Abstract

Lignin is a renewable resource, but it is also considered a waste or a very-low-value material. Herein, we propose a lignin-derived compatibilizing agent as an alternative to the current compatibilizing agents. We prepared a polypropylene-based carbon fiber-reinforced plastic (CFRP) with butylated lignin (C4 lignin). Upon the addition of C4 lignin, the dispersion of carbon fiber into the matrix, and the adhesion between the carbon fiber and the matrix were greatly improved. As a result, the tensile strength of the CFRP prepared with C4 lignin was greater than that of the CFRP without lignan lignin (37.1 compared to 40.2 MPa). This value is close to that of CFRPs prepared with maleic anhydride-modified polypropylene (40.9 MPa), an existing compatibilizing agent. C4 lignin is a promising candidate for biomass-derived compatibilizing agents for polypropylene-based CFRPs.

Similar content being viewed by others

Introduction

Plant biomass, especially polysaccharides such as cellulose, has been highlighted as a resource for biofuels and bio-plastics over the last few decades [1, 2]. However, unlike those of polysaccharides, the applications of lignin, another main component of plant biomass, have not been well developed. There is currently great demand for further applications of this material because portions of lignin are still considered waste; however, lignin has been proposed as a water reducer for concrete [3] and as an aromatic chemical source like vanillin [4, 5]. In this study, we paid special attention to the aromatic rings of lignin in order to find new and useful applications of this material. Aromatic polymers can be incorporated into carbon materials such as carbon nanotubes via π–π interactions [6]. Lignin has also been reported to be compatible with carbon nanotubes [7, 8] and graphene [9] due to similar interactions. We proposed that lignin would also be compatible with carbon fiber (CF) and thus be applicable as a compatibilizing agent for CF-reinforced plastics (CFRPs).

Polypropylene (PP) was selected as the matrix for the CFRPs in this study. PP is a typical thermoplastic and has advantages such as good chemical and mechanical properties and good processibility [10]. Thus, PP is used in various applications, e.g., automobile bumpers [11]. PP is therefore expected to be a suitable matrix for CFRPs. However, its compatibility with CF is poor, which hinders the preparation of a homogeneous composite. To improve the compatibility, maleic anhydride-modified PP (MAPP) is often used as a compatibilizing agent [12]. We have thus proposed lignin as a bio- and waste-derived alternative to MAPP.

We have performed a preliminary study on the potential of lignin as a compatibilizing agent using the microbond test [13]. The microbond test [14] is a conventional method to investigate the interfacial shear strength between polymer matrices and CF, which is roughly related to their compatibility. The greatest advantage of the microbond test is that only a few hundred milligrams of the sample is needed for measurements, i.e., it is the best method for an initial screening. We have synthesized ~200 mg of several alkylated lignins and optimized the structure of the lignin as a compatibilizing agent. The lignin in which 70% of the OH groups were substituted with butyl groups (C4 lignin, shown in Fig. 1) showed the highest interfacial shear strength. This derivatization is necessary to efficiently increase the interfacial shear strength because raw lignin is immiscible with PP due to the difference between the polarities of PP and the raw lignin. In addition, the residual 30% free OH groups in C4 lignin enhanced the interfacial shear strength presumably because of interaction with the OH groups present on the CF as defects. We report the preparation of CFRP with the optimized C4 lignin after synthesis on a several-gram scale as well as the mechanical properties of the CFRPs. We also compare the properties of the CFRP prepared with C4 lignin with those of CFRP prepared with MAPP.

Experimental procedure

Materials

Vinyl butyrate (Tokyo Chemical Industry Co., Ltd., Tokyo, Japan) was purchased and used as received. Lignin alkali (low sulfonate content) and dimethyl sulfoxide (Sigma-Aldrich Co., LLC., St. Louis, MO, USA) were purchased and used as received. 1-Ethyl-3-methylimidazolium acetate (Iolitec Ionic liquids Technologies GmbH, Heilbronn, Germany) was purchased and used after drying. Methanol, acetone, and xylene (Kanto Chemical Co., Inc., Tokyo, Japan) were purchased and used as received. PP (Novatech FY-6; Japan Polypropylene Corporation, Tokyo, Japan) was purchased and used as received. CF (T700/12 K; Toray Industries, Inc., Tokyo, Japan) was purchased and used after washing with acetone under sonication, washing with methanol, and then washing with water without sonication.

