Abstract

To synthesize CO2-derived polycarbonates with high Tg values, epoxides having rigid and bulky 2-norbornyl or 1-adamantyl substituents were selected as comonomers. The alternating copolymer obtained from 1-adamantylethylene oxide showed a Tg above 150 °C. This is the highest Tg among those observed for alternating copolymers obtained from CO2 and a terminal epoxide.

Similar content being viewed by others

Introduction

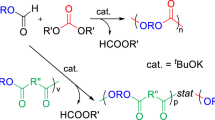

Carbon dioxide (CO2) is a renewable carbon resource, making it a potentially useful raw material in synthetic chemistry [1, 2]. New methodologies for the direct use of CO2 have focused on methods for CO2 reduction [1, 2]. One of the direct utilizations of CO2 in the production of organic materials, reported by Inoue et al. [3, 4] involves the synthesis of polycarbonates by the alternating copolymerization of CO2 and epoxides. Since then, the copolymerization of CO2 with various epoxides and the properties of their copolymers have been investigated [5,6,7,8,9,10,11]. For example, poly(propylene carbonate) (PPC; Fig. 1a, R1 = H, R2 = CH3) is synthesized by the alternating copolymerization of CO2 and propylene oxide, and 43% of the polymer by mass is derived from CO2. In addition, the thermal decomposition temperature range of PPC is narrow; hence, PPC has been utilized as a binder [12]. The effects of molecular weight [13], molecular weight distribution, stereoregularity [14], regioregularity [15, 16], and topology [17, 18] of the copolymer on the thermal properties have been studied. However, despite these investigations, the Tg values of the PPCs are not expected to be above 50 °C. This feature prevents us from using PPC in molding materials. Therefore, we have started to study the synthesis of polycarbonates with much higher Tg values than that of PPC.

It is well known that polymers with high Tg values can be obtained by introducing large and/or rigid side chains [19]. Previously, epoxides with rigid substituents have been investigated as comonomers to give CO2-derived polycarbonates with rigid side chains. For example, cyclohexene oxide [20], indene oxide [21], and limonene oxide [22] (Fig. 1b) have been employed to produce copolymers with high Tg values. Among the copolymers obtained from these epoxides, the Tg of poly(indene carbonate), which is the alternating copolymer of CO2 and indene oxide, was 138 °C. More recently, Kleij et al. [23] reported that the Tg of poly(limonene)dicarbonate was up to 180 °C. This value is the highest Tg of all the reported CO2-derived polycarbonates. Although the Tg values of copolymers with internal epoxides are higher than those of PPC, the reactivities of internal epoxides in the copolymerizations with CO2 are generally low [24]. Hence, the scope of epoxides that can be copolymerized with CO2 is limited.

In contrast to the above, terminal epoxides are more reactive than internal epoxides, and thus various terminal epoxides have been employed as comonomers in copolymerizations with CO2. For example, the copolymerizations of CO2 and epoxides having bulky alkyl groups on their side chains have been reported to show Tg values that were higher than that of PPC (Fig. 1c) [25]. We anticipated that polycarbonates derived from CO2 and terminal epoxides bearing large side groups should show higher Tg values than PPC.

To synthesize CO2-derived polycarbonates with higher Tg values, epoxides with substituents that are more rigid and bulky than cyclohexyl were selected as comonomers. The copolymers were synthesized by alternating copolymerization of CO2 and epoxides with 2-norbornyl (NB) or 1-adamantyl (Ad) groups as substituents (Fig. 1d), and the Tg values of the obtained copolymers were measured. As expected, we herein report that the alternating copolymerization of CO2 and various terminal epoxides with increasing steric bulk provides copolymers with much higher Tg values than that of PPC (high glass transition temperature photoimageable polycarbonate polymers with pendent polycyclic functional groups Patent WO2014134373A1. This patent differs from this paper in which cobalt salen complex was used as a catalyst for the alternating copolymerization).

