Abstract

Microbial corrosion of iron-based materials is a substantial economic problem. A mechanistic understanding is required to develop mitigation strategies, but previous mechanistic studies have been limited to investigations with relatively pure Fe(0), which is not a common structural material. We report here that the mechanism for microbial corrosion of stainless steel, the metal of choice for many actual applications, can be significantly different from that for Fe(0). Although H2 is often an intermediary electron carrier between the metal and microbes during Fe(0) corrosion, we found that H2 is not abiotically produced from stainless steel, making this corrosion mechanism unlikely. Geobacter sulfurreducens and Geobacter metallireducens, electrotrophs that are known to directly accept electrons from other microbes or electrodes, extracted electrons from stainless steel via direct iron-to-microbe electron transfer. Genetic modification to prevent H2 consumption did not negatively impact on stainless steel corrosion. Corrosion was inhibited when genes for outer-surface cytochromes that are key electrical contacts were deleted. These results indicate that a common model of microbial Fe(0) corrosion by hydrogenase-positive microbes, in which H2 serves as an intermediary electron carrier between the metal surface and the microbe, may not apply to the microbial corrosion of stainless steel. However, direct iron-to-microbe electron transfer is a feasible route for stainless steel corrosion.

Similar content being viewed by others

Introduction

Understanding of the mechanisms for iron-to-microbe electron transfer could lead to improved strategies to reduce the estimated 500 billion dollars of annual damage [1] associated with microbially enhanced corrosion. Corrosion develops when metallic iron, Fe(0), is oxidized to Fe(II), with a release of electrons [2, 3]. Although the role for microorganisms in iron corrosion has been recognized for over 100 years [4], the mechanisms for electron exchange between Fe(0) and microorganisms are still poorly understood.

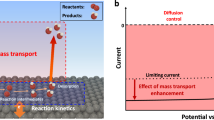

Economically important metal surfaces, such as the interior of oil pipelines and fuel storage tanks, as well as buried pilings and other structures, are usually anaerobic. Anaerobic mechanisms for iron metal corrosion have typically been studied with pure Fe(0). H2 can be an important electron carrier that shuttles electrons from Fe(0) to microorganisms [5,6,7,8,9]. Even in the absence of microorganisms, electrons derived from Fe(0) can reduce H+ to H2:

Various anaerobic microorganisms can consume the H2 released from Fe(0), coupling H2 oxidation to the reduction of electron acceptors other than oxygen [7,8,9,10].

Direct iron-to-microbe electron transfer, eliminating H2 as an intermediary electron carrier between Fe(0) and microorganisms, is a potential alternative for microbially catalyzed corrosion [11,12,13,14]. The concept of direct iron-to-microbe electron transfer is an extension of the general concept of electrotrophy, in which anaerobic microorganisms harvest energy to support growth by directly accepting electrons from other microbial cells or electrodes [15]. Direct microbial electron uptake from Fe(0) has been proposed for a diversity of sulfate-reducing, methane-producing, and acetogenic microorganisms [8, 12, 13, 16,17,18,19,20,21,22]. However, all of these microbes also have the ability to consume H2, raising the possibility that, rather than relying on electrotrophy, these microbes accelerate corrosion because they are effective in enzymatically accelerating H2 production and/or attaching to Fe(0) and consuming H2 as it is released at the surface [5, 10, 11, 23].

In order to rigorously rule out the potential for H2 serving as an intermediary electron carrier in Fe(0) corrosion, it is necessary to evaluate corrosion with strains that cannot use H2 [23]. This was accomplished in studies with a strain of Geobacter sulfurreducens genetically modified to prevent H2 consumption [11]. G. sulfurreducens strain ACLHF is unable to utilize H2 or formate because genes necessary for H2 and formate oxidation have been eliminated [11]. Strain ACLHF grew on the surface of Fe(0), which served as the sole electron donor for the energy-yielding anaerobic respiration with reduction of fumarate to succinate [11]. H2 abiotically produced from Fe(0) in the cultures was not consumed. Deletion of the gene for the outer-surface multi-heme c-type cytochromes OmcS or OmcZ inhibited growth on Fe(0) [11]. The capacity for growth on Fe(0) was restored when the genes for these cytochromes were reintroduced. These studies suggested that direct electron uptake from Fe(0), mediated by outer-surface c-type cytochromes, is possible and demonstrated that G. sulfurreducens is an effective model microbe for determining whether direct iron-to microbe electron transfer is feasible [11].