Synthesis of butylated lignin

Butylated lignin was synthesized through a transesterification reaction as reported [13, 15]. Lignin alkali (3.00 g) was added as a solution (31.5 mL) in 1-ethyl-3-methylimidazolium acetate and dimethyl sulfoxide (0.04:1.00, w/v) and stirred at 80 °C for 2 h with vinyl butyrate (2.79 g) under an Ar atmosphere. The butylated lignin was purified through dialysis with methanol. The structure was confirmed by 1H nuclear magnetic resonance (NMR) spectroscopy (Figure S1). The OH content of the raw- and butylated lignin was determined by 31P NMR following a reported method [16]. The OH content in the C4 lignin used in this study was 29 ± 3 mol%. This value has a certain error because fine control of the OH content is very difficult. In addition, the conversion ratios of aliphatic OH and phenolic OH were 25 ± 3 and 30 ± 3 mol%, respectively.

Determination of flow-beginning temperature

A capillary rheometer (CFT-500EX, Shimadzu Corporation, Kyoto, Japan) was used to measure the flow-beginning temperature. The sample (1 g) was loaded into the barrel and extruded as the temperature was increased at a rate of 3 °C/min. The extrusion was carried out using a die (diameter: 1.0 mm and length: 10.0 mm).

Preparation of the PP/CF/C4 lignin composites

PP (46.0 g) and C4 lignin (1.5 g) were mixed and stirred in hot xylene (600 mL, 130 °C). Short CF (2.5 g, diameter: 7 μm, average fiber length: 2 mm) was added to a PP/C4 lignin mixture and stirred for 1 h. The PP/CF/C4 lignin composite was dried in a fume hood for 1 day and in an oven at 55 °C for 5 h. The dried composite was cut (1 cm × 1 cm) and dried again under reduced pressure for 1 day. A twin-screw extruder (KZW20TW-45MG-NH; Technovel corporation, Osaka, Japan; L/D: 45, screw diameter: 20 mm, unidirectional rotation) was used to prepare homogeneous PP/CF/C4 lignin pellets with a pelletizer. Unlike in our previous report [13], the twin-screw extruder included includes a kneading element. The extrusion temperature and screw speed were 180 °C and 150 rpm, respectively. PP, PP/CF, and PP/CF/MAPP samples were prepared using similar procedures.

Tensile and bending tests

Specimens for tensile tests and bending tests were molded with an injection molding machine (IMC-5705, Imoto Machinery Co., Ltd., Kyoto, Japan). The sample and mold temperatures were 180 and 60 °C, respectively. Dumbbell-shaped specimens (JIS K7161) and strip specimens (thickness: 2 mm, width: 10 mm, and length: 75 mm) were prepared. The tensile strength and flexural strength of the samples were measured by tensile test and three-point bending test, respectively, using a universal testing machine (AG-5kNX plus, Shimadzu Corporation, Kyoto, Japan). The tensile test was carried out at a speed of 5.0 mm/min with a distance of 58 mm between the two grips. The three-point bending test was carried out at a speed of 5.0 mm/min with a distance of 40 mm between the two supports. The tests were repeated seven times, and the data shown in the manuscript are the average of the middle five values after excluding the maximum and minimum strength values. The elastic modulus of the samples was calculated from the relation between the tensile stress and tensile strain under a tensile stress of 10–20 N. The fracture surfaces of the specimens were investigated using scanning electron microscopy (SEM, JSM-6510LV, JEOL Ltd., Tokyo, Japan) to evaluate the adhesion between the PP and CF.

