Abstract

The recent progress of our research on proton exchange membranes (PEMs) for fuel cell applications is reviewed. In particular, we focus on fluorine-free sulfonated aromatic polymers as alternatives to the benchmark perfluorosulfonic acid ionomer (e.g., Nafion) PEMs. Most fluorine-free sulfonated aromatic polymers require improved proton conductivity (at high temperatures and low humidity) and chemical and mechanical stability. To address these issues, a wide range of molecular structures and their sequences were investigated. First, the effect of molecular structure on the membrane properties of sulfonated multiblock copoly(arylene ether)s is discussed. We emphasize that phosphine oxide moieties might improve chemical stability; however, aromatic ether linkages in the hydrophilic block are not suitable because oxidative degradation and excess water swelling followed by mechanical failure is essentially inevitable. We then developed a novel polymer synthetic method, an intrapolymer Heck reaction, to ladderize aromatic ether linkages in the hydrophilic block. The ladderized rigid hydrophilic structure is an effective molecular design for balancing proton conductivity and mechanical stability. We then discuss two types of segmented copolymers based on the rigid hydrophilic structural design via a Ni-mediated coupling reaction; the hydrophilic structures are sulfonated phenylene and sulfonated benzophenone. We found that the traditional multiblock structure as well as any additional polar groups (e.g., ether, sulfone, ketone) in the hydrophilic sections are not necessary for improving the membrane properties that are important for fuel cell applications, such as proton conductivity and chemical and mechanical stability. The results indicate that fluorine-free aromatic PEMs are a potentially applicable class of ionomers for the next generation of proton exchange membrane fuel cells.

Similar content being viewed by others

Introduction

Fuel cells are efficient and clean energy devices that can address global environmental issues.1 Proton exchange membrane fuel cells (PEMFCs) are attractive for applications in electric vehicles, portable devices and residential cogeneration systems. The commercialization of fuel cell vehicles has recently been achieved; however, efforts are still being made to further improve the performance, durability and cost effectiveness of the PEMFC in terms of both the component materials and the overall systems.2, 3, 4

PEMs are important component materials that transport protons from the anode to the cathode and prevent hydrogen and oxygen gases from mixing. Perfluorosulfonic acid ionomer-based membranes (e.g., Nafion) have been used as a benchmark PEM component because of the balanced membrane properties, including high proton conductivity and mechanical and chemical stability.5 Although the perfluorosulfonic acid-based PEMs also require improvement to their gas permeability, thermal stability, production cost and environmental compatibility, complicated synthetic processes for the perfluorosulfonic acid ionomers have impeded further progress with this class of ionomers.

Hydrocarbon-based PEMs are an attractive alternative because of their easy synthesis and versatility in molecular design.6, 7, 8, 9, 10 Among them, aromatic polymers with acidic functional groups have been most thoroughly studied in the past decade. Such polymers include sulfonated poly(arylene ether)s (SPEs),11, 12, 13 polyimides,14, 15, 16, 17, 18 polyphenylenes19, 20, 21, 22 and their copolymers. These studies have individually implied that fluorine-free aromatic PEMs have superior properties compared with perfluorosulfonic acid-based PEMs with lower cost; however, none of them simultaneously possessed the required properties, including proton conductivity and mechanical and chemical stability. Therefore, the next generation of PEMFCs can potentially be developed using fluorine-free aromatic PEMs by optimizing the molecular structure and their sequence.

This review highlights our recent studies on fluorine-free aromatic PEMs for fuel cell applications.23, 24, 25, 26, 27, 28, 29, 30 Our discussion focuses on the hydrophilic component because most PEM properties are associated with water (absorbed water as a plasticizer, hydrated proton for proton conduction, etc.). First, the effect of the molecular structure of sulfonated multiblock copoly(arylene ether)s on membrane properties, particularly chemical stability, is discussed. We then assess the effect of rigidity on mechanical stability through the development of a novel polymer synthetic method, an intrapolymer Heck reaction. To enhance both proton conductivity and mechanical stability over a wide range of humidities, the effect of polar groups (e.g., ether, sulfone, ketone) has also been clarified. Further, the fuel cell performance of a PEM with an optimized molecular structure is discussed in the last part of this review.

