Abstract

We investigated the effects of two metal salts, lithium trifluoromethanesulfonate (LiCF3SO3) and lithium bromide (LiBr), on the glass transition temperature (Tg) of poly(methyl methacrylate) (PMMA). Both LiCF3SO3 and LiBr greatly enhanced the Tg of PMMA under dry conditions. However, once the sample films were exposed to humidity, the PMMA containing LiCF3SO3 absorbed a large amount of water, which acts as a plasticizer. As a result, the Tg shifted to a lower temperature, which limits the utility of this polymer in industrial applications. In contrast, the Tg of PMMA containing LiBr was minimally affected by the absorption of water. This phenomenon can be explained by the ion–dipole interactions with the small number of dissociated lithium cations.

Similar content being viewed by others

Introduction

Amorphous plastics are widely used in various applications, and they inevitably affect people’s daily lives. For practical reasons, it is necessary that such plastics have high glass transition temperatures (Tgs). Therefore, various means of increasing the Tgs have been proposed, such as decreasing the number of chain ends, i.e., increasing the molecular weight [1,2,3,4], adding miscible polymers with higher Tgs [5, 6], and suppressing molecular motion by introducing chemical/physical crosslinking points [7,8,9,10,11]. In addition to the chemical crosslinking generally used in rubber processing, other crosslinking modes include hydrogen bonding [6, 10, 11], π–π stacking [12], and electrostatic interactions [13]. We have recently reported that the Tg of poly(methyl methacrylate) (PMMA) is greatly increased by the addition of lithium trifluoromethanesulfonate (LiCF3SO3) [14]. Although the addition of a metal salt was known to enhance the Tg of an ionomer [15,16,17], this is notable because PMMA does not contain any acid/base functional groups like carboxyl groups. The ion–dipole interactions between dissociated lithium cations and oxygen atoms in the carbonyl groups of PMMA reduce the segmental motion in the glass-to-rubber transition region, leading to an increase in Tg [14]. This phenomenon has a large impact on industrial applications. Therefore, the hygroscopic nature of polymers and the effect of moisture on their Tgs should be elucidated prior to their application because the water absorption of salts can have a substantial effect on properties.

In the present study, we focused on the effects of the addition of metal salts, i.e., LiCF3SO3 and lithium bromide (LiBr), on the Tg of PMMA under dry and humid conditions.

Experimental procedures

Materials

The polymer used in this study was a commercially available PMMA (Acrypet VH; Mitsubishi Chemical Corp.). The number- and weight-average molecular weights, which were determined by size-exclusion chromatography (HLC-8020; Tosoh Corp.) using chloroform as the solvent, were Mn = 54,000 and Mw = 120,000, respectively. Two lithium salts, LiBr (LiBr > 99.0 %; Tokyo Chemical Industry Co., Ltd.) and LiCF3SO3 (LiCF3SO3 ≥ 98.0 %; Kanto Chemical Co., Ltd.), were used without further purification.

Sample preparation

The PMMA and the metal salt were completely dissolved in a mixture of dichloromethane and methanol in 9-to-1 weight ratio, and the solution was stirred for 1 h. The molar ratios of lithium ions to PMMA carbonyl groups were 0, 0.01, 0.03, and 0.07, which corresponded to 0, 2, 5, and 10 wt.% LiCF3SO3, and 0, 1, 3, and 6 wt.% LiBr in the blends, respectively. The solutions were cast onto petri dishes and dried at 160 °C for 30 h under vacuum. The samples were then compression-molded into 300 μm-thick films. After heating at 200 °C for 10 min, the samples were quenched at 25 °C in a compression-molding machine. Some of the sample films were investigated immediately after compression-molding. The other films were kept at 25 °C and 50% RH in a temperature- and humidity-controlled chamber.

Measurements

The thermal properties of the polymer were measured on the second cycle by differential scanning calorimetry (DSC) using a DSC 8500 calorimeter (PerkinElmer Co., Ltd.) at a heating rate of 10 °C/min starting from room temperature. The samples (~ 10 mg each) were encapsulated in an aluminum pan. The second DSC-heating curve was used in this paper.

The temperature dependence of the oscillatory tensile moduli, such as the storage modulus, E', and loss modulus, E", were measured between 30 °C and 200 °C using a Rheogel-E4000 dynamic mechanical analyzer (UBM Co., Ltd.). The frequency and heating rate were 10 Hz and 2 °C/min, respectively. The frequency dependences of the oscillatory shear moduli were measured using an AR2000ex cone-and-plate rheometer (TA Instruments Co., Ltd.) under flowing nitrogen at 200, 220, and 240 °C. The steady-flow properties were also measured using the same plate under flowing nitrogen at 240 °C.

