Abstract

Tripodal amphiphilic molecules toward organic–inorganic hybrid emulsions were successfully synthesized based on incompletely condensed polyhedral oligomeric silsesquioxanes (POSSs). The three silanol groups provide an excellent scaffold for the construction of three-dimensional amphiphilic molecules, thus well-defined tripodal amphiphilic POSS derivatives were readily synthesized. Thermal analyses revealed that an incompletely condensed POSS exhibited lower crystallinity without loss of thermal stability in comparison with a completely condensed POSS, whereas readily forms aggregates because of its high crystallinity. The newly synthesized tripodal amphiphilic POSSs possessed good solubility in water and effectively stabilized oil-in-water emulsions, while a conventional mono-substituted amphiphilic POSS did not work as an emulsifier because of its lack of water solubility. The prepared organic–inorganic hybrid emulsions were stable against coalescence, and no demulsification occurred over 1 month.

Similar content being viewed by others

Introduction

Organic–inorganic hybrids have attracted much attention because of their advantages in the accurate design of organic syntheses and the durability of inorganic materials. Integration of inorganic components at the surface of organic components can lead to improvement of various properties.1, 2, 3, 4, 5 The oil–water interface can be utilized as a tool for solid particles to self-assemble. For example, based on Pickering emulsion engineering,6, 7, 8, 9 an increased number of studies on organic–inorganic hybrids stabilized by integrated inorganic components have been conducted,10, 11, 12, 13, 14, 15, 16 in which inorganic nano- or microparticles have been employed as emulsifiers.

For more sophisticated material design for integration of inorganic components at the oil–water interface, three-dimensional single molecules that can be exactly decorated are necessary. From this point of view, polyhedral oligomeric silsesquioxanes (POSSs)17, 18, 19, 20, 21 are one of the most suitable candidates because of their precisely defined three-dimensional structure. POSSs have been widely used as fillers,22, 23, 24, 25, 26, 27 cross-linkers,28, 29, 30, 31, 32, 33 monomers34, 35, 36, 37 and substituents to polymer side chains,38, 39, 40, 41, 42, 43 to attain high performance. To obtain a POSS emulsifier, the basic strategy is the construction of amphiphilic POSS derivatives.44, 45, 46, 47, 48, 49, 50 As an example of an amphiphilic POSS derivative, Cheng and coworkers synthesized amphiphilic POSS derivatives via the thiol-ene reaction, and investigated its phase separation behavior.44, 45, 46, 47 In previous works on amphiphilic POSS derivatives, molecular design has been limited to molecules based on mono-substituted POSSs because the synthesis of multi-substituted POSSs involves complicated synthesis and/or troublesome purification processes from many isomers. However, to maintain the structural balance between hydrophilic and hydrophobic substituents, both of these substituents should adopt three-dimensional architectures. Although organic nano- and microparticles with POSS emulsifiers are very attractive because of the high stability of POSS, development of POSS emulsifiers that adopt well-defined structures has not yet been achieved.

Herein, we focused on incompletely condensed POSS derivatives because they contain three silanol groups on the caged silsesquioxane skeletons. Although the incompletely condensed POSS derivatives have generally been used as precursors for mono-functionalized POSSs,51, 52 they can also serve as three-dimensional scaffolds of tripodal molecules such as initiators,53 ligands for transition metals54 and cross-linking agents.42, 55 Hence, precisely defined POSS emulsifiers with multiple hydrophobic and hydrophilic substituents would exploit the three-dimensional structure of POSS to its fullest extent. Additionally, it is expected that incompletely condensed POSSs can effectively restrict crystallinity by lowering the rigidity to gain solubility, without losing thermal stability, in comparison with completely condensed POSSs, which could result in aggregation (aggregation formation due to the high crystallinity has been utilized for construction of micro-structures; e.g., see Hayakawa et al.28, Hirai et al.29, Hirai et al.30, Ishida et al.31). Nonetheless, the thermal properties of incompletely condensed POSSs have never been investigated because they have not been previously recognized as candidates for building blocks of organic–inorganic hybrid materials. In this work, we synthesized tripodal amphiphilic POSS derivatives with hydrophilic poly(ethylene glycol) (PEG) tails, and investigated the thermal properties of hydrophobic POSS centers. The ability of the synthesized tripodal amphiphilic POSS derivatives as emulsifiers was evaluated in comparison with a conventional mono-substituted amphiphilic POSS derivative.

Experimental procedure

Materials

Tetrahydrofuran (THF), chloroform, n-hexane, ethyl acetate (EtOAc), methanol, triethylamine (NEt3), sodium hydroxide (NaOH) and magnesium sulfate anhydrous (MgSO4) were purchased from Nacalai Tesque (Kyoto, Japan). Sodium hydride (NaH, 60 wt% in oil), allyl bromide, distilled water, triethylene glycol monomethyl ether and silica gel for column chromatography (Wakogel-200) were purchased from Wako Pure Chemical Industry (Tokyo, Japan). Trichlorosilane and chlorodimethylsilane were purchased from Tokyo Chemical Industry (Tokyo, Japan). Xylene solution (0.1 m) of platinum(0)-1,3-divinyl-1,1,3,3-tetramethyldisiloxane (Pt(dvs)) and PEG monomethyl ethers (Mn=550 and 2000) were purchased from Sigma-Aldrich Japan (Tokyo, Japan). Heptaisobutyl trisilanol POSS (1) was purchased from Hybrid Plastics (Hattiesburg, MS, USA) (although compound 1 is commercially available, the synthetic procedure, see Zhou et al.52).