Sulfonated multiblock copoly(arylene ether)s

Multiblock copolymers composed of sulfonated (hydrophilic) and unsulfonated (hydrophobic) blocks have demonstrated improved proton conductivity compared with random copolymer equivalents.31 We have also shown that multiblock SPEs with sulfonated fluorenyl groups exhibit high proton conductivity and fuel cell performance even at low relative humidity (RH) and high temperature.32, 33, 34, 35 Although the membrane showed long-term stability under fuel cell operation at a constant current density of 200 mA cm−2 at 80 °C and 53% RH for 2000 h, the post-test analysis revealed that oxidative degradation occurred mainly at the sulfonated fluorenyl groups. The result prompted us to develop multiblock SPEs without the sulfonated fluorenyl groups for better performing, oxidatively stable membranes.

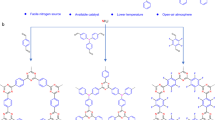

For this purpose, we compared two types of hydrophilic block structures based on sulfonated oligo(phenylene ether sulfone ketone) for SPE-1 and oligo(phenylene ether phosphine oxide ketone) for SPE-2, in which each phenyl group has one sulfonic acid group (Scheme 1). Both SPEs share the same hydrophobic block structure, oligo(biphenylene ether sulfone), and were synthesized in a similar manner. The hydrophobic oligomer was synthesized by nucleophilic substitution polymerization under basic conditions. The chain end (hydroxyl) and length (X) were controlled by changing the feed comonomer ratios. Hydrophilic oligomer precursors were synthesized under the similar reaction conditions to be the fluorine-terminated, chain length-controlled (Y) structure. Hydrophilic oligomers were obtained from a sulfonation reaction of the hydrophilic oligomer precursors in 30% oleum at room temperature. To achieve complete sulfonation (one sulfonic acid group per phenyl group), a longer reaction time (7 days) was needed for SPE-2 than for SPE-1 (4 days) because of the steric hindrance caused by the additional pendant phenylene groups of the phosphine oxide moieties of SPE-2. Note that the sulfonic acid groups were substituted regioselectively, that is, at the position meta to the electron withdrawing sulfone, ketone or phosphine oxide groups, or ortho to the electron donating ether groups. Block copolymerization of the oligomers under similar conditions gave high molecular weight polymers (Mw=275–362 kDa for SPE-1, 204–309 kDa for SPE-2) with a reasonable polydispersity index (2.0–3.7 for SPE-1, 2.3–3.7 for SPE-2) as estimated by gel permeation chromatography. Both SPEs gave transparent and bendable membranes by solution (e.g., dimethyl sulfoxide) casting.

Figure 1 displays the water uptake and proton conductivity of the membranes at 80 °C as a function of RH. For both SPEs, water uptake and proton conductivity increased with increasing ion exchange capacity (IEC). The maximum proton conductivity of SPE-1 (IEC=1.69 meq g−1) and SPE-2 (IEC=1.09 meq g−1) was 202 and 178 mS cm−1 at ca. 90% RH, which were 1.5 and 1.4 times higher than that (131 mS cm−1) of Nafion. The water uptake and proton conductivity of the SPEs were mainly dependent on the IEC rather than the molecular structure, that is, SPE-1 and -2 showed similar water uptake and proton conductivity when their IEC values were similar.

(a) Water uptake and (b) proton conductivity of the membranes at 80 °C as a function of relative humidity (RH). The ion exchange capacity (IEC) values (meq g−1) within parentheses were determined by acid–base titration. A full color version of this figure is available at the Polymer Journal journal online.

The difference in molecular structure affected the oxidative stability of the membranes. Figure 2 displays the residual weight and weight-average molecular weight (Mw) of the membranes after the oxidative stability (Fenton’s) test at 80 °C for 1 h. Most fluorine-free SPEs degrade under the harsh conditions with significant losses in weight, molecular weight and mechanical strength. The previous multiblock SPEs (IEC=1.07–2.12 meq g−1) that contained sulfonated fluorenyl groups also degraded significantly (residual weight=8–53%, Mw=11–28%). In contrast, SPE-1 (IEC=0.91–1.69 meq g−1) and SPE-2 (IEC=0.92–1.09 meq g−1) showed significantly improved oxidative stability: residual weight=11–85%, Mw=35–56% for SPE-1 and residual weight=96–100%, Mw=81–100% for SPE-2. Elimination of the sulfonated fluorenyl groups (SPE-1 and -2) as well as the introduction of the phosphine oxide moieties (SPE-2) are thought to have contributed to the improved oxidative stability. Our future agenda includes developing phosphine oxide-containing PEMs with higher IEC based on SPE and other polymer backbones to improve the proton conductivity without sacrificing the high oxidative stability.