However, under the same conditions, the parent strain of strain ACLHF, strain ACL, which is able to use H2, grew primarily on H2 released from Fe(0) [11]. This finding suggested that, although direct iron-to-microbe electron transfer is possible, microbially induced Fe(0) corrosion may proceed with H2 as an intermediary electron carrier in open environments where diverse H2-consuming microbes are found.

Pure Fe(0) is a convenient well-defined substrate for mechanistic studies, but iron is amended with other metals for most practical applications. For example, stainless steel (type 316L) is the metal of choice for many oilfield devices and marine applications [24]. Stainless steel contains a minimum of 11% chromium. As the outer surface corrodes, a layer of chromium oxides forms, providing protection to the underlying matrix from direct contact with the external environment [25]. Thus, the mechanisms for microbial electron extraction from stainless steel might be significantly different from that for pure Fe(0) corroded by hydrogenase-positive microbes.

Therefore, we evaluated the possibility of anaerobic microbial stainless steel corrosion either with H2 as an electron carrier, or via direct iron-to-microbe electron transfer, with genetically modified strains of G. sulfurreducens as well as wild-type Geobacter metallireducens, a species that is unable to use H2 [26]. The results suggest that H2 is unlikely to be an effective electron shuttle for microbial corrosion of stainless steel. However, microbial corrosion of stainless steel via direct iron-to-microbe electron transfer is possible.

Materials and methods

Materials

A 316L stainless steel (elemental composition (wt %): 0.021 C, 0.43 Si, 1.18 Mn, 16.78 Cr, 2.09 Mo, 0.0006 S, 0.032 P, 10.5 Ni, balance Fe) was supplied by the Institute of Metal Research, Chinese Academy of Sciences (Shenyang, China). The stainless steel was cut into coupons (10 mm × 10 mm × 5 mm), the surfaces abraded with three different grades of sandpaper (220, 600, and 1200 grits), washed with 100% ethanol, and air-dried. For electrochemical tests, the coupons were connected with rubber-coated copper wire and sealed with an epoxy resin to expose a surface area of 1 cm2. Prior to each experiment, the electrodes and coupons were sterilized in 75% (v/v) ethanol and dried in a UV chamber (XL-1500 Series UV Crosslinker, SPECTRONICS, New York, USA) for 30 min.

Bacterial strains and growth condition

G. sulfurreducens [27] and G. metallireducens [26, 28] strains were obtained from the Lovley lab culture collection. The following mutant strains were constructed as previously described: G. sulfureducens strain ACL [29], G. sulfurreducens strain ACLHF [11], G. sulfurreducens strain ACLHFΔomcS [11], G. sulfurreducens strain ACLHFΔomcS complemented with expression of omcS in trans [11], and G. metallireducens ∆Gmet 1868 [30].

All G. sulfurreducens strains were routinely maintained under strict anaerobic conditions at 30 °C in freshwater medium [31] (per liter: 2.5 g NaHCO3, 0.25 g NH4Cl, 0.6 g NaH2PO4·H2O, 0.1 g KCl), amended with 10 ml DL vitamins [27], 10 ml DL minerals [27], with acetate (20 mM) as the electron donor and fumarate (40 mM) as the electron acceptor. G. metallireducens strains were maintained in the freshwater medium with acetate (10 mM) as the electron donor and nitrate (5 mM) as the electron acceptor. Analyses of growth, H2 production, and pitting of stainless steel were conducted in 50 ml of medium in 160 ml serum bottles that were sealed with butyl rubber stoppers. Coupons of 316L stainless steel were provided as the sole electron donor. Fumarate (40 mM) was the sole electron acceptor for studies with G. sulfurreducens. Nitrate (5 mM) was the electron acceptor for G. metallireducens.

For electrochemical tests, once cultures reached an OD600 of 0.5, 50 ml was inoculated into electrochemical cells filled with 250 ml freshwater medium with fumarate (40 mM) or nitrate (5 mM) as the electron acceptor for G. sulfurreducens or G. metallireducens, respectively.