Instruments

1H (400 MHz), 13C (100 MHz) and 29Si (80 MHz) nuclear magnetic resonance (NMR) spectra were recorded on a Bruker DPX-400 spectrometer (Bruker Biospin GmbH, Rheinstetten, Germany) in CDCl3 and DMSO-d6 using Me4Si as an internal standard (for NMR spectra, see Supplementary Information). The following abbreviations are used: s, singlet; sep, septet; m, multiplet; br, broad. Thermogravimetric analysis was measured on a TGA-50 Shimadzu Thermogravimetric Analyzer (SHIMADZU, Kyoto, Japan). Differential scanning calorimetry (DSC) was recorded on a TA Instruments 2920 Modulated DSC (TA Instruments, New Castle, DE, USA). Preparative high-performance liquid chromatography for purification was performed on LC-6AD (SHIMADZU) with a tandem column system of two columns selected from Shodex KF-2001, KF-2002 and KF-2003 (SHOWADENKO, Tokyo, Japan) using chloroform as an eluent. A drop of the diluted emulsion was placed on a microscope slide and observed using an optical microscope Shimadzu Motic BA200 (SHIMADZU) fitted with a digital system Shimadzu Moticam 2000 (SHIMADZU).

Synthesis

Tris(dimethylsilyl) heptaisobutyl POSS (2)

A THF solution (40 ml) of 1 (3.16 g, 3.99 mmol) and NEt3 (5.6 ml, 40.2 mmol) was cooled to 0 °C under N2 atmosphere, to which chlorodimethylsilane (2.0 ml, 18.0 mmol) was slowly added. After stirring at 0 °C for 1 h and subsequently at room temperature for 3 h, distilled water (10 ml) was added to quench the reaction. The volatiles were removed in vacuo, and the residue was extracted with n-hexane (20 ml × 3). The combined organic layers were dried over MgSO4. After filtration and evaporation, the residue was subjected to column chromatography on silica gel (eluent: n-hexane/EtOAc=20/1). The solvents were removed in vacuo to obtain 2 (3.24 g, 3.36 mmol, 84%). 1H NMR (CDCl3, 400 MHz): δ 4.75 (sep, J=2.4 Hz, 3H); 1.86–1.82 (m, 7H); 0.98–0.94 (m, 42H); 0.58–0.54 (m, 14H); and 0.23–0.22 (m, 18H) p.p.m. 13C NMR (CDCl3, 100 MHz): δ 26.0, 25.8, 25.6, 24.6, 24.1, 24.0, 23.9, 23.6, 22.4 and 0.6 p.p.m. 29Si NMR (CDCl3, 80 MHz): δ −5.5, −67.1, −67.7 and −68.0 p.p.m.56

Heptaisobutyl POSS (3)

A THF solution (80 ml) of 1 (4.10 g, 5.18 mmol) and NEt3 (8.8 ml, 63.1 mmol) was cooled to 0 °C under N2 atmosphere to which a THF solution (20 ml) of trichlorosilane (0.64 ml, 6.33 mmol) was added dropwise. After stirring at 0 °C for 1 h and subsequently at room temperature for 3 h, n-hexane was added and the insoluble was removed by filtration. The volatiles were removed in vacuo, and the residue was extracted with n-hexane (20 ml × 3). The combined organic layers were dried over MgSO4. After filtration and evaporation, the residue was dissolved in small amounts of EtOAc and subjected to reprecipitation into cold methanol to obtain 3 (3.05 g, 3.73 mmol, 72%). 1H NMR (CDCl3, 400 MHz): δ 4.13 (s, 1H); 1.87–1.84 (m, 7H); 0.97–0.95 (m, 42H); and 0.64–0.59 (m, 14H) p.p.m. 13C NMR (CDCl3, 100 MHz): δ 25.7, 25.7, 23.9, 23.8, 22.5 and 22.3 p.p.m. 29Si NMR (CDCl3, 80 MHz): δ −66.6, −66.7, −66.9 and −67.9 p.p.m.

Allyloxy(poly(ethylene glycol)) methyl ether (A-PEG-200)

NaH (60 wt% in oil, 1.79 g, 44.8 mmol) was dispersed in THF (10 ml), to which a THF solution (5 ml) of tri(ethylene glycol) monomethyl ether (5.05 g, 30.7 mmol) was added to the dispersion liquid at 0 °C. After stirring 20 min, a THF solution of allyl bromide (3.90 ml, 45.1 mmol) was added dropwise to the solution at 0 °C. Subsequently, the reaction mixture was stirred overnight at room temperature. NaOHaq (2 n, 20 ml) was added to quench the reaction, and the organic layer was extracted with chloroform (20 ml × 3). The combined organic layers were dried over MgSO4. Filtration and evaporation gave A-PEG-200 (5.44 g, 26.6 mmol, 87%). 1H NMR (CDCl3, 400 MHz): δ 5.95–5.88 (m, 1H); 5.30–5.16 (m, 2H); 4.04–4.02 (m, 2H); 3.67–3.54 (m, 12H); and 3.38 (s, 3H) p.p.m.

