Abstract

The 13C NMR spectra of atactic copolymers of methyl methacrylate (MMA) and benzyl methacrylate (BnMA) show complicated resonance patterns due to variations in their configurational sequences and monomer sequences in the macromolecular chains. Principal component analysis (PCA) was found to be useful for extracting information regarding the chemical composition and monomer sequence from the complicated resonances of the copolymers. To assess the feasibility for monomer sequence analysis, a PCA approach was applied to the spectra of MMA-BnMA copolymers prepared by partial modification of atactic poly(benzyl methacrylate) through catalytic hydrogenolysis, acidic debenzylation, saponification, and transesterification and by two-step esterification of atactic poly(methacrylic acid) (PMAa). The analysis clearly showed the formation of highly blocky copolymers via hydrogenolysis, as well as the formation of copolymers with a somewhat alternating tendency via acidic debenzylation, saponification, and transesterification in the late processes of the reactions. The copolymers formed in early processes of these reactions were essentially random sequences. The analysis also revealed that the copolymer prepared through partial methylation of PMAa with diazomethane was a random copolymer, while the copolymer prepared through partial benzylation of PMAa with benzyl bromide was a blocky copolymer.

Similar content being viewed by others

Introduction

Manufactured plastics and rubbers largely consist of copolymers comprising several different types of monomer. The chemical and physical properties of a copolymer depend on the ratio and distribution of repeating units within the macromolecular chains, and thus, their analysis is essential to understanding the structure-property relationships of the copolymer. For this purpose, high-resolution nuclear magnetic resonance (NMR) spectroscopy is usually the method of choice.

Determination of the monomer sequence in a copolymer by NMR has been the subject of several publications. Binary vinyl copolymers that have been investigated include those obtained by copolymerization of styrene-methyl methacrylate (MMA) [1,2,3,4], vinylidene chloride-vinyl chloride [5,6,7], acrylonitrile-MMA [8, 9], butadiene-acrylonitrile [10], butadiene-styrene [11], styrene-maleic anhydride [12], acrylonitrile-styrene [13], ethyl acrylate-MMA [14], and vinyl ether-N-phenylmaleimide [15]. Much attention has also been directed toward the vinyl copolymers obtained by polymer reactions (partial modification) of poly(vinyl acetate) [16,17,18,19] and stereoregular polymethacrylates [20,21,22,23,24,25,26].

Generally, atactic copolymers of methacrylates give NMR spectra with complicated resonance patterns due to the superposed influence of monomer sequences and configurational sequences. Therefore, assigning the sequence and configuration for each individual resonance is troublesome [27, 28], and acquiring quantitative information about the monomer sequence distribution is even more difficult. Klesper and coworkers studied the 1H NMR spectra of MMA-methacrylic acid (MAa) copolymers derived from syndiotactic (92% in triads) poly(methyl methacrylate) (PMMA) by partial saponification [20, 21] or partial hydrolysis [22]. The simple resonance patterns arising from the stereoregular copolymers allowed investigation of the relative abundance of monomer sequence triads. The 1H and 13C NMR spectra of MMA-MAa copolymers obtained by partial modification of syndiotactic, isotactic, and atactic PMMAs were also studied subsequently in terms of monomer sequence distribution [23, 24]. Kawauchi and coworkers reported the 1H and 13C NMR spectra of random copolymers of methacrylates prepared by two-step esterification of highly syndiotactic (96% in triads) or highly isotactic (98% in triads) poly(methacrylic acid) (PMAa) [25]. A recent paper by Kitaura and coworkers showed the 1H NMR spectra of random and blocky copolymers obtained by a partial click reaction of highly isotactic poly(propargyl methacrylate) with organic azides [26].

