Abstract

A surface modification method of biocompatible poly(lactic acid) (PLA) with titanium oxide (TiOx) is proposed. Tetraethoxytitanium(IV) (TEOT) was used to construct a TiOx network with a few residual ethyl groups via an acid-catalyzed sol–gel reaction exploiting surface segregation. The surface of the resulting PLA-TiOx composite films was flat and homogeneous when the TEOT loading was <5 wt%. The properties of the PLA-TiOx composite films were examined by microscopy to explore the fibroblast affinity for the scaffold surface. The number of cells attached to the PLA-TiOx composite films increased with increasing surface TiOx content. Cell morphology was also dependent upon the surface TiOx content, and the attached cells on the composite film were better spread than those on the pristine PLA film. These results clearly show that our proposed method is a useful technique to improve the affinity of cells for PLA surfaces.

Similar content being viewed by others

Introduction

How to regulate the interaction between cells and material surfaces is one of the key fundamental topics in biotechnology and biomedical fields.1, 2, 3 Numerous types of cellular scaffolds have been developed using organic4, 5, 6, 7 and inorganic8, 9, 10 polymeric materials, and their composites11, 12 via various chemical and physical processing methods. In addition, how and why polymer properties affect the cell behavior, such as adhesion, migration, proliferation and differentiation, have been extensively studied. Until now, it has been accepted that the surface parameters of polymers, such as chemical composition,2 surface-free energy,13, 14 topology,5, 7, 15 roughness,16, 17 crystallinity16, 17, 18 and so on, have an important role in controlling the cell function in in vitro culturing systems.

Biocompatible polymers such as poly(lactic acid) (PLA), poly(glycolic acid) and their copolymers have attracted a great deal of attention as scaffold materials for cell culturing due to their high biocompatibility.17, 18, 19, 20 However, further application of these polymers without modification will be challenging because of inadequate cell–surface interactions.13, 21, 22, 23, 24 For example, a low affinity of the scaffold surface with the cells will be problematic, leading to an inflammatory response after implantation. To improve the affinity of the PLA-made scaffold with the cells, the surface was modified by incorporating various functional groups using a variety of approaches, such as copolymerization, graft polymerization25, 26, 27, 28, 29, 30, 31 and plasma irradiation.32, 33, 34, 35 After such modifications were performed, the surface properties including the hydrophilicity and chemical reactivity were altered, and the cell functionality was enhanced on the polymer scaffold surfaces. However, despite the abundance of literature documenting the surface modification of PLA, it appears that their industrial use remains limited. This is a consequence of the complicated and time-consuming methods currently used for the surface modification of PLA. In addition, it is quite difficult to introduce functional groups to an all-purpose polymer without damaging the material. Thus, a more versatile method that can be applied to such polymers is desirable.

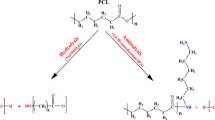

Recently, we applied the sol–gel reaction of tetraethoxysilane (TEOS) to modify the surfaces of polyisoprene36 and polystyrene37 films. TEOS is fed into a polymer solution and reacted to form an inorganic network before and/or during the film solidification and is then segregated at the film surface. This confers hardness and antioxidant properties to the surface. In this study, we extend our simple method to modify the surface of a PLA scaffold with tetraethoxytitanium(IV) (TEOT) rather than TEOS, which forms a titanium oxide (TiOx) network after the sol–gel process. TiOx is a well-known biocompatible inorganic material due to its corrosion resistance, mechanical properties, inertness and so forth, when in contact with biocomponents.38, 39, 40, 41, 42, 43 TiOx has been used in clinical applications as implants, specifically as a bone replacement. Here thin films of PLA-TiOx composite are prepared and used as a scaffold for cell culture. We clearly demonstrate that the small amount of TiOx network formed at the scaffold surface influences the cell behavior, including cell adhesion and proliferation.

