Abstract

Polymer brushes in which one polymer chain end is tethered to a substrate show permanent properties related to the chemical structure of the polymer. However, they cannot accommodate functional molecules in the desired space because of the steric hindrance between neighboring polymer chains. To overcome this problem, the preparation of polymer brushes with ordered nanopores is strongly desired. High-density poly(methyl methacrylate) brushes with well-controlled stereoregularity were prepared using a surface-initiated living anionic polymerization method in the presence of a Lewis acid. A molecular weight range from 6 to 400 K with a narrow polydispersity index was obtained. Grazing incidence wide-angle X-ray diffraction measurements indicated that the polymer brushes formed a helical structure approximately 1 nm in diameter and consisting of encapsulated functional molecules or polymers, leading to the formation of inclusion complexes or stereocomplexes.

Similar content being viewed by others

Introduction

Polymer brushes in which one polymer chain is tethered to the substrate show permanent and specific properties caused by the chemical structure [1]. They are roughly divided according to their synthetic approach into two types: “grafting to” and “grafting from” [2]. In the former approach, a polymer containing functional groups that can react or interact with the substrate is first prepared, and subsequently, the polymers are tethered to the substrate. Although this method is very simple, the preparation of high-density polymer brushes by this approach is extremely difficult. On the other hand, in the “grafting from” method, polymerization is initiated from an initiator immobilized on the substrate. The size of monomers is much smaller than that of polymers, leading to a high-density polymer brush.

A polymer brush with a well-defined structure was first prepared in 1997 using a surface-initiated controlled radical polymerization method [3]. Accordingly, various kinds of high-density polymer brushes with well-controlled primary structures have been prepared using controlled radical polymerization [4,5,6,7,8], living anionic polymerization [8,9,10,11,12], living cationic polymerization [13,14,15], and chain-growth polycondensation [16, 17] methods. The advantages of these reactions are a high initiation efficiency and sustainable propagation without undesired side reactions, leading to the formation of polymer brushes with a high grafting density and well-controlled molecular weight (Mn), functional groups, and block sequences. The high-density polymer brushes obtained by this method have potential to be incorporated in sophisticated and smart functional surfaces, which is anticipated to be applicable in the fields of nanotechnology, biomaterials, and electronic devices.

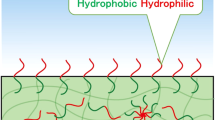

High-density polymer brushes become swollen and orient perpendicular to the substrate in a good solvent because of the excluded volume effect, which applies to neighboring polymer chains under high osmotic pressure [18, 19]. The swollen state of polymer brushes leads to low friction [20, 21], specific adhesion [22, 23], and antifouling properties [24]. Conventional high-density polymer brushes, however, cannot encapsulate functional molecules and polymers because of the steric hindrance between neighboring polymer chains. To overcome this problem, we have focused on the preparation of a polymer brush that forms a helical structure, which is anticipated to encapsulate functional molecules. A polymer brush with a helical structure was first prepared by surface-initiated ring-opening anionic polymerization of N-carboxyamino acid anhydrides [25, 26]. However, the cylindrical cavity in the helical structure of the polyamide brush was too small to encapsulate functional molecules and polymers. Moreover, the introduction of various kinds of functional groups in the polyamide brush remains synthetically difficult.

Poly(methyl methacrylate) (PMMA) with well-controlled stereoregularity shows a specific structure and properties. In particular, syndiotactic PMMA (st-PMMA) forms a helical structure and encapsulates fullerene molecules or isotactic PMMA (it-PMMA), leading to the formation of an inclusion complex or stereocomplex [27,28,29,30,31,32,33]. If PMMA with well-controlled stereoregularity can be grafted with a high density, this strategy offers an approach to introducing a high density of functional molecules and polymers on a desired substrate. This focus review describes recent work on the preparation of high-density PMMA brushes with well-controlled stereoregularity and the ability to encapsulate functional molecules and polymers.