Experimental section

Materials

Commercially available CO2 was used without further purification. Propylene oxide (PO) was purchased from NACALAI TESQUE, INC., and tert-butylethylene oxide (tBuEO) was synthesized according to the literature method [26]. All epoxides, including cyclohexylethylene oxide (CyEO), exo-2-norbornylethylene oxide (NBEO), and 1-adamantylethylene oxide (AdEO), the syntheses of which are described below, were distilled over CaH2 under a nitrogen atmosphere before use. Tetraphenylporphyrinatocobalt (III) chloride ((TPP)CoCl) was synthesized according to the reported procedure [27]. 4-(Dimethylamino)pyridine (DMAP) was recrystallized from toluene. CH2Cl2, when used as a polymerization solvent, was washed sequentially with concentrated H2SO4, water, aqueous NaHCO3, and brine, dried over CaCl2, and distilled over CaH2 under nitrogen. Other commercially available reagents were used as received.

Synthesis of CyEO

3-Chloroperbenzoic acid (460 g, 2.00 mol, <75%) was mechanically stirred with 7300 mL of CH2Cl2 inside a 4-neck 12-L flask fitted with a mechanical stirrer, a thermowell, a nitrogen inlet, and an addition funnel. The mixture cooled itself to 7.8 °C before warming to 9.1 °C after 3 min when a turbid but precipitate-free solution formed. The solution was then chilled with ice water to 1.8 °C. Vinylcyclohexane was added rapidly over 10 min via the addition funnel. After that addition, the temperature increased over the next 10 min to 3.6 °C and then cooled gradually to 1.8 °C during the following 2 h. The reaction was stirred and warmed to room temperature overnight. Subsequent gas chromatography (GC) analysis showed no remaining vinylcyclohexane. The reaction mixture was treated with two portions of 10% aqueous NaHSO3 solution (300 mL and 260 mL) to give a negative KI/starch paper test for peroxide. Then, 3 × 300 mL portions of saturated NaHCO3 solution were added carefully to the stirred mixture. After the vigorous effervescence subsided, approximately 100 mL of solid NaHCO3 was added, at which point very vigorous effervescence occurred. After the liquids had become clear, the aqueous phase was found to have a pH of 6. Approximately 100 mL of solid Na2CO3 was added, which increased the pH to 9, and the phases were separated. The CH2Cl2/aqueous interface was slowly filtered to remove the solids, and the resulting clear phases were separated. The CH2Cl2 phase was washed with 1000 mL of brine to achieve a pH of 6–7. The CH2Cl2 solution was dried over MgSO4, filtered, and the volume of solvent was carefully reduced by rotary evaporation at 189 to 91 Torr and 10–20 °C to 262 g of liquid containing a large amount of precipitate. The solids were isolated by filtration and rinsed with pentane. More crystals precipitated from the filtrate, and these were also removed by filtration. The filtrate was repeatedly treated with pentane until the total volume reached 1800 mL and no further precipitation of 3-chlorobenzoic acid occurred. The volume of the pentane solution was carefully reduced by rotary evaporation at 215 to 15 Torr and 10–20 °C to give 198.3 g (97% yield) of a yellow liquid. This crude product was distilled through a 12-inch Hempel column filled with 0.16 × 0.16-inch Pro-Pak metal packing to afford 115.7 g (57% yield) of CyEO (b.p. 109 °C/102 Torr).