Results and discussion

The flow-beginning temperatures of the samples were determined. The temperatures of PP and PP/CF were 180 and 176 °C, respectively. Here we do not think that the addition of CF affects the flow-beginning temperature of PP. We used a capillary rheometer to determine flow-beginning temperature, and the flow-beginning temperature was measured by extruding the samples while continuously increasing the temperature at 3 °C/min. Therefore, the thermal conductivity of the sample slightly affects the flow-beginning temperature, i.e., samples that have higher thermal conductivities show slightly lower flow-beginning temperatures. CF has high thermal conductivity, which may slightly decrease the apparent flow-beginning temperature of PP. The sample with C4 lignin as a compatibilizing agent (PP/CF/C4 lignin) showed a flow-beginning temperature of 175 °C, indicating that C4 lignin has very little effect on the flow-beginning temperature. This is because the amount of C4 lignin added was only 3 wt% because the sample with 5 wt% C4 lignan showed a flow-beginning temperature of 171 °C. MAPP did not affect the flow-beginning temperature (176 °C). From these results, we chose 180 °C as the molding temperature.

The tensile strength of pure PP was 35.1 MPa (Fig. 2). The addition of CF slightly increased the tensile strength to 37.1 MPa because of the poor compatibility between PP and CF. SEM observations showed that CF did not disperse well in PP without a compatibilizing agent, and consequently, approximately 70% of the CFs were aggregated (Figure S2a). PP/CF/C4 lignin showed a further increase in tensile strength to 40.2 MPa, and this improvement is similar to what is seen with MAPP (40.9 MPa), a well-known oil-derived compatibilizing agent for PP/CF composites. This increase was attributed to the compatibility of C4 lignin with both PP and CF; presumably, hydrophobic interactions/van der Waals interactions between PP and C4 lignin and π–π interactions between CF and the aromatic rings of C4 lignin are generated. CF dispersed well in the PP/C4 lignin composite, and no aggregates were found in the SEM images (Figure S2b). It is noted here that CF is also well dispersed in the PP/MAPP matrix. The trend observed in the tensile tests is consistent with that observed in the microbond tests [13]. The interfacial shear strengths between CF and PP, PP/C4 lignin, and PP/MAPP measured by the microbond tests were 8.2, 17.2, and 18.3 MPa, respectively. This clearly suggests that increasing the interfacial shear strength between PP and CF is important, and that C4 lignin works as a compatibilizing agent by improving the interfacial shear strength.

Figure 3 shows the elastic modulus of each sample. The elastic modulus of PP was 1631 MPa. The addition of CF increased the elastic modulus to 3223 MPa because CF is harder than PP. On the other hand, PP/CF/C4 lignin showed an elastic modulus of 2534 MPa, which is lower than that of PP/CF. The elastic modulus of PP/CF/C4 lignin was not substantially different from that of PP/CF/MAPP (2807 MPa). Unlike in this case, the elastic modulus generally increases with the addition of compatibilizing agents [17,18,19]. On the other hand, in some cases, the elastic modulus decreases with the addition of compatibilizing agents despite good dispersion of nanofillers; however, the mechanism of this phenomenon has not been described in the literature [18]. Further investigation is required to clarify the mechanism. Figure 4 shows the flexural strength of each sample. The flexural strengths of PP and PP/CF were 50.9 and 51.1 MPa, respectively, showing that the addition of CF did not affect the flexural strength. The addition of C4 lignin slightly improved the flexural strength (53.2 MPa) although the value was still less than that of PP/CF/MAPP (56.9 MPa).

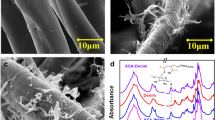

The fracture surfaces of the samples were investigated by SEM after the tensile test to monitor the adhesion between PP and CF. On the fracture surface of PP/CF, there was no adhesion, and small voids between PP and CF were seen, as shown in Fig. 5a, confirming the incompatibility of these components. In the PP/CF/C4 lignin composite, the PP/C4 lignin matrix adheres to CF as well as the PP/MAPP matrix (Fig. 5b, c). The adhesion of the PP/C4 lignin matrix to CF was not observed in all CFs, but the proportion of CFs covered by PP/C4 lignin was similar to the proportion of CFs covered by PP/MAPP (~50%). This observation is consistent with the previous results of the microbond test [13] and directly supports the mechanism underlying the increase in the tensile strength by the addition of C4 lignin: the compatibility between PP and CF increased, consequently increasing the adhesion between them and the interfacial shear strength.