(a) Residual weight and (b) weight-average molecular weight (Mw) of the membranes after the oxidative stability (Fenton’s) test at 80 °C for 1 h. The ion exchange capacity (IEC) values (meq g−1) were determined by acid–base titration. A full color version of this figure is available at the Polymer Journal journal online.

Elimination of aromatic ether linkages

Mechanical strength is another important property of PEMs. During the course of the SPE-based PEM studies, however, we found that this class of PEMs suffers from poor mechanical stability under humidified conditions, which became more pronounced in higher IEC (i.e., higher water uptake) PEMs for higher proton conductivity (e.g., Figure 4, and further discussion in the subsequent section). We considered that the disadvantage might arise from the aromatic ether linkages in the hydrophilic sections, that is, the polar and flexible characteristics might cause excess water swelling followed by mechanical failure under humidified conditions. To eliminate the aromatic ether linkages as well as to enhance the rigidity of the hydrophilic sections, we developed a novel polymer synthetic method, an intrapolymer Heck reaction (Scheme 2). This reaction enabled the selective and quantitative conversion of flexible aromatic ether-type ionomers (SPE) to rigid ladder-type ionomers (SPL).

First, both the hydrophobic (X=5) and hydrophilic (Y=5, 10) oligomers were synthesized in a similar manner. Block copolymerization provided SPL precursors with a high molecular weight (Mw=343 kDa for X5Y5, 435 kDa for X5Y10) and a reasonable polydispersity index (4.34 for X5Y5, 3.51 for X5Y10) as calculated from gel permeation chromatography, which were comparable to the above SPEs. Note that milder reaction conditions (120 °C, 15 h) than those used for SPE-1 (140 °C, 72 h) and SPE-2 (150 °C, 1 week) gave comparably high molecular weight polymers due to the higher reactivity of ortho bromo-substituted fluorobenzene chain ends compared with the others. Next, we conducted the intrapolymer Heck reaction under the optimized conditions as follows: 5 mol% Pd(OAc)2/sPPh3 (benzene-3-sulfonate) as a catalyst, Cs2CO3 as a base and N,N-dimethylacetamide (10 mm for Br) as a solvent. Consequently, 1H nuclear magnetic resonance spectroscopy spectra revealed that the ladderization reaction proceeded selectively and quantitatively. The resulting SPLs possessed a high molecular weight (Mw=317 kDa for X5Y5, 314 kDa for X5Y10) and a reasonable polydispersity index (4.88 for X5Y5, 3.83 for X5Y10). The values were comparable to the parent SPL precursors, which was indicative of negligible side reactions such as crosslinking. Surprisingly, the SPLs possessed high solubility in polar organic solvents (e.g., N,N-dimethylformamide, N,N-dimethylacetamide, DMSO) despite their rigid structures and gave transparent and bendable membranes by solution casting.

Figure 3 displays the water uptake and proton conductivity of the SPL membranes under the same measurement conditions as Figure 1. Data are also included for SPE-1 and -2, which share the hydrophobic blocks. The water uptake and proton conductivity of the SPLs increased with increasing IEC, which is the same trend that was observed for the SPEs. When comparing similar IEC values, SPL showed comparable proton conductivity to SPE-1 under low humidity conditions (e.g., <40% RH), but became lower under high humidity conditions (e.g., >60% RH). The difference probably arises from the difference in water uptake, that is, SPL absorbed less water than SPE-1 under the humidified conditions. The maximum proton conductivity of SPL (IEC=2.12 meq g−1) was 3.38 mS cm−1 at ca. 20% RH, which was 2.1 times higher than that (1.58 mS cm−1) of SPE-1 (maximum possible IEC=1.69 meq g−1).

