Abstract

Ion-conductive polymer electrolytes are remarkable materials that have recently been proposed for use as flexible solid electrolytes in next-generation energy storage devices. In particular, the author has proposed the synthesis of novel polymer electrolytes with very high ionic conductivities and the essential properties of polymeric materials. This review describes the synthesis of alternating copolymers of CO2 with epoxides and their application as novel ion-conductive polymers in the place of typical polyether-based systems. The Li salt electrolytes of poly(ethylene carbonate) (PEC) and of other polycarbonates with different side groups exhibit unique ion-conductive properties, such as increasing conductivity with higher salt concentrations, very high Li transference numbers and good electrochemical stability. The Li-ion conductivity of a PEC-lithium bis(fluorosulfonyl)imide LiFSI electrolyte was estimated to be greater than 10−4 S cm−1, and excellent battery performance of this material was also demonstrated at room temperature.

Similar content being viewed by others

Introduction

In 1973, Wright et al.1 first reported the ion-conductive properties of ‘solvent-free’ poly(ethylene oxide) (PEO) systems containing alkali metal salts. In 1978, Armand et al.2 showed that these materials can act as a new class of solid electrolytes for energy storage applications. These new ‘polymer electrolytes’ have recently attracted significant interest as solid state alternatives to liquid electrolytes in electrochemical devices, ranging from rechargeable batteries3, 4, 5 to solar cells,6, 7 ion sensors and electrochromic displays.8 Secondary Li-ion batteries based on polymer electrolytes offer outstanding performance by combining easy processability, mechanical stability, reliability and safety.9 In the past few decades, numerous studies have been focused on the macromolecular design of polyethers as electrolyte materials, mainly with reduced degrees of crystallinity, good electrochemical stability and improved salt solubility.8 Unfortunately, these materials suffer from low ionic conductivities in the solid state, relative to most liquid or ceramic electrolytes. The maximum conductivity of polyether-based electrolytes is usually on the order of 10−4 S cm−1 at room temperature. To facilitate faster migration of ions in these polymers, the local mobility of chains containing cation–anion and cation–dipole interactions should be increased due to the fact that ions are transported via the segmental motion of the ether chains.10 However, cation–dipole interactions may inhibit the migration of cations because of their strong coordination, which increases the glass transition temperature (Tg) of the polymer. Additionally, the coordination structure limits the cation transference values to <0.5 in polyethers,11, 12 affecting the cathodes of electrochemical devices driven under DC polarization.8 To overcome these problems and to develop superior polymer electrolytes, novel polymer candidates are needed that are not based on oxyethylene (OE).

Many polymers without OE, such as poly(acrylonitrile),13, 14 poly(vinyl alcohol)15, 16 and poly(phosphazene),17, 18 have been used as polymer electrolytes, and their ion-conductive properties have been determined. However, it is difficult to achieve good conductivity in these polymers in the solid state. In previous studies of polymers without OE, the present author and his group observed that a novel electrolyte system based on poly(trimethylene carbonate)19, 20 has unique properties and an unusual change in Tg with increasing salt concentration.21 Over the past few years, the electrochemical performance of polymer electrolytes based on poly(trimethylene carbonate) have also been studied by Brandell et al.22, 23, 24, 25, 26, 27 Carbonate-based organic solvents such as ethylene carbonate and diethyl carbonate are still used commercially as electrolyte solutions in Li-ion secondary batteries because of their high dielectric constants.28 The carbonate group, when used in polymer construction, is therefore capable of providing a polar environment suitable for the dissociation of salts and the solvation of ions. This review focuses on poly(ethylene carbonate) (PEC) and its derivatives as novel candidates for ion-conductive polymer electrolytes.

Synthesis of polycarbonates having different side groups

Alternating copolymerization of CO2 with epoxides was first carried out by the Tsuruta group at the University of Tokyo in 1968.29, 30 This group has published many studies, especially on the development of highly active copolymerization catalysts.31, 32, 33 The resulting polycarbonates, which are CO2/epoxide copolymers, have excellent properties compared with other polymers, including a lack of crystallinity, lightness, high transparency and ease of processing as well as are colored.34 The synthetic method is promising not only for the implementation of a novel polymerization reaction but also for the environmental and sustainability potential of carbon sources. Polycarbonates have recently been used as novel functional materials, including as biodegradable polymers,35, 36 nanocomposites,37 liquid–crystalline hybrids38 and ion-conductive polymers.39, 40, 41, 42, 43, 44, 45, 46, 47, 48, 49, 50

