Abstract

Over the past few years, extremely high charge-storage capacities of glucose-based oligo- or polysaccharides have been discovered that enables such materials to hold a great potential in electronics applications due to their abundant and renewable materials. Typically, the introduction of an α-glucan-containing polysaccharide into the dielectric layer of a transistor-type memory device causes excellent irreversible electron-capture properties; hence, a transistor device embedded with oligosaccharide maltoheptaose domains expresses write-once-read-many (WORM)-type behavior, which confirms that green materials can be used for advanced electronics. However, their irreversible WORM-type characteristics also restrict the application α-glucan-containing polysaccharides in high-performance electronic devices. Recent advances in oligosaccharide-based block copolymers through the inherent immiscibility of different polymer segments can enhance not only the formation of self-assembled nanostructures but also the switching of memory properties. Furthermore, supramolecular structures composed of oligosaccharide-based block copolymers and conjugated moieties can be developed into high-performance nonvolatile organic field-effect transistor (OFET) memory devices. This mini review presents an overview of the recent literature in oligosaccharide maltoheptaose-based block copolymers and their promising applications in organic memory devices.

Similar content being viewed by others

Introduction

In recent years, organic nonvolatile memory (ONVM) devices have attracted considerable research attention in the field of electronics because of their advantages including their low cost, light weight, structural flexibility, and simple processing, which make them applicable in a variety of applications, for example, radio-frequency identification (RFID), flexible displays, and smart phones [1, 2]. With the continuous advances in non-destructive reading behavior, low power consumption, ease of circuit structure integration, and multi-bit storage capability, the memory devices based on organic field-effect transistor (OFET) configurations have rapidly become an inexpensive alternative to the other proposed categories of ONVM devices for developing data-storage applications [3,4,5,6,7,8]. An OFET memory cell is a conventional transistor integrated with a charge-storage layer sandwiched between a semiconducting layer and a dielectric layer to modulate its high-conducting and low-conducting states. Charge-trapping layers, including layers of the three major types of trapping materials (metallic nanofloating gate dielectrics, organic ferroelectric oriented–dipole dielectric materials, and polymer electrets), have been developed to store charge within the bulk of the dielectric film or at the interface between the gate dielectric and the semiconducting channel [1, 9,10,11,12,13,14,15,16]. Among them, an impressive polymer-based electret charge-storage material is an important and preferred candidate to improve memory behaviors because of their structural design flexibility, large-area fabrication, and low-temperature processability. Difference design concepts for the chemical composition, π-conjugation length, polymer architecture, and self-assembled morphology for these polymer electrets have been proposed and demonstrated to effectively tune the memory characteristics in OFET memory devices [16,17,18,19]. In fact, broadening the applications of polymer-based electronic devices is correlated with an increase in environmental issues because synthetic polymers are typically produced from petroleum-derived synthetic resources. With increasing demand for plastic products including everyday items and emerging soft electronics, fossil fuel materials or traditional sources have had to be gradually replaced by non-petroleum-based polymers and those derived from environmentally sustainable sources to decrease petroleum consumption and non-biodegradable waste. For example, several materials, including numerous proteins and naturally biodegradable polymers of cellulose, chitin, and starch, from animal, plant, and bacterial sources have been investigated and widely used in diverse fields, such as paper-making, adhesives, coating materials, biomedical applications and manufacturing biofuels to protect the environment and conserve energy sources [20,21,22,23,24,25,26,27,28,29,30,31]. However, due to the insulating properties of bio-based materials, applying bio-based materials to electronics is widely accepted as challenging. More recently, green chemistry techniques based on carbohydrate polymers have innovatively bridged the environmental friendliness and biocompatibility of natural resources into electronic applications. Nevertheless, turning these renewable polymers into high-performance electronic devices is still a significant challenge since carbohydrate polymers are electronically inactive. To address this problem, an additional electroactive ingredient can be chemically modified or physically blended into the carbohydrate polymers to actively control the electrical signals generated by organic electronics [32,33,34]. Designing electronics that can be integrated into biomaterials has become an efficient procedure to broaden the electrical applications of the carbohydrate polymers. Notably, Chiu and Chen et al. exploited the charge-storage behaviors of an α-glucan-containing polysaccharides, including oligosaccharide maltoheptaose (MH), dextran and polysucrose, in bio-based materials and successfully proposed an MH-based copolymer as the charge-storage layer for preparing high-performance nonvolatile memory devices [35,36,37,38,39]. Herein, this article mainly discusses the electron-trapping mechanism of oligosaccharide MH, the relationships between chemical structures and the corresponding supramolecular structures, self-assembly morphologies and the memory device characteristics of some newly reported MH-based copolymers and their promising future as the next generation of green electronics.