Electrochemical tests

Electrochemical studies were carried out in a three-electrode glass cell containing 300 ml of culture medium incubated anaerobically at 25 °C. A 316L stainless steel electrode served as the working electrode, the counter electrode was platinum, and the reference electrode consisted of a saturated calomel electrode. All open circuit potential (OCP), linear polarization resistance (LPR), electrochemical impedance spectroscopy (EIS), and potential dynamic polarization measurements were obtained with a potentiostat (G300, Gamry Instrument, USA). LPR tests were recorded at a scan rate of 0.125 mV s−1 in the range of −5 to 5 mV versus EOCP. EIS was performed under a steady-state EOCP using a 5 mV amplitude sinusoidal wave in the frequency range of 10,000–0.01 Hz. Before the potentiodynamic polarization scans, the electrodes were in the open circuit mode until a steady free OCP was reached. The polarization curves were performed at a scan rate of 0.5 mV s−1 from −0.5 to 2 V versus EOCP. Each electrochemical test was conducted in triplicate in three separate experiments to ensure reproducibility.

Analytical techniques

Succinate production was monitored over time with a Shimadzu high-performance liquid chromatograph outfitted with an Aminex HPX-87H ion exclusion column (300 mm by 7.8 mm) and 0.5 ml min−1 eluent of 8.0 mM sulfuric acid, as previously described [32]. pH values were determined with a pH meter (UltraBASIC UB-5, Denver Instrument, USA).

Hydrogen in the headspace of cultures was measured with a trace analytical instrument (ta3000 gas analyzer, AMETEK, USA). The reduction gas detection (RGD) bed was filled with mercuric oxide (HgO). The RGD bed temperature was set to 285 °C, and the RGD column temperature 105 °C. The carrier gas was N2 at 80 psi. The lower and upper detection limits for the instrument were 1 part per billion and 3 parts per million by volume, respectively.

Surface analysis

After incubation, coupons were gently rinsed with 0.1 M phosphate buffer (pH 7.2) and fixed with 2.5% (v/v) glutaraldehyde overnight at 4 °C. The coupons were then washed three times in the phosphate buffer and then dehydrated with a graded series (35, 50, 70, 80, 90, 95, and 100% v/v) of ethanol solutions for 10 min each. Anhydrous ethanol dehydration was repeated three times. scanning electron microscopy (SEM) was conducted with an ultrahigh-resolution field emission scanning electron microscope (FEI Magellan 400; Nanolab Technologies, CA, USA).

To observe corrosion pits underneath biofilms, coupons were first cleaned with Clarke’s solution (strong hydrochloric acid combined with antimony chloride and stannous chloride prepared as previously described [33]) to remove corrosion products and biofilms on coupon surfaces. Pit depth was measured with a Nikon A1 Resonant Scanning Confocal Microscope with Structured Illumination Super-Resolution (Nikon Instruments Inc., Japan).

Biofilms on coupons were stained with LIVE/DEAD BacLight Bacterial Viability Kit (Invitrogen, USA). The kit has two fluorescent dyes, the green-fluorescent SYTO-9 dye designed to measure live cells and the red-fluorescent propidium iodide (PI) dye designed to measure dead cells. After staining, samples were observed under CLSM at two wavelengths (488 nm for dye SYTO-9 and 559 nm for dye PI). Cell numbers in the 3D scanned images were calculated with NIS-Elements software (https://www.nikonmetrology.com/en-us/product/nis-elements-microscope-imaging-software).

Data analysis

All the experiments were conducted in triplicate and each experiment was repeated at least three times. Each data point was the result from a single test of each device. Uncertainty in a reported measurement was expressed by standard error. P value was determined to compare the differences between each group. Results were considered significantly different for P value < 0.05.

Results and discussion

Growth of G. sulfurreducens strains on stainless steel

Over 7 days, both strain ACL (Fig. 1A, E), which can grow with H2 or formate as the electron donor, and strain ACLHF (Fig. 1B, F), which is unable to use H2 or formate, grew as biofilms on stainless steel. Cell growth was accompanied with the reduction of fumarate to succinate (Fig. 2). As expected from previous studies with Fe(0) [11], there was no turbidity in the stainless steel cultures of strain ACLHF (Supplementary Fig. S1), which has to rely on direct iron-to-microbe electron transfer. In previous studies with Fe(0), strain ACL primarily grew on the H2 evolved from Fe(0), producing substantial culture turbidity attributable to planktonic cell growth on H2 [11]. However, there was no turbidity in cultures of strain ACL growing on stainless steel (Supplementary Fig. S1).

Confocal scanning laser microscopy (CLSM) images (scale bar = 50 µm) of biofilms attached to stainless steel after the surface was treated with live/dead stain: A strain ACL; B strain ACLHF; C strain ACLHFΔomcS. D Strain in which ACLHFΔomcS was complemented by expressing omcS in trans. High magnification (main image) and lower magnification (upper right insert) scanning electron microscope images (scale bar = 5 µm) of the following biofilms: E strain ACL; F strain ACLHF; G strain ACLHFΔomcS; H strain in which ACLHFΔomcS was complemented by expressing omcS in trans.