Another approach to the complicated spectra of copolymers is the application of multivariate chemometric methods [29,30,31]. Multivariate analysis is a statistical tool that can transform complex information into more useful sets of information and extract vital differences from data that may look similar using conventional approaches. Among the standard procedures for multivariate analysis, principal component analysis (PCA) [32, 33] is one of the simplest. In our previous papers, the 13C NMR spectra of atactic copolymers of MMA and tert-butyl methacrylate with various chemical compositions were subjected to PCA, together with the spectra of homopolymer blends (PMMA and poly(tert-butyl methacrylate)) with various blend ratios [29, 30]. The analysis successfully and separately extracted information regarding chemical composition and monomer sequence as the first and second principal components (PC1 and PC2), respectively. This procedure does not require assignment of individual resonance peaks.

The objective of the present paper is to assess the feasibility and limitations of this PCA approach for the monomer sequence analysis of copolymers. A binary system of MMA and benzyl methacrylate (BnMA) was selected because copolymer series with a variety of sequence distributions, ranging from blocky to alternating tendencies, were expected to be obtained by partial modifications of poly(benzyl methacrylate) (PBnMA) through catalytic hydrogenolysis [34, 35], acidic debenzylation, saponification, transesterification, and two-step esterification of PMAa [25, 36,37,38] (Fig. 1) and by free-radical copolymerization of MMA and BnMA.

Experimental section

Materials

BnMA monomer (98%, Mitsubishi Rayon Co. Ltd., Tokyo, Japan) and toluene (Kishida Chemical Co. Ltd., Osaka, Japan) were distilled immediately prior to use. Trifluoroacetic acid (TFA), N-methyl-N-nitroso-p-toluenesulfonamide, 2-(2-ethoxyethoxy)ethanol, tert-butyl methyl ether, 5% palladium on carbon (wetted with approximately 55% water), benzyl bromide and 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU) were purchased from Tokyo Chemical Industry Co., Ltd. (Tokyo, Japan). Potassium methylate (KOCH3), potassium hydroxide (KOH), 18-crown-6, methanol, dioxane, dimethyl sulfoxide (DMSO), tetrahydrofuran (THF), and n-hexane were purchased from Kanto Chemical Co., Inc. (Tokyo, Japan).

Polymerization and copolymerization

Polymerization was performed in a three-necked 300-mL round-bottom flask equipped with a magnetic stirrer and nitrogen supply. To a 20 wt% solution of BnMA in toluene, AIBN (0.5 mol% of the monomer) was added, and the solution was stirred at 60 °C for 24 h. The polymer was recovered by precipitation in excess methanol and dried under vacuum for 24 h. Copolymers of MMA and BnMA with various compositions were prepared in a similar manner. Table 1 summarizes the chemical composition (mol% in MMA units) and molecular weight of the polymer samples used in the present work. The nine copolymers and two homopolymers were abbreviated as C-14 to C-93 and H0 to H100, respectively; the number corresponds to the percentage of MMA units. Table 2 lists the chemical compositions of the blends of PMMA (H100) and PBnMA (H0) as determined by 1H NMR.

Catalytic hydrogenolysis (CH) of PBnMA

PBnMA (H0, 0.5 g, corresponding to 2.8 mmol in BnMA units) was dissolved in a mixture of THF and methanol (5:1 v/v, 30 mL) in a one-necked 100-mL round-bottom flask fitted with a tap and balloon. To this solution, 0.25 g of Pd/C (5%) catalyst was added, with stirring, under a hydrogen atmosphere (1 atm) at ambient temperature. After the reaction, the solution was filtered to remove solid catalyst residues, and the resultant copolymer was recovered through precipitation in excess n-hexane. The copolymer of MAa and BnMA was converted to MMA–BnMA copolymer through methylation with diazomethane. Complete chemical conversion was confirmed by 1H NMR spectroscopy. Table 3 lists the experimental conditions required to obtain the copolymer products CH18–CH65 and their chemical compositions.

Acidic debenzylation (AD) of PBnMA

PBnMA (H0, 0.5 g) was dissolved in 15 mL of TFA in a one-necked 100-mL round-bottom flask fitted with a serum cap. After stirring at a predetermined temperature for a predetermined time, TFA was removed from the reaction mixture by evaporation. The resultant copolymer was recovered by precipitation in excess n-hexane. Subsequently, the copolymer of MAa and BnMA was converted to MMA–BnMA copolymer through methylation with diazomethane. Complete chemical conversion was confirmed by 1H NMR spectroscopy. The experimental conditions required to obtain the copolymer products AD12–AD91 are shown in Table 3.