Discussion

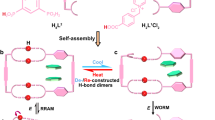

Glucose-based oligo- or polysaccharides can potentially serve as charge-storage layers induced by charge carriers at the dielectric/semiconductor interface for the next generation of green transistor-type memory devices. Chiu, Chen and co-workers first recognized the charge-storage behaviors of oligosaccharide MH, the α-glucan-containing polysaccharide, and then successfully developed MH-based copolymers as dielectric layers for high-performance green memory devices [35,36,37,38,39]. It began by inserting a thin film of the linear oligosaccharide MH between the semiconducting pentacene layer and the SiO2 layers of a transistor configured as shown in Fig. 1a [36]. To examine the electrical transfer characteristics, a positive gate bias was applied to the transistor device, and as a result, a large threshold voltage shift was observed in the transfer curve and did not dissipate (Fig. 1b). In other words, the oligosaccharides possess an extremely strong charge-trapping capability, which allows the MH layer to effectively and irreversibly trap electrons when the pentacene/the MH layer interface is subjected to a sufficient built-in electric field. Therefore, the device could maintain a nonvolatile high-current state with highly stable retention characteristics even after a treatment of erasing voltage stress, which presents as write-once-read-many-type (WORM-type) behavior. Although the electron-trapping phenomena in OFETs and OFET memory devices are regularly caused by other synthetic polymers containing considerable numbers of hydroxyl groups in their structures [40,41,42,43], the negative charges cannot be stabilized in the dielectric materials. The unique mechanism used by MH-based materials for electron trapping at the interface between the oligosaccharide gate dielectric and the semiconductor was postulated to involve deprotonating the hydroxyl groups in the semiconducting layer to give negatively charged O− moieties when an external gate voltage is applied. MH molecules with one negative charge tend to share a hydrogen atom with another molecule. Other than that the length of the hydrogen bonds ranges from 1.6 to 1.9 Å, much shorter hydrogen bonds (≈1.4 Å) are formed by the strong intermolecular interactions of the charged MH molecules (Fig. 1c, d). The higher electron density of the resulting hydroxyl anions can potentially enhance the hydrogen bonding to stabilize and tightly trap the electrons injected into the polysaccharide structure leading to the irreversible WORM-type characteristics of the material. In addition, other α-glucan-containing polysaccharides in bio-based materials, including dextran and polysucrose, have shown similar carrier-trapping abilities, which further implies the important role of the α-glucan moieties in the memory behavior. As the oligosaccharide MH-based devices express nonvolatile memory characteristics, a substantial amount of effort has been dedicated to changing the memory behavior of these devices from nonvolatile to volatile using electrets of MH-based block copolymers and their supramolecules (Fig. 2).

a Schematic of the pentacene-based OFET device with a maltoheptaose (MH) dielectric layer and its molecular structure. b Transfer characteristics of an MH-based transistor memory device at Vd = −30 V. c Schematic illustration of the irreversible electron-trapping mechanism within the MH dielectric. d The geometry of neutral and charged MH molecules according to a theoretical molecular simulation using density functional theory (DFT) with B3LYP and 6–31G. Reproduced with permission from Chiu et al. [36]. Copyright 2015, Wiley-VCH