Synthesis of NBEO

3-Chloroperbenzoic acid (363 g, 1.58 mol) was mechanically stirred with 4300 mL of CH2Cl2 inside a 4-neck 12-L flask fitted with a mechanical stirrer, a thermowell, a nitrogen inlet, and an addition funnel. The mixture cooled itself to 9.9 °C before warming to 13.2 °C after 12 min when essentially all solid had dissolved. The solution was chilled with ice water to 2.1 °C. A mixture of vinylnorbornane and ethyl norbornane (240 g) was added rapidly via the addition funnel; the mixture was obtained from the hydrogenation of 5-vinyl-2-norbornene following the literature procedure [27], and it contained approximately 158 g (1.30 mol) of vinylnorbornane. The addition was completed within 3 min. The temperature increased over the next 4 min to 5.3 °C and then cooled steadily to 2.1 °C during the following 2 h. The reaction was allowed to stir and warm to room temperature overnight. Subsequent GC analysis showed no vinylnorbornane remaining. The reaction mixture was treated with 300 mL of 10% aqueous NaHSO3 solution to give a negative KI/starch paper test for peroxide. Then, 4 × 300 mL portions of saturated NaHCO3 solution were carefully added to the stirred mixture. After vigorous effervescence, the aqueous phase was found to have a pH of 7. Approximately 100 mL of solid NaHCO3 was added, which brought the pH to 8, and then the phases were separated. The CH2Cl2 phase was filtered to remove the solids and then was washed with 500 mL of saturated NaHCO3 solution to achieve a pH of 9–10 and 1000 mL of brine to reach a pH of 7–8. The CH2Cl2 solution was dried over MgSO4 and filtered, and then the volume of the solution was reduced by rotary evaporation to give 262 g of liquid. After sitting overnight, crystals of 3-chlorobenzoic acid formed in the solution. These were separated by filtration and rinsed with pentane. More solids crystalized out of the solution and were removed by filtration. The filtrate was repeatedly treated with pentane until the final volume reached 1800 mL and no further crystallization of 3-chlorobenzoic acid occurred. The volume of the pentane solution was reduced by rotary evaporation to give 231 g of liquid. The crude product was distilled through a 12-inch Hempel column filled with 0.16 × 0.16-inch Pro-Pak metal packing to afford 115.9 g (0.85 mol, 65% yield) of exo-NBEO (b.p. 91 °C/40 Torr).

Synthesis of AdEO

3-Chloroperbenzoic acid (344 g, 1.51 mol, 1.51 equivalents, <77%) was placed into a 4-neck 5-L flask fitted with a mechanical stirrer, a thermowell, a nitrogen inlet, and an addition funnel. CH2Cl2 (2000 mL) was added, and the mixture was stirred. Some but not all of the peracid dissolved. The mixture was chilled to 2.5 °C in a methanol-ice bath. 1-Vinyladamantane (165 g, 1.02 mol) was added dropwise over 27 min during which the temperature ranging from 2.5 to –7.8 °C. When the temperature reached –5.0 °C, the methanol-ice bath was drained and replaced with an ice water bath. The reaction mixture was stirred for 2 h between –0.4 and 5.0 °C. A mild exotherm occurred within the first hour. The ice bath was removed, and the reaction mixture was allowed to warm to room temperature. The mixture was allowed to stir overnight; after which, GC analysis showed no remaining vinyladamantane. The reaction mixture tested positive with KI/starch paper; thus, 450 mL of 10% aqueous NaHSO3 solution was added. The quench was exothermic and caused the temperature to increase to ~38 °C, which resulted in some unexpected boiling of the CH2Cl2. Following the quench, the KI/starch paper test was negative. The reaction mixture was then filtered. Solids precipitated in the filtrate, so the filtrate was filtered through a filter cake. The filter cake was washed with copious amounts of CH2Cl2, and a clear phase separated out of the filtrate. The upper aqueous phase had a pH of 2. The CH2Cl2 phase was stirred as three portions of 100 mL pf saturated NaHCO3 solution were cautiously added. The mixture was then carefully treated with 55, 79, and 58 g portions of solid NaHCO3 until the effervescence ceased. The aqueous phase was at pH = 8–9. The organic phase contained a large amount of white solid, so it was treated with 300 mL of water. The phases were separated, and the CH2Cl2 phase was decanted away from the remaining solids. The solids were treated with 200 mL of water and then returned to the organic phase. The phases were separated again, and the pH of the aqueous phase was 8. The solids at the interface were filtered, and the resulting phases were separated. The organic phases were combined, dried over Na2SO4 until clear, filtered, and reduced by rotary evaporation to give 179.6 g of clear, nearly colorless liquid in 99% yield. GC analysis shows the AdEO was 99.1% pure. AdEO can be further purified by vacuum distillation (85 °C/3.5 Torr).