The lack of planktonic growth of strain ACL suggested that, unlike Fe(0), the stainless steel was not generating sufficient H2 to support the growth of planktonic cells. Direct measurements revealed that the concentration of H2 in abiotic controls (approximately 0.1 Pa) containing stainless steel were 50,000-fold lower than comparable abiotic controls with Fe(0), demonstrating that there was little, if any, production of H2 from stainless steel (Fig. 3). This finding was consistent with electrochemical measurements, discussed later, that demonstrated that H2 production was thermodynamically unfavorable in both the abiotic control and in the presence of strain ACL and ACLHF. H2 levels in cultures of strain ACL with stainless steel were comparable to those of the abiotic control, indicating that even though strain ACL can grow on H2, it was unable to consume H2 at the low concentrations available. These results suggested that strain ACL relied on direct electron uptake when grown on stainless steel.

H2 concentration in the headspace in the presence of stainless steel (A) or Fe(0) (B). Note the differences in units on the y-axis in the two panels. Data in (B) from reference [11]. Results are the mean and standard deviation (n = 3).

A strain in which the gene for the outer-surface cytochrome OmcS was deleted from strain ACLHF (ACLHFΔomcS) cell grew much less on the stainless steel than strain ACLHF (Fig. 1C, G) and reduced about 60% less fumarate to succinate (Fig. 2). Expression of omcS in trans restored the capacity for growth on the stainless steel (Fig. 1D, H) and fumarate reduction (Fig. 2). This result is consistent with the previous finding that OmcS is an important component for direct electron uptake from Fe(0) [11]. Deletion of OmcS did not completely inhibit growth on stainless steel, presumably because G. sulfurreducens has multiple outer-surface electrical contacts [34,35,36] that would all need to be deleted to completely inhibit extracellular electron exchange.

The pH of the culture medium in the biotic incubations and the abiotic control was 7.0 ± 0.1 after 7 days, which was statistically equivalent to the initial pH (6.9 ± 0.1) measured at the time of inoculation. These results ruled out pH changes as a potential explanation for the corrosion observed.

Pitting

In order to determine whether growth on the stainless steel surface resulted in pitting, the biofilms and corrosion products were removed with an acidic solution after 7 days of incubations. The stainless steel surfaces of abiotic controls were relatively smooth (Fig. 4A, F) and the few pits that were observed were relatively shallow (Fig. 4K). The average depth of the ten largest pits was only 0.9 ± 0.4 μm. In contrast, large and deep pits were visible on stainless steel incubated in the presence of strains ACL and ACLHF (Fig. 4B, C, G, H, K, L). Consistent with its poor growth on stainless steel, the pit depths associated with strain ACLHFΔomcS were much smaller than for strain ACLHF (Fig. 4D, I), the average depth of ten largest pits was 1.6 ± 0.5 μm (Fig. 4K) with average diameter of 3.8 ± 1.0 μm (Fig. 4L). Complementation of ACLHFΔomcS with expression of omcS in trans restored higher corrosion rates with a pit size comparable with strains ACL and ACLHF (Fig. 4E, J, K, L).

Scanning electron micrographs of stainless steel surfaces (scale bar = 50 µm) in: A abiotic control; B strain ACL; C strain ACLHF; and D strain ACLHFΔomcS. E Strain in which ACLHFΔomcS was complemented by expressing omcS in trans. Scale bar = 50 μm. Confocal scanning laser microscopy images of stainless steel surfaces: F abiotic control; G strain ACL; H strain ACLHF; I strain ACLHFΔomcS; J strain in which ACLHFΔomcS was complemented by expressing omcS in trans. Analysis of K pit depth and L pit diameter for the ten largest pits as well as M pit density (data from ten random fields (0.1 mm2) examined on each of five coupons for each treatment; mean ± standard deviation).

A similar pattern of corrosion was observed from quantifying the abundance of pits on the stainless steel surface (Fig. 4M). The pit density of the abiotic control (24 ± 15 pits mm−2) was much less than for strains ACL and ACLHF (110 ± 28 and 126 ± 20 pits mm−2, respectively). When omcS was deleted from strain ACLHF, the pit density decreased to 40 ± 17 pits mm−2. Complementation of the omcS mutation increased the pit density to 85 ± 18 pits mm−2.