Schematic configuration of the pentacene-based OFET memory device and molecular structures of a MH-b-PS and MH(APy)-b-PS supramolecules, b MH-b-PStFln (n = 1 or 2), c MH-b-PPyMAn and MH(4Py-Acceptor-4Py)x-b-PPyMAn supramolecules (n = 10, 20, and 40; x = 1 and 1.5), and d MH-b-PIn (n = 3800 or 12,600)

MH-b-polystyrene block copolymer (MH-b-PS) was used as the electret in a transistor memory device to switch from WORM behavior to flash-type memory characteristics (Fig. 2a) [35]. In this manner, the thin film of MH-b-PS with a thickness of 43–45 nm could be tuned such that the ordered MH nanodomain in the PS matrix could have different orientations from spherical to cylindrical by increasing the solvent (H2O/THF at a ratio of 1/1) annealing time (Fig. 3a, b) [1, 35, 43]. The PS block served as an insulating matrix and a tunneling layer with a low k to reduce the interactions between the polysaccharide/semiconductor and facilitate the release of trapped charges in the very hydrophilic and polyhydroxylated MH block. In one approach, changes in the morphology of the MH-b-PS significantly affected its memory behaviors and retention capability, as shown in Fig. 3c, d, which is similar to what is seen with state-of-the-art in nanofloating gate and block copolymer-nanoparticle hybrid memory devices [1, 43,44,45]. A horizontal cylindrical MH domain triggers a stronger electron-trapping ability than what is achieved with a randomly oriented sphere or a vertical cylinder, as illustrated in Fig. 4. Thus, the larger interface between the pentacene and the MH domains in the case of horizontal cylinders can be attributed to the effective contact area of the polarized hydroxyl groups. Although the electron storage could be controlled by the MH structure, the MH-b-PS-based devices possess poor hole-trapping ability. To further improve the memory properties, increasing the content of 1-aminopyrene (APy) supramolecules in the electrets via hydrogen bonding can help reduce the number of free hydroxyl groups in the MH block and increase the hole-storage capacity of the conjugated pyrene structure. As a result, the polarizability of the MH-b-PS and the trend in the dielectric constant decrease (Fig. 2a), and the optimized device using horizontal cylinders of the APy composite electrets were reported as excellent flash memory devices with a wide memory window (52.7 V), retention times longer than 104 s, high hole mobility of ~10−1 cm2/Vs, and high on/off ratio of > 105, and the device was stably reversible over 200 cycles without decay. High-performance OFET memory could possibly be achieved by using green electrets derived from MH-based block copolymers composed of the trapping and low-k tunneling moieties and their supramolecules.

Atomic force microscopy phase images of an MH-b-PS diblock copolymer film: a random sphere structure (as-cast); b horizontal cylinder (12 h of annealing); and reversible shift in the transfer characteristic of the pentacene-based OFET memory devices with different MH-b-PS electrets with c random sphere and d horizontal cylinder geometries. Reproduced with permission from Chiu et al. [35]. Copyright 2014, Wiley-VCH

Illustration of the effect of the morphology on the memory characteristics of pentacene-based OFET memory devices under a positive and a negative bias using electrets of a MH-b-PS block copolymer and b MH(APy)-b-PS supramolecule. Reproduced with permission from Chiu et al. [35]. Copyright 2014, Wiley-VCH