In previous studies,39, 40, 42, 48 Tominaga et al. synthesized eleven polycarbonates having different side groups as electrolyte materials. The synthetic procedures for two types of polycarbonates, with glycidyl ether (GE) and hydrocarbon (HC) side groups, are shown in Figure 1. These polymers were synthesized by alternating copolymerization of CO2 with epoxides having R1 or R2 groups in the presence of copolymerization catalysts, zinc glutarate (ZnGA)51, 52 or cobalt salen complex ((R,R)-SalcyCoOCOBzF5, CoSa).31 Polycarbonates synthesized in previous studies39, 40, 42, 48 were obtained as high molecular weight polymers, as summarized in Table 1. The nature of the substituents (denoted by R1 and R2 in Figure 1) of the polycarbonates determines their Tg, which varies from −33 to 45 °C, color and stiffness. GE-type polycarbonates obtained from differential scanning calorimeter (DSC) were transparent and amorphous; only P(GE-tBu) was obtained as a white fibrous solid, as indicated by an endothermic transition at 141 °C. P(GE-nBu), P(GE-Et) and P(GE-iPr) were jellylike rubbers. P(GE-OE1) and P(GE-OE2) were sticky paste-like solids, much softer than the others at room temperature. All of the HC-type polycarbonates and PECs were transparent solids. Commercial PEC and poly(propylene carbonate) (PPC) were obtained as rubbery films. HC-type polycarbonates with alkyl side chains became softer with increasing chain length. In both cases, polycarbonates possessing a phenyl end group, P(GE-Phe) and P(HC-Bn), were glassy polymers. Table 1 also summarizes the thermal properties of these polycarbonates. P(GE-Phe) and P(HC-Bn) were unable to form films because their Tg values were greater than room temperature. Polycarbonates having longer alkyl or ether side groups had lower Tg values.53 P(GE-OE1) and P(GE-OE2) have flexible ether side groups and very low Tg values. The introduction of side groups increased weight-loss temperatures by 5% (Td5, in dry N2); these temperatures are more than 10 °C higher than that of PEC. The steric hindrance of side groups may prevent the backbiting reaction,54 which involves terminal groups on the main chain.

Temperature dependence of the ionic conductivity of polycarbonate-Li salt electrolytes

Tominaga et al. have revealed that PEC, PPC and polycarbonates synthesized in their work can dissolve many different types of Li salts over wide concentrations, giving rise to transparent films without any salt precipitation. Figure 2 summarizes the temperature dependence of the ionic conductivity for these polycarbonate-Li salt electrolytes. The polycarbonates gave characteristic amorphous-type Arrhenius plots, similar to previous polyether-based electrolytes, which are convex in shape throughout the temperature range measured. This characteristic implies that ionic conduction in the polycarbonates occurs via segmental motion of the main chain. As Figure 2a shows, the conductivity values of the GE-type polycarbonates strongly depend on the structure of the side groups. The conductivity of the P(GE-Phe) electrolyte was the lowest of the GE-type polycarbonate electrolytes, at ~10−8 S cm−1 at 80 °C, whereas the addition of 10 mol% lithium bis(trifluoromethane sulfonyl)imide (LiTFSI) reduced the Tg slightly from 45 to 41 °C.39 This result occurred because P(GE-Phe) is a glassy polymer with the highest Tg of all polycarbonates, as shown in Table 1. The P(GE-tBu) electrolyte also had very low conductivity, on the order of 10−9 S cm−1 at 40 °C, but the P(GE-nBu) electrolyte had good conductivity relative to P(GE-Phe) and P(GE-tBu) because of its low Tg value. This improved conductivity stems from the large difference in Tg between polymers and their electrolytes, as a result of steric hindrance involving the side groups.

Temperature dependence of the ionic conductivities of (a) glycidyl ether (GE)-type or hydrocarbon (HC)-type polycarbonate electrolytes with LiTFSI (lithium bis(trifluoromethane sulfonyl)imide); (b) PEC-LiX electrolytes (X: anion) with a salt concentration of 20 mol%; and (c) PEC-LiFSI (lithium bis(fluorosulfonyl)imide) electrolytes with differing salt concentrations. PEC, poly(ethylene carbonate).

Electrolytes of polycarbonates having smaller side groups, such as Et and iPr, had higher relative conductivities,40 and the conductivity of the P(GE-OE1) electrolyte was the highest of all the GE-type polycarbonates tested (2.2 × 10−6 S cm−1 at 30 °C).39 These materials still have lower conductivities than typical polyether electrolytes at the same concentration, however, and the value for the P(GE-OE1) electrolyte is ten times less than that of the PEO10LiTFSI electrolyte. The conductivities of HC-type polycarbonate electrolytes are very low, below 10−8 S cm−1, at room temperature. To analyze the effect of the side group structure, the author and his group have compared the effect of the presence of ether linkages in the side groups on the ion-conductive properties of P(GE-Et) and P(HC-Et). The difference in the conductivity between these electrolytes was quite large, and the conductivity of the P(GE-Et) electrolyte was >100 times greater than that of P(HC-Et).40 This conductivity difference is due to the large difference in the Tg of the LiTFSI electrolytes (10 mol%) between P(GE-Et) (−32 °C) and P(HC-Et) (−4 °C).40 The presence of an ether side group in the polycarbonate increases the ionic conduction because the ether group has low rotational energy and undergoes fast relaxation. In FT-IR ATR measurements of these electrolytes, the spectrum of P(GE-Et) in the region from 1700 to 1800 cm−1 had a single peak, representing the stretching vibration mode for the free carbonyl group in the main chain, whereas P(HC-Et) showed two peaks, which were due to the existence of free and interacting (C=O…Li+) carbonyl groups.21 This difference suggests that the increase in conductivity for the P(GE-Et) electrolyte is due to the interaction of Li ions with the flexible ether side groups.