Saponification (SP) of PBnMA

PBnMA (H0, 0.5 g) was dissolved in 15 mL of toluene or dioxane containing a 15-fold excess of KOH or KOCH3 (42 mmol, solution in 2 mL of water) and 18-crown-6 (0.7 mmol) in a one-necked 100-mL round-bottom flask fitted with a condenser. After the reaction, aqueous HCl was added to the solution for neutralization, and the mixture was stirred overnight at room temperature. Subsequently, THF was added to the mixture to remove KCl by filtration. The THF was removed from the mixture by evaporation, and the copolymer was recovered by precipitation in excess n-hexane. The resultant copolymer of MAa and BnMA was converted to MMA–BnMA copolymer through methylation with diazomethane. Complete chemical conversion was confirmed by 1H NMR spectroscopy. The experimental conditions required to obtain the copolymer products SP50–SP63 are also shown in Table 3.

Transesterification (TE) of PBnMA

PBnMA (H0, 0.5 g) was dissolved in 16 mL of dioxane containing 8 mL of methanol and KOCH3 (42 mmol) in a one-necked 100-mL round-bottom flask fitted with a condenser. After the reaction at 85 °C, aqueous HCl was added to the solution for neutralization, and the mixture was stirred overnight at room temperature. Subsequently, THF was added to the mixture to remove KCl by filtration. Excess THF was removed by evaporation, and the copolymer was recovered by precipitation in excess n-hexane. The experimental conditions required to obtain the copolymer products TE23–TE92 are shown in Table 3. The absence of MAa units in the TE copolymers was confirmed by 1H and 13C NMR spectroscopy.

Two-step benzylation-methylation (BM) of PMAa

PMAa was prepared by full debenzylation of PBnMA (H0) with TFA in the manner described above (AD, 80 °C, 24 h). In a one-necked 100-mL round-bottom flask, 0.4 g of PMAa (4.64 mmol in MAa units) was dissolved in 20 mL of DMSO. To the solution, 0.397 g of benzyl bromide (2.32 mmol) and 0.354 g of DBU (2.32 mmol) were added, and the mixture was allowed to stand overnight at room temperature. The copolymer was recovered by precipitation in excess water. The resultant copolymer of MAa and BnMA was converted to MMA–BnMA copolymer through methylation with diazomethane. The chemical composition of the copolymer was 57.0% in MMA units, and thus, the sample code BM57 was assigned to this copolymer (Table 3).

Two-step methylation–benzylation (MB) of PMAa

In a one-necked 100-mL round-bottom flask, 0.4 g of PMAa was dissolved in 20 mL of a mixture of DMSO and methanol (8:2 v/v). A diazomethane solution (0.5 eq) was added to the polymer solution, and the mixture was stirred overnight at room temperature. The solvent was removed from the reaction mixture by evaporation, and the resultant copolymer of MMA and MAa was recovered by precipitation in excess n-hexane. The MMA-MAa copolymer was converted to MMA-BnMA copolymer (MB49 in Table 3) using a procedure similar to that described above (BM).

NMR measurement and PCA procedure

The 1H and 13C NMR spectra of the samples were measured in chloroform-d (8% w/v) at 55 °C using a JEOL ECX400 spectrometer equipped with a 10-mm multinuclear probe (1H: 45° pulse (8.5 μs), pulse repetition = 8.90 s, 16 scans; 13C: 45° pulse (7.5 μs), pulse repetition = 2.73 s, 5000 scans, with 1H broadband decoupling). A line-broadening factor of 2.0 Hz was applied before Fourier transformation of the 13C NMR data. The chemical composition was determined from the relative intensities of 1H NMR signals from the ester groups of the MMA and BnMA units. Tetramethylsilane and the residual chloroform in CDCl3 were used as an internal reference at 0.00 and 7.27 ppm in 1H NMR and at 0.00 and 77.0 ppm in 13C NMR.