Preparation of st-PMMA brushes on the basis of surface-initiated living anionic polymerization

Pioneering research on the surface-initiated anionic polymerization of methyl methacrylate (MMA) monomer was reported by Schomaker and coworkers [9]. They immobilized 3-(methacryloxy)propyltrimethoxysilane on a silica substrate and subsequently added phenylmagnesium bromide to prepare the initiator. Then, MMA was added to the reaction mixture, resulting in the formation of it-PMMA. During this reaction, however, side reactions between neighboring initiators occur. Hence, high-density polymer brushes could not be obtained using this process. To remedy this problem, 2-bromo-2-methyl propinonyloxyhexyltriethoxy silane (BHE) was immobilized on flat and spherical silica substrates, and subsequently, an initiator was prepared using a lithium/halogen exchange reaction in the presence of excess tertiary butyl lithium (tert-BuLi) and triethyl aluminum (Et3Al) [8, 34]. Then, MMA was added to the system to obtain the target PMMA brushes (Fig. 1a). Here, Et3Al serves not only to increase the stereoregularity but also acts as a dehydrating agent in the reaction system. During this polymerization reaction, free polymer that is not tethered to the solid substrate is generated. The Mn, polydispersity index (PDI), and stereoregularity of the free polymers are summarized in Table 1. It is clear that free polymers with a narrow PDI and well-controlled stereoregularity were obtained using surface-initiated living anionic polymerization.

The Mn, PDI, and stereoregularity of the polymer brush are not always the same as those of the free polymer. To reveal the relationship between the primary structure of the free polymer and the polymer brush, a PMMA220 brush, which was prepared on silica particles with a diameter of 200 nm, was cleaved using a hydrogen fluoride aqueous solution, and the primary structure was evaluated. Figure 1b, c shows the proton nuclear magnetic resonance (1H NMR) spectra and size exclusion chromatography (SEC) curves, respectively, of the free and cleaved polymers. The Mn, PDI, and stereoregularity of the free polymer and polymer brush were comparable. This indicates that the primary structure of the polymer brush prepared on the basis of surface-initiated living anionic polymerization in the presence of Et3Al could be evaluated using the free polymer.

High-density polymer brushes are defined as having a graft density higher than 0.1 chains/nm2. The graft density of the polymer brush was higher than 0.1 chains/nm2, strongly supporting the conclusion that high-density polymer brushes with a well-controlled PDI and stereoregularity can be obtained on both flat and spherical substrates using the technique presented here (Table 1).

Formation of inclusion complex between a PMMA brush and fullerene molecules

st-PMMA has been previously reported to form a helical structure and encapsulate fullerene molecules in the helical nanocavity [27, 28]. Moreover, the helical cavity in st-PMMA can recognize and adapt to the fullerene size, leading to the selective separation of C70 from a mixture of C60 and C70 in solution [35]. If this principle can be applied in high-density PMMA brushes, a novel functional solid surface with a molecular recognition capability could be formed.

To investigate whether high-density PMMA brushes could form helical structures and encapsulate fullerene molecules in the helical nanocavity, a high-density PMMA brush was immersed in C60/toluene and C70/toluene solutions, and subsequently, grazing incidence wide-angle X-ray diffraction (GIWAXD) measurements were performed to characterize the structure of the polymer brush. The scattering vector is defined as q = (4π/λ)sinθ, where θ is the Bragg angle. Figure 2a–c shows the GIWAXD patterns and line profiles along the equatorial direction of the st-PMMA4,000/C60 and st-PMMA4,000/C70 brushes. st-PMMA4,000/C60 showed diffraction peaks at q = 3.35 nm−1 along the equatorial axis and q = 7.79 nm−1 along the meridional axis. The former peak can be assigned to the long-period structure of the PMMA/C60 inclusion complex, while the latter peak is associated with the helical pitch of st-PMMA. This indicates that high-density st-PMMA forms a helical structure and encapsulates C60 in the nanocavity, leading to the formation of an inclusion complex. Moreover, the st-PMMA brush/C60 inclusion complex is oriented perpendicular to the substrate (Fig. 2d). The st-PMMA4,000 brush/C70 also showed a diffraction peak at q = 3.23 nm−1 along the equatorial axis, which indicated that this system formed an inclusion complex that was oriented perpendicular to the substrate. The diffraction peak at q = 7.79 nm−1, which is assigned to the helical pitch of st-PMMA, could not be observed for the st-PMMA/C70 brush. This is because the asymmetric nature of C70 leads to a disordered alignment of C70 in the st-PMMA helix, resulting in the formation of a poorly ordered inclusion complex compared with that of st-PMMA/C60.

