles attached onto SBA-15 type mesoporous silica. J Membr Sci. 2010;357:1–5.

Chandan A, Hattenberger M, El-kharouf A, Du S, Dhir A, Self V et al. High temperature (HT) polymer electrolyte membrane fuel cells (PEMFC)-a review. J Power Sources. 2013;231:364–78.

Xu X, Wang H, Lu S, Guo Z, Rao S, Xiu R et al. A novel phosphoric acid doped poly(ether sulphone)-poly(vinyl pyrrolidone) blend membrane for high-temperature proton exchange membrane fuel cells. J Power Sources. 2015;286:458–63.

Wang K, Yang L, Wei W, Zhang L, Chang G. Phosphoric acid-doped poly(ether sulfone benzotriazole) for high temperature proton exchange membrane fuel cell applications. J Membr Sci. 2018;549:23–7.

Heinzel A, Barragan VM. A review of the state-of-the-art of the methanol crossover in direct methanol fuel cells. J Power Sources. 1999;84:70–4.

Steele BCH, Heinzel A. Materials for fuel-cell technologies. Nature. 2001;414:345–52.

Chen C, Levitin G, Hess DW, Fuller TF. XPS investigation of Nafion® membrane degradation. J Power Sources. 2007;169:288–95.

Silva BBR, Soares JB, Malfatti CF, Forte MMC. Benzimidazole effect on the performance of polyelectrolyte membranes based on sulfonated hydrocarbon resin. J Membr Sci. 2011;374:12–9.

Çelik SÜ, Bozkurt A, Hosseini S. Alternatives toward proton conductive anhydrous membranes for fuel cells: heterocyclic protogenic solvents comprising polymer electrolytes. Prog Polym Sci. 2012;37:1265–91.

Ahn MK, Lee S, Min C, Yu Y, Jang J, Gim M et al. Enhanced proton conductivity at low humidity of proton exchange membranes with triazole moieties in the side chains. J Membr Sci. 2017;523:480–6.

Henkensmeier D, Duong NMH, Brela M, Dyduch K, Michalak A, Jankova K et al. Tetrazole substituted polymers for high temperature polymer electrolyte fuel cells. J Mater Chem A. 2015;3:14389–400.

Xu J, Ni H, Wang S, Wang S, Wang Z, Zhang H. Direct polymerization of a novel sulfonated poly(arylene ether ketone sulfone)/sulfonated poly(vinylalcohol) crosslinked membrane for direct methanol fuel cell applications. J Membr Sci. 2015;492:505–17.

Zhang N, Zhao C, Ma W, Wang S, Wang B, Zhang G et al. Macromolecular covalently cross-linked quaternary ammonium poly(ether ether ketone) with polybenzimidazole for anhydrous high temperature proton exchange membranes. Polym Chem. 2014;5:4939–47.

Yang J, Xu Y, Zhou L, Che Q, He R, Li Q. Hydroxyl pyridine containing polybenzimidazole membranes for proton exchange membrane fuel cells. J Membr Sci. 2013;466:318–25.

Wang S, Zhao C, Ma W, Zhang G, Liu Z, Ni J et al. Preparation and properties of epoxy-cross-linked porous polybenzimidazole for high temperature proton exchange membrane fuel cells. J Memb Sci. 2012;411:54–63.

Mader JA, Benicewicz BC. Sulfonated polybenzimidazoles for high temperature PEM fuel cells. Macromolecules. 2010;43:6706–15.

Li X, Ma H, Shen Y, Hu W, Jiang Z, Liu B et al. Dimensionally-stable phosphoric acid–doped polybenzimidazoles for high-temperature proton exchange membrane fuel cells. J Power Sources. 2016;336:391–400.

Chen JC, Chen PY, Liu YC, Chen KH. Polybenzimidazoles containing bulky substituents and ether linkages for high-temperature proton exchange membrane fuel cell applications. J Memb Sci. 2016;513:270–9.

Hubner G, Roduner E. EPR investigation of HO/ radical initiated degradation reactions of sulfonated aromatics as model compounds for fuel cell proton conducting membranes. J Mater Chem. 1999;9:409–18.

Panchenko A, Dilger H, Möller E, Sixt T, Roduner E. In situ EPR investigation of polymer electrolyte membrane degradation in fuel cell applications. J Power Sources. 2004;127:325–30.

Bu F, Zhang Y, Hong L, Zhao W, Li D, Li J et al. 1,2,4-Triazole functionalized poly(arylene ether ketone) for high temperature proton exchange membrane with enhanced oxidative stability. J Membr Sci. 2018;545:167–75.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (21504073, 21202134, 11447215), the Fundamental Science on Nuclear Wastes and Environmental Safety Laboratory (15kffk03), the Scientific Research Fund of Sichuan Provincial Education Department (16ZA0136, 18ZA0495), and the Longshan academic talent research supporting program of SWUST (18LZX308 and 18LZX446). Li Yang and Guanjun Chang are grateful for financial support from the China Scholarship Council.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Du, M., Yang, L., Luo, X. et al. Novel phosphoric acid (PA)-poly(ether ketone sulfone) with flexible benzotriazole side chains for high-temperature proton exchange membranes. Polym J 51, 69–75 (2019). https://doi.org/10.1038/s41428-018-0118-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0118-7

This article is cited by

-

Aggregation states, thermal molecular motion and carrier properties in functional polymer thin films

Polymer Journal (2023)

-

Development of proton conductive polymer electrolytes composed of sulfonated poly(ether ether ketone) and Brønsted acidic ionic liquid (1-methylimidazolium tetrafluoroborate)

Journal of Materials Science: Materials in Electronics (2021)