Bucket integration was performed for the spectral regions 15–23 ppm (the α-methyl groups) and 175–179 ppm (the carbonyl groups) at an interval of 0.01 ppm. The sum of the integral intensities in each spectral region was normalized to 100. The average integral intensity was subtracted from each integral intensity. Each dataset thus obtained comprised 32 mean-centered bucket integral values. The bucket integration and PCA of the datasets were performed using Alice2 ver.5 for metabolome ver.1.6 software (JEOL Ltd., Tokyo, Japan). The calculation of PC1 and PC2 values followed the standard procedure of PCA [33].

Size-exclusion chromatography (SEC) measurement

Size-exclusion chromatography was performed using an HLC 8220 chromatograph (Tosoh Corp., Tokyo, Japan) equipped with the TSK gel columns SuperHM-M (6.5 mm ID × 150 mm) and SuperHM-H (6.5 mm ID × 150 mm) and a PL-ELS-2100 evaporative light scattering detector (Polymer Laboratories Ltd., Church Stretton, UK). THF was used as the eluent (0.35 mL min−1, 40 °C), and the molecular weight was calibrated against standard PMMA samples.

Results and discussion

Principal component score plots for 13C NMR spectra of radical copolymers and homopolymer blends: constructing the reference framework for monomer sequence analysis

In the 13C NMR spectra of MMA-BnMA copolymers, the influence of monomer sequences and configurational sequences appeared mostly in the resonances due to the α-methyl groups and carbonyl groups. Figure 2 illustrates the resonance patterns for the homopolymers (H0 and H100), a blend of the homopolymers (B49), and a radical copolymer (C49). The resonance patterns for the homopolymers are typical of polymethacrylates obtained by free-radical polymerization, reflecting the configurational triads (α-methyl groups) or pentads (carbonyl groups) in the atactic (or syndiotactic-rich) polymer chains. The triad tacticities (rr: rm: mm) determined from the α-methyl resonances were 60.0: 35.6: 4.4 for H0 and 62.0: 33.8: 4.2 for H100. It is clear that the resonances for the copolymer are broader than those for the homopolymer blend with a similar chemical composition. The broadness of the resonances arises from MMA-BnMA cross-linkages that do not exist in the homopolymer blend. However, further information about the monomer sequences is not directly available from the broad resonances.

To extract useful information about the monomer sequences from the resonances, PCA was performed for the dataset comprising the α-methyl and carbonyl resonances of the two homopolymers, nine radical copolymers with various compositions (C14 to C93 in Table 1) and nine blends of homopolymers with various blend ratios (B12 to B86 in Table 2). Figure 3 shows the principal component score plots produced by the analysis. The contribution rates for the first and second principal components (PC1 and PC2) were 84.8 and 12.6%, respectively, indicating that spectral information from the dataset was explained well by these two parameters (a cumulative contribution rate of 97.4%). The plots of homopolymers and homopolymer blends showed a linear relationship with PC1, while the plots of the copolymers exhibited a parabolic relationship between PC1 and PC2. PC1 scores were proportional to the MMA composition of the samples. PC2 showed a minimum near the plot of copolymer C49, which has a nearly equimolar composition of MMA and BnMA. Therefore, PC2 is reasonably assumed to correlate to the abundance of MMA-BnMA cross-linkages. The products of comonomer reactivity ratios r1 × r2 for the free-radical copolymerization of MMA and BnMA in the literature (0.90–1.08) [39] suggest that copolymers C14 to C93 are statistical copolymers with ideally random sequences. The principal component score plots for the datasets are thus suitable as a reference framework for the sequence analysis described below.