Experimental procedure

Preparation of PLA-TiOx composite films

PLA prepared via ring opening polymerization of racemic DL-lactide was purchased from Polymer Source (Montreal, Quebec, Canada) and purified by reprecipitation. Using gel permeation chromatography analysis, the number-average molecular weight (Mn) and polydispersity index were determined to be 92k and 1.93, respectively. A sol was prepared by acid-catalyzed hydrolysis of TEOT (Sigma-Aldrich, St Louis, MO, USA). TEOT mixed with ethanol, ultrapure water and hydrochloric acid at the desired ratio, called TEOThyd, was stirred at room temperature under a nitrogen atmosphere for 10 min. The rate of hydrolysis of TEOT was regulated to prevent complete gelation. TEOThyd was then added to a solution of PLA in tetrahydrofuran, and it was stirred for 30 min to obtain a homogeneous solution. PLA thin films with a thickness of ~170 nm that contained titanium oxide (PLA-TiOx composite) were prepared by spin-coating the solutions onto silicon wafers and borosilicate cover glasses. The films were annealed at 353 K under reduced pressure for 24 h. The loading ratios of PLA/TEOT (weight/weight) selected were 97/3, 95/5, 90/10 and 80/20. As a reference, homogeneous PLA and TEOThyd films were also prepared and labeled 100/0 and 0/100 PLA/TEOT (weight/weight).

Surface characterization

The surface morphology of the films was characterized by atomic force microscopy (E-sweep with a SPI3800 controller, Hitachi High-Technologies, Tokyo, Japan) using dynamic force mode at room temperature. A cantilever tip with a nominal spring constant of 1.3 N m−1 and a resonance frequency of 27 kHz was used for the observations. Static and dynamic contact angle measurements were performed using a Drop Master 500 (Kyowa Interface Science, Niiza, Japan). A droplet of pure water was used as a probe liquid. For dynamic contact angle measurements, a film on a silicon wafer was tilted until a 20-μl water droplet began to slide down the surface. The advancing (θa) and receding (θr) angles were measured and used to calculate the contact angle hysteresis (Δθ=θa−θr). The surface chemical composition of the PLA-TiOx composite films was examined using X-ray photoelectron spectroscopy (XPS, PHI 5800 ESCA system, Physical Electronics, Chanhassen, MN, USA) with a monochromatized AlKα source. The emission angle was fixed at 45°, corresponding to an analytical depth of ~7 nm from the outermost surface. The C1s peak was calibrated using the binding energy of neutral carbon (285.0 eV) to correct for charging energy shifts.

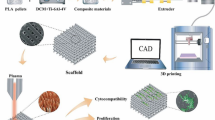

Cell culturing

The PLA-TiOx composite films on the borosilicate substrates were used as a scaffold for cell culturing. The scaffold films were washed with a phosphate-buffered saline solution, and, then, they were placed on the base of a 24-well culture dish filled with commercially available culture media, normal Roswell Park Memorial Institute 1640 (Life Technologies, Tokyo, Japan), with or without 10% fetal bovine serum. Suspensions of fibroblast L929 (RIKEN BRC Cell Bank, Tsukuba, Japan), derived from mice, were seeded onto the scaffold films at 5.0 × 104 cells per well. The cultures were maintained at 310 K (37 °C) in a humid atmosphere containing 5% CO2. The cell adhesion state was evaluated using phase contrast microscopic observations. To assess the cell viability accurately, fluorescence microscopy was used after cell staining with a LIVE/DEAD solution (Life Technologies) containing calcein O,O’-diacetate tetrakis(acetoxymethyl) ester (Calcein-AM, excitation/emission maxima (λex/λem) of 494/517 nm) and ethidium homodimer-1 (EthD-1, λex/λem of 528/617 nm).44 Observations were performed using a GFP-BP filter cube (center wavelength/bandwidth (CWL/BW)=470/40 nm for excitation, CWL/BW=535/50 nm for emission, Keyence, Osaka, Japan) and a TRITC filter cube (CWL/BW=540/25 (nm/nm) for excitation, CWL/BW=605/55 nm/nm for emission, Keyence), respectively.