Allyloxy(poly(ethylene glycol)) methyl ether (A-PEG-600)

The same procedure used for A-PEG-200, but with PEG monomethyl ether (Mn=550) instead of tri(ethylene glycol) monomethyl ether, was employed. The isolated yield was 98%. 1H NMR (CDCl3, 400 MHz): δ 5.97–5.87 (m, 1H); 5.30–5.17 (m, 2H); 4.04–4.02 (m, 2H); 3.66–3.54 (m, 60H); and 3.38 (s, 3H) p.p.m.

Allyloxy(poly(ethylene glycol)) methyl ether (A-PEG-2000)

The same procedure used for A-PEG-200, but with a THF solution (20 ml) of PEG monomethyl ether (Mn=2000) instead of a THF solution (5 ml) of tri(ethylene glycol) monomethyl ether, was employed. The isolated yield was 91%. 1H NMR (CDCl3, 400 MHz): δ 5.95–5.88 (m, 1H); 5.30–5.16 (m, 2H); 4.04–4.02 (m, 2H); 3.83–3.46 (m, 204H); and 3.38 (s, 3H) p.p.m.

Tripodal amphiphilic POSS (4a)

A THF solution (5 ml) of 2 (193 mg, 0.207 mmol), A-PEG-200 (194 mg, 0.952 mmol) and Pt(dvs) (0.1 m in xylene, 0.05 ml, 5.0 × 10−3 mmol) was refluxed for 6 h under N2 atmosphere. The solvents were removed in vacuo and the impure product (395 mg) was obtained. Because of the limitation of the amounts of loadable sample, a portion of the product (274 mg) was subjected to preparative high-performance liquid chromatography to give 4a (129 mg, 0.082 mmol, 57%). 1H NMR (CDCl3, 400 MHz): δ 3.67–3.54 (m, 36H); 3.42–3.38 (m, 15H); 1.85–1.81 (m, 7H); 1.62–1.58 (m, 6H); 0.97–0.93 (m, 42H); 0.56–0.51 (m, 20H); and 0.15–0.12 (s, 18H) p.p.m. 13C NMR (CDCl3, 100 MHz): δ 74.1, 71.8, 70.5, 70.4, 69.9, 58.8, 25.9, 25.7, 25.5, 24.9, 24.0, 23.8, 23.7, 23.6, 23.2 and 13.8 p.p.m. 29Si NMR (CDCl3, 80 MHz): δ 9.2, −67.4, −67.8 and −68.2 p.p.m.

Tripodal amphiphilic POSS (4b)

The same procedure used for 4a, but with A-PEG-600 instead of A-PEG-200, was employed. The isolated yield was 51%. 1H NMR (CDCl3, 400 MHz): δ 3.67–3.52 and 3.42–3.36 (m, 132H); 1.86–1.82 (m, 7H); 1.62–1.58 (m, 6H); 0.97–0.94 (m, 42H); 0.57–0.53 (m, 20H); and 0.14–0.13 (s, 18H) p.p.m. 13C NMR (CDCl3, 100MHz): δ 73.8, 71.7, 70.3, 70.2, 69.7, 58.6, 25.8, 25.6, 25.4, 24.7, 23.8, 23.7, 23.5, 23.5, 23.1, 22.1 and 13.7 p.p.m. 29Si NMR (DMSO-d6, 80 MHz): δ 9.7, -67.3, -68.0 and −68.1 p.p.m.

Tripodal amphiphilic POSS (4c)

The same procedure used for 4a, but with A-PEG-2000 instead of A-PEG-200, was employed. The isolated yield was 54%. 1H NMR (CDCl3, 400 MHz): δ 3.70–3.56 and 3.38 (m, 469H); 1.87–1.79 (m, 7H); 1.64–1.56 (m, 6H); 0.97–0.94 (m, 42H); 0.57–0.53 (m, 20H); and 0.12 (s, 18H) p.p.m. 13C NMR (CDCl3, 100 MHz): δ 73.9, 71.7, 70.3, 69.8, 58.7, 25.8, 25.7, 25.4, 24.8, 23.8, 23.7, 23.1 and 13.7 p.p.m. 29Si NMR (CDCl3, 80 MHz): δ 9.1, -67.5, -67.9 and −68.3 p.p.m.

Mono-substituted amphiphilic POSS (5)

A THF solution (5 ml) of 3 (166 mg, 0.203 mmol), A-PEG-2000 (413 mg, 0.202 mmol) and Pt(dvs) (0.1 m in xylene, 0.05 ml, 5.0 × 10−3 mmol) was refluxed for 6 h under N2 atmosphere. The solvents were removed in vacuo and the impure product (585 mg) was obtained. Because of the limitation of the amounts of loadable sample, a portion of the product (103 mg) was subjected to preparative high-performance liquid chromatography to give 5 (47.6 mg, 0.017 mmol, 47%). 1H NMR (CDCl3, 400 MHz): δ 3.65 (br, 359H); 3.38 (s, 3H); 1.87–1.84 (m, 7H); 1.71–1.65 and 1.58–1.53 (m, 5H); 0.96–0.94 (m, 42H); and 0.61–0.59 (m, 16H) p.p.m. 13C NMR (CDCl3, 100 MHz): δ 71.9, 71.2, 70.9, 70.7, 70.5, 70.4, 70.3, 69.9, 58.9, 25.6, 23.8 and 22.4 p.p.m. 29Si NMR (CDCl3, 80 MHz): δ −67.4, −67.8 and −68.0 p.p.m.