Infrared spectra were acquired with attenuated total reflection (ATR) measurements using a KRS-5 ATR prism under a nitrogen flow. The accumulation count and the resolution were 16 times and 4 cm−1, respectively.

Results and discussion

The DSC-heating curves of the dried samples, i.e., immediately after compression-molding, are shown in Fig. 1. The molar ratio of the salt to the carbonyl groups in the PMMA was 0.07 in both blends. The glass-to-rubber transition was observed in all samples, and the transitions occurred at higher temperatures following the salt addition, and the addition of LiCF3SO3 caused an intense change.

Figure 2 shows the temperature dependencies of the dynamic tensile moduli of PMMA/LiCF3SO3 and PMMA/LiBr with the same molar ratio, i.e., [Li]/[C = O] of 0.07. For comparison, the data for pure PMMA are also shown in the figure as gray symbols.

As demonstrated in the previous study, the addition of LiCF3SO3 extended the glassy region to higher temperatures, i.e., increased the Tg. Consequently, the E'' peak ascribed to the Tg was located at a high temperature. Furthermore, E′ was high and insensitive to temperature in the glassy region at high temperatures. However, after storage for 400 h in a temperature- and humidity-controlled chamber (25 °C and 50% RH), the E′ in the glassy region decreased. Furthermore, in addition to the peak at 137 °C, there was an ambiguous broad peak in the E″ curve at 90 °C, which is indicated in the figure by an arrow. The low-temperature peak represents the Tg in the region containing a large amount of water, meaning the water molecules are acting as a plasticizer [18,19,20], as discussed later. As a result, the E′ of PMMA/LiCF3SO3 was much lower than that of pure PMMA over a wide temperature range after moisture absorption. Moreover, it was impossible to clearly define the rheological glassy and transition regions. This demonstrates that following moisture absorption, the addition of LiCF3SO3 reduces the service temperature of PMMA and limits its applicability at high temperatures.

The dynamic mechanical properties of PMMA/LiBr (Fig. 2b) were different from those of PMMA/LiCF3SO3, although PMMA/LiBr also had a higher Tg than pure PMMA. In the glassy region, the E′ decreased slightly with temperature following a trend similar to that of pure PMMA. However, beyond the glass-to-rubber transition, the E′ was significantly higher than that of pure PMMA. Furthermore, the E″ peak became broad, especially in the high-temperature region, suggesting a relaxation mode. These results indicate that the ion–dipole interactions in the PMMA/LiBr system were significant and provided a slow relaxation mechanism. Finally, it should be noted that the dynamic mechanical properties of PMMA/LiBr were not substantially affected by moisture absorption. This is a very important phenomenon because it implies that LiBr can be used to increase the Tg of PMMA in industrial applications. The results of the samples with an [Li]/[C = O] ratio of 0.01 are shown in the supporting information (Figure S1). Although the shift in the Tg and the effect of moisture were reduced compared with those shown in Fig. 2, similar effects were still detected.

The growth curves of the sample weight measured using a chemical balance at 25 °C and 50% relative humidity (RH) are shown in Fig. 3.

The figure reveals that water adsorption occurred after several hundred hours, and the moisture content became constant, i.e., reached equilibrium. The equilibrium moisture content of PMMA with LiCF3SO3 was ~4%. In contrast, the PMMA containing LiBr had a moisture content of only 1.5% at equilibrium. Although the values were both larger than that of pure PMMA (~0.5%), this result demonstrates that the identity of the salt strongly affects the hygroscopicity of the polymer. Furthermore, the equilibrium moisture contents of the samples with an [Li]/[C = O] ratio of 0.01 were found to be 1.3% for PMMA/LiCF3SO3 and 0.8% for PMMA/LiBr as shown in Figure S2. Because the moisture contents were low, the added salt did not have a substantial impact on the dynamic mechanical properties (Figure S1).

The difference in the moisture contents of the polymers containing the two types of salt, which greatly affects the Tg when the salt content is high, presents a fundamental question about the interactions between the salt and the PMMA. The dissociation and ionization of the salts in the PMMA are described using the binding energy based on coulombic interactions as defined by the following equation: [21]

where Q1 and Q2 are charges, ε=3.6 and ε0 are the dielectric constants of the medium and vacuum, respectively [22, 23], and r is the distance between the cation and the anion. Here, we can assume that r is equal to the sum of the radii of the cation and anion (where a+ is the radius of the cation [24] and a- is the radius of the anion [25], which are shown in Table 1). Based on this equation, dissociation occurs readily when the sum of the ionic radii is large, as shown in Table 1.