Principal component score plots for α-methyl and carbonyl resonances of PBnMA (H0, □), PMMA (H100, ■), blends of PMMA and PBnMA with various blend ratios (B12-B86, ○), and radical copolymers of MMA and BnMA with various chemical compositions (C14-C93, ●). The contribution rates for the first and second principal components (PC1 and PC2) were 84.8 and 12.6%, respectively

Principal component analysis of monomer sequences in MMA-BnMA copolymers prepared by various polymer reactions

Partial modification of homopolymers is well known to sometimes afford copolymers with various sequence distributions, from blocky to alternating tendencies, which cannot currently be achieved through direct copolymerization. Monomer sequences of this kind are often explained by the neighboring group effect (or anchimeric assistance) [26, 40,41,42] during reaction processes. For example, alkaline hydrolysis of syndiotactic PMMA gives MMA-MAa copolymers with monomer sequences with approximately random, blocky, or alternating tendencies, depending on the reaction conditions [22].

To assess the feasibility of the monomer sequence analysis by PCA, several series of MMA-BnMA copolymers were prepared by partial modification of PBnMA through CH, acidic AD, SP, and TE and by two-step esterification of PMAa (BM and MB) (Table 3). Because the degree of polymerization and the stereoregularity of the copolymers remain unchanged during the polymer reactions, the chemical composition and monomer sequence in the copolymers are the only factors affecting the resonance patterns.

Figure 4 illustrates the carbonyl resonances of the copolymer samples CH50, AD52, SP50, and TE49 with nearly equimolar MMA-BnMA compositions. The resonances of the copolymer samples BM57 and MB49 are shown in Fig. 5. Although all of these resonances appear to be similar, small but significant differences are found in the line widths of resonances and the relative intensity of minor splittings, reflecting differences in the monomer sequences of the copolymer samples.

13C NMR spectra for carbonyl regions of MMA-BnMA copolymers obtained through partial modification of PBnMA by (a) catalytic hydrogenolysis [CH50] (highly blocky), (b) acidic debenzylation [AD52] (nearly random), (c) saponification [SP50] (random with alternating tendency), and (d) transesterification [TE49]. All samples have nearly equimolar compositions of MMA and BnMA units

The resonance data for the four CH series (CH18 to CH65), seven AD series (AD12 to AD91), three SP series (SP50 to SP63), five TE series (TE23 to TE92), and two BM/MB series (BM57 and MB49) were combined into the reference dataset mentioned above, and the resulting dataset comprising the resonance data of the total of 41 samples was subjected to the PCA procedure. Figure 6 shows the score plots. The contribution rates for PC1 and PC2 changed to 72.4 and 20.9%, respectively, from the values described above. The increase in the contribution rate for PC2 from 12.6% indicates the improvement of the sensitivity in monomer sequence analysis.

Principal component score plots for α-methyl and carbonyl resonances of MMA-BnMA copolymers obtained through partial modification of PBnMA by catalytic hydrogenolysis (CH series, ●), acidic debenzylation (AD series, ○), saponification (SP series, ◇), and transesterification (TE series, ☓) and two-step esterification of PMAa (BM57, ▲ and MB49, △). The reference framework of homopolymer blends and random copolymers is shown as a straight line and a parabolic curve accompanying small dot plots for H, B, and C series. The contribution rates for the first and second principal components (PC1 and PC2) were 72.4 and 20.9%, respectively

The plots of the CH series were found along the reference line for the homopolymer blends, suggesting that copolymers prepared through the catalytic hydrogenolysis were highly blocky. A study of the Pd/charcoal-catalyzed cleavage of poly(benzyl acrylate) and PBnMA showed that partial hydrogenolysis can lead to the formation of blocky copolymers or mixtures of homopolymers depending on the structure of the Pd/charcoal catalytic system [34]. In the present study, small differences in the PC2 scores between the CH series and the homopolymer blends did not allow us to discriminate between highly blocky copolymers and mixtures of homopolymers. Because multivariate analysis is a statistical approach, larger sets of reference and sample data will be necessary to investigate these small differences.

The plots of AD91, TE92, and TE85 with positive PC1 values were found to be significantly below the parabolic curve for ideally random sequences, whereas the plots of the other samples for the AD and TE series with negative PC1 scores were distributed such that they almost lie on the parabolic curve. The neighboring group effects promoting the formation of alternating sequences are suggested to have become prominent as the acidic debenzylation or transesterification of PBnMA proceeded to conversions approximately above 80%. A similar tendency was observed for the plots of the SP series, where the formation of copolymers with an alternating tendency was clearly indicated for SP59 and SP63. Unfortunately, the saponification of PBnMA did not proceed to conversions above 63%.