Furthermore, fluorescence microscopy was used to examine the formation of stress fibers in the cells adhered onto the polymer scaffolds. The cells were immobilized onto the scaffolds before the observations. After the removal of the culture medium, the samples were fixed with 4% paraformaldehyde for 30 min and washed with phosphate-buffered saline at 310 K three times. Alexa Fluor 594 phalloidin (λex/λem of 581/609 nm, Life Technologies) was used to stain the F-actin filament formed in the fibroblast. All cell nuclei were stained with 4’,6-diamidino-2-phenylindole (λex/λem of 358/461 nm for bound to double-stranded DNA, Life Technologies).

Results and Discussion

Surface properties of PLA-TiOx composite films

Figures 1a–c show the topographic images for PLA and the PLA-TiOx composite films. Figures 1d–f show the relative height profiles along lines in the corresponding topographic images. The surface of the PLA-TiOx composite films with a loading weight ratio of 97/3 and 95/5 was quite flat and featureless. The root mean square roughness values for these films were 0.87 and 1.4 nm, respectively. These results are almost comparable to the PLA homogeneous film, which exhibited a value of 0.67 nm. When the weight ratio of TEOT exceeded 10%, the surface roughness increased significantly (data not shown). The root mean square roughness for the 90/10 and 80/20 films were 16 and 34 nm, respectively. In the following section, only 97/3 and 95/5 films are discussed.

Table 1 summarizes the wettability of the PLA and PLA-TiOx composite films. Although the static contact angle of water (φwater) on the PLA film was (78.8±0.4)°, for the 97/3 and 95/5 PLA-TiOx composite films the static contact angles were (83.0±0.3)° and (84.5±0.5)°, respectively. These results are contrary to what was expected on the addition of hydrophilic TiOx. A possible explanation for this result may be that the TEOT hydrolysis reaction did not proceed to completion. Therefore, some ethyl groups originating from the unhydrolyzed TEOT remain at the surface of the composite film, reducing its hydrophilicity compared with TiOx. To confirm this hypothesis, XPS measurements were performed. Figures 2a and b show the survey spectra for the homogeneous PLA film and the 95/5 PLA-TiOx composite films, respectively. For the composite film, a weak peak assigned to Ti2p was observed at ~460 eV in addition to the intense C1s and O1s peaks at ~285 and 540 eV, respectively. Figures 2c and d show the C1s core-level spectra for the PLA-TiOx composite and TEOThyd homogeneous films, respectively. In the case of the PLA-TiOx composite film, the C1s peaks corresponding to neutral, ether and carbonyl carbons were observed at 285.0, 286.5 and 289.0 eV, respectively (Figure 2c). Because PLA chains contain these three carbons types, the spectrum obtained is reasonable. Peaks associated with neutral and ether carbons were visible in the TEOThyd film C1s spectrum (Figure 2d). This result indicates that the hydrolysis of TEOT was incomplete under the current conditions. Taking into account the integrated intensity of the C1s and Ti2p spectra,45 the amount of TEOT that was hydrolyzed was determined to be ~40%. Thus, although the difference in the C1s XPS spectra between the homogeneous PLA film and the PLA-TiOx composite film was very small, the C1s peaks shown in Figure 2c may represent the summation of the peaks derived from PLA chains and the hydrophobic ethyl groups originating from TEOT that remained after hydrolysis. This is in good agreement with the higher φwater observed for the PLA-TiOx composite film compared with the pristine one.

XPS survey spectra for a (a) homogeneous PLA film and (b) 95/5 (wt/wt) PLA-TiOx composite film. XPS core-level spectra of C1s for a (c) 95/5 PLA-TiOx composite film and (d) TEOThyd homogeneous film. The neutral C1s peak was assigned to a binding energy of 285.0 eV to correct for the charging energy shift. XPS core-level spectra of Ti2p for a (e) 95/5 PLA-TiOx composite film and (f) TEOThyd film. PLA, poly(lactic acid); TEOT, tetraethoxytitanium(IV); TiOx, titanium oxide; XPS, X-ray photoelectron spectroscopy.