Measurements

1H NMR measurements were performed in CDCl3 at 30 °C on a Bruker DPX-400 spectrometer, and tetramethylsilane (δ = 0.00 ppm) was used as an internal standard. The infrared (IR) spectra of the films polymer cast on an NaCl plate from CHCl3 solutions were recorded on a JASCO spectrometer FT/IR-4100. Gel permeation chromatography (GPC) was performed at 40 °C on a Tosoh model HLC-8220 high-speed liquid chromatography system equipped with two TSKgel SuperMultiporeHZ-H columns and a differential refractive index detector with THF as the eluent at a flow rate of 0.35 mL min–1. The molecular weight calibration curve was prepared with standard polystyrenes (TSK standard polystyrene from Tosoh Co.); their weight-average molecular weights (Mw’s) by light scattering (weight-average molecular weight/number-average molecular weight (Mw/Mn) by GPC) were 1.90 × 105 (1.04), 3.79 × 104 (1.01), 1.81 × 104 (1.01), 9.1 × 103 (1.02), 5.97 × 103 (1.02). The differential scanning calorimetry (DSC) measurements were performed using a Mettler-Toledo DSC 3 analyzer at a heating and cooling rate of 10 °C min–1. The reported Tg values were determined from the second heating scan.

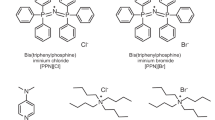

Copolymerizations of CO2 and epoxide

A typical procedure for the copolymerization of CO2 and epoxide by (TPP)CoCl is as follows. A stainless steel autoclave (150 mL) containing (TPP)CoCl (0.05 mmol) and DMAP (0.0375 mmol, dried in vacuo) (Fig. 2) was purged with nitrogen. CH2Cl2 (3.0 mL) and epoxide (25 mmol) were added with syringes. The copolymerization was initiated by the pressurization of the solution by CO2 up to 5.0 MPa. The mixture was stirred at 40 °C. After the prescribed time, the autoclave was cooled, and the excess CO2 was discharged. CHCl3 (3 mL for PO, 6 mL for CyEO and tBuEO, 12 mL for NBEO, and 25 mL for AdEO) was added to the reaction mixture, and then the solution was poured into methanol to stop the polymerization and precipitate the produced polymer. After being dried in vacuo, a small portion of the polymer was subjected to 1H NMR and IR analyses to determine the structure of the polymer, to GPC to estimate the Mn and Mw/Mn and to DSC to determine the glass transition temperature (Tg).

Results and discussion

Copolymerization of CO2 and epoxide

After CO2 and PO were reacted in the autoclave for 2 days, the reaction mixture was characterized by 1H NMR and IR spectroscopy (Table 1, run 1). Based on the 1H NMR spectrum, the conversion of PO was 74.0% (Figure S1). Absorption bands at 1799 and 1748 cm–1 were observed in the IR spectrum (Figure S2). These absorptions are attributed to carbonyl stretching vibrations of cyclic and polycarbonates, respectively. The Mn was 18800 g mol–1 (the degree of polymerization (DP) = 184) and the Mw/Mn was 1.21. These Mn and Mw/Mn values are comparable to those reported previously [26]. In the cases of the copolymerization of CO2 with CyEO or NBEO, the reaction was carried out over 5 days. The conversions were 71.5 and 78.1%, and the Mns of obtained copolymers were 26400 (DP = 155) and 25900 (DP = 142) (Table 1, runs 2 and 4), respectively. Copolymerizations with tBuEO or AdEO gave copolymers with Mn = 32800 (DP = 228) and 9600 (DP = 43) and conversions of 69.4% and 75.6%, respectively. The reactions proceeded very slowly and required 15 and 10 days, respectively, to achieve these conversions (Table 1, runs 3 and 5). In all the copolymerization reactions, consumption of the epoxide stopped at approximately 70% conversion. As polymer growth increased, the fluidity of the reaction mixture was lost, which inhibited the dissolution of CO2 into the reaction mixture, and thus the rate of the copolymerization reaction dramatically decreased (To maintain the fluidity of the copolymerization media, use of larger amount of solvent provably is one of effective means. However, the thinner concentration causes deceleration of the copolymerization. On the other hand, raising the reaction temperature should certainly accelerate the reaction, but simultaneously promote the side reactions, such as cyclic carbonate formation. Therefore, these common methods for the acceleration of organic reactions cannot be employed in the present study).