In the present method, the C4 lignin was first mixed with PP in hot xylene, and then the mixture was dried and kneaded. C4 lignin was only partially dissolved by the hot xylene (dissolved part: 17 wt%) because lignin is a very complex natural polymer and does not have a homogeneous structure. Nonetheless, we used the mixture without removing the xylene-insoluble C4 lignin because C4 lignin has a softening point of 160 °C; therefore, the xylene-insoluble C4 lignin is expected to be homogeneous after kneading at 180 °C and have a positive effect on the tensile strength. To clarify this, we prepared the analogous PP/CF/C4 lignin sample after removing the xylene-insoluble C4 lignin by filtration. The composite showed a tensile strength of 38.2 MPa, which was lower than that of the unfiltered composite (40.2 MPa), as shown in Fig. 6. This result suggests that the xylene-insoluble lignin has a positive effect on the tensile strength. Furthermore, considering that the tensile strength of PP/CF was 37.1 MPa, the xylene-insoluble C4 lignin made a greater contribution to the increase in the tensile strength than did the xylene-soluble C4 lignin.

We further investigated whether the xylene-insoluble C4 lignin was well dispersed in the PP after kneading and molding at 180 °C. A specimen of the PP/CF/C4 lignin (without filtration) for the tensile tests was sonicated in methanol, which is a good solvent for C4 lignin, for 3 h, and then, the resulting sample was subjected to SEM observations (Fig. 7). A smooth sample surface was observed; there were no lignin aggregates or pores resulting from the removal of lignin. This indicated that not only the xylene-soluble C4 lignin but also the xylene-insoluble C4 lignin is homogeneous throughout the matrix, and both are important to increasing the tensile strength.

Conclusion

C4 lignin, a derivative of a waste biomass polymer, was tested for use as a compatibilizing agent for PP-based CFRP. C4 lignin improved the tensile strength of the CFRP from 37.1 to 40.2 MPa, which was similar to what was achieved with MAPP (40.9 MPa), a well-known oil-based compatibilizing agent. While PP/CF had the highest elastic modulus (3223 MPa), the value for PP/CF/C4 lignin was not significantly different (2534 MPa) to that of PP/CF/MAPP (2807 MPa). Good dispersion and adhesion of PP/C4 lignin was confirmed through SEM observations. A portion of the C4 lignin was xylene-soluble, while some was xylene-insoluble, and both contributed to the increase in tensile strength. These results confirm that C4 lignin is applicable as an alternative to the current compatibilizing agent, MAPP.

References

Lim LT, Auras R, Rubino M. Processing technologies for poly(lactic acid). Prog Polym Sci. 2008;33:820–52.

Ragauskas J, Williams CK, Davison HB, Britovsek G, Cairney J, Eckert AC, Frederick JW Jr., Hallett PJ, Leak JD, Liotta LC, Mielenz RJ, Murphy R, Templer R, Tschaplinski T. The path forward for biofuels and biomaterials. Science. 2206;311:484–9.

Uchikawa H, Sawaki D, Hanehara S. Influence of kind and added timing of organic admixture on the composition, structure and property of fresh cement paste. Cem Concr Res. 1995;25:353–64.

Mialon L, Pemba GA, Miller AS. Biorenewable polyethylene terephthalate mimics derived from lignin and acetic acid. Green Chem. 2010;12:1704–6.

Borges da Silva AE, Zabkova M, Araujo DJ, Cateto AC, Barreiro FM, Belgacem NM, Rodrigues EA. An integrated process to produce vanillin and lignin-based polyurethanes from Kraft lignin. Chem Eng Res Des. 2009;87:1276–92.

Umeyama T, Kadota N, Tezuka N, Matano Y, Imahori H. Photoinduced energy transfer in composites of poly[(p-phenylene-1,2-vinylene)-co-(p-phenylene-1,1vinylidene)] and single-walled carbon nanotubes. Chem Phys Lett. 2007;444:263–7.