The addition of salt species to the polymer matrix caused clear changes in the Tg and ion-conductive properties of the electrolytes because of their solubility. The addition of Li salts with low lattice energies and large anion radii, as calculated from the van der Waals volume, to polyether is an effective method of increasing conductivity; the conductivities of LiPF6 and LiClO4 electrolytes should therefore be higher than that of LiBF4.55 Imide-type Li salts with larger anionic radii, such as LiTFSI and lithium bis(fluorosulfonyl)imide (LiFSI), have a plasticizing effect and the potential to have a high conductivity with a low Tg in PEO polymers.56, 57, 58 As shown in Figure 2b, LiClO4 gave rise to the highest conductivity of all electrolytes in PEC at a salt concentration of 20 mol%. The conductivity of LiPF6 in particular was lower than that for other systems, and LiPF6 has a larger anionic radius than LiClO4. The local structure of PEC in the presence of ions is different from that of the PEO system; this difference suggests that the PEC does not form the solvated structures observed in PEO, in which a stable ion-dipole interaction is formed.

An increase in the salt concentration of PEC electrolytes induced a significant change in the ion-conductive behavior, as shown in Figure 2c. The conductivity increased, and the slope of the plots decreased, with increasing LiFSI concentration. The greatest conductivity resulted from a very high concentration of electrolyte; the ratio of Li ions to the monomer unit of PEC was 1.88 (that is, 188 mol% Li).43 The smaller slope of the plot indicates that the activation energy for the ionic conduction in PEC becomes smaller with increasing salt concentration. This remarkable behavior can also be observed in the LiTFSI system41, 42 and has not been observed in polyether-based electrolytes. It is possible that the ion-conduction mechanism in PEC is quite different from that in the typical polyether system.

Dependence on the salt concentration of the ionic conductivity and the glass transition temperature

The relationship between ionic conductivity and salt concentration is essential in explaining the behavior of polymer electrolytes because the addition of salt usually leads to a drastic increase in the Tg value of polymers, especially in the case of polyethers. Figure 3a shows the dependence of salt concentration on the conductivity at 60 °C, as well as on the Tg values, for PEO and PEC-LiFSI electrolytes. In the PEO electrolyte, the conductivity was greatest at a salt concentration of ~5 mol%. This value is almost the same as that previously reported for other electrolytes.8, 55 At salt concentrations above 5 mol%, the Tg value of the PEO electrolyte gradually increases, and the conductivity decreases, with increasing concentration. This effect is most likely due to the increase in cross-linking structures between Li ions and the dipoles of the polyether chains, so that the coupling structure prevents the segmental motion of local chains in the amorphous regions, resulting in an increase in Tg.10 However, the conduction and glass transition behavior of the PEC-based electrolytes are very different from those of the PEO system. The conductivity of PEC-LiFSI electrolytes increases linearly with increasing concentration, and the electrolyte with 188 mol% LiFSI has the highest conductivity, 4.0 × 10−4 S cm−1 at 60 °C.43 The glass transition behavior is very different from the typical PEO system; the Tg value of the PEC electrolytes decreased with increasing concentration, and the lowest value was for electrolytes with 188 mol% LiFSI, which is ~60 °C lower than that of neat PEC. Figure 3b shows that samples of neat PEC as a film become softer upon addition of LiFSI, becoming a gel-like solid. As Figure 3c shows, neat PEC and the electrolytes are amorphous, without any further transitions above the glass transition, and Tg decreases with increasing salt concentration. The addition of salts to PEO induces a large increase in Tg as a result of the strong interactions between ether oxygen atoms and dissociated Li ions, as well as coordination with the polymer chains.8, 10 For PEC-based electrolytes, the dipole moment of the carbonate group in the main chain is strong enough to dissociate salts and interact with Li ions. Tight coordination or solvation, as observed in polyether-based electrolytes, is likely negligible.

(a) Dependence of the conductivities for PEC (poly(ethylene carbonate)) and poly(ethylene oxide) (PEO)-based electrolytes at 60 °C on the LiFSI (lithium bis(fluorosulfonyl)imide) concentration; (b) photographs of neat PEC and electrolytes with 12 and 188 mol% LiFSI; and (c) DSC curves of neat PEC and electrolytes with different concentrations of LiFSI.

Spectroscopic analysis of the salt solvation structure in PEC

The dissociation of salt added to ionic polymers can be confirmed using spectroscopic analysis techniques, such as FT-IR and Raman spectroscopy. Many studies of ionic association in polyethers, including amorphous poly(propylene oxide)59, 60 and crystalline PEO,61, 62 have been published. FT-IR measurements on the PEC system revealed a stretching vibration mode of C=O in the main chain that appeared clearly at ~1700–1800 cm−1 (Figure 4a). The C=O band can be divided into two peaks (Figure 4b); one appears at 1740 cm−1 and is indicative of the free PEC chains, and the other appears at 1720 cm−1 and is indicative of chains interacting with cations (C=O…Li+).63, 64 As Figure 4a shows, the C=O…Li+ peak at 1720 cm−1 gradually becomes larger with increasing salt concentration, whereas the free peak at 1740 cm−1 becomes smaller. The proportion corresponding to the C=O…Li+ peak fraction was nearly saturated at ~70%, above salt concentrations of 50 mol% (Figure 4c); this phenomenon is due to the drastic increase in the conductivity that occurs at higher concentrations.

Spectroscopic analysis of PEC-LiFSI electrolytes using FT-IR (a, b, c) and Raman (d, e, f) techniques: (a, d) original spectra; (b, e) examples of peak separation analysis; and (c, f) dependence on LiFSI concentration on peak fractions in the stretching vibrational modes. The unassigned peak (black line) at ~1700 cm−1 in b was ignored in the estimation of the peak fraction, as shown in c. LiFSI, lithium bis(fluorosulfonyl)imide; PEC, poly(ethylene carbonate).