Figure 4 displays the results of the dynamic mechanical analysis (DMA) of the membranes. The measurement was conducted under conditions similar to those for the water uptake and proton conductivity experiments (80 °C, ca. 0–90% RH). Most aromatic ether-type ionomer membranes (SPEs) are mechanically unstable with significant humidity dependence, for example, E' (storage modulus) considerably decreases with increasing RH, and glass transition behavior can be observed in the tan δ (E''/E') curve, as was the case for both SPE-1 and -2. In contrast, the SPLs were mechanically stable over a wide range of humidities. The glass transition behavior was not observed for the SPLs, independent of the IEC. Furthermore, the E' retention value (E' at 85% RH/E' at 5% RH × 100 (%)) was 57% for SPL (IEC=1.60 meq g−1) and 49% for SPL (IEC=2.12 meq g−1), which were one order of magnitude higher than that (4.6%) for SPE-1 (IEC=1.69 meq g−1). This was surprising because SPL (IEC=2.12 meq g−1) absorbed more water (ca. 40% at 90% RH) than (ca. 32% at 90% RH) SPE-1 (IEC=1.69 meq g−1) as a plasticizer, because of the former’s higher IEC.

Sulfophenylene as the best possible hydrophilic structure

In the previous section, we found that the elimination of the aromatic ether linkages (in other words, decreasing polarity) as well as the enhancement of the rigidity in the hydrophilic sections might be an effective molecular design for balancing the countervailing properties, that is, the proton conductivity and mechanical stability. Furthermore, Kunimatsu et al.36 reported that polar groups such as ether (C-O-C), sulfonyl (O=S=O) and carbonyl (C=O) moieties in PEMs reduce the proton conductivity, especially under low humidity conditions (i.e., low hydration levels) because the limited amount of absorbed water would be used not only for the dissociation of the sulfonic acid groups but also for the formation of hydrogen bonds with such polar groups.36 From these observations, we identified sulfonated p-phenylene as an ideal hydrophilic structure that can be incorporated into the polymer main chain via a well-established synthetic method. The rigid, robust sulfophenylene main chain without any polar groups (except for sulfonic acid groups) in the hydrophilic sections was expected to enhance the proton conductivity, especially under low humidity conditions, as well as the mechanical and chemical stability.

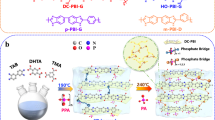

We designed a novel segmented copolymer (SPP) for this purpose (Scheme 3). Ni-mediated coupling copolymerization of the hydrophilic monomer and the hydrophobic oligomer (X=5) provided SPP with a high molecular weight (Mw=202–240 kDa) and polydispersity index (8.42–10.9). The obtained SPP copolymer showed high solubility in polar organic solvents and gave transparent, flexible and self-standing membranes by solution casting.

Figure 5 shows a cross-sectional transmission electron microscopy image of the segmented copolymer SPP (IEC=1.78 meq g−1) membrane stained with lead ions. For comparison, a transmission electron microscopy image of the aforementioned multiblock copolymer, SPE-1 (IEC=1.69 meq g−1) membrane, is also included. In the transmission electron microscopy images, the dark area represents hydrophilic domains and the bright area represents hydrophobic domains. It has been reported that PEMs with multiblock structures are likely to form well-developed hydrophilic/hydrophobic phase separation, as was the case for SPE-1 (Figure 5a). Surprisingly, SPP also showed a similar phase-separated morphology, probably due to the semiblock structure of SPP caused by the use of the presequenced hydrophobic oligomer.

The water uptake and proton conductivity of the SPP membranes are shown in Figure 6. To evaluate the effect of the polar groups in the hydrophilic sections on the membrane properties, data for SPK (carbonyl group) and SPL (sulfonyl and carbonyl groups) are also included. The water uptake of the SPPs followed the order of the IEC at all RHs. Although SPP (IEC=2.67 meq g−1) and SPK (IEC=2.53 meq g−1) showed similar water uptakes at <80% RH, a significant increase was observed for SPK at >80% RH. Furthermore, SPL (IEC=2.12 meq g−1) showed a similar water uptake at all RHs despite its much lower IEC, suggesting that the presence of polar groups in the hydrophilic sections may account for the excess water absorption. This observation was rationalized from the number of absorbed water molecules per sulfonic acid group (λ), that is, the λ values were 8.96 (SPP, 2.67 meq g−1), 10.0 (SPK, 2.53 meq g−1) and 10.4 (SPL, 2.12 meq g−1) at 80 °C and 90% RH.