Emulsion preparation

Aqueous solutions of the POSS (3 ml) with a solid content of 1 wt% were prepared. These solutions were then homogenized at 23 °C with 3 ml of methyl myristate for two minutes using an IKA Ultra-Turrax T25 digital homogenizer (IKA, Staufen, Germany) with a 10 mm dispersing tool operating at 20 000 r.p.m. Emulsion stabilities after standing for 24 h and 1 week at 23 °C were assessed by visual inspection. In some cases, emulsion stabilities were assessed more accurately by using graduated vessels by monitoring the movement of the emulsion–water interface with time.

Laser diffraction droplet size analysis

The sizes of the emulsion droplets were determined using a particle size analyzer (Malvern Mastersizer 2000, Malvern, UK) equipped with a small volume sample dispersion unit (Hydro 2000SM; ~150 ml including flow cell and tubing), a HeNe laser (633 nm) and a solid-state blue laser (466 nm). The stirring rate was adjusted to 2000 r.p.m. The emulsion droplet size did not change under these measurement conditions, which indicates no coalescence of the droplets. The raw data were analyzed using Malvern software. The mean droplet diameter was taken to be the volume mean diameter (Dv), which is mathematically expressed as Dv=ΣDi4Ni/ΣDi3Ni, where Di is the diameter of the individual droplets and Ni is the number of droplets corresponding to the specific diameter. The light diffraction measurements conducted in this study were highly reproducible. For laser diffraction (LD) charts, see Supplementary Information.

Results and discussion

Synthesis and characterization of amphiphilic POSS derivatives

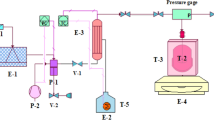

The synthesis of amphiphilic POSS derivatives from commercially available heptaisobutyl incompletely condensed POSS (1)52 as a hydrophobic block is summarized in Scheme 1. The three silanol groups of 1 were reacted with chlorodimethylsilane and trichlorosilane to obtain 2 and 3,56 respectively. The former and the latter were used to obtain tripodal amphiphilic POSSs and a mono-substituted POSS, respectively. Allyloxy(PEG) methyl ethers (A-PEGs), with number average molecular weights (Mn) were ~200, 600 and 2000 (A-PEG-200, 600 and 2000, respectively), were prepared as precursors for the hydrophilic moieties (the number average molecular weights of A-POSS-600 and 2000 were posted in the commercial source of the precursors PEG monomethyl ethers (Sigma-Aldrich). A-POSS-200 was composed of allyloxy tri(ehylene glycol) methyl ether (the molecular weight is 204) without molecular weight distribution). Platinum-catalyzed hydrosilylations57, 58 with A-PEG-200, 600 and 2000 were employed for synthesis of the tripodal POSS derivatives (4a–c, respectively), and A-PEG-2000 was employed for the synthesis of the mono-substituted POSS derivative (5). The obtained amphiphilic POSS derivatives were purified with preparative high-performance liquid chromatography to remove low molecular weight impurities.

The structures of the POSS derivatives were confirmed by 1H, 13C and 29Si NMR spectroscopy. As representative examples, the 1H NMR spectra of A-PEG-600, 2 and 4b are shown in Figure 1. The 1H NMR spectrum of A-PEG-600 exhibits multiplet peaks at δ 6.00–5.87 and 5.30–5.17 p.p.m. attributable to the vinyl group, and that of 2 exhibits a peak at δ 4.71 p.p.m attributable to the Si–H group. These peaks disappear in the spectrum of 4b, suggesting that the hydrosilylation reaction proceeded. Judging from the integrated ratio, nine protons from the methoxy groups at the terminals of the three PEG chains and 42 protons from the methyl groups of the seven isobutyl groups were detected. Thus, three PEG chains were introduced quantitatively. Each of the 29Si NMR spectra of 4a–c showed four signals. For example, in the case of 4b (Figure 2), the signal at δ 9.7 p.p.m was derived from the silyl ether moieties, whereas the three signals at δ −67.3, −68.0 and −68.1 p.p.m. were derived from the silsesquioxane moieties, suggesting that no decomposition of the POSS skeletons occurred.

Thermal analyses of hydrophobic POSS moieties

The thermal properties of 2 and 3 were examined to understand the nature of the hydrophobic POSS centers. To support the idea that an incompletely condensed POSS can serve as an alternative to a completely condensed POSS, the degradation temperatures for 5% and 10% weight loss (Td5 and Td10, respectively) of 2 and 3 were measured by thermogravimetric analysis. The Td5 and Td10 of 2 were 203 and 214 °C, respectively, whereas those of 3 were 207 and 217 °C, respectively (Figure 3), suggesting the thermal stabilities of 2 and 3 were approximately the same. In the case of 2, no residue was observed likely as a result of sublimation as described in the previous literature.59 Therefore, an incompletely condensed POSS exhibits the thermal stability equivalent to that of a completely condensed POSS.