Raman spectroscopy can also provide information on the dissociation of LiFSI in PEC using the S–N–S stretching vibrational mode of the FSI anions, which appears at ~700–800 cm−1 (Figure 4d). The S–N–S band can be divided into the following three different dissociation states (Figure 4e): free FSI anions at 720 cm−1, contact ion pairs at 732 cm−1 (FSI ions interacting with a single Li-ion), and aggregates at 746 cm−1 (FSI ions interacting with two or more Li ions).65 As shown in Figure 4d, the peak at ~730 cm−1 shifts gradually to higher frequencies ~750 cm−1 with increasing salt concentration. This shift implies that there is a small amount of free FSI anions in PEC electrolytes with low salt concentrations and that the number of contact ion pairs increases with increasing salt concentration. The aggregates gradually predominate, and all anions exist as aggregates above 50 mol% (Figure 4f). A previous study found that a less stable coordination structure between poly(trimethylene carbonate) chains and Li ions causes significant ion-pairing, which leads to a high value of the Li transference number (t+).27 PEC-based electrolytes also do not have a tight coordination structure between the PEC chains and Li ions, which induces an increase in Tg, in contrast to the polyethers. Salt-rich PEC electrolytes above a salt concentration of 50 mol% can be referred to as a ‘polymer-in-salt’ system.66, 67 Polymer-in-salt electrolytes invoke a decoupling ion-conductive mechanism, in which the mobility of ions is less correlated with segmental motion of the polymers because the salts quantitatively dominate the system.66, 67, 68 Tominaga et al. reported that the aggregated ions may migrate in the salt-rich electrolyte phase such as an ionic liquid, as has been proposed in a poly(acrylonitrile)-based polymer-in-salt system,13, 14 in which there is moderate interaction with C=O groups via the segmental motion of PEC chains.49

Li transference number measurements of PEC electrolytes

The value of t+ can be estimated using the method of Bruce et al.69 This method is based on electrochemical measurements in combination with d.c. polarization and a.c. impedance techniques. As shown in Figure 5a, the direct current of the PEO electrolyte drops sharply within a few minutes and then gradually decreases over time. This fall is due to polarization at the Li cathode, arising mainly from the migration of anions. In contrast, t+ was higher for the PEC electrolyte. In a composite with only 1 wt% TiO2, the current and impedance response were highly stable. This behavior implies that there are many mobile ions, especially Li ions in PEC, that can migrate faster than coordinated, paired, and aggregated ions; these free ions may be responsible for the large decrease in Tg.43 Figure 5b shows the values of t+ for PEC-Li salt electrolytes as a function of salt concentration. The LiTFSI electrolytes behaved in an opposite manner than electrolytes in other systems; the values of t+ increased with increasing concentration, up to 0.63 at a concentration of 80 mol%.46 The values of t+ in PEC and polycarbonates possessing side groups are summarized in the table in Figure 5c. Surprisingly, the TiO2 composite had a t+ value greater than 0.8; this value is as high as that of single-ion-conductive polymers.70, 71 These higher t+ values for the PEC system have been confirmed via estimation from the self-diffusion coefficients of ions measured by solid state NMR with the pulsed field gradient technique.43 There are no previous reports of such high t+ values for bis-ion systems, and these values are usually lower than 0.5 in PEO-salt mixtures. Munshi et al.11 reported that crystalline PEO-based electrolytes also have low t+ values, <0.2, at Li salt concentrations greater than 30 mol%. It is well known that dissociated Li ions interact with dipoles of ether oxygens in polymer chains where the transference number is lower. A previous study showed that the Li-ion conductivity σLi (=t+ × ionic conductivity (σ) at 80 °C) of a PEC-LiTFSI electrolyte (80 mol%) was estimated to be ~2.0 × 10−4 S cm−1.43

(a) d.c. polarization and a.c. impedance measurements for PEO- and PEC-based electrolytes; (b) dependence of t+ on salt concentration for PEC-LiX electrolytes; and (c) summary of t+ values for PEO and polycarbonate-based electrolytes. PEC, poly(ethylene carbonate); PEO, poly(ethylene oxide). A full color version of this figure is available at Polymer Journal online.

Electrochemical performance of PEC electrolytes

The redox reactions of Li/Li+, and the electrochemical stability of polymer electrolytes, have been evaluated by standard electrochemical techniques such as cyclic voltammetry (CV) and linear sweep voltammetry (LSV). The measurement cells for PEC-based electrolytes were made of two electrodes comprising a stainless steel plate as a working electrode and a Li foil on a Cu plate as a reference/counter electrode. From the CV data in Figure 6, a deposition and a stripping process of Li/Li+ in a PEC-LiTFSI electrolyte is clearly observed at 0 V, and the anodic limit was irreversible oxidation at ~4.5 V. The LSV measurement in Figure 6 shows that the PEC-LiFSI electrolyte has an oxidation stability above 5 V at 30 °C. This stability may enable its use as a 5 V-class cathode material in Li batteries.47

Cyclic voltammogram of a PEC-LiTFSI electrolyte (scan rate: 0.1 mV s−1) at 80 °C and linear sweep voltammogram of a PEC-LiFSI electrolyte (scan rate: 0.1 mV s−1) at 30 °C (working electrode: stainless steel, counter/reference electrode: Li). LiFSI, lithium bis(fluorosulfonyl)imide; LiTFSI, lithium bis(trifluoromethane sulfonyl)imide; PEC, poly(ethylene carbonate).