The presence of polar groups also had a significant impact on the proton conductivity under low humidity conditions. The proton conductivity at 20% RH decreased in the order 7.32 mS cm−1 (SPP, 2.67 meq g−1)>4.62 mS cm−1 (SPK, 2.53 meq g−1)>3.38 mS cm−1 (SPL, 2.12 meq g−1)≈3.22 mS cm−1 (SPP, 1.78 meq g−1), which was clearly independent of the water uptake. The effectiveness of the water in promoting proton conduction was highest for SPP at 20% RH, which was in accordance with the aforementioned literature.36 Note that the high-IEC SPP membrane (2.67 meq g−1) exhibited a higher proton conductivity than Nafion at all RHs. Furthermore, the membrane retained the high proton conductivity even at higher temperature, for example, 55 mS cm−1 at 120 °C and 50% RH.

The high mechanical stability of the SPP membranes was comparable to that of the SPLs over a wide range of humidities (Figure 7). In contrast, the SPK membrane showed clear glass transition behavior at ca. 60% RH and significant humidity dependence of the mechanical properties. The E' retention (E' at 85% RH/E' at 5% RH × 100 (%)) decreased in the order SPL≈SPP>SPK (Figure 8). The high mechanical stability of the SPP membranes was further confirmed by a tensile test at 80 °C and 60% RH, in which the SPP membranes possessed high initial Young's modulus (>1 GPa), high yield stress (>30 MPa) and reasonable strain at the break point (>66%).

A membrane-electrode assembly was prepared with the SPP (IEC=2.67 meq g−1) membrane and subjected to fuel cell performance tests at 80 °C. Figure 9 displays the polarization curves (ohmic (IR) drop-included) and ohmic resistances under humidity conditions of 100 and 30% RH. For comparison, the result of the SPK (IEC=2.53 meq g−1) cell under the same operating conditions is also included. At 100% RH, the open circuit voltage of the cells was 0.972 V for SPP and 0.970 V for SPK, indicating that both membranes possessed good gas barrier properties. Although both cells showed comparable cell voltages and ohmic resistances at 100% RH, the SPP cell exhibited much better fuel cell performance than the SPK cell at 30% RH. The improved fuel cell performance of the SPP cell resulted from its lower ohmic resistance, reflecting the higher proton conductivity of the SPP membrane under low humidity conditions.

Summary and outlook

We have developed a series of fluorine-free aromatic copolymer PEMs for fuel cell applications. In particular, we have focused on the effect of the molecular structures on membrane properties such as proton conductivity and chemical and mechanical stability. First, we observed that phosphine oxide moieties might contribute to the improved oxidative stability of the PEMs. Furthermore, we found that rigid hydrophilic structures that contain fewer polar groups (e.g., ether, sulfone, ketone, phosphine oxide) are preferable for balancing proton conductivity and mechanical stability. Finally, we achieved an optimized hydrophilic molecular design (sulfophenylene as SPP), that is, SPP simultaneously exhibited the highest proton conductivity (Figure 10) and excellent mechanical stability over a wide range of humidities (Figure 11).

This comparative study suggests that fluorine-free aromatic PEMs are potentially applicable to the next generation of PEMFCs that require less expensive, more environmental friendly and durable, and better performing PEMs. However, issues still remain, including lower fuel cell performance than Nafion membrane (Figure 9) and insufficient oxidative stability for long-term fuel cell operation. We believe that further optimizing the molecular structure in both the hydrophilic and hydrophobic sections of the PEMs, the morphology of the PEMs, and the membrane-electrode interface (i.e., improving the compatibility of PEMs and catalyst layers) will enable the realization of next-generation PEMFCs.

Synthesis of the multiblock copolymers (SPE-1 and -2). SPE, sulfonated poly(arylene ether).

Synthesis of the multiblock copolymer (SPL).

Synthesis of the segmented copolymers (SPP and SPK).

References

Carrette, L., Friedrich, K. A. & Stimming, U. Fuel cells—fundamentals and applications. Fuel Cells 1, 5–39 (2001).

de Bruijn, F. A., Dam, V. A. T. & Janssen, G. J. M. Review: durability and degradation issues of PEM fuel cell components. Fuel Cells 8, 3–22 (2008).

Park, C. H., Lee, S. Y., Hwang, D. S., Shin, D. W., Cho, D. H., Lee, K. H., Kim, T.-W., Kim, T.-W., Lee, M., Kim, D.-S., Doherty, C. M., Thornton, A. W., Hill, A. J., Guiver, M. D. & Lee, Y. M. Nanocrack-regulated self-humidifying membranes. Nature 532, 480–483 (2016).