Teng YN, Dallmeyer I, Kadla FJ. Effect of softwood kraft lignin fractionation on the dispersion of multiwalled carbon nanotubes. Ind Eng Chem Res. 2013;52:6311–7.

Liu Y, Gao L, Sun J. Noncovalent functionalization of carbon nanotubes with sodium lignosulfonate and subsequent quantum dot decoration. J Phys Chem C. 2007;111:1223–9.

Yang Q, Pan X, Huang X, Li K. Fabrication of high-concentration and stable aqueous suspensions of graphene nanosheets by noncovalent functionalization with lignin and cellulose derivatives. J Phys Chem C. 2010;114:3811–6.

Valentini L, Biagiotti J, Kenny MJ, Santucci S. Morphological characterization of single-walled carbon nanotube-PP composites. Compos Sci Technol. 2003;3:1149–53.

Lloyd MS, Vave B. Life cycle economic and environmental implications of using nanocomposites in automobiles. Environ Sci Technol. 2003;37:3458–66.

Karsli GN, Aytac A. Effects of maleated polypropylene on the morphology, thermal and mechanical properties of short carbon fiber reinforced polypropylene composites. Mater Des. 2011;32:4069–73.

Sakai H, Kuroda K, Muroyama S, Tsukegi T, Kakuchi R, Takada K, Hata A, Kojima R, Ogoshi T, Omichi M, Ninomiya K, Takahashi K. Alkylated alkali lignin for compatibilizing agents of carbon fiber reinforced plastics with polypropylene. Polym J. 2018;50:281–4.

Wong HK, Mohammed SD, Pickering JS, Brooks R. Effect of coupling agents on reinforcing potential of recycled carbon fiber for polypropylene composite. Compos Sci Technol. 2012;72:835–44.

Kakuchi R, Yamaguchi M, Endo T, Shibata Y, Ninomiya K, Ikai T, Maeda K, Takahashi K. Efficient and rapid direct transesterification reactions of cellulose with isopropenyl acetate in ionic liquids. RSC Adv. 2015;88:72071–4.

Granata A, Argyropoulos DS. 2-Chloro-4,4,5,5-tetramethyl-1,3,2-dioxaphospholane, a reagent for the accurate determination of the uncondensed and condensed phenolic moieties in lignins. J Agric Food Chem. 1995;43:1538–44.

Kada D, Koubaa A, Tabak G, Migneault S, Garnier B, Boudenne A. Tensile properties, thermal conductivity, and thermal stability of short carbon fiber reinforced polypropylene composites. Polym Compos. 2016. https://doi.org/10.1002/pc.24093.

Lin J-H, Huang C-L, Liu C-F, Chen C-K, Lin Z-I, Lou C-W. Polypropylene/short glass fibers composites: effects of coupling agents on mechanical properties, thermal behaviors, and morphology. Materials. 2015;8:8279–91.

Bhaskar J, Haq S, Yadaw SB. Evaluation and testing of mechanical properties of wood plastic composite. J Thermoplast Compos Mater. 2011;25:391–401.

Acknowledgements

This research was promoted by the COI program, “Construction of next-generation infrastructure using innovative materials—Realization of safe and secure society that can coexist with the Earth for centuries” supported by MEXT and JST. This study was also supported in part by an Advanced Low Carbon Technology Research and Development Program of the JST and the Cross-ministerial Strategic Innovation Promotion Program, also from the JST. This study was also partly supported by KAKENHI (18K14281) and Leading Initiative for Excellent Young Researchers from the Japan Society for the Promotion of Science.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Sakai, H., Kuroda, K., Tsukegi, T. et al. Butylated lignin as a compatibilizing agent for polypropylene-based carbon fiber-reinforced plastics. Polym J 50, 997–1002 (2018). https://doi.org/10.1038/s41428-018-0088-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0088-9

This article is cited by

-

Selective substitution of long-acyl groups into alcohols of kraft lignin over transesterification using ionic liquid

Journal of Wood Science (2021)

-

Flame-retardant plant thermoplastics directly prepared by single ionic liquid substitution

Polymer Journal (2019)