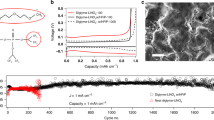

An all-solid-state Li|SPE|LiFePO4 cell, based on a PEC-LiFSI electrolyte, has been assembled successfully with a 3DOM separator by the direct casting of the electrolyte solution onto the cathode.47 In a galvanostatic battery test at 30 °C, the third charge–discharge profile of the PEC electrolyte exhibited flat plateaus centered at 3.45 V, indicating a good electrochemical reaction at the LiFePO4 cathode (Figure 7a). This coin cell exhibited a reversible capacity close to 120 mAh g−1 at the C/20 rate, a performance comparable to that of the copolymer-based systems reported by Brandell et al.24

(a) Charge–discharge curves of the third cycles for P(EO/PO)-LiFSI (5 mol%) and PEC-LiFSI (188 mol%) electrolytes at C/20 rate; and (b) charge–discharge cycling behavior of the PEC-LiFSI electrolytes at different C-rates. The operating temperature was fixed at 30 °C. LiFSI, lithium bis(fluorosulfonyl)imide; PEC, poly(ethylene carbonate). A full color version of this figure is available at Polymer Journal online.

The same coin cell, assembled with a typical electrolyte based on an ethylene oxide/propylene oxide random copolymer (P(EO/PO), [EO]:[PO]=89:11), had a discharge capacity lower than 60 mAh g−1. Battery tests on cells using polyether-based electrolytes are usually performed at higher temperatures of least 40 °C because of the low conductivity and also the crystalline nature of the PEO domain.72 The difference in conductivity at 30 °C between PEC-LiFSI (188 mol%, 2.5 × 10−5 S cm−1) and P(EO/PO)-LiFSI (5 mol%, 3.4 × 10−5 S cm−1) is very small. The good cell performance of the PEC system is due probably to the following factors as an electrolyte: (1) a higher t+; (2) a higher salt concentration; and (3) better adhesiveness at the electrodes.47 The charge/discharge cycling behavior of the coin cell of the PEC-LiFSI electrolyte is shown in Figure 7b. The efficiency after the second cycle was close to 100% and fairly constant. Capacities ranging from 80 to 120 mAh g−1 were delivered at different C-rates, C/5, C/10 and C/20, at an operating temperature of 30 °C. The high t+ values of the PEC system and good contact between the electrode and electrolyte promote stable battery performance at 30 °C, due to attenuated polarization at the cathode and, probably, the formation of a better solid electrolyte interface.

Conclusions

Recent studies on the ion-conductive properties and electrochemical performance of electrolytes based on PEC and its derivatives possessing GE and HC side groups have been reviewed. The author and his group determined the physicochemical properties of PEC and synthesized polycarbonate-based Li electrolytes and found the following deviations from the typical polyether system: (1) the ionic conductivity increases and the Tg value decreases with increasing salt concentration when imide-type salts are used; (2) Li transference numbers are higher than 0.5; (3) the oxidative stability is greater than 5 V vs Li; and (4) the resulting battery can operate at room temperature. This unique combination of desirable properties is due essentially to the unique solvation structure that is based on a very high salt concentration of greater than 50 mol%, where the polycarbonate chain does not form a strong coordination with Li ions, which is observed in polyether-based electrolytes. An interesting feature of this work is that it demonstrates that polycarbonate is a uniquely good candidate for polymer electrolytes because of its flexible, hydrophobic, transparent and ion-conductive properties. In view of increasing environmental concerns regarding the rising global concentration of CO2 gas in the atmosphere, the results summarized here offer a way of mitigating CO2 by fixing it on polymers.

References

Fenton, D. E., Parker, J. M. & Wright, P. V. Complexes of alkali metal ions with poly(ethylene oxide). Polymer 14, 589 (1973).

Armand, M. B., Chagagno, J. M., Duclot, M. T. in Fast Ion Transport in Solids (eds Vashishta, P., Mumdy, J. N. & Shennoy, G. K.) 131 (Elsevier, Amsterdam, Netherland, 1979).

Tarascon, J. M. & Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 414, 359–367 (2001).

Armand, M. & Tarascon, J. M. Building better batteries. Nature 451, 652–657 (2008).

Scrosati, B., Hassoun, J. & Sun, Y.-K. Lithium-ion batteries. A look into the future. Energy Environ. Sci. 4, 3287–3295 (2011).

Nogueira, A. F., Durrant, J. R. & De Paoli, M. A. Dye-sensitized nanocrystalline solar cells employing a polymer electrolyte. Adv. Mater. 13, 826–830 (2001).

Wang, P., Zakeeruddin, S. M., Moser, J. E., Nazeeruddin, M. K., Sekiguchi, T. & Gratzel, M. A stable quasi-solid-state dye-sensitized solar cell with an amphiphilic ruthenium sensitizer and polymer gel electrolyte. Nat. Mater. 2, 402–407 (2003).

Takeoka, S., Ohno, H. & Tsuchida, E. Recent advancement of ion-conductive polymers. Polym. Adv. Technol. 4, 53–73 (1993).

Muldoon, J., Bucur, C. B., Boaretto, N., Gregory, T. & Di Noto, V. Polymers: opening doors to future batteries. Polym. Rev. 55, 208–246 (2015).

Ratner, M. A. & Shriver, D. F. Ion transport in solvent-free polymers. Chem. Rev. 88, 109–124 (1988).