Figures 2e and f show the Ti2p core-level spectra obtained for the PLA-TiOx composite and TEOThyd homogeneous films, respectively. Two peaks corresponding to different spin orbit components, (Ti2p 3/2) and (Ti2p 1/2), were observed. It is known that Ti2p peaks from the pure metal (Ti) are observed at 454.6 and 460.6 eV, respectively. However, their binding energies for the PLA-TiOx composite film were shifted by ~3.5 eV to 458.3 and 464.0 eV, respectively. This indicates that the Ti was oxidized in the composite film to Ti4+.46, 47 That is, TiOx exists at the surface of the PLA-TiOx composite film. The surface Ti content at a depth of 6.9 nm was calculated to be 2.2 wt% from the ratio of the integrated intensity of C1s and Ti2p spectra.47 The Ti content in the 95/5 PLA-TiOx composite film was calculated to be 1.1 wt%, assuming the TEOT is 40% hydrolyzed. Therefore, the partially hydrolyzed TEOT formed Ti-O-Ti networks at the film surface. Unfortunately, in the case of the 97/3 PLA-TiOx composite film, the Ti2p peaks were not clearly observed. However, the φwater for this film was also larger than that for the homogeneous PLA film. This indicates the 97/3 PLA-TiOx composite film also has the Ti-O-Ti network with ethyl groups at the surface similarly to the 95/5 PLA-TiOx composite film.

Regarding the dynamic contact angle for the prepared films, it was noted that the θa values were almost constant regardless of the fractional amount of TiOx; however, the Δθ values for the PLA-TiOx films were smaller than that for the homogeneous PLA film by ~4°. This is due to the larger θr values for the composite films, as shown in Table 1. This result implies that the chain dynamics within the surface region are restricted after the incorporation of TiOx.

Cell behavior on the PLA-TiOx composite films

Now, we will explore the effect of TiOx on the cell behavior. Before the measurement, the stability of the scaffold films in a culture medium was examined on the basis of topographic observation using digital microscopy, as shown in Supplementary Figure S1 of the Supplementary Information (SI). To determine the toxicity of the hydrolyzed TEOT, cell adhesion and proliferation on the homogeneous TEOThyd film were examined. The cells behaved favorably on such surfaces, as shown in Supplementary Figures S2a and b in the SI. In addition, mortal cells were rarely observed on the homogeneous TEOThyd film according to the live/dead assay, as shown in Supplementary Figures S2c and d. This indicates that the hydrolyzed TEOT surface was not cytotoxic.

Figure 3 shows the phase contrast images of L929 fibroblasts on the homogenous PLA film in comparison with the 97/3 and 95/5 PLA-TiOx composite films after culturing under serum-free conditions for 4 and 24 h. After culturing for 4 h, the number of cells adhered to the surface was greater for the PLA-TiOx composite films than for the homogenous PLA film, as shown in Figures 3a–c. In addition, although the shape of the majority of the cells on the pristine film remained spherical, cells on the composite films spread out noticeably. These results clearly show that the fibroblasts were affected by the presence of TiOx at the film surface during the initial adhesion process. Furthermore, this trend became more striking after culturing for 24 h, as shown in Figures 3d–f. This was particularly evident in the 95/5 composite film, where the observed spreading affected a more significant quantity of cells. Furthermore, mortal cells were rarely observed on all scaffold films examined, as shown in Supplementary Figure S3. The following two figures present a quantitative discussion of the above results based on the cell images in Figure 3.

Phase contrast images of L929 fibroblasts adhered on (a, d) a homogenous PLA film, (b, e) 97/3 (wt/wt) PLA-TiOx composite film and (c, f) 95/5 (wt/wt) PLA-TiOx composite film after culturing under serum-free conditions for (a–c) 4 and (d–f) 24 h. Scale bars correspond to 50 μm. PLA, poly(lactic acid); TiOx, titanium oxide.