The coulombic interaction energies of the salt crystals in the PMMA are estimated as shown in the table. Because the sum of the ionic radii of LiCF3SO3 is relatively large owing to the large ionic radius of the triflate anion, the dissociation of LiCF3SO3 occurs more readily than that of LiBr in the same solvent. Furthermore, smaller ions tend to be more easily solvated by the surrounding molecules because of their higher charge density. Therefore, lithium cations are strongly solvated, whereas substantial solvation is not expected for triflate ions. Moreover, water adsorption by the lithium cations and bromide anions was prevented by their strong dipole interactions owing to their relatively high charge densities. However, the triflate anion was not bound to other ions, which increased its solvation by water molecules. This is reasonable because metal trifluoromethanesulfonates act as Lewis acids in water [26] and are therefore stable in aqueous media.

The ATR spectra (Fig. 4) of each film suggest that the lithium ions and the PMMA carbonyl groups interacted with each other.

The IR spectra were collected immediately after compression-molding at 200 °C to eliminate the effect of water absorption on the surfaces of the samples. The spectra were normalized using the peak at 1724 cm−1, which is attributed to the stretching vibration of the C = O bonds. In the case of PMMA/LiCF3SO3, the peak was broadened to lower wavenumbers, i.e., the higher energy region, at room temperature. This phenomenon was reduced at high temperatures, leading to good melt-processability [14]. In contrast, the PMMA/LiBr peak was located at the same wavenumber as that of PMMA. This suggests that the ion–dipole interactions between the lithium cation and the carbonyl groups in PMMA/LiCF3SO3 were stronger on average than those in PMMA/LiBr. This may be attributed to the greater number of lithium cations owing to the larger degree of dissociation of LiCF3SO3.

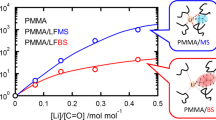

The dynamic tensile moduli of PMMA/LiCF3SO3 and PMMA/LiBr with different salt concentrations are shown in Fig. 5.

Temperature dependence of the dynamic tensile modulus at 10 Hz of (a) PMMA/LiCF3SO3 and (b) PMMA/LiBr films with different salt concentrations. The salt was present at molar ratios of 0–0.07 (lithium ions to PMMA carbonyl groups); (black) 0 molar ratio, (blue) 0.01 molar ratio, (green) 0.03 molar ratio, and (red) 0.07 molar ratio of each salt to PMMA carbonyl groups. ‘(Color figure online)’

The peak temperature of the E″ curve of PMMA/LiCF3SO3, attributed to the glass-to-rubber transition, increased dramatically as the salt content increased. The E″ peak of PMMA/LiBr is located at a lower temperature than that of PMMA/LiCF3SO3 at the same molar ratio of salt to PMMA. Furthermore, it is highly significant that the E″ peak position did not substantially change as the LiBr content increased at [Li]/[C = O] ratios > 0.01. Moreover, the E″ peak became broad, especially in the high-temperature region.

To investigate the rheological properties in the molten state, the frequency dependence of the oscillatory shear moduli was evaluated for pure PMMA and both blends at an [Li]/[C = O] ratio of 0.01 at various temperatures. The salt concentration in the samples was determined based on practical concerns, i.e., for samples with an [Li]/[C = O] ratio of > 0.01, it was almost impossible to prepare flat films without strong molecular orientation, which leads to shrinkage during the rheological measurements.

The master curves of the oscillatory shear moduli are shown in Fig. 6 at a reference temperature (Tr) of 200 °C. The time–temperature superposition principle was not applicable to PMMA/LiBr. This is reasonable because the ion–dipole interactions between the lithium cations and the carbonyl groups in PMMA decreased with temperature, as demonstrated in our previous paper. However, the time–temperature superposition principle was apparently applicable for PMMA/LiCF3SO3. This phenomenon was detected because the contribution of the ion–dipole interactions to the oscillatory moduli was much smaller than that of reptation motion. When the molecular weight of PMMA is low, a thermorheological complex is observed, as shown in a previous report [14]. Furthermore, the rubbery region of PMMA/LiBr was significantly broad, demonstrating that even at 240 °C, the ion–dipole interactions slow the reptation motion of the polymer chains. The slower relaxation of PMMA/LiBr was also quantitatively suggested by the fact that the inverse of the angular frequency at the cross point of G′ and G′′, i.e., an average relaxation time, for PMMA/LiBr, 180 s, was significantly longer than that for PMMA/LiCF3SO3, 0.63 s.