Munshi, M. Z. A., Owens, B. B. & Nguyen, S. Measurement of Li+ ion-transport numbers in poy(ethylene oxide)-LiX complexes. Polym. J. 20, 597–602 (1988).

Kato, Y., Watanabe, M., Sanui, K. & Ogata, N. Ionic transport number of network PEO electrolytes. Solid State Ionics 40-1, 632–636 (1990).

Forsyth, M., Sun, J. Z. & MacFarlane, D. R. Novel polymer-in-salt electrolytes based on polyacrylonitrile (PAN) lithium triflate salt mixtures. Solid State Ionics 112, 161–163 (1998).

Forsyth, M., Sun, J. Z., MacFarlane, D. R. & Hill, A. J. Compositional dependence of free volume in PAN/LiCF3SO3 polymer-in-salt electrolytes and the effect on ionic conductivity. J. Polym. Sci. Part B Polym. Phys. 38, 341–350 (2000).

Every, H. A., Zhou, F., Forsyth, M. & MacFarlane, D. R. Lithium ion mobility in poly(vinyl alcohol) based polymer electrolytes as determined by Li-7 NMR spectroscopy. Electrochim. Acta 43, 1465–1469 (1998).

Rajendran, S., Sivakumar, M. & Subadevi, R. Li-ion conduction of plasticized PVA solid polymer electrolytes complexed with various lithium salts. Solid State Ionics 167, 335–339 (2004).

Allcock, H. R., Napierala, M. E., Cameron, C. G. & Oconnor, S. J. M. Synthesis and characterization of ionically conducting alkoxy ether alkoxy mixed-substituent poly(organophosphazenes) and their use as solid solvents for ionic conduction. Macromolecules 29, 1951–1956 (1996).

Allcock, H. R., Oconnor, S. J. M., Olmeijer, D. L., Napierala, M. E. & Cameron, C. G. Polyphosphazenes bearing branched and linear oligoethyleneoxy side groups as solid solvents for ionic conduction. Macromolecules 29, 7544–7552 (1996).

Smith, M. J., Silva, M. M., Cerqueira, S. & MacCallum, J. R. Preparation and characterization of a lithium ion conducting electrolyte based on poly(trimethylene carbonate). Solid State Ionics 140, 345–351 (2001).

Barbosa, P. C., Rodrigues, L. C., Silva, M. M. & Smith, M. J. Characterization of pTMCnLiPF6 solid polymer electrolytes. Solid State Ionics 193, 39–42 (2011).

Tominaga, Y. in Synthesis and Applications of Copolymers (ed. Parthiban, A.) 217–238 (John Wiley & Sons, Hoboken, NJ, USA, 2014).

Sun, B., Mindemark, J., Edstrom, K. & Brandell, D. Polycarbonate-based solid polymer electrolytes for Li-ion batteries. Solid State Ionics 262, 738–742 (2014).

Mindemark, J., Imholt, L. & Brandell, D. Synthesis of high molecular flexibility polycarbonates for solid polymer electrolytes. Electrochim. Acta 175, 247–253 (2015).

Mindemark, J., Sun, B., Torma, E. & Brandell, D. High-performance solid polymer electrolytes for lithium batteries operational at ambient temperature. J. Power Sources 298, 166–170 (2015).

Mindemark, J., Torma, E., Sun, B. & Brandell, D. Copolymers of trimethylene carbonate and epsilon-caprolactone as electrolytes for lithium-ion batteries. Polymer 63, 91–98 (2015).

Sun, B., Mindemark, J., Edstrom, K. & Brandell, D. Realization of high performance polycarbonate-based Li polymer batteries. Electrochem. Commun. 52, 71–74 (2015).

Sun, B., Mindemark, J., Morozov, E. V., Costa, L. T., Bergman, M., Johansson, P., Fang, Y., Furo, I. & Brandell, D. Ion transport in polycarbonate based solid polymer electrolytes: experimental and computational investigations. Phys. Chem. Chem. Phys. 18, 9504–9513 (2016).

Xu, K. Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 104, 4303–4417 (2004).

Inoue, S., Koinuma, H. & Tsuruta, T. Copolymerization of carbon dioxide and epoxide. J. Polym. Sci. Polym. Lett. Ed. 7, 287–292 (1969).

Inoue, S., Koinuma, H. & Tsuruta, T. Copolymerization of carbon dioxide and epoxide with organometallic compounds. Makromol. Chem. 130, 210–220 (1969).

Cohen, C. T., Chu, T. & Coates, G. W. Cobalt catalysts for the alternating copolymerization of propylene oxide and carbon dioxide: Combining high activity and selectivity. J. Am. Chem. Soc. 127, 10869–10878 (2005).

Sugimoto, H. & Inoue, S. Copolymerization of carbon dioxide and epoxide. J. Polym. Sci. Part A Polym. Chem. 42, 5561–5573 (2004).

Nakano, K., Nakamura, M. & Nozaki, K. Alternating copolymerization of cyclohexene oxide with carbon dioxide catalyzed by (salalen)CrCl complexes. Macromolecules 42, 6972–6980 (2009).

Darensbourg, D. J. Making plastics from carbon dioxide: Salen metal complexes as catalysts for the production of polycarbonates from epoxides and CO2 . Chem. Rev. 107, 2388–2410 (2007).

Lukaszczyk, J., Jaszcz, K., Kuran, W. & Listos, T. Synthesis of functional polycarbonates by copolymerization of carbon dioxide with allyl glycidyl ether. Macromol. Rapid Commun. 21, 754–757 (2000).