Figure 4 shows the number of L929 cells attached to the various film surfaces. As shown in Figure 4a, the number of cells on the composite films initially was twice that on the PLA film. In addition, the difference in the number of cells between the composite and pristine films became larger after culturing for 24 h, as shown in Figure 4b. Therefore, it can be concluded that the TiOx component at the surface enhanced the cell proliferation and the initial adhesion.

Generally, when fibroblast cells such as mouse L929 are cultured under appropriate conditions, they attach to a surface and then spread out. The cell spreading on the PLA and PLA-TiOx composite films was also evaluated based on the cell images. Figure 5 shows the abundance of the projected area of the L929 cells adhered on the films after culturing for 4 and 24 h. All histograms were fitted using simple Gaussian distributions. The peak position and full width at half maximum for each distribution in Figure 5 are summarized in Table 2. Both the peak position and full width at half maximum are larger for the composite films than for the PLA film. This indicates that the cells attached to the PLA composite films more strongly than to the homogenous PLA film, resulting in the cell spreading observed. These results indicate that the fibroblast cells recognize the TiOx component introduced within the surface region of the PLA scaffold film, where the chain dynamics may be restricted due to the presence of the Ti-O-Ti network.

The abundance of the projected area of the L929 fibroblasts adhered on (a, d) a homogeneous PLA film, PLA-TiOx composite films with a loading weight ratio of (b, e) 97/3 (wt/wt) and (c, f) 95/5 (wt/wt) under serum-free conditions. Culturing times were (a–c) 4 and (d–f) 24 h. The normal distribution curves are superimposed. The number of cells used for calculation of the abundance was 300 for each sample. PLA, poly(lactic acid); TiOx, titanium oxide.

Cytoskeleton formation of cells adhered on the scaffolds

The tension induced by the formation of actin stress fibers inside the cells is one of the forces affecting the cell morphology and proliferation. To gain a better understanding of the structural response of cells attached to the scaffolds with a TiOx component, the formation of F-actin filaments was observed by fluorescence microscopy using cells stained with fluorescent dyes after glutaraldehyde fixation. As shown in Figure 6, F-actin filaments clearly formed in the cells that adhered to the PLA-TiOx composite surface. This was not the case for the homogeneous PLA surface. Therefore, the introduction of TiOx to the PLA film surface contributes to the formation of F-actin filaments, resulting in enhanced cell adhesion to the polymer scaffold surface.

To study the impact of serum proteins such as fibronectin and collagen on cell adhesion and proliferation, L929 fibroblast cells were cultured under serum conditions. Figures 7a–f show the phase contrast images of L929 fibroblasts on the homogenous PLA film in comparison with the 97/3 and 95/5 PLA-TiOx composite films after culturing for 4 h and 3 days. The shape of the majority of the cells remained spherical regardless of the amount of TiOx. However, the number of cells adhered to the surface was greater for the PLA-TiOx composite films than for the PLA film regardless of culturing time. Figure 7g shows the culturing time dependence of the number of cells attached to the scaffold films, the so-called growth curves. The cell behavior was strongly dependent on the existence of TiOx from around the middle to the end of the time period being examined. The number of cells on the 95/5 PLA-TiOx composite film was larger than that on the other scaffold films. Hence, it is plausible that the TiOx component that suppresses the surface mobility of the PLA also enhances the cell proliferation and the initial adhesion via the layer of serum proteins on the scaffold.

Phase contrast images of L929 fibroblasts adhered on (a, d) a homogenous PLA film, (b, e) 97/3 (wt/wt) PLA-TiOx composite film and (c, f) 95/5 (wt/wt) PLA-TiOx composite film after culturing for (a–c) 4 h and (d–f) 3 days under serum conditions. Scale bars correspond to 50 μm. (g) Growth curves of L929 fibroblasts on the homogeneous PLA film and PLA-TiOx composite films. The data represent the mean±s.d. PLA, poly(lactic acid); TiOx, titanium oxide.