Electrochemical analysis of corrosion

Several classical electrochemical methods further demonstrated that strain ACL and strain ACLHF actively corroded stainless steel and that the presence of an uptake hydrogenase did not enhance the corrosion capacity of strain ACL over strain ACLHF. The lowest OCP for the stainless steel in the abiotic control was 160.9 mVSHE (Fig. 5A), much more electropositive than the midpoint potential for H2 evolution under the conditions (pH 7, 25 °C, 0.1 Pa) in the culture medium:

A Open circuit potential over time. B 1/Rp over time. C Rct over time (obtained from EIS data, Supplementary Table S1). D Corrosion current density after 7 days. ACL, ACLHF, ACLHFΔomcS, Strain in which ACLHFΔomcS was complemented by expressing omcS in trans, and abiotic control. Results are the mean and standard deviation (n = 3).

Thus, H2 formation was thermodynamically unfavorable, explaining the observed lack of H2 production.

In contrast, the OCP of the stainless steel colonized by strains ACL and ACLHF was much lower than the abiotic control, stabilizing at approximately −141.4 and −116.6 mVSHE, respectively (Fig. 5A). This low potential indicated that release of electrons from the stainless steel was much more favorable in the presence of the strain ACL and ACLHF biofilms, consistent with the high rates of corrosion associated with these biofilms. However, that was still too electropositive to support H2 production (reaction 2), consistent with the lack of H2 accumulation in the strain ACLHF cultures and the lack of planktonic growth of strain ACL.

The OCP for the stainless steel in the presence of strain ACLHFΔomcS was intermediate between the abiotic control and the stainless steel colonized by the strain ACL and ACLHF biofilms (Fig. 5A), in accordance with the low rates of corrosion in those samples. When the omcS deletion was complemented the OCP was comparable to the wild-type control (Fig. 5A).

Several other electrochemical techniques for corrosion characterization also signified higher rates of corrosion in the presence of strains ACL and ACLHF and reduced corrosion in the absence of OmcS. For example, LPR (Rp) is inversely proportional to the corrosion rate [37]. 1/Rp was low in the abiotic control, further demonstrating that the medium was not corrosive (Fig. 5B). There was more variability in the 1/Rp of culture replicates of strain ACLHF than strain ACL. The 1/Rp of strain ACL was stable at around 0.009 kΩ−1·cm−2, whereas strain ACLHF had a range from 0.012 to 0.029 kΩ−1·cm−2. The mean values for two strains were not statistically significantly different. Both had 1/Rp values that were more than five-fold higher than the abiotic control (Fig. 5B). Strain ACLHFΔomcS was comparable to the abiotic control, consistent with the other results indicative of slow corrosion with this strain. Complementation restored 1/Rp to a level found in the ACLHF strain (Fig. 5B).

Modeling of EIS data (Supplementary Figs. S2 and S3 and Supplementary Table S1) indicated that charge transfer resistance between the biofilm and the stainless steel matrix, designated Rct, was much higher in the abiotic control and strain ACLHFΔomcS than for strain ACL and strain ACLHF (Fig. 5C). The charge transfer resistance for strain ACL was not statistically significantly different than for strain ACLHF, further demonstrating that the elimination of hydrogenase activity did not impact corrosion.

A measure of corrosion current density, designated icorr (Fig. 5D), which is directly proportional to the corrosion rate, can be derived from potentiodynamic polarization curves (Supplementary Fig. S4) [38]. The icorr for the abiotic control and strain ACLHFΔomcS were similar, about 32 ± 23 nA·cm−2, and significantly lower than the icorr for strain ACL (614 ± 47 nA·cm−2), strain ACLHF (760 ± 58 nA·cm−2), and the omcS complemented strain of strain ACLHFΔomcS (741 ± 50 nA·cm−2) (Fig. 5D). These results further demonstrate the importance of OmcS in the corrosion. The differences in corrosion between strains with and without OmcS could not be attributed to the difference in the number of cells colonizing the stainless steel surface because normalization for cell numbers to calculate icorr/cell and Rct/cell continued to indicate reduced corrosion in the absence of OmcS (Supplementary Fig. S5).