Gu, L., Qin, Y., Gao, Y., Wang, X. & Wang, F. Hydrophilic CO2-based biodegradable polycarbonates: synthesis and rapid thermo-responsive behavior. J. Polym. Sci. Part A Polym. Chem. 51, 2834–2840 (2013).

Tan, C. S., Juan, C. C. & Kuo, T. W. Polyethercarbonate-silica nanocomposites synthesized by copolymerization of allyl glycidyl ether with CO2 followed by sol-gel process. Polymer 45, 1805–1814 (2004).

Yu, T., Zhou, Y., Zhao, Y., Liu, K. P., Chen, E. Q., Wang, D. J. & Wang, F. S. Hydrogen-bonded thermostable liquid crystalline complex formed by biodegradable polymer and amphiphilic molecules. Macromolecules 41, 3175–3180 (2008).

Tominaga, Y., Shimomura, T. & Nakamura, M. Alternating copolymers of carbon dioxide with glycidyl ethers for novel ion-conductive polymer electrolytes. Polymer 51, 4295–4298 (2010).

Nakamura, M. & Tominaga, Y. Utilization of carbon dioxide for polymer electrolytes II: synthesis of alternating copolymers with glycidyl ethers as novel ion-conductive polymers. Electrochim. Acta 57, 36–39 (2011).

Tominaga, Y., Nanthana, V. & Tohyama, D. Ionic conduction in poly(ethylene carbonate)-based rubbery electrolytes including lithium salts. Polym. J. 44, 1155–1158 (2012).

Nanthana, V. & Tominaga, Y. Synthesis and fundamental properties of carbon dioxide/alkylene oxide copolymers as ion-conductive polymers. Kobunshi Ronbunshu 70, 23–28 (2013).

Tominaga, Y. & Yamazaki, K. Fast Li-ion conduction in poly(ethylene carbonate)-based electrolytes and composites filled with TiO2 nanoparticles. Chem. Commun. 50, 4448–4450 (2014).

Kimura, K., Hassoun, J., Panero, S., Scrosati, B. & Tominaga, Y. Electrochemical properties of a poly(ethylene carbonate)-LiTFSI electrolyte containing a pyrrolidinium-based ionic liquid. Ionics 21, 895–900 (2015).

Kimura, K., Matsumoto, H., Hassoun, J., Panero, S., Scrosati, B. & Tominaga, Y. A quaternary poly(ethylene carbonate)-lithium bis (trifluoromethanesulfonyl)imide-ionic liquid-silica fiber composite polymer electrolyte for lithium batteries. Electrochim. Acta 175, 134–140 (2015).

Tominaga, Y., Yamazaki, K. & Nanthana, V. Effect of anions on lithium ion conduction in poly(ethylene carbonate)-based polymer electrolytes. J. Electrochem. Soc. 162, A3133–A3136 (2015).

Kimura, K., Yajima, M. & Tominaga, Y. A highly-concentrated poly(ethylene carbonate)-based electrolyte for all-solid-state Li battery working at room temperature. Electrochem. Commun. 66, 46–48 (2016).

Morioka, T., Ota, K. & Tominaga, Y. Effect of oxyethylene side chains on ion-conductive properties of polycarbonate-based electrolytes. Polymer 84, 21–26 (2016).

Kimura, K., Motomatsu, J. & Tominaga, Y. Correlation between solvation and ion-conductive behavior of concentrated poly(ethylene carbonate)-based electrolytes. J. Phys. Chem. C 120, 12385–12391 (2016).

Motomatsu, J., Kodama, H., Furukawa, T. & Tominaga, Y. Dielectric relaxation behavior of a poly(ethylene carbonate)-lithium bis-(trifluoromethanesulfonyl) imide electrolyte. Macromol. Chem. Phys. 216, 1660–1665 (2015).

Motika, S. A., Pickering, T. L., Rokicki, A. & Stein, B. K. Catalyst for the copolymerization of epoxides with CO2. United States patent No. 5026676 (1991).

Ree, M., Bae, J. Y., Jung, J. H. & Shin, T. J. A new copolymerization process leading to poly(propylene carbonate) with a highly enhanced yield from carbon dioxide and propylene oxide. J. Polym. Sci. Part A Polym. Chem. 37, 1863–1876 (1999).

Thorat, S. D., Phillips, P. J., Semenov, V. & Gakh, A. Physical properties of aliphatic polycarbonates made from CO2 and epoxides. J. Appl. Polym. Sci. 89, 1163–1176 (2003).

Li, X. H., Meng, Y. Z., Zhu, Q. & Tjong, S. C. Thermal decomposition characteristics of poly(propylene carbonate) using TG/IR and Py-GC/MS techniques. Polym. Degrad. Stab. 81, 157–165 (2003).

Robitaille, C. D. & Fauteux, D. Phase-diagrams and conductivity characterization of some PEO-LiX electrolytes. J. Electrochem. Soc. 133, 315–325 (1986).

Armand, M., Gorecki, W. & Andreani, R. in 2nd International Symposium on Polymer Electrolytes (ISPE-2), (ed. Scrosati, B.) 91–97 (Elsevier, London, UK, 1990).

Sylla, S., Sanchez, J. Y. & Armand, M. Eloectrochemical study of linear and cross-linked POE-based polymer electrolytes. Electrochim. Acta 37, 1699–1701 (1992).