Conclusions

PLA-TiOx composite films were successfully prepared using a simple sol–gel method with TEOT as a source of TiOx. When the loading of TEOT in the film was <5% by weight, the surface was smooth on the nanometer scale. XPS analysis revealed that TiOx was slightly segregated at the composite surface. Once TiOx was incorporated into the PLA surface, initial cell adhesion and proliferation on the scaffolds were enhanced, accompanied by the formation of F-actin filaments due to the high biocompatibility of TiOx derivatives, which led to the suppression of the chain surface mobility. In addition, the enhanced cell behavior was further observed under serum-present conditions. We believe that this facile surface modification method could be applied to many polymeric scaffolds and contribute to the development of highly functional novel scaffolds for cell culture.

References

Ratner, B. D. & Bryant, S. J. Biomaterials: where we have been and where we are going. Annu. Rev. Biomed. Eng. 6, 41–75 (2004).

Williams, D. F. On the mechanisms of biocompatibility. Biomaterials 29, 2941–2953 (2008).

Williams, D. F. On the nature of biomaterials. Biomaterials 30, 5897–5909 (2009).

Shastri, V. P. & Lendlein, A. Materials in regenerative medicine. Adv. Mater. 21, 3231–3234 (2009).

Alves, N. M., Pashkuleva, I., Reis, R. L. & Mano, J. F. Controlling cell behavior through the design of polymer surfaces. Small 6, 2208–2220 (2010).

Lendlein, A. & Shastri, V. P. Stimuli-sensitive polymers. Adv. Mater. 22, 3344–3347 (2010).

Yao, X., Peng, R. & Ding, J. Cell-material interactions revealed via material techniques of surface patterning. Adv. Mater. 25, 5257–5286 (2013).

Bagherifard, S., Ghelichi, R., Khademhosseini, A. & Guagliano, M. Cell response to nanocrystallized metallic substrates obtained through severe plastic deformation. ACS Appl. Mater. Interfaces 6, 7963–7985 (2014).

Kulkarni, M., Mazare, A., Gongadze, E., Perutkova, Š., Kralj-Iglič, V., Milošev, I., Schmuki, P., Iglič, A. & Mozetič, M. Titanium nanostructures for biomedical applications. Nanotechnology 26, 062002 (2015).

Lipski, A. M., Pino, C. J., Haselton, F. R., Chen, I. W. & Shastri, V. P. The effect of silica nanoparticle-modified surfaces on cell morphology, cytoskeletal organization and function. Biomaterials 29, 3836–3846 (2008).

Ventrelli, L., Fujie, T., Del Turco, S., Basta, G., Mazzolai, B. & Mattoli, V. Influence of nanoparticle-embedded polymeric surfaces on cellular adhesion, proliferation, and differentiation. J. Biomed. Mater. Res. A 102, 2652–2661 (2014).

Jones, J. R. Review of bioactive glass: from hench to hybrids. Acta Biomater. 9, 4457–4486 (2013).

Tamada, Y. & Ikada, Y. Fibroblast growth on polymer surfaces and biosynthesis of collagen. J. Biomed. Mater. Res. 28, 783–789 (1994).

Gentleman, M. M. & Gentleman, E. The role of surface free energy in osteoblast-biomaterial interactions. Int. Mater. Rev. 59, 417–429 (2014).

Greco, F., Fujie, T., Ricotti, L., Taccola, S., Mazzolai, B. & Mattoli, V. Microwrinkled conducting polymer interface for anisotropic multicellular alignment. ACS Appl. Mater. Interfaces 5, 573–584 (2013).

Washburn, N. R., Yamada, K. M., Simon, C. G. Jr, Kennedy, S. B. & Amis, E. J. High-throughput investigation of osteoblast response to polymer crystallinity: influence of nanometer-scale roughness on proliferation. Biomaterials 25, 1215–1224 (2004).

Simon, C. G. Jr ., Eidelman, N., Kennedy, S. B., Sehgal, A., Khatri, C. A. & Washburn, N. R. Combinatorial screening of cell proliferation on poly(L-lactic acid)/poly(D,L-lactic acid) blends. Biomaterials 26, 6906–6915 (2005).