To determine whether high-density st-PMMA brushes could achieve the selective separation of C60 from a mixture of C60 and C70 in solution, a high-density st-PMMA320 brush, which was prepared on silica particle with a diameter of 200 nm, was dispersed in a solution of C60 and C70 in toluene. Then, the particles were collected by centrifugation and washed with pure toluene. Subsequently, the fullerene that was encapsulated in the st-PMMA brush was extracted using o-dichlorobenzene. The fullerene molecules thus obtained were characterized by ultraviolet–visible (UV–vis) spectroscopy and matrix-assisted laser desorption ionization time-of-flight mass spectrometry (MALDI-TOF-MS). Figure 3a, b shows the UV–vis spectra of the mixedC60/C70 solution, the supernatant of the mixed solution following treatment by the st-PMMA320 brush, and the extracted fullerene, respectively. The UV–vis spectra of the extracted fullerene showed good agreement with that of C70, which implied that C70 was selectively separated from the mixture of C60 and C70 in solution using the high-density st-PMMA brush. Figure 3c–e shows the MALDI-TOF-MS spectra of the C60/C70 mixed solution, the supernatant, and the extracted fullerene. The MALDI-TOF-MS spectrum of the C60/C70 mixture showed two peaks for C60 and C70 (m/z = 720 (C60–M+) and 840 (C70–M+)), while the spectrum of the extracted fullerene showed only the C70 peak.

The use of the polymer brush as a separation material has two advantages. One advantage is the molecular weight. Bulk st-PMMA could form a helical structure and encapsulate fullerene; however, this specific phenomenon is limited to st-PMMA with a high molecular weight. To separate fullerene from solution, gel formation is necessary. st-PMMA forms a helical structure and aggregates to form a network structure, leading to the formation of a gel. However, the formation of a gel by st-PMMA is strongly related to the molecular weight. Although st-PMMA with a low molecular weight in the bulk state might form a helical structure and encapsulate fullerene molecules within the helical nanocavity in toluene, the st-PMMA/fullerene inclusion complex cannot form a gel, leading to regulation of the selective separation of fullerene molecules from solution. The st-PMMA brush prepared on silica particles can be easily separated from the fullerene solution even with the use of st-PMMA with a low molecular weight. To emphasize this advantage, bulk st-PMMA was added to a C60 toluene solution and annealed at 383 K for 30 min. Subsequently, centrifugation was performed to separate the inclusion complex. Figure 4a shows the UV–vis spectra of the C60 toluene solution before and after treatment using bulk st-PMMA with Mn values of 240,000, 32,000, 23,000, and 10,000, which are designated st-PMMA2400, st-PMMA320, st-PMMA230, and st-PMMA100, respectively. Although st-PMMA2400 induced a significant change in the spectrum, the others did not produce any changes in the spectrum before and after the addition of bulk st-PMMA to the solution. Figure 4b shows the UV–vis spectra of a C60 toluene solution before and after the above treatment using st-PMMA brushes with different Mn values. In the case of the polymer brushes, clear changes were observed before and after this treatment, indicating that even the st-PMMA brush with a low Mn could form a helical structure and encapsulate C60 in the helical nanocavity, leading to the selective separation of C60 from solution. The other advantage is the reusability of the polymer brush. The st-PMMA brush was tethered to a substrate, and thus, the polymer brush could be collected and reused after the separation of fullerene molecules from solution. Even after five cycles, the selectivity for the fullerene molecules remained at 99% [36].