Zhang, H., Liu, C., Zheng, L., Xu, F., Feng, W., Li, H., Huang, X., Armand, M., Nie, J. & Zhou, Z. Lithium bis(fluorosulfonyl)imide/poly(ethylene oxide) polymer electrolyte. Electrochim. Acta 133, 529–538 (2014).

Schantz, S. On the ion association at low salt concentrations in polymer electrolytes; a Raman study of NaCF3SO3 and LiClO4 dissolved in poly(propylene oxide). J. Chem. Phys. 94, 6296–6306 (1991).

Schantz, S., Torell, L. M. & Stevens, J. R. Ion-pairing effects in poly(propylene glyco)-salt complexes as a function of molecular-weight and temperature: A Raman scattering study using NaCF3SO3 and LiClO4 . J. Chem. Phys. 94, 6862–6867 (1991).

Edman, L. Ion association and ion solvation effects at the crystalline-amorphous phase transition in PEO-LiTFSI. J. Phys. Chem. B 104, 7254–7258 (2000).

Rhodes, C. P. & Frech, R. Local structures in crystalline and amorphous phases of diglyme-LiCF3SO3 and poly(ethylene oxide)-LiCF3SO3 systems: Implications for the mechanism of ionic transport. Macromolecules 34, 2660–2666 (2001).

Selvasekarapandian, S., Baskaran, R., Kamishima, O., Kawamura, J. & Hattori, T. Laser Raman and FTIR studies on Li+ interaction in PVAc-LiClO4 polymer electrolytes. Spectrochim. Acta Part A 65, 1234–1240 (2006).

Wang, J. J., Wu, Y. P., Xuan, X. P. & Wang, H. Q. Ion-molecule interactions in solutions of lithium perchlorate in propylene carbonate plus diethyl carbonate mixtures: an IR and molecular orbital study. Spectrochim. Acta Part A 58, 2097–2104 (2002).

Yamada, Y., Yaegashi, M., Abe, T. & Yamada, A. A superconcentrated ether electrolyte for fast-charging Li-ion batteries. Chem. Commun. 49, 11194–11196 (2013).

Angell, C. A., Liu, C. & Sanchez, E. Rubbery solid electrolytes with dominant cationic transport and high ambient conductivity. Nature 362, 137–139 (1993).

Fan, J., Marzke, R. F., Sanchez, E. & Angell, C. A. Conductivity and nuclear-spin relaxation in superionic glasses, polymer electrolytes and the new polymer-in-salt electrolyte. J. Non-Cryst. Solids 172, 1178–1189 (1994).

Wang, Y. & Sokolov, A. P. Design of superionic polymer electrolytes. Curr. Opin. Chem. Eng. 7, 113–119 (2015).

Evans, J., Vincent, C. A. & Bruce, P. G. Electrochemical measurement of transference numbers in polymer electrolytes. Polymer 28, 2324–2328 (1987).

Bouchet, R., Maria, S., Meziane, R., Aboulaich, A., Lienafa, L., Bonnet, J. P., Phan, T. N. T., Bertin, D., Gigmes, D., Devaux, D., Denoyel, R. & Armand, M. Single-ion BAB triblock copolymers as highly efficient electrolytes for lithium-metal batteries. Nat. Mater. 12, 452–457 (2013).

Matsushita, K., Shimazaki, Y., Mehta, M. A. & Fujinami, T. Synthesis and characterization of aluminate polymer electrolytes and their blends with poly(ether)s. Solid State Ionics 133, 295–301 (2000).

Gauthier, M., Belanger, A., Bouchard, P., Kapfer, B., Ricard, S., Vassort, G., Armand, M., Sanchez, J. Y. & Krause, L. Large lithium polymer battery development—the immobile solvent concept. J. Power Sources 54, 163–169 (1995).

Acknowledgements

The author thanks the following entities for financial support: the Sumitomo Foundation in 2008, the Ogasawara Foundation in 2009, and the Inamori Foundation in 2011. This work was supported financially by a Grant for Advanced Industrial Technology Development (Project ID: 11B01015c) of NEDO, the Specially Promoted Research for Innovative Next Generation Batteries of the Advanced Low Carbon Technology Research and Development Program (ALCA-SPRING) of JST, and JSPS KAKENHI Grant Numbers 25288095 and 16H04199. The 3DOM polyimide separator was kindly donated from Professor Kiyoshi Kanamura and Dr Hirokazu Munakata of Tokyo Metropolitan University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The author declares no conflict of interest.

Rights and permissions

About this article

Cite this article

Tominaga, Y. Ion-conductive polymer electrolytes based on poly(ethylene carbonate) and its derivatives. Polym J 49, 291–299 (2017). https://doi.org/10.1038/pj.2016.115

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2016.115

This article is cited by

-

Accelerating amorphous polymer electrolyte screening by learning to reduce errors in molecular dynamics simulated properties

Nature Communications (2022)

-

Cationic polymer-in-salt electrolytes for fast metal ion conduction and solid-state battery applications

Nature Materials (2022)

-

An acrylate-based quasi-solid polymer electrolyte incorporating a novel dinitrile poly(ethylene glycol) plasticizer for lithium-ion batteries

Journal of Materials Science (2022)

-

Effect of plasticizer on the ion-conductive and dielectric behavior of poly(ethylene carbonate)-based Li electrolytes

Polymer Journal (2021)

-

Polymer heat-proofing using defibered plants obtained by wet-type bead milling of Japanese cedar

Polymer Journal (2021)