The steady-state shear stress data at 240 °C for pure PMMA and both blends at an [Li]/[C = O] ratio of 0.01 are shown in Fig. 7.

The steady-state shear stress values for PMMA/LiBr were an order of magnitude higher than those for PMMA/LiCF3SO3. This indicates that even at 240 °C, the ion–dipole interactions persisted and acted as a means of crosslinking as corroborated by the linearity of the viscoelastic properties. Furthermore, the shear stress of PMMA/LiCF3SO3 was slightly lower than that of pure PMMA, indicating that LiCF3SO3 acts as a diluent for the PMMA at high temperatures, although it behaved like an antiplasticizer in the blends near their Tg.

As demonstrated by the rheological properties, PMMA/LiBr has a slower relaxation mechanism, i.e., stronger interactions, even though the dissociation degree of LiBr is smaller than that of LiCF3SO3. These results could be explained by assuming strong association between the PMMA and LiBr, which is not substantially reduced even at high temperatures. Although the exact mechanism of this strong interaction is unknown, there is the possibility of an association between the carbonyl groups and part of the ionic aggregates, as suggested by previous studies [27,28,29].

Conclusion

We investigated the thermal and dynamic mechanical properties of PMMA containing two lithium salts: LiCF3SO3 and LiBr. Both salts increased the Tg of PMMA owing to the ion–dipole interactions between the lithium cations and the carbonyl groups, and LiCF3SO3 caused a marked increase in the Tg. However, the addition of salt also increases moisture absorption. Because water acts as a plasticizer, an effect that was more predominant in the case of LiCF3SO3, the Tg and modulus were depressed even in the glassy region of PMMA/LiCF3SO3. In contrast, the plasticization owing to moisture absorption was not substantial in the case of LiBr. The strong interactions between PMMA and undissociated LiBr, which led to a slower relaxation mechanism, explains the difference between the properties of the PMMA/LiBr and PMMA/LiCF3SO3 systems.

References

Cowie JMG. Some general features of T g-M relations for oligomers and amorphous polymers. Eur Polym J. 1975;11:297–300.

Tadlaoui K, Pietrasanta Y, Michel A, Verney V. Influence of molecular weight on the glass transition temperature and the melt rheological behaviour of methyl methacrylate telomers. Polymer. 1991;32:2234–7.

Wooley KL, Hawker CJ, Pochan JM, Frechet JMJ. Physical properties of dendritic macromolecules: a study of glass transition temperature. Macromolecules. 1993;26:1514–9.

Forrest JA, Dalnoki-Veress K, Dutcher JR. Interface and chain confinement effects on the glass transition temperature of thin polymer films. Phys Rev E. 1997;56:5705–16.

Painter PC, Graf JF, Coleman MM. Effect of hydrogen bonding on the enthalpy of mixing and the composition dependence of the glass transition temperature in polymer blends. Macromolecules. 1991;24:5630–8.

Lodge TP, McLeish TCB. Self-concentrations and effective glass transition temperatures in polymer blends. Macromolecules. 2000;33:5278–84.

Shefer A, Gottlieb M. Effect of crosslinks on the glass transition temperature of end-linked elastomers. Macromolecules. 1992;25:4036–42.

Liu H, Zheng S. Polyurethane networks nanoreinforced by polyhedral oligomeric silsesquioxane. Macromol Rapid Commun. 2005;26:196–200.

Fairbanks BD, Scott TF, Kloxin CJ, Anseth KS, Bowman CN. Thiol−Yne photopolymerizations: novel mechanism, kinetics, and step-growth formation of highly cross-linked networks. Macromolecules. 2009;42:211–7.

Juang TY, Liu JK, Chang CC, Shau SM, Tsai MH, Dai SA, et al. A reactive modifier that enhances the thermal mechanical properties of epoxy resin through the formation of multiple hydrogen-bonded network. J Polym Res. 2011;18:1169–76.

Shangguan Y, Yang J, Zheng Q. Rheology of nitrile rubber with hybrid crosslinked network composed of covalent bonding and hydrogen bonding. RSC Adv. 2017;7:15978–85.

Donat BP, Viallat A, Blachot JF, Lombard C. Electromechanical polymer gels combining rubber elasticity with electronic conduction. Adv Matter. 2006;18:1401–5.

Yang S, Fan H, Jiao Y, Cai Z, Zhang P, Li Y. Improvement in mechanical properties of NBR/LiClO4/POSS nanocomposites by constructing a novel network structure. Comp Sci Technol. 2017;138:161–8.