Direct metal-microbe electron transfer with G. metallireducens

G. metallireducens, which is unable to utilize H2 [26], but is capable of directly receiving electrons from electrodes to support nitrate reduction [39], heavily colonized stainless steel in medium with nitrate provided as an electron acceptor (Fig. 6A). This was accompanied with the reduction of nitrate (Fig. 6C) and obvious pitting (Fig. 6D, E). The corrosion mechanism was further evaluated with a strain of G. metallireducens in which the gene Gmet 1868 was deleted. This gene encodes a multi-heme c-type cytochrome that is important for extracellular electron exchange [30, 40]. The cytochrome-deficient mutant only lightly colonized the stainless steel surface (Fig. 6B) with minimal pitting (Fig. 6F, G) and nitrate reduction (Fig. 6C). The greater corrosivity of the wild-type strain was apparent from electrochemical data (Fig. 6H, I). The 1/Rp (ca. 0.01 kΩ−1·cm−2; Fig. 6H) and icorr (1098 ± 87 nA·cm−2; Fig. 6I) of the wild-type strain were much higher than those of the cytochrome-deficient mutant, which had values (1/Rp (ca. 0.003 kΩ−1·cm−2; Fig. 6H and icorr 101 ± 22 nA·cm−2; Fig. 6I)) similar to those of the uninoculated control. The wild-type also achieved a much lower OCP (Fig. 6J). These results demonstrated that cytochrome Gmet 1868 is important for electron uptake from stainless steel. However, like G. sulfurreducens, G. metallireducens is likely to express multiple electrical connects on its outer surface that would all need to be deleted in order to completely prevent electron uptake from stainless steel.

Scanning electron micrographs of biofilm formation on stainless steel after 7 days of wild-type (A) and a mutant strain in which the c-type cytochrome Gmet 1868 was deleted (B). C Nitrate concentrations over time. Scanning electron micrographs (D, F) and confocal scanning laser micrographs (E, G) of pits on stainless steel after 7 days for wild-type (D, E), and cytochrome mutant strain (F, G). H 1/Rp over time. I Potentiodynamic polarization curves after 7 days of incubation. J Open circuit potential over time.

Implications

The results demonstrate that microbial corrosion of stainless steel, a common structural material, is possible, but in contrast to corrosion of pure Fe(0), H2 is unlikely to serve as an intermediary electron carrier. This distinction between corrosion of stainless steel and pure Fe(0) is significant because prior studies on the mechanisms for microbial iron corrosion have focused on pure Fe(0) [5, 7, 8, 10, 12, 16], which unlike stainless steel, readily evolves H2 and is not a common structural material. Even microbes capable of direct electron uptake may favor H2 uptake as their primary route for Fe(0) corrosion if they possess uptake hydrogenases [11]. These results suggest that future corrosion studies should focus on actual iron materials rather than pure Fe(0) in order to develop corrosion models and mitigation strategies for economically important iron materials.

Outside of artificial laboratory studies, the microorganisms that are actually responsible for accelerating the corrosion of iron-containing metals and their mechanisms for gaining electrons from Fe(0) are poorly understood [23]. The finding that multi-heme c-type cytochromes, a common feature of many electroactive microbes, can be associated with direct iron-to-microbe electron transfer ([11] and this study) provides an important molecular target to hunt for such microbes.

References

Skovhus TL, Eckert RB, Rodrigues E. Management and control of microbiologically influenced corrosion (MIC) in the oil and gas industry—overview and a North Sea case study. J Biotechnol. 2017;256:31–45.

Procopio L. The era of ‘omics’ technologies in the study of microbiologically influenced corrosion. Biotechnol Lett. 2020;42:341–56.

Gu T, Jia R, Unsal T, Xu D. Toward a better understanding of microbiologically influenced corrosion caused by sulfate reducing bacteria. J Mater Sci Technol. 2019;35:631–6.

Gaines RH. Bacterial activity as a corrosive influence in the soil. Ind Eng Chem. 1910;2:128–30.

Philips J. Extracellular electron uptake by acetogenic bacteria: Does H2 consumption favor the H2 evolution reaction on a cathode or metallic iron? Front Microbiol. 2020;10:2997.

Daniels L, Belay N, Rajagopal BS, Weimer PJ. Bacterial methanogenesis and growth from CO2 with elemental iron as the sole source of electrons. Science. 1987;237:509–11.

Deutzmann JS, Sahin M, Spormann AM. Extracellular enzymes facilitate electron uptake in biocorrosion and bioelectrosynthesis. mBio. 2015;6:e00496–15.

Philips J, Monballyu E, Georg S, De Paepe K, Prevoteau A, Rabaey K, et al. An Acetobacterium strain isolated with metallic iron as electron donor enhances iron corrosion by a similar mechanism as Sporomusa sphaeroides. FEMS Microbiol Ecol. 2019;95:fiy222.