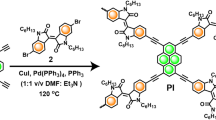

In addition to using APy supramolecules, electroactive moieties (such as oligofluorenyl groups) were employed as the side chains of PS to replace the above PS blocks and form MH-based block copolymers MH-b-PStFln (n = 1 or 2, Fig. 2b) [37]. By incorporating an electron-trapping MH block, the p-type nature of the PStFln film allows it to act as a charge transport layer, which strengthens its retention characteristics. Otherwise, a large electron injection barrier, such as that formed by embedding an MH block into an StFln moiety, can reduce the charge-trapping ability of the MH block. Unlike non-conjugated PS blocks [35], the self-assembled morphology, the memory window, and the OFET memory characteristics of the MH-b-PStFln-based memory devices were correlated with oligofluorenyl chain length (Fig. 5). The well-defined self-assembled spherical microdomains with sub-10 nm sizes in both 50 nm-thick bulk (Fig. 5a, b) and thin film diblock polymers generated using thermal or solvent annealing processes were preferred morphological designs for inducing memory characteristics in MH-b-PStFln devices. As the conjugation length of the pendent oligofluorene moiety increased, the grain size decreased and the memory windows increased in these devices (Fig. 5c, d) because of the well-ordered arrangement of the PStFln blocks after the incorporation of MH and the improved electron-donating or electron-accepting abilities of the PStFl2 blocks. However, the extremely strong hole trapping by the PStFl2 segment is related to the poor switching stability of MH-b-PStFl2-based devices. Therefore, the MH-b-PStFl1-based memory device was announced as a better and greener polymeric candidate for nonvolatile flash-type memory applications as it could be subjected to >180 write-read-erase-read (WRER) cycles with not only high mobility (0.52 cm2/Vs) and ION/IOFF ratios (106−108) but also a long-term retention time >104 s.

a TEM image and b SAXS data of the self-assembled spherical structure of a thermally annealed MH-b-PStFl2 bulk sample and the electron transfer curves of memory devices prepared from thermally annealed MH-b-PStFln (n = 1 or 2) electrets: c MH-b-PStFl1 and d MH-b-PStFl2. Reproduced with permission from Sun et al. [37]. Copyright 2015, ACS Publishing

Obviously, the major effects of the structural and morphological properties of the MH-based electret layer on the device memory characteristics have been determined for the above MH(APy)-b-PS and MH-b-PStFln devices. Further studies were conducted to confirm the effects of the structure of the block copolymer-based supramolecular complex, maltoheptaose-block-poly(1-pyrenylmethyl methacrylate) (MH-b-PPyMA, Fig. 2c), and the morphology of its supramolecular complex, MH(4Py-Acceptor-4Py)x-b-PPyMA, on the OFET memory characteristics [38]. Consistent with a previous report on MH-b-PStFln-based devices, the trapping ability of MH blocks embedded in PPyMA is reduced by the electron injection barrier of the densely packed PPyMAn shell, and as a result, a 4Py-Acceptor-4Py moiety was added to improve the electron-trapping ability of the polymer electret layer. In this study, the thermally annealed MH-b-PPyMA bulk samples can nanomorphologically be converted from cylindrical to spherical by controlling the composition of the MH and PPyMA segments (Fig. 6a); however, only spherical nanodomains, which have strong intermolecular interactions and high surface energy of MH, are formed in both the thermally annealed MH-b-PPyMA and MH(4Py-Acceptor-4Py)x-b-PPyMA film due to the strong intermolecular interactions and high surface energy of MH. The thickness of the polymer film was also controlled to be approximately 50 nm. Among the MH(4Py-Acceptor-4Py)x-b-PPyMAn-based devices, the MH(4Py-BT-4Py)1.5-b-PPyMA10-based device exhibited the best memory characteristics and showed a higher hole mobility of ~1 cm2/Vs, high ION/IOFF ratios of 106–107, a long-term retention time larger than 104 s and the ability to withstand more than 100 WRER cycles (Figs. 6b, c). For this study, the proportion of the acceptor and donor in a block copolymer-based supramolecular was found to be the crucial factor for enhancing the memory characteristics, which improved the potential of the electret layer for applications in nonvolatile flash memory devices.

a SAXS data of thermally annealed, self-assembled MH-b-PPyMA bulk samples that shifted from cylindrical to spherical morphologies as the DP of the PPyMA segments increased from 10 to 40; b the electron transfer curves and c the switching stability of the memory devices prepared from thermally annealed MH(4Py-BT-4Py)1.5-b-PPyMA10 supramolecular electrets. Reproduced with permission from Sun et al. [38]. Copyright 2016, RSC Publishing