To confirm the formation of the polycarbonate and cyclic carbonate, IR spectroscopy was carried out to characterize the reaction mixture (Figures S2, S4, S6, S8, and S10). For the copolymerization with CyEO or NBEO, a set of small and large absorptions was observed at 1805 and 1748 cm–1 (CyEO; Figure S4) or at 1809 and 1747 cm–1 (NBEO; Figure S8). These absorptions were attributed to carbonyl stretching vibrations of cyclic carbonate and polycarbonate, respectively.

On the other hand, an absorption at 1749 cm–1 attributable to polycarbonate was observed in the IR spectrum, and an absorption at approximately 1800 cm–1 was not observed for the copolymerization with tBuEO (Figure S6). Similarly, for the copolymerization with AdEO, the large absorption was observed at 1749 cm–1, while the very small absorption was observed at 1812 cm–1 (Figure S10). Cyclic carbonate is formed in the reaction system due to a back-biting reaction from the end of the growing polymer. Introducing bulky substituents such as tBu or Ad groups may block the back-biting reaction from the end chain of the growing polymer by steric hindrance. Therefore, only trace cyclic carbonates were produced in these systems.

In the cases of PO, CyEO, and NBEO, the degrees of polymerization were between 142 and 184 with conversions between 71–78%. Since water, a common contaminant in the complex, acts as a bifunctional initiator and/or a chain transfer agent, the DP values do not match the theoretical values [28].

When CyEO, tBuEO, and NBEO were used as comonomers, the DP values were 155, 228, and 142 (Mn = 26400, 32800, and 25900; Mw/Mn = 1.24, 1.17, and 1.20), respectively. Compared with the DP of PPC synthesized with the same cobalt porphyrin complex, the DPs of the CyEO and NBEO-containing polymers are adequate. Although the conversion was almost the same, the DP of the tBuEO-containing polymer was larger than those of CyEO and NBEO. Because, as described above, cyclic carbonates were not produced during the polymerization, all the epoxide that was consumed was converted into polycarbonate. Much like in the copolymerization of CO2 and tBuEO, only a small amount of cyclic carbonate was produced in the copolymerization of CO2 and AdEO at a conversion of 75.6% (Figure S10). Nevertheless, the DP of the obtained copolymer of CO2 and AdEO was smaller (Table 1, run 5, Mn = 9600, DP = 43, Mw/Mn = 1.39). The Mn of PAdEC is possibly underestimated by using GPC calibrated with standard polystyrenes.

Microstructures and T g values of the copolymers

The products obtained by the copolymerization of CO2 and epoxides were purified by reprecipitation from chloroform solutions using methanol. In the 1H NMR spectra, signals between δ 3.0–3.5 ppm due to ether linkages were difficult to observe, which indicates the content of carbonate linkages in the polymer main chain reached 99% (Table 2). The 13C NMR spectra suggested that the regioselectivity of PPC was 89% head-to-tail (Figure S12), whereas the contents of H-T structures in the other polymers were almost 100% (Figures S16, S20, S24, and S28). The bulkiness and electron-donating nature of the alkyl groups on the epoxides controlled the mechanism of the epoxide ring-opening, leading exclusively to the β-cleavage of the epoxide ring. The GPC chromatograms of the copolymers were all bimodal (Figures S13, S17, S21, S25, and S29). As already mentioned, these peaks correspond to the high-molecular-weight polymers resulting from water and the low-molecular-weight polymers resulting from interference from the axial ligand of the catalyst complex [29].

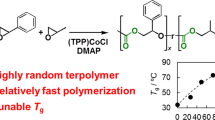

The Tg values of the resulting copolymers were measured by DSC (Fig. 3). The Tg of PPC was 29.5 °C, which was consistent with the values reported to date (Table 2, run 1). The Tg values of PCyEC, PtBuEC, and PNBEC were 54.7, 70.4, and 85.3 °C, respectively (Table 2, run 2–4). The increase in the Tg values is believed to be closely related to the bulkiness of the side chains. To our delight, DSC analysis showed the Tg of PAdEC was 157.5 °C (Table 2, run 5). This is the highest Tg among in polycarbonates synthesized by alternating copolymerization of CO2 and a terminal epoxide.