The plot of MB49, a copolymer prepared by half methylation of PMAa with diazomethane followed by full benzylation with benzyl bromide in the presence of an organic base, was found on the parabolic curve. The result is in accordance with a publication reporting the formation of random copolymers in the partial methylation of syndiotactic PMAa with diazomethane [36]. The plot of BM57, obtained by half benzylation of PMAa followed by full methylation, was located significantly above the parabolic curve, indicating a somewhat blocky monomer sequence. In the literature, however, the formation of random copolymers was claimed for the two-step esterification of highly syndiotactic PMAa under similar conditions [25]. A possible reason for the discrepancy is the difference in the stereoregularity and molecular weight of the PMAa used in the esterification. Several papers have mentioned the marked influence of stereoregularity and molecular weight on the reactivity of polymethacrylates [34, 43,44,45].

There is growing interest in the synthesis of sequence-controlled polymers by newly developed copolymerizations, as discussed in a recent review article [46] and in a volume of symposia [47]. Partial modification of polymers by chemical reactions can provide another strategy to control the monomer sequence of copolymers. The multivariate approach to the NMR analysis shown in the present paper is promising as a general tool to assist these studies.

References

Bovey FA, Polymer NMR, Spectroscopy. VI. Methyl methacrylate-styrene and methyl methacrylate-alpha-methylstyrene copolymers. J Polym Sci. 1962;62:197–209.

Hirai H, Koinuma H, Tanabe T, Takeuchi K. Polymerization of coordinated monomers. XV. 13C-NMR study on the alternating copolymers of methyl methacrylate with styrene. J Polym Sci Polym Chem. 1979;17:1339–52.

San Roman J, Madruga EL, Del Puerto MA. Microstructure and tacticity in radical copolymerization. I. Proton NMR of styrene-methyl methacrylate copolymers. Angew Makromol Chem. 1979;78:129–43.

Aerdts AM, de Haan JW, German AL. Proton and carbon NMR spectra of alternating and statistical styrene-methyl methacrylate copolymers revisited. Macromolecules. 1993;26:1965–71.

Chujo R, Satoh S, Nagai E. High resolution NMR study of vinylidene chloride-vinyl chloride copolymer. J Polym Sci, Part A. 1964;2:895–905.

McClanahan JL, Previtera SA. NMR study of vinyl chloride-vinylidene chloride copolymer. J Polym Sci, Part A. 1965;3:3919–27.

Ito K, Iwase S, Yamashita Y. High-resolution nuclear magnetic resonance studies on sequence distribution of vinylidene chloride copolymers. Makromol Chem. 1967;110:233–45.

Chujo R, Ubara H, Nishioka A. Determination of monomer reactivity ratios in copolymerization from a single sample and its alpplication to the acrylonitrile - methyl methacrylate system. Polym J. 1972;3:670–4.

Kapur GS, Brar AS. Determination of compositional and configurational sequence distribution of acrylonitrile-methyl methacrylate copolymers by carbon-13 NMR spectroscopy. Polym. 1991;32:1112–8.

Katrizky AR, Weiss DE. Carbon-13 nuclear magnetic resonance spectroscopy of polymers. Part ii. Determination of monomer sequence distribution in butadiene–acrylonitrile copolymer. J Chem Soc,Perkin Trans 2. 1974;13:1542–7.

Segre AL, Delfini M, Conti F, Boicelli A. NMR studies of butadiene-styrene copolymers. Polym. 1975;16:338–44.

Buchak BE, Ramey KC. Monomer sequence distribution in styrene-maleic anhydride copolymers. J Polym Sci Polym Lett. 1976;14:401–5.

Arita K, Ohtomo T, Tsurumi Y. Analysis of the monomer sequence distribution in alternating acrylonitrile-styrene copolymers by carbon-13-NMR. J Polym Sci Polym Lett. 1981;19:211–6.