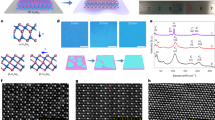

Despite the great advances in their memory properties, carbohydrate-based materials limit their attractiveness in stretchable electronics applications due to the lack of elastic properties. Recently, flexible electronics have attracted tremendous attention for their future prospects for wearable electronics, e-skin, and biomedical applications. To take advantage of block copolymers as the inherent immiscibility of different polymer segments, Chen and co-workers successfully designed block copolymers of oligosaccharides and polyisoprene that can be tuned from solid to stretchable memory devices (Fig. 2d) [39]. As usual, MH blocks with a large number of hydroxyl moieties can trap electrons and serve as the charge-trapping material. In addition, the properties of PI in a block copolymer system have been defined not only impact the flexibility of the material but also insulate the matrix to control the charge trapping through the nanostructures of the block copolymer film. By controlling the ratio between the PI and MH blocks, the non-stretching moiety can spontaneously assemble into nanodomains (Fig. 7a-c). Typically, the formation of a 50-nm-thick MH-b-PI3.8k or MH-b-PI12.6k thin film with a vertical cylinder, horizontal cylinder or ordered sphere nanostructure can be achieved using a solvent annealing. Again, the effect of thin film morphologies with different nanostructures and orientations of the MH domain was clearly shown to have a substantial impact on the memory behaviors (Fig. 7d-f). At positions perpendicular to the electrodes, the vertical cylindrical MH-b-PI3.8k thin film provides a direct and active route for charge trapping, giving this material WORM-type memory properties (Fig. 7d). In the case of the horizontal MH cylinders, the cylindrical domain device shows flash-type behavior because the separated PI matrix cannot form an immediate channel connecting the two electrodes, and the active route may fall away when a reverse bias is applied (Fig. 7e). On the other hand, MH-b-PI12.6k-based device with spherical MH domains show reduced trapping abilities and showed dynamic random access memory (DRAM)-type behavior (Fig. 7f). In contrast to the memory behavior, as the elastic characteristics of the MH-b-PI12.6k thin film could be fully recovered under 100% strain, the MH-b-PI12.6k block polymer was used to fabricate stretchable memory devices based on the Polydimethylsiloxane (PDMS) substrate/Carbon nanotubes (CNT)/MH-b-PI thin film/Al configuration (Fig. 7j). The PDMS/CNT/MH-b-PI12.6k/Al memory devices were reported to have an excellent ON/OFF current ratio of over 106 (reading at −1 V) with a stable Vset of approximately −2 V under 0%–100% strain or over 1000 cycles of continuous stretch relaxation under 40% strain. Compared with using the rubber-like, stretchable, conducting PDMS/CNT composite, which could maintain good conductivity and stretchability over 100% strain, as the bottom electrode or other high-performance OFET devices, these MH-based block copolymers hold great potential for developing wearable and stretchable devices [36,37,38, 46, 47]. For this reason, in addition to the switching of the resistive memory behaviors as a response to the nanostructured morphology, the design of polymer segments into MH-based block copolymer systems can be used to achieve advanced properties to meet the various requirements for MH-based memory devices.

Atomic force microscopy images of MH-b-PI3.8k diblock copolymer film that self-assembled into a a vertical cylinder after 8 h of annealing; b horizontal cylinder after 48 h of annealing; and c MH-b-PI12.6k diblock copolymer film that self-assembled into a spherical structure (24 h of annealing). I-V characteristics of the MH-b-PIn-based resistive memory device with MH-b-PIn films with different morphologies: d vertical cylinder; e horizontal cylinder; and f sphere. j An illustration of the stretchable, rubber-based memory device with a PDMS substrate/CNTs/MH-b-PI thin film/Al structure with high stretchability under (i) 0% and (ii) 100% strains. Reproduced with permission from Hung et al. [39]. Copyright 2017, Wiley-VCH