Park, A. & Cima, L. G. In vitro cell response to differences in poly-L-lactide crystallinity. J. Biomed. Mater. Res. 31, 117–130 (1996).

Wang, S. G., Cui, W. & Bei, J. Bulk and surface modifications of polylactide. Anal. Bioanal. Chem. 381, 547–556 (2005).

Ma, P. X. Scaffolds for tissue fabrication. Mater. Today 7, 30–40 (2004).

Oh, S. H. & Lee, J. H. Hydrophilization of synthetic biodegradable polymer scaffolds for improved cell/tissue compatibility. Biomed. Mater. 8, 014101 (2013).

Lee, J. H., Khang, G., Lee, J. W. & Lee, H. B. Interaction of different types of cells on polymer surfaces with wettability gradient. J. Colloid Interface Sci. 205, 323–330 (1998).

Van Wachem, P. B., Beugeling, T., Feijen, J., Bantjes, A., Detmers, J. P. & Van Aken, W. G. Interaction of cultured human endothelial cells with polymeric surfaces of different wettabilities. Biomaterials 6, 403–408 (1985).

Tamada, Y. & Ikada, Y. Effect of preadsorbed proteins on cell adhesion to polymer surfaces. J. Colloid Interface Sci. 155, 334–339 (1993).

Vert, M. in Biopolymers: Biology, Chemistry, Biotechnology, Application Vol. 4 (eds Doi Y., Steinbüchel A.) 179 (Wiley-VCH Verlag GmbH, Weinheim, 2002).

Tsuji, H. in Biopolymers: Biology, Chemistry, Biotechnology, Application Vol. 4 (eds Doi Y., Steinbüchel A.) 129, (Wiley-VCH Verlag GmbH, Weinheim, 2002).

Södergård, A. & Stolt, M. Properties of lactic acid based polymers and their correlation with composition. Prog. Polym. Sci. 27, 1123–1163 (2002).

Albertsson, A. C. & Lofgren, A. Synthesis and characterization of poly(1,5-dioxepan-2-one-co-L-lactic acid) and poly(1,5-dioxepan-2-one-co-D-lactic acid). J. Macromol. Sci. Pure Appl. Chem. A32, 41–59 (1995).

Fujiwara, T. & Kimura, Y. Macromolecular organization of poly(l-lactide)-block-polyoxyethylene into bio-inspired nano-architectures. Macromol. Biosci. 2, 11–23 (2002).

Kimura, Y., Matsuzaki, Y., Yamane, Y. & Kitao, T. Preparation of block copoly(ester-ether) comprising poly(l-lactide) and poly(oxypropylene) and degradation of its fibre in vitro and in vivo. Polymer 30, 1342–1349 (1989).

Třesohlavá, E., Popelka, S, Machová, L. & Rypáček, R. Modification of polylactide surfaces with lactide-ethylene oxide functional block copolymers: accessibility of functional groups. Biomacromolecules 11, 68–75 (2010).

Saulnier, B., Ponsart, S., Coudane, J., Garreau, H. & Vert, M. Lactic acid-based functionalized polymers via copolymerization and chemical modification. Macromol. Biosci. 4, 232–237 (2004).

Yang, J., Bei, J. Z. & Wang, S. G. Improving cell affinity of poly(D,L-lactide) film modified by anhydrous ammonia plasma treatment. Polym. Adv. Technol. 13, 220–226 (2002).

Alves, C. M., Yang, Y., Marton, D., Carnes, D. L., Ong, J. L. & Sylvia, V. L. Plasma surface modification of poly(D,L-lactic acid) as a tool to enhance protein adsorption and the attachment of different cell types. J. Biomed. Mater. Res. B 87B, 59–66 (2008).

Jacobs, T., Declercq, H., Geyter, N. D., Cornelissen, R., Dubruel, P., Leys, C., Beaurain, A., Payen, E. & Morent, R. Plasma surface modification of polylactic acid to promote interaction with fibroblasts. J. Mater. Sci. Mater. Med 24, 469–478 (2013).