Miyagawa A, Ayerdurai V, Nobukawa S, Yamaguchi M. Viscoelastic properties of poly(methyl methacrylate) with high glass transition temperature by lithium salt addition. J Polym Sci B Polym Phys. 2016;54:2388–94.

Eisenberg A, Kim JS. Introduction to ionomers. New York, Wiley; 1998.

Kim JS, Jackman RJ, Eisenberg A. Filler and percolation behavior of ionic aggregates in styrene-sodium methacrylate ionomers. Macromolecules. 1994;27:2789–803.

Hara M, Eisenberg A. Miscibility enhancement via ion-dipole interactions. 1. Polystyrene ionomer/poly(alkylene oxide) systems. Macromolecules. 1984;17:1335–40.

Zhou J, Lucas JP. Hygrothermal effects of epoxy resin. Part II: variations of glass transition temperature. Polymer. 1999;40:5513–22.

Shen J, Chen CC, Sauer JA. Effects of sorbed water on properties of low and high molecular weight PMMA: 1. Deformation and fracture behaviour. Polymer. 1985;26:511–8.

Smith LSA, Schmitz V. The effect of water on the glass transition temperature of poly(methyl methacrylate). Polymer. 1988;29:1871–8.

Israelachvili, JN, Intermolecular and Surface Forces, 3rd ed. Elsevier, Amsterdam; 2011.

Brandup, J, Immergut, EH, Grulke, EA, Polymer Handbook, 4th ed. Wiley Interscience, Hoboken; 1999.

Atkins, P, Paula, JD, Atkins’. Physical Chemistry, 8th ed. Oxford University Press, Oxford; 2006.

Saito Y, Yamamoto H, Nakamura O, Kageyama H, Ishikawa H, Miyoshi T, et al. Determination of ionic self-diffusion coefficients of lithium electrolytes using the pulsed field gradient NMR. J Power Sources. 1999;81–82:772–6.

Custelcean R, Moyer BA. Anion separation with metal-organic frameworks. Eur J Inorg Chem. 2007;10:1321–40.

Frech R, Huang W. Polymer conformation and ionic association in complexes of lithium, sodium and potassium triflate with poly (ethylene oxide) oligomers. Solid State Ion. 1994;72:103–7.

Londono JD, Annis BK, Habenschuss A, Borodin O, Smith GD, Turner JZ, et al. Cation environment in molten lithium iodide doped poly(ethylene oxide). Macromolecules. 1997;30:7151–7.

Tominaga Y, Izumi Y, Kwak G, Asai S, Sumita M. Effect of supercritical carbon dioxide processing on ionic association and conduction in a crystalline poly(ethylene oxide)-LiCF3SO3 complex. Macromolecules. 2003;36:8766–72.

Kobayashi S, Nagayama S, Busujima T. Lewis acid catalysts stable in water. Correlation between catalytic activity in water and hydrolysis constants and exchange rate constants for substitution of inner-sphere water ligands. J Am Chem Soc. 1998;120:8287–8.

Acknowledgements

We express our sincere gratitude to Mitsubishi Chemical Holdings for their valuable suggestions and their kindness in supplying the sample employed in this study.

Funding

This work was supported by the COI program “Construction of next-generation infrastructure system using innovative materials”—Realization of safe and secure society that can coexist with the Earth for centuries—Supported by Japan Science and Technology Agency (JST).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Ito, A., Phulkerd, P., Ayerdurai, V. et al. Enhancement of the glass transition temperature of poly(methyl methacrylate) by salt. Polym J 50, 857–863 (2018). https://doi.org/10.1038/s41428-018-0080-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0080-4

This article is cited by

-

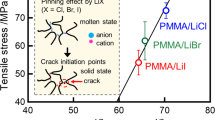

Enhancing the transparency and tensile properties of immiscible poly(methyl methacrylate)/ethylene-vinyl alcohol copolymer blends by lithium salt addition

Polymer Journal (2023)

-

Additive effects of lithium halides on the tensile and rheological properties of poly(methyl methacrylate)

Polymer Journal (2022)

-

Rheological and mechanical properties of poly(methyl methacrylate) doped with lithium salts

Polymer Journal (2022)

-

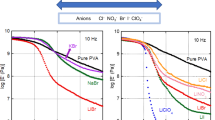

Application of the Hofmeister series to the structure and properties of poly(vinyl alcohol) films containing metal salts

Polymer Journal (2021)

-

Impact of Lithium halides on rheological properties of aqueous solution of poly(vinyl alcohol)

Journal of Polymer Research (2020)