Conclusion

In recent years, increasing environmental awareness has made the identification of natural materials for use in electronics more desirable. Compared with other synthetic polymers, glucose-based oligo- or polysaccharides, particularly MH, have advantages including their high abundance, renewability, and extremely high charge-storage capacity. Currently, the advances in MH-based block copolymers with self-assembled nanostructures and their supramolecules have been used to achieve promising polymer electrets with excellent electrical and memory properties that are much more affordable to be replaced. Notably, the rational design of sugar block polymers with different functional segments can provide not only high-performance memory characteristic but also some of the intrinsic properties associated with conjugated molecules. However, in addition to the very impressive result reported thus far, several factors that impact the electron injection barrier and efficient charge trapping such as the structure of the block polymer, the morphology of the electret layer, and even the supramolecular complex are still challenging on block copolymers concerns for the preparation of OFET memory devices. In the future, glucose-based block copolymer materials have great potential to develop into high-performance nonvolatile memory devices with expectation as the next generation of green electronics.

References

Baeg K-J, Noh Y-Y, Sirringhaus H, Kim D-Y. Controllable shifts in threshold voltage of top-gate polymer field-effect transistors for applications in organic nano floating gate memory. Adv Funct Mater. 2010;20:224–30.

Yang Y, Ouyang J, Ma L, Tseng RJH, Chu CW. Electrical switching and bistability in organic/polymeric thin films and memory devices. Adv Funct Mater. 2006;16:1001–14.

Chou Y-H, Chang H-C, Liu C-L, Chen W-C. Polymeric charge storage electrets for non-volatile organic field effect transistor memory devices. Polym Chem. 2015;6:341–52.

Guo Y, Yu G, Liu Y. Functional organic field-effect transistors. Adv Mater. 2010;22:4427–47.

Han S-T, Zhou Y, Roy VAL. Towards the development of flexible non-volatile memories. Adv Mater. 2013;25:5425–49.

Leong WL, Mathews N, Tan B, Vaidyanathan S, Dotz F, Mhaisalkar S. Towards printable organic thin film transistor based flash memory devices. J Mater Chem. 2011;21:5203–14.

Li J, Tan H-S, Chen Z-K, Goh W-P, Wong H-K, Ong K-H, Liu W, Li CM, Ong BS. Dialkyl-substituted dithienothiophene copolymers as polymer semiconductors for thin-film transistors and bulk heterojunction solar cells. Macromolecules. 2011;44:690–3.

Dhar BM, Özgün R, Dawidczyk T, Andreou A, Katz HE. Threshold voltage shifting for memory and tuning in printed transistor circuits. Mater Sci Eng R Rep. 2011;72:49–80.

Tseng C-W, Tao Y-T. Electric bistability in pentacene film-based transistor embedding gold nanoparticles. J Am Chem Soc. 2009;131:12441–50.

Hoffman J, Pan X, Reiner JW, Walker FJ, Han JP, Ahn CH, Ma TP. Ferroelectric field effect transistors for memory applications. Adv Mater. 2010;22:2957–61.

Naber RCG, Asadi K, Blom PWM, de Leeuw DM, de Boer B. Organic nonvolatile memory devices based on ferroelectricity. Adv Mater. 2010;22:933–45.

Wu W, Zhang H, Wang Y, Ye S, Guo Y, Di C, Yu G, Zhu D, Liu Y. High-performance organic transistor memory elements with steep flanks of hysteresis. Adv Funct Mater. 2008;18:2593–601.

Chou Y-H, You N-H, Kurosawa T, Lee W-Y, Higashihara T, Ueda M, Chen W-C. Thiophene and selenophene donor–acceptor polyimides as polymer electrets for nonvolatile transistor memory devices. Macromolecules. 2012;45:6946–56.

Chiu Y-C, Shih C-C, Chen W-C. Nonvolatile memories using the electrets of conjugated rod-coil block copolymer and its nanocomposite with single wall carbon nanotubes. J Mater Chem C. 2015;3:551–8.