DSC analysis was performed on 2 and 3 to investigate the differences in their crystallinity (Figure 4). The detected melting points of 2 and 3 were −18 and 130 °C, respectively, indicating that the completely condensed POSS formed much more stable crystals than the incompletely condensed POSS. This result is likely because the rigidity of incompletely condensed POSSs is much lower than that of completely condensed POSSs. Judging from the results of the thermogravimetric analysis and DSC measurements, the crystallinity of POSS, which could lead to poor solubility, was significantly regulated while maintaining its thermostability by employing an incompletely condensed POSS skeleton.

Preparation and evaluation of emulsions

To evaluate the obtained POSS derivatives as emulsifiers, 1 wt% aqueous solutions of the POSS derivatives were prepared. Although 4b and c were dissolved in water to obtain 1 wt% aqueous solutions, 4a and 5 were not completely dissolved in the same volume of water, and submillimeter-sized droplets were formed in the continuous aqueous media. The PEG tails of 4a are the shortest of those of the amphiphilic POSS derivatives studied herein, and 4a does not appear to have enough hydrophilicity to be dissolved in water. It is interesting as to why the solubility of 4b in water was higher than that of 5 even though both contain the same total amount of the PEG component. One possible answer is that the high crystallinity of the POSS moiety of 5 lowered its solubility, as indicated in the results of the DSC analysis of 2 and 3. Another possibility is that the three PEG tails of 4b might cover a larger surface area of the hydrophobic bulky POSS head group than the single PEG tail of 5.

The resulting 1 wt% aqueous dispersions of 4a and 5 were homogenized with the same volumes of methyl myristate at 20 000 r.p.m. for 2 min using a homogenizer. Unfortunately, upon 4a and 5, oil–water macrophase separation occurred after the homogenization followed by 1 h of rest (Supplementary Figure S23). The amount of the POSS derivatives dissolved in the aqueous phase as an effective emulsifier was most likely too low to stabilize the oil–water interface, thus leading to unstable emulsions. (Note that 4a and 5 did not dissolve completely in the aqueous media.) However, the emulsions stable against coalescence were prepared using 1 wt% aqueous solutions of 4b and c (Em4b and Em4c, respectively), and the volume-average diameters (Dv) were measured to be 9.2±4.1 and 8.4±5.0 μm, respectively (Supplementary Figure S22). Homogenization of methyl myristate in the absence of any POSS derivatives led to no emulsion, which strongly indicates that the POSS derivatives have an important role in the stabilization of the emulsions. The emulsion type was confirmed using the ‘drop test’. One drop of the emulsion was added to both water and methyl myristate, where its ease of dispersion was monitored by visual inspection. The relatively ease of dispersion indicates that the continuous phase of the emulsion was the same as the diluent (either water or methyl myristate). Em4b and Em4c were smoothly dispersed in pure water, which indicates the formation of the oil-in-water emulsion. From optical microscopy studies, the number average diameters (Dn) of Em4b and Em4c were determined to be 7.0±2.6 and 7.7±3.0 μm, respectively (Figure 5). The emulsions were stable against coalescence for at least 1 month, that is, nearly 100% of the emulsions were retained in closed system where the evaporation of oil and water were not permitted, and only slow creaming was observed with time. The Dv values of Em4b and Em4c 1 month after the homogenization were measured to be 9.2±4.1 and 8.4±5.0 μm, respectively, by a laser diffraction particle size analyzer (Supplementary Figure S22), which were nearly the same sizes measured 1 h after the homogenization (Table 1). These results indicate that the POSS derivatives can function as effective emulsifiers to form highly stable emulsions.

Conclusions

In conclusion, tripodal amphiphilic molecules based on incompletely condensed POSS derivatives were successfully synthesized by a facile synthetic procedure. Thermal analyses indicate that incompletely condensed POSS 2 showed lower crystallinity without loss of thermal stability in comparison to completely condensed POSS 3. Incompletely condensed POSSs are potential candidates for easy-to-handle building blocks of organic–inorganic hybrid materials. The tripodal amphiphilic POSS derivatives worked as effective emulsifiers, where the resulting oil-in-water emulsions, which were stable over 1 month with no demulsification, were fabricated by homogenizing aqueous solutions of the POSS derivatives and oil. The present molecular design will open a new pathway toward the construction of a novel class of emulsifiers to achieve unique organic–inorganic architectures. The detailed structural analyses, stabilization of other oils and investigation into the effect of POSS at the interface are underway.

Synthesis of amphiphilic polyhedral oligomeric silsesquioxane derivatives 4a–c and 5, where A-poly(ethylene glycol)-200, 600, 2000 and 2000 were employed in the synthesis of 4a–c and 5, respectively.

References

Usuki, A., Kojima, Y., Kawasumi, M., Okada, A., Fukushima, Y., Kurauchi, T. & Kamigaito, O. Synthesis of nylon 6-clay hybrid. J. Mater. Res. 8, 1179–1184 (1993).