San Roma J, Valero M. Quantitative evaluation of sequence distribution and stereoregularity in ethyl acrylate methyl methacrylate copolymers by 13C n.m.r, spectroscopy. Polym. 1990;31:1216–21.

Olson KG, Butler GB. Stereochemical evidence for the participation of a donor-acceptor complex in alternating copolymerizations. 2. Copolymer structure. Macromolecules. 1984;17:2486–501.

Moritani T, Fujiwara Y. 13C and 1H-NMR investigations of sequence distribution in vinyl alcohol-vinyl acetate copolymers. Macromolecules. 1977;10:532–5.

Van der Velden G, Beulen J. 300-MHz H NMR and 25-MHz I3C NMR investigations of sequence distributions in vinyl alcohol-vinyl acetate copolymers. Macromolecules. 1982;15:1071–5.

Denisova YI, et al. Chain statistics in vinyl acetate–vinyl alcohol multiblock copolymers. Polym Sci Ser B. 2012;54:375–82.

Ilyin SO, Malkin AY, Kulichikhin VG, Denisova YI, Krentsel LB. Effect of chain structure on the rheological properties of vinyl acetate−vinyl alcohol copolymers in solution and bulk. Macromolecules. 2014;47:4790–4804.

Klesper E. NMR investigation of cosyndiotactic methyl methacrylate-methacrylic acid copolymers. J Polym Sci Polym Lett. 1968;6:313–21.

Klesper E. NMR investigation of triad statistics in cosyndiotactic methyl methacrylate-methacrylic acid copolymers. J Polym Sci Polym Lett. 1968;6:663–72.

Klesper E, Gronski W, Barth V. Triad statistics in dependence of the reaction conditions during partial hydrolysis of syndiotactic poly(methyl methacrylate). Makromol Chem. 1970;139:1–16.

Klesper E, Johnsen A, Gronski W, Wehrili FW. Evaluation of triads in methyl methacrylate/methacrylic acid copolymers by proton NMR in different solvents and carbon-13 NMR. Makromol Chem. 1975;176:1071–119.

Johnsen A, Klesper E, Wirthlin T. Further evaluation of sequences in methyl methacrylate/methacrylic acid copolymers by proton NMR in different solvents and carbon-13 NMR. Makromol Chem. 1976;177:2397–429.

Kawauchi T, Kawauchi M, Takeichi T. Facile synthesis of highly syndiotactic and isotactic polymethacrylates via esterification of stereoregular poly(methacrylic acid)s. Macromolecules. 2011;44:1066–71.

Kitaura T, Tomioka H, Fukatani N, Kitayama T. Anchimeric assistance on sequence regulation in partial modification of isotactic poly(propargyl methacrylate) by click reaction. Polym Chem. 2013;4:887–90.

Brar AS, Kapur GS. Sequence determination in methyl methacrylate-n-butyl methacrylate copolymers by C-13 nmr spectroscopy. Polym J. 1988;20:811–7.

Nishiura T, Kitayama T, Hatada K. Carbon-13 NMR spectra of stereoregular copolymers of methyl and butyl methacrylates. Int J Polym Anal Charact. 2000;5:401–13.

Momose H, Hattori K, Hirano T, Ute K. Multivariate analysis of 13C NMR spectra of methacrylate copolymers and homopolymer blends. Polym. 2009;50:3819–21.

Momose H, Maeda T, Hattori K, Hirano T, Ute K. Statistical determination of chemical composition and monomer sequence distribution of poly(methyl methacrylate-co-tert-butyl methacrylate)s by multivariate analysis of 13C NMR spectra. Polym J. 2012;44:808–14.

Hirano T, Kamiike R, Hsu Y, Momose H, Ute K. Multivariate analysis of 13C NMR spectra of branched copolymers prepared by initiator-fragment incorporation radical copolymerization of ethylene glycol dimethacrylate and tert-butyl methacrylate. Polym J. 2016;48:793–800.

Kowalski BR, Bender CF. Pattern recognition. Powerful approach to interpreting chemical data. J Am Chem Soc. 1972;94:5632–9.