Dong L, Sun H-S, Wang J-T, Lee W-Y, Chen W-C. Fluorene based donor-acceptor polymer electrets for nonvolatile organic transistor memory device applications. J Polym Sci, Part A: Polym Chem. 2015;53:602–14.

Chi H-Y, Hsu H-W, Tung S-H, Liu C-L. Nonvolatile organic field-effect transistors memory devices using supramolecular block copolymer/functional small molecule nanocomposite electret. ACS Appl Mater Interfaces. 2015;7:5663–73.

Hsu J-C, Lee W-Y, Wu H-C, Sugiyama K, Hirao A, Chen W-C. Nonvolatile memory based on pentacene organic field-effect transistors with polystyrenepara-substituted oligofluorene pendent moieties as polymer electrets. J Mater Chem. 2012;22:5820–7.

Chiu YC, Chen TY, Chen Y, Satoh T, Kakuchi T, Chen WC. High-performance nonvolatile organic transistor memory devices using the electrets of semiconducting blends. ACS Appl Mater Interfaces. 2014;6:12780–8.

Chou Y-H, Takasugi S, Goseki R, Ishizone T, Chen W-C. Nonvolatile organic field-effect transistor memory devices using polymer electrets with different thiophene chain lengths. Polym Chem. 2014;5:1063–71.

Owusu PA, Asumadu-Sarkodie S. A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent Eng. 2016;3:1167990.

Nigam PS, Singh A. Production of liquid biofuels from renewable resources. Prog Energy Combust Sci. 2011;37:52–68.

Bozell, JJ. Chemicals and materials from renewable resources, in Chemicals and Materials from Renewable Resources. American Chemical Society; 2001. p. 1–9

Rinaudo M. Chitin and chitosan: properties and applications. Prog Polym Sci. 2006;31:603–32.

Sunilkumar M, Gafoor AA, Anas A, Haseena AP, Sujith A. Dielectric properties: a gateway to antibacterial assay—a case study of low-density polyethylene/chitosan composite films. Polym J. 2014;46:422–9.

Kumar MN, Muzzarelli RA, Muzzarelli C, Sashiwa H, Domb AJ. Chitosan chemistry and pharmaceutical perspectives. Chem Rev. 2004;104:6017–84.

Xu C, Arancon RA, Labidi J, Luque R. Lignin depolymerisation strategies: towards valuable chemicals and fuels. Chem Soc Rev. 2014;43:7485–500.

Besson M, Gallezot P, Pinel C. Conversion of biomass into chemicals over metal catalysts. Chem Rev. 2014;114:1827–70.

Damager I, Engelsen SB, Blennow A, Moller BL, Motawia MS. First principles insight into the alpha-glucan structures of starch: their synthesis, conformation, and hydration. Chem Rev. 2010;110:2049–80.

Lligadas G, Ronda JC, Galià M, Cádiz V. Renewable polymeric materials from vegetable oils: a perspective. Mater Today. 2013;16:337–43.

Mobin S, Alam F. Some promising microalgal species for commercial applications: a review. Energy Procedia. 2017;110:510–7.

Chen GQ. A microbial polyhydroxyalkanoates (PHA) based bio- and materials industry. Chem Soc Rev. 2009;38:2434–46.

Karakawa M, Chikamatsu M, Yoshida Y, Azumi R, Yase K, Nakamoto C. Organic memory device based on carbazole-substituted cellulose. Macromol Rapid Commun. 2007;28:1479–84.

Valentini L, Cardinali M, Fortunati E, Kenny JM. Nonvolatile memory behavior of nanocrystalline cellulose/graphene oxide composite films. Appl Phys Lett. 2014;105:153111.

Nagashima K, Koga H, Celano U, Zhuge F, Kanai M, Rahong S, Meng G, He Y, De Boeck J, Jurczak M, Vandervorst W, Kitaoka T, Nogi M, Yanagida T. Cellulose nanofiber paper as an ultra flexible nonvolatile memory. Sci Rep. 2014;4:5532.