Conclusions

In conclusion, we synthesized alternating copolymers from CO2 and terminal epoxides with rigid and bulky alkyl substituents. The copolymerizations provided copolymers with narrow molecular weight distributions. Except for that of PAdEC, the degrees of polymerization were between 142 and 240. Since the optimized conditions for the alternating copolymerization of CO2 and PO were adopted for all the copolymerizations investigated here, as the substituents on the epoxides became bulkier, the polymerizations proceeded more slowly and required longer reaction times to reach high epoxide conversions. The rate of polymerization must be increased by changing the reaction temperature and/or pressure. The results of DSC analyses showed that the Tg values of the copolymers are correlated with the rigidity and bulkiness of the substituents on their polymer side chains. Notably, the Tg of PAdEC is 157.5 °C, which is the highest Tg among in alternating copolymers of CO2 and a terminal epoxide.

References

Poliakoff M, Fitzpatrick JM, Farren TR, Anastas PT. Green chemistry: science and politics of change. Science. 2002;297:807–10.

Zhu Y, Romain C, Williams CK. Sustainable polymers from renewable resources. Nature. 2016;540:354–62.

Inoue S, Koinuma H, Tsuruta T. Copolymerization of carbon dioxide and epoxide. J Polym Sci Part B Polym Lett. 1969;7:287–92.

Inoue S, Koinuma H, Tsuruta T. Copolymerization of carbon dioxide and epoxide with organometallic compounds. Makromol Chem. 1969;130:210–20.

Lu X-B, Ren W-M, Wu G-P. CO2 copolymers from epoxides: catalyst activity, product selectivity, and stereochemistry control. Acc Chem Res. 2012;45:1721–35.

Sugimoto H, Inoue S. Recent progress in the synthesis of polymers based on carbon dioxide. Pure Appl Chem. 2006;78:1823–34.

Sugimoto H, Inoue S. Copolymerization of carbon dioxide and epoxide. J Polym Sci Part A Polym Chem. 2004;42:5561–73.

Lu X-B, Darensbourg DJ. Cobalt catalysts for the coupling of CO2 and epoxides to provide polycarbonates and cyclic carbonates. Chem Soc Rev. 2012;41:1462–84.

Coates GW, Moore DR. Discrete metal-based catalysts for the copolymerization of co2 and epoxides: discovery, reactivity, optimization, and mechanism. Angew Chem Int Ed. 2004;43:6618–39.

Luinstra GA, Borchardt E. Material properties of poly(propylene carbonates). Adv Polym Sci. 2012;245:29–48.

Martín C, Kleij AW. Terpolymers derived from limonene oxide and carbon dioxide: access to cross-linked polycarbonates with improved thermal properties. Macromolecules. 2016;49:6285–6295.

Empower Materials Inc. QPAC poly(alkylene carbonate) copolymers (2010). http://www.empowermaterials.com. Accessed 8 July 2017.

Li XH, Meng YZ, Chen GQ, Li RKY. Thermal properties and rheological behavior of biodegradable aliphatic polycarbonate derived from carbon dioxide and propylene oxide. J Appl Polym Sci. 2004;94:711–6.

Nakano K, Hashimoto S, Nakamura M, Kamada T, Nozaki K. Stereocomplex of poly(propylene carbonate): synthesis of stereogradient poly(propylene carbonate) by regio and enantioselective copolymerization of propylene oxide with carbon dioxide. Angew Chem Int Ed. 2011;50:4868–71.

Qin Y, Wang X, Zhang S, Zhao X, Wang F. Fixation of carbon dioxide into aliphatic polycarbonate, cobalt porphyrin catalyzed regio-specific poly(propylene carbonate) with high molecular weight. J Polym Sci, Part A: Polym Chem. 2008;46:5959–67.