Jousseaume, B., Lahcini, M., Rascle, M.-C., Ribot, F. & Sanchez, C. General routes to functional organotin trichlorides and trialkoxides involving the tricyclohexylstannyl group. Organometallics 14, 685–689 (1995).

Tamaki, R., Tanaka, Y., Asuncion, M. Z., Choi, J. & Laine, R. M. Octa(aminophenyl)silsesquioxane as a nanoconstruction site. J. Am. Chem. Soc. 123, 12416–12417 (2001).

Kageyama, K., Tamazawa, J. & Aida, T. Extrusion polymerization: catalyzed synthesis of crystalline linear polyethylene nanofibers within a mesoporous silica. Science 285, 2113–2115 (1999).

Naka, K., Yamaguchi, M. & Chujo, Y. Synthesis of poly(oxyethylene)-grafted palladium clusters. Chem. Mater. 11, 849–851 (1999).

Ramsden, W. Separation of solids in the surface-layers of solutions and ‘‘suspensions’’ (observations on surface-membranes, bubbles, emulsions, and mechanical coagulation). Proc. R. Soc. Lond. 72, 156–164 (1903).

Pickering, S. U. Emulsions. J. Chem. Soc. 91, 2001–2021 (1907).

Binks, B. P. & Horozov, T. S. Colloidal Particles at Liquid Interfaces (Cambridge University Press New York, USA, 2006).

Aveyard, R., Binks, B. P. & Clint, J. H. Emulsions stabilised solely by colloidal particles. Adv. Colloid Interface Sci. 100–102, 503–546 (2003).

Moore, W. C. Emulsification of water and of ammonium chloride solutions by means of lamp black. J. Am. Chem. Soc. 41, 940–946 (1919).

Lin, Y., Skaff, H., Emrick, T., Dinsmore, A. D. & Russell, T. P. Nanoparticle assembly and transport at liquid-liquid interfaces. Science 299, 226–229 (2003).

Wang, D., Duan, H. & Möhwald, H. The water/oil interface: the emerging horizon for self-assembly of nanoparticles. Soft Mater. 1, 412–416 (2005).

Takahara, Y. K., Ikeda, S., Ishino, S., Tachi, K., Ikeue, K., Sakata, T., Hasegawa, T., Mori, H., Matsumura, M. & Ohtani, B. Asymmetrically modified silica particles: a simple particulate surfactant for stabilization of oil droplets in water. J. Am. Chem. Soc. 127, 6271–6275 (2005).

Fujii, S., Okada, M. & Furuzono, T. Hydroxyapatite nanoparticles as stimulus-responsive particulate emulsifiers and building block for porous materials. J. Colloid Interface Sci. 315, 287–297 (2007).

Fujii, S., Okada, M., Sawa, H., Furuzono, T. & Nakamura, Y. Hydroxyapatite nanoparticles as particulate emulsifier: fabrication of hydroxyapatite-coated biodegradable microspheres. Langmuir 25, 9759–9766 (2009).

Fujii, S., Yokoyama, Y., Miyanari, Y., Shiono, T., Ito, M., Yusa, S. & Nakamura, Y. Micrometer-sized gold−silica Janus particles as particulate emulsifiers. Langmuir 29, 5457–5465 (2013).

Laine, R. M. Nanobuilding blocks based on the [OSiO1.5]x (x=6, 8, 10) octasilsesquioxanes. J. Mater. Chem. 15, 3725–3744 (2005).

Cordes, D. B., Lickiss, P. D. & Rataboul, F. Recent developments in the chemistry of cubic polyhedral oligosilsesquioxanes. Chem. Rev. 110, 2081–2173 (2010).

Kuo, S. W. & Chang, F. C. POSS related polymer nanocomposites. Prog. Polym. Sci 36, 1649–1696 (2011).

Tanaka, K. & Chujo, Y. Advanced functional materials based on polyhedral oligomeric silsesquioxane (POSS). J. Mater. Chem. 22, 1733–1746 (2012).

Zhang, W.-B., Yu, W., Wang, C.-L., Sun, H.-J., Hsieh, I.-F., Li, Y., Dong, X.-H., Yue, K., Horn, R. V. & Cheng, S. Z. D. Molecular nanoparticles are unique elements for macromolecular science: from “nanoatoms” to giant molecules. Macromolecules 47, 1221–1239 (2014).

Tanaka, K., Adachi, S. & Chujo, Y. Structure-property relationship of octa-substituted POSS in thermal and mechanical reinforcements of conventional polymers. J. Polym. Sci. A Polym. Chem. 47, 5690–5697 (2009).

Tanaka, K., Adachi, S. & Chujo, Y. Side-chain effect of octa-substituted POSS fillers on refraction in polymer composites. J. Polym. Sci. A Polym. Chem. 48, 5712–5717 (2010).

Jeon, J.-H., Tanaka, K. & Chujo, Y. Rational design of POSS fillers for simultaneous improvements of thermomechanical properties and lowering refractive indices of polymer films. J. Polym. Sci. A Polym. Chem. 51, 3583–3589 (2013).

Fina, A., Monticelli, O. & Camino, G. POSS-based hybrids by melt/reactive blending. J. Mater. Chem. 20, 9297–9305 (2010).