Chiu Y-C, Otsuka I, Halila S, Borsali R, Chen W-C. High-performance nonvolatile transistor memories of pentacence using the green electrets of sugar-based block copolymers and their supramolecules. Adv Funct Mater. 2014;24:4240–9.

Chiu YC, Sun HS, Lee WY, Halila S, Borsali R, Chen WC. Oligosaccharide carbohydrate dielectrics toward high-performance non-volatile transistor memory devices. Adv Mater. 2015;27:6257–64.

Sun H-S, Chiu Y-C, Lee W-Y, Chen Y, Hirao A, Satoh T, Kakuchi T, Chen W-C. Synthesis of oligosaccharide-based block copolymers with pendent π-conjugated oligofluorene moieties and their electrical device applications. Macromolecules. 2015;48:3907–17.

Sun H-S, Chen Y, Lee W-Y, Chiu Y-C, Isono T, Satoh T, Kakuchi T, Chen W-C. Synthesis, morphology, and electrical memory application of oligosaccharide-based block copolymers with π-conjugated pyrene moieties and their supramolecules. Polym Chem. 2016;7:1249–63.

Hung C-C, Chiu Y-C, Wu H-C, Lu C, Bouilhac C, Otsuka I, Halila S, Borsali R, Tung S-H, Chen W-C. Conception of stretchable resistive memory devices based on nanostructure-controlled carbohydrate-block-polyisoprene block copolymers. Adv Funct Mater. 2017;27:1606161.

Chua LL, Zaumseil J, Chang JF, Ou EC, Ho PK, Sirringhaus H, Friend RH. General observation of n-type field-effect behaviour in organic semiconductors. Nature. 2005;434:194–9.

Egginger M, Irimia-Vladu M, Schwödiauer R, Tanda A, Frischauf I, Bauer S, Sariciftci NS. Mobile ionic impurities in poly(vinyl alcohol) gate dielectric: possible source of the hysteresis in organic field-effect transistors. Adv Mater. 2008;20:1018–22.

Tsai T-D, Chang J-W, Wen T-C, Guo T-F. Manipulating the hysteresis in poly(vinyl alcohol)-dielectric organic field-effect transistors toward memory elements. Adv Funct Mater. 2013;23:4206–14.

Kang M, Baeg K-J, Khim D, Noh Y-Y, Kim D-Y. Printed, flexible, organic nano-floating-gate memory: effects of metal nanoparticles and blocking dielectrics on memory characteristics. Adv Funct Mater. 2013;23:3503–12.

Wei Q, Lin Y, Anderson ER, Briseno AL, Gido SP, Watkins JJ. Additive-driven assembly of block copolymer-nanoparticle hybrid materials for solution processable floating gate memory. ACS Nano. 2012;6:1188–94.

Chen C-M, Zhang Q, Zhao X-C, Zhang B, Kong Q-Q, Yang M-G, Yang Q-H, Wang M-Z, Yang Y-G, Schlögl R, Su DS. Hierarchically aminated graphene honeycombs for electrochemical capacitive energy storage. J Mater Chem. 2012;22:14076.

Wu H-C, Liu C-L, Chen W-C. Donor–acceptor conjugated polymers of arylene vinylene with pendent phenanthro[9,10-d]imidazole for high-performance flexible resistor-type memory applications. Polym Chem. 2013;4:5261.

Xu F, Wang X, Zhu Y, Zhu Y. Wavy ribbons of carbon nanotubes for stretchable conductors. Adv Funct Mater. 2012;22:1279–83.

Acknowledgements

A-NA-D and C-CK acknowledge financial support from the National Taipei University of Technology, Taipei, Taiwan. Y-CC acknowledges the Ministry of Science and Technology, Taiwan, for their financial support (105-2218-E-011-017-MY3).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Au-Duong, AN., Kuo, CC. & Chiu, YC. Self-assembled oligosaccharide-based block copolymers as charge-storage materials for memory devices. Polym J 50, 649–658 (2018). https://doi.org/10.1038/s41428-018-0059-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0059-1