Lee, K.-S., Spendelow, J. S., Choe, Y.-K., Fujimoto, C. & Kim, Y. S. An operationally flexible fuel cell based on quaternary ammonium-biphosphate ion pairs. Nat. Energy 1, 16120 (2016).

Mauritz, K. A. & Moore, R. B. State of understanding of Nafion. Chem. Rev. 104, 4535–4585 (2004).

Hickner, M. A., Ghassemi, H., Kim, Y. S., Einsla, B. R. & McGrath, J. E. Alternative polymer systems for proton exchange membranes (PEMs). Chem. Rev. 104, 4587–4612 (2004).

Peckham, T. J. & Holdcroft, S. Structure–morphology–property relationships of non-perfluorinated proton-conducting membranes. Adv. Mater. 22, 4667–4690 (2010).

Park, C. H., Lee, C. H., Guiver, M. D. & Lee, Y. M. Sulfonated hydrocarbon membranes for medium-temperature and low-humidity proton exchange membrane fuel cells (PEMFCs). Prog. Polym. Sci. 36, 1443–1498 (2011).

Zhang, H. & Shen, P. K. Recent development of polymer electrolyte membranes for fuel cells. Chem. Rev. 112, 2780–2832 (2012).

Kreuer, K. D. Ion conducting membranes for fuel cells and other electrochemical devices. Chem. Mater. 26, 361–380 (2014).

Miyatake, K., Chikashige, Y., Higuchi, E. & Watanabe, M. Tuned polymer electrolyte membranes based on aromatic polyethers for fuel cell applications. J. Am. Chem. Soc. 129, 3879–3887 (2007).

Tian, S., Meng, Y. & Hay, A. S. Membranes from poly(aryl ether)-based ionomers containing randomly distributed nanoclusters of 6 or 12 sulfonic acid groups. Macromolecules 42, 1153–1160 (2009).

Li, N., Wang, C., Lee, S. Y., Park, C. H., Lee, Y. M. & Guiver, M. D. Enhancement of proton transport by nanochannels in comb-shaped copoly(arylene ether sulfone)s. Angew. Chem., Int. Ed. 50, 9158–9161 (2011).

Asano, N., Aoki, M., Suzuki, S., Miyatake, K., Uchida, H. & Watanabe, M. Aliphatic/aromatic polyimide ionomers as a proton conductive membrane for fuel cell applications. J. Am. Chem. Soc. 128, 1762–1769 (2006).

Yin, Y., Suto, Y., Sakabe, T., Chen, S., Hayashi, S., Mishima, T., Yamada, O., Tanaka, K., Kita, H. & Okamoto, K. Water stability of sulfonated polyimide membranes. Macromolecules 39, 1189–1198 (2006).

Lee, H.-S., Badami, A. S., Roy, A. & McGrath, J. E. Segmented sulfonated poly(arylene ether sulfone)-b-polyimide copolymers for proton exchange membrane fuel cells. I. copolymer synthesis and fundamental properties. J. Polym. Sci. Part A 45, 4879–4890 (2007).

Badami, A. S., Roy, A., Lee, H.-S., Li, Y. & McGrath, J. E. Morphological investigations of disulfonated poly(arylene ether sulfone)-b-naphthalene dianhydride-based polyimide multiblock copolymers as potential high temperature proton exchange membranes. J. Membr. Sci. 328, 156–164 (2009).

Yamazaki, K. & Kawakami, H. High proton conductive and low gas permeable sulfonated graft copolyimide membrane. Macromolecules 43, 7185–7191 (2010).

Fujimoto, C. H., Hickner, M. A., Cornelius, C. J. & Loy, D. A. Ionomeric poly(phenylene) prepared by Diels–Alder polymerization: synthesis and physical properties of a novel polyelectrolyte. Macromolecules 38, 5010–5016 (2005).

Goto, K., Rozhanskii, I., Yamakawa, Y., Otsuki, T. & Naito, Y. Development of aromatic polymer electrolyte membrane with high conductivity and durability for fuel cell. Polym. J. 41, 95–104 (2009).

Si, K., Wycisk, R., Dong, D., Cooper, K., Rodgers, M., Brooker, P., Slattery, D. & Litt, M. Rigid-rod poly(phenylenesulfonic acid) proton exchange membranes with cross-linkable biphenyl groups for fuel cell applications. Macromolecules 46, 422–433 (2013).