Pramoda, K. P., Koh, C. B., Hazrat, H. & He, C. B. Performance enhancement of polylactide by nanoblending with POSS and graphene oxide. Polym. Compos 35, 118–126 (2014).

Blanco, I., Bottino, F. A., Cicala, G., Latteri, A. & Recca, A. Synthesis and characterization of differently substituted phenyl hepta isobutyl-polyhedral oligomeric silsesquioxane/polystyrene nanocomposites. Polym. Compos 35, 151–157 (2014).

Hayakawa, T., Seino, M., Goseki, R., Hirai, T., Kikuchi, R., Kakimoto, M., Tokita, M., Yokoyama, H. & Horiuchi, S. Fabrication of hierarchically ordered hybrid structures over multiple length scales via direct etching of self-organized polyhedral oligomeric silsesquioxane (POSS) functionalized block copolymer films. Polym. J. 38, 567–576 (2006).

Hirai, T., Leolukman, M., Hayakawa, T., Kakimoto, M. & Gopalan, P. Hierarchical nanostructures of organosilicate nanosheets within self-organized block copolymer films. Macromolecules 41, 4558–4560 (2008).

Hirai, T., Leolukman, M., Jin, S., Goseki, R., Ishida, Y., Kakimoto, M., Hayakawa, T., Ree, M. & Gopalan, P. Hierarchical self-assembled structures from POSS-containing block copolymers synthesized by living anionic polymerization. Macromolecules 42, 8835–8843 (2009).

Ishida, Y., Hirai, T., Goseki, R., Tokita, M., Kakimoto, M. & Hayakawa, T. Synthesis and self-assembly of thermotropic block copolymer with long alkyl tethered cage silsesquioxane in the side chain. J. Polym. Sci. A Polym. Chem. 49, 2653–2664 (2011).

Sun, D., Zhou, Z., Chen, G.-X. & Li, Q. Regulated dielectric loss of polymer composites from coating carbon nanotubes with a cross-linked silsesquioxane shell through free-radical polymerization. ACS Appl. Mater. Interfaces 6, 18635–18643 (2014).

Franczyk, A., He, H., Burdyńska, J., Hui, C. M., Matyjaszewski, K. & Marciniec, B. Synthesis of high molecular weight polymethacrylates with polyhedral oligomeric silsesquioxane moieties by atom transfer radical polymerization. ACS Macro Lett. 3, 799–802 (2014).

Wu, S., Hayakawa, T., Kikuchi, R., Grunzinger, S. J. & Kakimoto, M. Synthesis and characterization of semiaromatic polyimides containing POSS in main chain derived from double-decker-shaped silsesquioxane. Macromolecules 40, 5698–5705 (2007).

Wu, S., Hayakawa, T., Kakimoto, M. & Oikawa, H. Synthesis and characterization of organosoluble aromatic polyimides containing POSS in main chain derived from double-decker-shaped silsesquioxane. Macromolecules 41, 3481–3487 (2008).

Hoque, M. A., Kakihana, Y., Shinke, S. & Kawakami, Y. Polysiloxanes with periodically distributed isomeric double-decker silsesquioxane in the main chain. Macromolecules 42, 3309–3315 (2009).

Maegawa, T., Irie, Y., Fueno, H., Tanaka, K. & Naka, K. Synthesis and polymerization of a para-disubstituted T8-caged hexaisobutyl-POSS monomer. Chem. Lett. 43, 1532–1534 (2014).

Tamaki, R., Choi, J. & Laine, R. M. A polyimide nanocomposite from octa(aminophenyl)silsesquioxane. Chem. Mater. 15, 793–797 (2003).

Asuncion, M. Z. & Laine, R. M. Silsesquioxane barrier materials. Macromolecules 40, 555–562 (2007).

Tanaka, K., Inafuku, K., Adachi, S. & Chujo, Y. Tuning of properties of POSS-condensed water-soluble network polymers by modulating the crosslinking ratio between POSS. Macromolecules 42, 3489–3492 (2009).

Tanaka, K., Ohashi, W., Kitamura, N. & Chujo, Y. Glutathione-responsive molecular release using water-soluble POSS network polymers. Bull. Chem. Soc. Jpn. 84, 612–616 (2011).

Miyasaka, M., Fujiwara, Y., Kudo, H. & Nishikubo, T. Synthesis and characterization of hyperbranched polymer consisting of silsesquioxane derivatives. Polym. J. 42, 799–803 (2010).

Wu, J., Wu, Z. L., Yang, H. & Zheng, Q. Crosslinking of low density polyethylene with octavinyl polyhedral oligomeric silsesquioxane as the crosslinker. RSC Adv. 4, 44030–44038 (2014).

Li, Y., Dong, X.-H., Guo, K., Wang, Z., Chen, Z., Wesdemiotis, C., Quirk, R. P., Zhang, W.-B. & Cheng, S. Z. D. Synthesis of shape amphiphiles based on POSS tethered with two symmetric/asymmetric polymer tails via sequential “grafting-from” and thiol–ene “click” chemistry. ACS Macro Lett. 1, 834–839 (2012).