Preparation of a high-density polymer brush consisting of a stereocomplex

High-density polymer brushes show excellent antifouling properties against various kinds of natural polymers, including peptides, at the surface in good solvents. Generally, free polymer cannot penetrate the high-density polymer brush owing to the enormous steric hindrance between neighboring polymer chains in the polymer brush. Mixtures of it-PMMA and st-PMMA are well known to form a stereocomplex consisting of a multihelical structure [29,30,31,32,33]. If this principle can be applied to a high-density polymer brush system, free polymer can penetrate the polymer brush, resulting in the formation of a stereocomplex. st-PMMA brushes prepared on silica particles and a silicon wafer were immersed in an it-PMMA acetonitrile/water solution to form the stereocomplex. Figure 5a shows the differential scanning calorimetry (DSC) measurements for the 1st and 2nd heating scans of the st-PMMA320 brush prepared on silica particles following immersion in the it-PMMA solution. Two endothermic peaks, which are assigned to the crystalline structure formed from fringed micellar growth and lamellar growth, could be observed during the 1st heating run [37]. This implies the formation of a stereocomplex in the high-density st-PMMA brush. The molecular aggregate structure of the st-PMMA brush330 prepared on a silicon wafer was evaluated using GIWAXD measurements. Figure 5b, c, d shows the two-dimensional GIWAXD patterns and line profiles along the equatorial axis and a schematic illustration of the stereocomplex prepared in bulk, which was previously reported [32]. Although the diffraction contrast was weak, diffraction peaks were observed at q = 2.79 nm−1, 7.92 nm−1, 9.84 nm−1, and 10.8 nm−1. These diffraction peaks could also be seen in the bulk stereocomplex, and each peak was characterized as follows: the domain spacing of the cylindrical structure forming the stereocomplex (q = 2.79 nm−1, d = 2.25 nm), the pitch of the outermost helical structure in the stereocomplex induced by st-PMMA (q = 7.92 nm−1, d = 0.79 nm), the pitch of the inside of the double-helical structure formed by it-PMMA (q = 9.84 nm−1, d =0.63 nm), and the distance between the st- and it-PMMA chains in the helical structure (q = 10.8 nm−1, d = 0.58 nm), respectively (Fig. 5d). These results indicate the formation of a stereocomplex in the high-density st-PMMA brush. To evaluate the molecular aggregate structure of the st-PMMA brush in more detail, it is necessary to improve the contrast in the GIWAXD measurements. To overcome this problem, 2,2,2-trifluoroethyl methacrylate (FEMA), which consists of fluoroalkyl groups with a high electron density, was introduced into the st-PMMA brush (Fig. 6a). The resulting st-PMMA-r-PFEMA brush, which consisted of 80% PMMA and 20% PFEMA, was immersed in an it-PMMA acetonitrile/water mixture (Mn: 36,000, PDI: 1.42, rr:mr:mm = 86:14:0). Figure 6b, c, d depicts the 2D GIWAXD patterns with improved contrast, the line profile along the equatorial axis, and a schematic illustration of the stereocomplex formed in the polymer brush. The peaks could be assigned to the domain spacing of the cylindrical structure forming the stereocomplex (q = 2.74 nm−1, d = 2.29 nm), the pitch of the outermost helical structure formed in the st-PMMA-r-PFEMA brush (q = 8.02 nm−1, d = 0.78 nm), the pitch of the inside of the double-helical structure formed by it-PMMA (q = 9.93 nm−1, d = 0.63 nm), and the distance between the st-PMMA-r-PFEMA brush and the it-PMMA chains (q = 10.9 nm−1, d = 0.58 nm). Although the orientation is not high, the diffraction at q = 2.74 nm−1 is clearly concentrated along the equator, and that at q = 8.02 nm−1 is concentrated along the meridional axis, which indicates that the stereocomplex of the polymer brush is oriented perpendicular to the substrate [38].

Conclusion

The preparation of high-density st-PMMA brushes with well-controlled stereoregularity could be achieved using a novel surface-initiated living anionic polymerization method in the presence of a Lewis acid. The polymer brushes consisted of a narrow PDI and an Mn of up to 400,000, and they encapsulated functional materials and free polymers to form inclusion complexes and stereocomplexes. The polymer brushes can recognize the size of the functional molecules, leading to selective separation. We hope that this principle will be utilized in next-generation surface modification.

References

Advincula RC, Brittain WJ, Baster KC, Ruhe J. Polymer brushes: synthesis, characterization, applications. Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, 2005.

Vana P. Controlled radical polymerization at and from solid surfaces. In: Vana Philipp eds., Advances in polymer science. Cham: Springer; vol. 270, 2016.

Huang XY, Wirth MJ. Surface-initiated radical polymerization on porous silica. Anal Chem. 1997;69:4577–80.

Ejaz M, Yamamoto S, Ohno K, Tsujii Y, Fukuda T. Controlled graft polymerization of methyl methacrylate on silicon substrate by the combined use of the Langmuir–Blodgett and atom transfer radical polymerization techniques. Macromolecules. 1998;31:5934–6.