Tsurumaru H, Ito N, Mori K, Wakai S, Uchiyama T, Iino T, et al. An extracellular [NiFe] hydrogenase mediating iron corrosion is encoded in a genetically unstable genomic island in Methanococcus maripaludis. Sci Rep. 2018;8:1–10.

Philips J, Van den Driessche N, De Paepe K, Prévoteau A, Gralnick JA, Arends JBA, et al. A novel Shewanella isolate enhances corrosion by using metallic iron as the electron donor with fumarate as the electron acceptor. Appl Environ Microbiol. 2018;84:e01154–18.

Tang H-Y, Holmes DE, Ueki T, Palacios PA, Lovley DR. Iron corrosion via direct metal-microbe electron transfer. mBio. 2019;10:e00303–19.

Dinh HT, Kuever J, Mußmann M, Hassel AW, Stratmann M, Widdel F. Iron corrosion by novel anaerobic microorganisms. Nature. 2004;427:829–32.

Kato S. Microbial extracellular electron transfer and its relevance to iron corrosion. Micro Biotechnol. 2016;9:141–8.

Enning D, Garrelfs J. Corrosion of iron by sulfate-reducing bacteria: new views of an old problem. Appl Environ Microbiol. 2014;80:1226–36.

Lovley DR. Powering microbes with electricity: direct electron transfer from electrodes to microbes. Environ Microbiol Rep. 2011;3:27–35.

Palacios PA, Snoeyenbos-West O, Loscher CR, Thamdrup B, Rotaru AE. Baltic Sea methanogens compete with acetogens for electrons from metallic iron. ISME J. 2019;13:3011–23.

Yu L, Duan J, Du X, Huang Y, Hou B. Accelerated anaerobic corrosion of electroactive sulfate-reducing bacteria by electrochemical impedance spectroscopy and chronoamperometry. Electrochem Commun. 2013;26:101–4.

Xu D, Li Y, Song F, Gu T. Laboratory investigation of microbiologically influenced corrosion of C1018 carbon steel by nitrate reducing bacterium Bacillus licheniformis. Corros Sci. 2013;77:385–90.

Xu D, Gu T. Carbon source starvation triggered more aggressive corrosion against carbon steel by the Desulfovibrio vulgaris biofilm. Int Biodeterior Biodegrad. 2014;91:74–81.

Venzlaff H, Enning D, Srinivasan J, Mayrhofer KJJ, Hassel AW, Widdel F, et al. Accelerated cathodic reaction in microbial corrosion of iron due to direct electron uptake by sulfate-reducing bacteria. Corros Sci. 2013;66:88–96.

Vigneron A, Head IM, Tsesmetzis N. Damage to offshore production facilities by corrosive microbial biofilms. Appl Microbiol Biotechnol. 2018;102:2525–33.

Sharma M, Bajracharya S, Gildemyn S, Patil SA, Alvarez-Gallego Y, Pant D, et al. A critical revisit of the key parameters used to describe microbial electrochemical systems. Electrochim Acta. 2014;140:191–208.

Lekbach Y, Liu T, Li Y, Moradi M, Dou W, Xu D, et al. Microbial corrosion of metals-the corrosion microbiome. Adv Microb Physiol. 2021;78. https://doi.org/10.1016/bs.ampbs.2021.01.002.

Iannuzzi M, Barnoush A, Johnsen R. Materials and corrosion trends in offshore and subsea oil and gas production. npj Mater Degrad. 2017;1:2.

Ohmi T, Nakagawa Y, Nakamura M, Ohki A, Koyama T. Formation of chromium oxide on 316L austenitic stainless steel. J Vac Sci Technol A. 1996;14:2505–10.

Lovley DR, Giovannoni SJ, White DC, Champine JE, Phillips E, Gorby YA, et al. Geobacter metallireducens gen. nov. sp. nov., a microorganism capable of coupling the complete oxidation of organic compounds to the reduction of iron and other metals. Arch Microbiol. 1993;159:336–44.

Caccavo F, Lonergan DJ, Lovley DR, Davis M, Stolz JF, McInerney MJ. Geobacter sulfurreducens sp. nov., a hydrogen- and acetate-oxidizing dissimilatory metal-reducing microorganism. Appl Environ Microbiol. 1994;60:3752–9.