Yue, K., Liu, C., Guo, K., Yu, X., Huang, M., Li, Y., Wesdemiotis, C., Cheng, S. Z. D. & Zhang, W.-B. Sequential “click” approach to polyhedral oligomeric silsesquioxane-based shape amphiphiles. Macromolecules 45, 8126–8134 (2012).

Liu, H., Hsu, C.-H., Lin, Z., Shan, W., Wang, J., Jiang, J., Huang, M., Lotz, B., Yu, X., Zhang, W.-B., Yue, K. & Cheng, S. Z. D. Two-dimensional nanocrystals of molecular Janus particles. J. Am. Chem. Soc. 136, 10691–10699 (2014).

Feng, X., Zhu, S., Yue, K., Su, H., Guo, K., Wesdemiotis, C., Zhang, W.-B., Cheng, S. Z. D. & Li, Y. T10 polyhedral oligomeric silsesquioxane-based shape amphiphiles with diverse head functionalities via “click” chemistry. ACS Macro Lett. 3, 900–905 (2014).

Liu, D., Yu, B., Jiang, X. & Yin, J. Responsive hybrid microcapsules by the one-step interfacial thiol–ene photopolymerization. Langmuir 29, 5307–5314 (2013).

Liu, D., Jiang, X. & Yin, J. One-step interfacial thiol-ene photopolymerization for metal nanoparticle-decorated microcapsules (MNP@MCs). Langmuir 30, 7213–7220 (2014).

Ogi, K., Miyauchi, S. & Naka, K. Amphiphilic POSS-core dendrons for optically transparent thermoplastic films with tunable wettability. Polym. J. 47, 259–266 (2015).

Di Iulio, C., Jones, M. D., Mahon, M. F. & Apperley, D. C. Zinc(II) silsesquioxane complexes and their application for the ring-opening polymerization of rac-lactide. Inorg. Chem. 49, 10232–10234 (2010).

Zhou, J., Zhao, Y., Yu, K., Zhou, X. & Xie, X. Synthesis, thermal stability and photoresponsive behaviors of azobenzene-tethered polyhedral oligomeric silsesquioxanes. New J. Chem. 35, 2781–2792 (2011).

Yamahiro, M., Oikawa, H., Yoshida, K., Ito, K., Yamamoto, Y., Tanaka, M., Ootake, N., Watanabe, K., Ohno, K., Tsujii, Y. & Fukuda, T. Silicon compound useful as polymerization initiators PCT Int. Appl. WO 2004026883: A1 20040401

Ionescu, G., van der Vlugt, J. I., Abbenhuis, H. C. L. & Vogt, D. Synthesis and applications of chiral phosphite ligands derived from incompletely condensed silsesquioxane backbones. Tetrahedron 16, 3970–3975 (2005).

Bian, Y. & Mijović, J. Effect of side-chain architecture on dielectric relaxation in polyhedral oligomeric silsesquioxane/polypropylene oxide nanocomposites. Polymer 50, 1541–1547 (2009).

Lu, C.-H., Tsai, C.-H., Chang, F.-C., Jeong, K.-U. & Kuo, S.-W. Self-assembly behavior and photoluminescence property of bispyrenyl-POSS nanoparticle hybrid. J. Colloid Interface Sci. 358, 93–101 (2011).

Speier, J. L., Webster, J. A. & Barnes, G. H. The addition of silicon hydrides to olefinic double bonds. part II. The use of group VIII metal catalysts. J. Am. Chem. Soc. 79, 974–979 (1957).

Itami, K., Mitsudo, K., Nishino, A. & Yoshida, J. Metal-catalyzed hydrosilylation of alkenes and alkynes using dimethyl(pyridyl)silane. J. Org. Chem. 67, 2645–2652 (2002).

Araki, H. & Naka, K. Syntheses of dumbbell-shaped trifluoropropyl-substituted poss derivatives linked by simple aliphatic chains and their optical transparent thermoplastic films. Macromolecules 44, 6039–6045 (2011).

Acknowledgements

This study is part of a Grant-in-Aid for Scientific Research on Innovative Areas ‘New Polymeric Materials Based on Element-Blocks (no. 2401)’ (no. 24102003) of The Ministry of Education, Culture, Sports, Science and Technology of Japan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on Polymer Journal website .

Supplementary information

Rights and permissions

About this article

Cite this article

Imoto, H., Nakao, Y., Nishizawa, N. et al. Tripodal polyhedral oligomeric silsesquioxanes as a novel class of three-dimensional emulsifiers. Polym J 47, 609–615 (2015). https://doi.org/10.1038/pj.2015.38

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2015.38

This article is cited by

-

Tripod-shaped POSS compounds as single-component silsesquioxane hybrids

Polymer Journal (2024)

-

Preparation of molecularly well-defined silicone resins based on trifluoropropyl-substituted trisilanol and their thermal, mechanical, and UV-resistance properties

Polymer Journal (2024)

-

Double-cyclopolymerization using trifunctional incompletely condensed cage silsesquioxane with methacryloyl groups

Polymer Journal (2023)

-

Development of macromolecules and supramolecules based on silicon and arsenic chemistries

Polymer Journal (2018)

-

Self-association behavior of amphiphilic molecules based on incompletely condensed cage silsesquioxanes and poly(ethylene glycol)s

Polymer Journal (2018)