Husseman M, Malmstrom EE, McNamara M, Mate M, Mecerreyes D, Benoit DG, Hedrick JL, Mansky P, Huang E, Russell TP, Hawker CJ. Controlled synthesis of polymer brushes by “Living” free radical polymerization techniques. Macromolecules. 1999;32:1424–31.

Donovan MS, Sumerlin BS, Lowe AB, McCormick CL. Controlled/“lfiving” polymerization of sulfobetaine monomers directly in aqueous media via RAFT. Macromolecules. 2002;35:8663–6.

Higaki Y, Kobayashi M, Hirai T, Takahara A. Direct polymer brush grafting to polymer fibers and films by surface-initiated polymerization. Polym J. 2018;50:101–8.

Hirai T, Kobayashi M, Takahara A. Control of the primary and secondary structure of polymer brushes by surface-initiated living/controlled polymerization. Polym Chem. 2017;8:5456–68.

Schomaker E, Zwarteveen AJ, Challa G, Capka M. Synthesis of isotactic poly(methyl methacrylate) covalently bound to microparticulate silica. Polym Commun. 1988;29:158–60.

Jordan R, Ulman A, Kang JF, Rafailovich MH, Sokolov J. Surface-initiated anionic polymerization of styrene by means of self-assembled monolayers. J Am Chem Soc. 1999;121:1016–22.

Zhou QY, Wang SX, Fan XW, Advincula R, Mays J. Living anionic surface-initiated polymerization (LASIP) of a polymer on silica nanoparticles. Langmuir. 2002;18:3324–31.

Fan XW, Zhou QY, Xia CJ, Cristofoli W, Mays J, Advincula R. Living anionic surface-initiated polymerization (LASIP) of styrene from clay nanoparticles using surface bound 1,1-diphenylethylene (DPE) initiators. Langmuir. 2002;18:4511–8.

Jordan R, Ulman A. Surface initiated living cationic polymerization of 2-oxazolines. J Am Chem Soc. 1998;120:243–7.

Kim IJ, Faust R. Synthesis and characterization of novel silicon-functional polyisobutylenes and their applications: polyisobutylene brushes on silicate substrates via living cationic polymerization. J Macromol Sci Pure. 2003;A40:991–1008.

Zhao B, Brittain WJ. Synthesis of polystyrene brushes on silicate substrates via carbocationic polymerization from self-assembled monolayers. Macromolecules. 2000;33:342–8.

Prehn FC, Boyes SG. Surface-initiated chain growth polyaramid brushes. Macromolecules. 2015;48:4269–80.

Sontag SK, Sheppard GR, Usselman NM, Marshall N, Locklin J. Surface-confined nickel mediated cross-coupling reactions: characterization of initiator environment in Kumada catalyst-transfer polycondensation. Langmuir. 2011;27:12033–41.

Tsujii Y, Ohno K, Yamamoto S, Goto A, Fukuda T. Structure and properties of high-density polymer brushes prepared by surface-initiated living radical polymerization. Surf-Initiat Polym I. 2006;197:1–45.

Higaki Y, Frohlich B, Yamamoto A, Murakami R, Kaneko M, Takahara A, Tanaka M. Ion-specific modulation of interfacial interaction potentials between solid substrates and cell-sized particles mediated via zwitterionic, super-hydrophilic poly(sulfobetaine) brushes. J Phys Chem B. 2017;121:1396–404.

Chen M, Briscoe WH, Armes SP, Klein J. Lubrication at physiological pressures by polyzwitterionic brushes. Science. 2009;323:1698–701.

Kobayashi M, Terayama Y, Hosaka N, Kaido M, Suzuki A, Yamada N, Torikai N, Ishihara K, Takahara A. Friction behavior of high-density poly(2-methacryloyloxyethyl phosphorylcholine) brush in aqueous media. Soft Matter. 2007;3:740–6.

La Spina R, Tomlinson MR, Ruiz-Perez L, Chiche A, Langridge S, Geoghegan M. Controlling network-brush interactions to achieve switchable adhesion. Angew Chem Int Ed. 2007;46:6460–3.

Kobayashi M, Terada M, Takahara A. Reversible adhesive-free nanoscale adhesion utilizing oppositely charged polyelectrolyte brushes. Soft Matter. 2011;7:5717–22.