Ren W-M, Liu Y, Wu G-P, Liu J, Lu X-B. Stereoregular polycarbonatesynthesis: alternating copolymerization of co2 with aliphatic terminal epoxides catalyzed by multichiral cobalt(iii) complexes. J Polym Sci, Part A Polym Chem. 2011;49:4894–901.

Yoshida A, Honda S, Goto H, Sugimoto H. Synthesis of H-shaped carbon-dioxide-derived poly(propylene carbonate) for topology-based reduction of the glass transition temperature. Polym Chem. 2014;5:1883–90.

Honda S, Sugimoto H. Polymer cyclization inhibits thermal decomposition of carbon-dioxide-derived poly(propylene carbonate)s. J Polym Sci Part A Polym Chem. 2016;54:3336–42.

Odian G (eds). Principles of polymerization, 4th ed. Hoboken, NJ: John Wiley & Sons; 2004.

Inoue S. High polymers from CO2. CHEMTECH. 1976;6:588–94.

Darensbourg DJ, Wilson SJ. Synthesis of CO2-derived poly(indene carbonate) from indene oxide utilizing bifunctional cobalt(iii) catalysts. Macromolecules. 2013;46:5929–5934.

Hauenstein O, Reiter M, Agarwal S, Riegerb B, Greiner A. Bio-based polycarbonate from limonene oxide and CO2 with high molecular weight, excellent thermal resistance, hardness and transparency. Green Chem. 2016;18:760–70.

Kindermann N, Cristòfol À, Kleij AW. Access to biorenewable polycarbonates with unusual glass-transition temperature (tg) modulation. ACS Catal. 2017;7:3860–63.

Darensbourg DJ. Making plastics from carbon dioxide: salen metal complexes as catalysts for the production of polycarbonates from epoxides and CO2. Chem Rev. 2007;107:2388–410.

Zhang X-H, Wei R-J, Zhang Y-Y, Du B-Y, Fan Z-Q. Carbon dioxide/epoxide copolymerization via a nanosized zinc−cobalt(iii) double metal cyanide complex: substituent effects of epoxides on polycarbonate selectivity, regioselectivity and glass transition temperatures. Macromolecules. 2015;48:536–44.

Lamb JR, Jung Y, Coates GW. Meinwald-type rearrangement of monosubstituted epoxides to methyl ketones using an (Al porphyrin)+(Co(CO)4)− catalyst. Org Chem Front. 2015;2:346–9.

Sugimoto H, Kuroda K. The cobalt porphyrin–lewis base system: a highly selective catalyst for alternating copolymerization of CO2 and epoxide under mild conditions. Macromolecules. 2008;41:312–7.

Brown CA, Ahuja VK. Catalytic hydrogenation. VI. Reaction of sodium borohydride with nickel salts in ethanol solution. P-2 Nickel, a highly convenient, new, selective hydrogenation catalyst with great sensitivity to substrate structure. J Org Chem. 1973;38:2226–30.

Sugimoto H, Ohtsuka H, Inoue S. Alternating copolymerization of carbon dioxide and epoxide catalyzed by an aluminum schiff base–ammonium salt system. J Polym Sci Part A Polym Chem. 2005;43:4172–86.

Acknowledgements

We are grateful to Mrs. Isamu Esashika, Takayuki Shimozaki, and Yuya Ohshima for their active collaborations.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Arai, R., Seto, K., Bell, A. et al. Synthesis of CO2-derived polycarbonates with high glass transition temperatures. Polym J 50, 301–307 (2018). https://doi.org/10.1038/s41428-017-0020-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-017-0020-8

This article is cited by

-

Hydrolyzable and biocompatible aliphatic polycarbonates with ether-functionalized side chains attached via amide linkers

Polymer Journal (2024)

-

Polycarbonate-block-polycycloalkenes via epoxide/carbon dioxide copolymerization and ring-opening metathesis polymerization

Polymer Journal (2021)

-

Alternating terpolymerization of carbon dioxide, propylene oxide, and various epoxides with bulky side groups for the tuning of thermal properties

Polymer Journal (2021)