Tsuruta, H., Fujii, Y. & Tanaka, K. One-pot surface modification of rubbery polymer films. Polym. Chem. 3, 319–321 (2012).

Tsuruta, H., Ikinaga, Y., Fujii, Y. & Tanaka, K. A simple approach for surface hardening of polystyrene. Appl. Surf. Sci. 264, 589–592 (2013).

Brånemark, P. I. Osseointegration and its experimental background. J. Prosthet. Dent. 50, 399–410 (1983).

Verket, A., Tiainen, H., Haugen, H. J., Lyngstadaas, S. P., Nilsen, O. & Reseland, J. E. Enhanced osteoblast differentiation on scaffolds coated with TiO2 compared to SiO2 and CaP coatings. Biointerphases 7, 36–45 (2012).

Jokinen, M., Pätsi, M., Rahiala, H., Peltola, T., Ritala, M. & Rosenholm, J. B. Influence of sol and surface properties on in vitro bioactivity of sol-gel-derived TiO2 and TiO2-SiO2 films deposited by dip-coating method. J. Biomed. Mater. Res. 42, 295–302 (1998).

Nygren, H., Tengvall, P. & Lundström, I. The initial reactions of TiO2 with blood. J. Biomed. Mater. Res. 34, 487–492 (1997).

Sato, M., Aslani, A., Sambito, M. A., Kalkhoran, N. M., Slamovich, E. B. & Webster, T. J. Nanocrystalline hydroxyapatite/titania coatings on titanium improves osteoblast adhesion. J. Biomed. Mater. Res. Part A 84, 265–272 (2008).

Kim, H. W., Kim, H. E., Salih, V. & Knowles, J. C. Hydroxyapatite and titania sol-gel composite coatings on titanium for hard tissue implants; mechanical and in vitro biological performance. J. Biomed. Mater. Res. Part B 72, 1–8 (2005).

Papadopoulos, N. G., Dedoussis, G. V., Spanakos, G., Gritzapis, A. D., Baxevanis, C. N. & Papamichail, M. An improved fluorescence assay for the determination of lymphocyte-mediated cytotoxicity using flow cytometry. J. Immunol. Methods 177, 101–111 (1994).

Scofield, J. H. Hartree-slater subshell photoionization cross-sections at 1254 and 1487 eV. J. Electron Spectrosc. Relat. Phenom. 8, 129–137 (1976).

Diebold, U. & Madey, T. E. TiO2 by XPS. Surf. Sci. Spectra 4, 227–231 (1998).

Mayer, J., Garfunkel, E., Madey, T. E. & Diebold, U. Titanium and reduced titania overlayers on titanium dioxide(110). J. Electron Spectrosc. Relat. Phenom. 73, 1–11 (1995).

Acknowledgements

This research was partly supported by JST SENTANKEISOKU (13A0004) and JSPS KAKENHI Scientific Research on Innovative Area ‘New Polymeric Materials Based on Element-Blocks’ (No. 25102535), ‘Molecular Soft-Interface Science’ (No. 23106716) programs, and a Grant-in-Aid for Scientific Research (B) (No. 24350061).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Matsuno, H., Matsuyama, R., Yamamoto, A. et al. Enhanced cellular affinity for poly(lactic acid) surfaces modified with titanium oxide. Polym J 47, 505–512 (2015). https://doi.org/10.1038/pj.2015.30

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2015.30

This article is cited by

-

Cellular behaviors on polymeric scaffolds with 2D-patterned mechanical properties

Polymer Journal (2018)

-

Bio-Composites Based on Poly(lactic acid) Containing Mallow and Eucalyptus Surface Modified Natural Fibers

Journal of Polymers and the Environment (2018)

-

Platelet-adhesion behavior synchronized with surface rearrangement in a film of poly(methyl methacrylate) terminated with elemental blocks

Polymer Journal (2016)