Skalski, T. J. G., Britton, B., Peckham, T. J. & Holdcroft, S. Structurally-defined, sulfo-phenylated, oligophenylenes and polyphenylenes. J. Am. Chem. Soc. 137, 12223–12226 (2015).

Miyatake, K., Hirayama, D., Bae, B. & Watanabe, M. Block poly(arylene ether sulfone ketone)s containing densely sulfonated linear hydrophilic segments as proton conductive membranes. Polym. Chem. 3, 2517–2522 (2012).

Miyahara, T., Hayano, T., Matsuno, S., Watanabe, M. & Miyatake, K. Sulfonated polybenzophenone/poly(arylene ether) block copolymer membranes for fuel cell applications. ACS Appl. Mater. Interfaces 4, 2881–2884 (2012).

Miyake, J., Watanabe, M. & Miyatake, K. Sulfonated poly(arylene ether phosphine oxide ketone) block copolymers as oxidatively stable proton conductive membranes. ACS Appl. Mater. Interfaces 5, 5903–5907 (2013).

Miyake, J., Watanabe, M. & Miyatake, K. Intrapolymer Heck reaction for proton conductive ladder-type aromatic block copolymers. RSC Adv. 4, 21049–21053 (2014).

Miyake, J., Sakai, M., Sakamoto, M., Watanabe, M. & Miyatake, K. Synthesis and properties of sulfonated block poly(arylene ether)s containing m-terphenyl groups as proton conductive membranes. J. Membr. Sci. 476, 156–161 (2015).

Miyahara, T., Miyake, J., Matsuno, S., Watanabe, M. & Miyatake, K. A sulfonated polybenzophenone/polyimide copolymer as a novel proton exchange membrane. RSC Adv. 5, 50082–50086 (2015).

Miyake, J., Mochizuki, T. & Miyatake, K. Effect of the hydrophilic component in aromatic ionomers: simple structure provides improved properties as fuel cell membranes. ACS Macro Lett. 4, 750–754 (2015).

Miyake, J., Hosaka, I. & Miyatake, K. Effect of sulfonated triphenylphosphine oxide groups in aromatic block copolymers as proton-exchange membranes. Chem. Lett. 45, 33–35 (2016).

Elabd, Y. A. & Hickner, M. A. Block copolymers for fuel cells. Macromolecules 44, 1–11 (2011).

Bae, B., Miyatake, K. & Watanabe, M. Synthesis and properties of sulfonated block copolymers having fluorenyl groups for fuel-cell applications. ACS Appl. Mater. Interfaces 1, 1279–1286 (2009).

Bae, B., Miyatake, K. & Watanabe, M. Sulfonated poly(arylene ether sulfone ketone) multiblock copolymers with highly sulfonated block. Synthesis and properties. Macromolecules 43, 2684–2691 (2010).

Bae, B., Yoda, T., Miyatake, K., Uchida, H. & Watanabe, M. Proton-conductive aromatic ionomers containing highly sulfonated blocks for high-temperature-operable fuel cells. Angew. Chem. Int. Ed. 49, 317–320 (2010).

Bae, B., Miyatake, K., Uchida, M., Uchida, H., Sakiyama, Y., Okanishi, T. & Watanabe, M. Sulfonated poly(arylene ether sulfone ketone) multiblock copolymers with highly sulfonated blocks. Long-term fuel cell operation and post-test analyses. ACS Appl. Mater. Interfaces 3, 2786–2793 (2011).

Kunimatsu, K., Yagi, K., Bae, B., Miyatake, K., Uchida, H. & Watanabe, M. ATR-FTIR analysis of the state of water in a sulfonated block poly(arylene ether sulfone ketone) membrane and proton conductivity measurement during the hydration/dehydration cycle. J. Phys. Chem. C 117, 3762–3771 (2013).

Acknowledgements

This work was partly supported by the New Energy and Industrial Technology Development Organization (NEDO) through the SPer-FC Project, and the Ministry of Education, Culture, Sports, Science and Technology of Japan through a Grant-in-Aid for Young Scientists (16K18258) and Scientific Research (26289254).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Miyake, J., Miyatake, K. Fluorine-free sulfonated aromatic polymers as proton exchange membranes. Polym J 49, 487–495 (2017). https://doi.org/10.1038/pj.2017.11

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2017.11