Lovley DR, Stolz JF, Nord GL, Phillips EJ. Anaerobic production of magnetite by a dissimilatory iron-reducing microorganism. Nature. 1987;330:252–4.

Ueki T, Nevin KP, Woodard TL, Aklujkar MA, Holmes DE, Lovley DR. Construction of a Geobacter strain with exceptional growth on cathodes. Front Microbiol. 2018;9:1512.

Smith JA, Lovley DR, Tremblay P-L. Outer cell surface components essential for Fe (III) oxide reduction by Geobacter metallireducens. Appl Environ Microbiol. 2013;79:901–7.

Lovley DR, Phillips EJ. Novel mode of microbial energy metabolism: organic carbon oxidation coupled to dissimilatory reduction of iron or manganese. Appl Environ Microbiol. 1988;54:1472–80.

Nevin KP, Richter H, Covalla S, Johnson J, Woodard T, Orloff A, et al. Power output and columbic efficiencies from biofilms of Geobacter sulfurreducens comparable to mixed community microbial fuel cells. Environ Microbiol. 2008;10:2505–14.

ASTM G1-03. Standard practice for preparing, cleaning, and evaluation corrosion test specimens. ASTM International. 2003.

Lovley DR, Ueki T, Zhang T, Malvankar NS, Shrestha PM, Flanagan KA. et al. Geobacter: the microbe electric’s physiology, ecology, and practical applications. Adv Microb Physiol. 2011;59:1–100.

Ueki T, DiDonato LN, Lovley DR. Toward establishing minimum requirements for extracellular electron transfer in Geobacter sulfurreducens. FEMS Microbiol Lett. 2017;364:fnx093.

Voordeckers JW, Kim B-C, Izallalen M, Lovley DR. Role of Geobacter sulfurreducens outer surface c-type cytochromes in reduction of soil humic acid and anthraquinone-2, 6-disulfonate. Appl Environ Microbiol. 2010;76:2371–5.

Durrani F, Wesley R, Srikandarajah V, Eftekhari M, Munn S. Predicting corrosion rate in chilled HVAC pipe network: coupon vs linear polarisation resistance method. Eng Fail Anal. 2020;109:104261.

McCafferty E. Validation of corrosion rates measured by the Tafel extrapolation method. Corros Sci. 2005;47:3202–15.

Gregory KB, Bond DR, Lovley DR. Graphite electrodes as electron donors for anaerobic respiration. Environ Microbiol. 2004;6:596–604.

Rotaru AE, Shrestha PM, Liu F, Shrestha M, Shrestha D, Embree M, et al. A new model for electron flow during anaerobic digestion: direct interspecies electron transfer to Methanosaeta for the reduction of carbon dioxide to methane. Energy Environ Sci. 2014;7:408–15.

Acknowledgements

We thank James J. Chambers of UMass Amherst Life Sciences Laboratories’ Light Microscopy Core for facilitating CLSM and image analysis, and Louis E. Raboin of UMass Amherst Electron Microscopy Center for facilitating SEM. This work was supported by grants to DX from the National Natural Science Foundation of China (Nos. U2006219 and 51871050), the National Key Research and Development Program of China (2020YFA0907300), the Fundamental Research Funds for the Central Universities (Nos. N180203019 and N2002019), and Liaoning Revitalization Talents Program (No. XLYC1907158).

Author information

Authors and Affiliations

Contributions

H-YT, DX, FW, and DRL designed the research. H-YT, CY, DEH, TU, and CCP conducted the experiments and analyses. TLW performed the HPLC experiment and data analysis. All authors contributed to data interpretation, writing, and editing of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Tang, HY., Yang, C., Ueki, T. et al. Stainless steel corrosion via direct iron-to-microbe electron transfer by Geobacter species. ISME J 15, 3084–3093 (2021). https://doi.org/10.1038/s41396-021-00990-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41396-021-00990-2

This article is cited by

-

Understanding biofouling and contaminant accretion on submerged marine structures

npj Materials Degradation (2023)

-

Metagenomic insights into nutrient and hypoxic microbial communities at the macrofouling/steel interface leading to severe MIC

npj Materials Degradation (2023)

-

Insights into the various mechanisms by which Shewanella spp. induce and inhibit steel corrosion

npj Materials Degradation (2023)

-

Microbially mediated metal corrosion

Nature Reviews Microbiology (2023)

-

A Strong Inhibitory Effect of Microbe-Induced Mineralization on Corrosion on Steel Surfaces

Journal of Materials Engineering and Performance (2023)