Varmuza K & Filzmoser P. Introduction to multivariate statistical analysis in chemometrics. CRC Press; Boca Raton, FL, 2009.

Caron A, Bunel C, Braud C, Vert M. Pd/charcoal-catalysed cleavage of benzyl ester protecting groups in poly(benzyl acrylate) and poly(benzyl methacrylate). Polym. 1991;32:2659–65.

Mykytiuk J, Armes SP, Billingham NC. Group-transfer polymerization of benzyl methacrylate: a convenient method for synthesis of near-monodisperse poly(methacrylic acids). Polym Bull. 1992;29:139–45.

Klesper E, Strasilla D, Regel W. Copolymer statistics during esterification of syndiotactic poly(methacrylic acid) with diazomethane. Makromol Chem. 1974;175:523–34.

Strasilla D, Klesper E. Copolymer statistics during esterification of syndiotactic poly(methacrylic acid) with diazotoluene and diazodiphenylmethane. Makromol Chem. 1974;175:535–51.

Nishikubo T, Kameyama A, Yamada Y, Yoshida Y. Synthesis of polymers in aqueous solutions: esterification reaction of poly(methacrylic acid) with alkyl halides Using DBU in aqueous solutions. J Polym Sci Part A Polym Chem. 1996;34:3531–7.

Greenley RZ. Free radical copolymerization reactivity ratios. In: Polymer handbook. Brandrup J, Immergut EH & Grulke EA, editors. 4th ed. Vol. 1. John Wiley & Sons;Hoboken, NJ; 1999. p. II–225.

De Loecker W, Smets G. Hydrolysis of methacrylic acid–methyl methacrylate copolymers. J Polym Sci. 1959;40:203–16.

Glavis FJ. Hydrolysis of crystallizable poly(methyl methacrylate). J Polym Sci. 1959;36:547–9.

Smets G, De Loecker W. Reaction kinetics and tacticity of macromolecules. I. Methacrylic acid-ester copolymers. J Polym Sci. 1960;45:461–7.

Barth V, Klesper E. Relative rate constants during the acidic hydrolysis of syndiotactic poly(methyl methacrylate). Polym. 1976;17:893–7.

Barth V, Klesper E. Relative rate constants during the hydrolysis of syndiotactic poly(methyl methacrylate) with base. Polym. 1976;17:777–86.

Klesper E, Gronski W. NMR investigation of compositional and configurational parameters in methyl methacrylate-methacrylic acid radical copolymers. J Polym Sci, Polym Lett. 1969;7:661–9.

Huang J, Turner SR. Recent advances in alternating copolymers: The synthesis, modification, and applications of precision polymers. Polym. 2017;116:572–86.

Luts J-F. Sequence-controlled polymers: synthesis, self-assembly, and properties. In: Luts J-F, Meyer TY, Ouchi M & Sawamoto M, editors. ACS symposium series. American Chemical Society; Washington, DC, 2014.

Acknowledgements

A part of the present work was supported by JSPS KAKENHI Grant Number 17H03069.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Hsu, Y., Chuang, M., Hirano, T. et al. Multivariate analysis of 13C NMR spectra to extract information about monomer sequences in poly(methyl methacrylate-co-benzyl methacrylate)s prepared by various polymer reactions. Polym J 50, 355–363 (2018). https://doi.org/10.1038/s41428-018-0027-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0027-9

This article is cited by

-

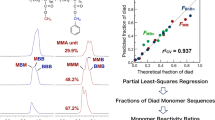

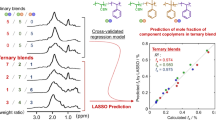

Multivariate statistical analyses of 1H NMR data for binary and ternary copolymer blends to determine the chemical compositions and blending fractions of the components

Polymer Journal (2023)

-

Determination of monomer reactivity ratios from a single sample using multivariate analysis of the 1H NMR spectra of poly[(methyl methacrylate)-co-(benzyl methacrylate)]

Polymer Journal (2022)

-

Human-autonomous devices for weak signal detection method based on multimedia chaos theory

Journal of Ambient Intelligence and Humanized Computing (2020)