Higaki Y, Hatae K, Ishikawa T, Takanohashi T, Hayashi J, Takahara A. Adsorption and desorption behavior of asphaltene on polymer-brush-immobilized surfaces. ACS Appl Mater Inter. 2014;6:20385–9.

Whitesell JK, Chang HK. Directionally aligned helical peptides on surfaces. Science. 1993;261:73–6.

Whitesell JK, Chang HK. Surface oriented polymers for nonlinear optics. Mol Cryst Liq Cryst. 1994;240:251–8.

Kawauchi T, Kumaki J, Kitaura A, Okoshi K, Kusanagi H, Kobayashi K, Sugai T, Shinohara H, Yashima E. Encapsulation of fullerenes in a helical PMMA cavity leading to a robust processable complex with a macromolecular helicity memory. Angew Chem Int Ed. 2008;47:515–9.

Kawauchi M, Kawauchi T, Takeichi T. Solubilization of [60]Fullerene owing to inclusion complex formation between syndiotactic poly(methyl methacrylate) and the fullerenes in polar solvents. macromolecules. 2009;42:6136–40.

Liquori AM, Anzunino G, Coiro VM, Dalagni M, Desantis P, Savino M. Complementary stereospecific interaction between isotactic and syndiotactic polymer molecules. Nature. 1965;206:358–62.

Kusanagi H, Tadokoro H, Chatani Y. Double strand helix of isotactic poly(methyl methacrylate). Macromolecules. 1976;9:531–2.

Kumaki J, Kawauchi T, Ute K, Kitayama T, Yashima E. Molecular weight recognition in the multiple-stranded helix of a synthetic polymer without specific monomer-monomer interaction. J Am Chem Soc. 2008;130:6373–80.

Christofferson AJ, Yiapanis G, Ren JM, Qiao GG, Satoh K, Kamigaito M, Yarovsky I. Molecular mapping of poly(methyl methacrylate) super-helix stereocomplexes. Chem Sci. 2015;6:1370–8.

Fox TG, Garrett BS, Goode WE, Gratch S, Kincaid JF, Spell A, Stroupe JD. Crystalline polymers of methyl methacrylate. J Am Chem Soc. 1958;80:1768–9.

Sato M, Kato T, Ohishi T, Ishige R, Ohta N, White KL, Hirai T, Takahara A. Precise synthesis of poly(methyl methacrylate) brush with well-controlled stereoregularity using a surface-initiated living anionic polymerization method. Macromolecules. 2016;49:2071–6.

Kawauchi T, Kitaura A, Kawauchi M, Takeichi T, Kumaki J, Iida H, Yashima E. Separation of C-70 over C-60 and selective extraction and resolution of higher fullerenes by syndiotactic helical poly(methyl methacrylate). J Am Chem Soc. 2010;132:12191–3.

Sato M, Kato T, Shimamoto H, Kamitani K, Ohta N, Hirai T, Takahara A. Design of high-density helical polymer brush on silica nanoparticles for the size recognition of fullerene molecules. ACS Macro Lett. 2018;7:148–52.

Schomaker E, Challa G. Complexation of stereoregular poly(methyl methacrylates) .11. A mechanistic model for stereocomplexation in the bulk. Macromolecules. 1988;21:2195–203.

Kato T, Sato M, Shimamoto H, Uno K, Yokomachi K, Konishi Y, Kamitani K, Nishibori M, Ohta N, Ishige R, White KL, Otozawa N, Hirai T, Takahara A. Preparation of high-density polymer brush with multi-helical structure. Langmuir. 2018;34:3283–8. https://doi.org/10.1021/acs.langmuir.7b04167. (In the press)

Acknowledgements

This work was supported by the Photon and Quantum Basic Research Coordinated Development Program from the Ministry of Education, Culture, Sports, Science and Technology, Japan. We also acknowledge support from the World Premier International Research Center Initiative (WPI) MEXT, Japan, and the Cooperative Research Program of “Network Joint Research Center for Materials and Devices”. Part of this work was supported by the Impulsing Paradigm Change through Disruptive Technologies (ImPACT) Program. This work was performed under the Cooperative Research Program of “Network Joint Research Center for Materials and Devices.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Hirai, T., Sato, M., Kato, T. et al. Preparation of polymer brushes with well-controlled stereoregularity and evaluation of their functional properties. Polym J 50, 931–939 (2018). https://doi.org/10.1038/s41428-018-0078-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0078-y