Abstract

Polymer brushes have been utilized as a proper model interface for the investigation of wetting, lubrication, hydrated chain dimension and the structure of hydrated water at hydrated polymer interfaces. Zwitterionic polyelectrolyte-tethered surfaces represent significant anti-fouling materials for bio-macromolecules, marine fouling organisms and pipeline foulants. Systematic anti-fouling tests for various polymer brushes were performed to demonstrate the critical factors for universal anti-fouling properties. In this focused review, material design concepts and recent progress on anti-fouling polymer materials are reviewed, and our recent research on anti-fouling studies using polymer brushes is provided.

Similar content being viewed by others

Material design for anti-fouling

Material interfaces are always exposed to the threat of foreign substance adhesion. Materials lose their original interfacial performance following coverage by foulants. The deposition accumulates to immediately lead to a serious impact on the materials. Thus, anti-fouling is a conventional yet markedly important research subject in the medical and industrial fields. Medical devices that contact human blood are required to prevent protein adsorption and blood cell adhesion, which trigger an organism’s defense cascade system.1 Marine organism settlement leads to reductions in both fuel efficiency and navigation performance of ocean vessels as well as the deterioration in heat exchange capacity of seawater cooling systems in thermal and atomic power plants.2, 3, 4 Pipeline fouling is a crucial problem in the petroleum industry because it reduces the transportation efficiency and generates maintenance costs.5 Biocide releasing coatings and the addition of surface-active agents are extremely effective but generate adverse effects on the environment, and these coatings are not applicable to medical devices and implantable artificial organs. Therefore, non-toxic anti-fouling technologies without active chemicals have garnered interest in both the medical and industrial fields.

The adhesion of foreign substances to polymeric material surfaces is dictated by their chemical, physical and mechanical parameters. Four mechanisms are regarded as the common mechanisms for foulant adhesion, including (1) chemical bonding, (2) electromagnetic interactions and physical adsorption, (3) mechanical inter-locking and (4) surface rearrangement.6 Nonpolar surfaces without dipolar, ionic or reactive functional groups as well as conformationally mobile dynamic surfaces prevent attractive electromagnetic interactions based on surface charge and van der Waals forces and their reactions with foreign substances. The interpenetration of foulants into surface cavities on rough and porous materials allows adhesion in the absence of chemical compatibility. Contact with bio-adhesives causes surface rearrangement in both topography and chemical components to lead to temporary adhesive micro-defects that may then accumulate foulants. Therefore, ‘non-polar, chemically inert, neutral charged surfaces that are conformationally mobile but stable in topography and chemical component at the foulant interface with smooth and impenetrable geometry' have been recognized as the general approach for versatile anti-fouling surfaces. However, recent studies indicate that the composite structure at the material interface, including hydrated polymer chains, the hydrogen-bonded network structure of hydrated water and local chain dynamics has been recognized as a key factor for biofouling and fouling release in wet conditions.7, 8, 9, 10, 11, 12 Moreover, the appropriate combination of surface topography and dynamic liquids is proposed as a new concept for low adhesive, slippery surfaces.13

Bio-mimetic anti-fouling strategies

The bio-mimetic approach is a recent trend in material design for biocompatible and non-toxic anti-fouling materials. The current bio-mimetic anti-fouling strategies can be divided into two main categories: (i) microtopography and (ii) lubricant retention.

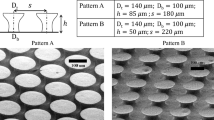

Microtopography is one of the nature-inspired, non-toxic anti-fouling strategies, as it is found in nature as a defense system against biofouling.14, 15, 16 Shark skin and clam shells are representative examples, and these systems demonstrated effectiveness for barnacles,17 algae18 and bacteria adhesion. While the anti-fouling mechanism has not been elucidated, surface wettability, surface fluid dynamics and attachment point reduction have been cited as potential factors to account for the improved anti-fouling performance.2 When fouling substances are much larger than the surface texture, the topographic surface exhibits reduced adhesion strength due to the reduction of attachment points. Thus, multi-scale topographic surfaces are necessary to give versatile anti-fouling performance because of the broad size range of fouling substances. However, the surface energy and mechanical properties of the microtopographic surfaces must be optimized depending on the target foulants.

Secretion and subsequent retention of a lubricant is the other anti-fouling strategy in nature. The retention of slippery low-surface-tension oils or hydrophilic proteoglycan aggregates induce the repulsion of foreign foulants as well as self-cleaning properties. This anti-fouling strategy is found in mollusk shells, the Nepenthes pitcher plant, fish skin and articular cartilage. The lubricant components are retained on the substrate by wetting into topographical surface textures or by grafting to substrates through chemical bonds or electromagnetic interactions. The Nepenthes pitcher plant uses microtopographic textures to retain an aqueous lubricant liquid that makes insects slide down into the dining site by repelling the oils on their feet.19 Aizenberg and colleagues13 proposed that synthetic low adhesive surfaces be named ‘slippery liquid-infused porous surfaces’, which consist of lubricating liquids retained on a microporous substrate infused by conditioning solid and liquid surface energies. The infusion of low-surface-tension perfluorinated liquids into fluorinated nano-texture affords a highly stable, defect-free liquid film that repels oils, insects and ice.20, 21, 22 Recently, a non-fluorinated oleophilic slippery surface was also reported.23 Articular cartilages consist of a collagen fiber substrate and surface-tethered bottle-brush structure chains of hyaluronic acid with proteoglycan side chains. The proteoglycan subunits are hydrated to give a hydrogel-like swollen lubrication layer along with the joint synovia.1 While the lubrication mechanism has not been clearly demonstrated, it is generally believed to involve ‘elasto-hydrodynamic lubrication (EHL)’.24 The highly hydrated polyelectrolyte surface layer leads to the formation of a fluid lubrication film at the interface of the friction probe and the swollen polyelectrolyte layer. Although low-viscosity liquids hardly encourage fluid film formation, the high viscosity of a hydrated polyelectrolyte layer induces a fluid lubrication film with the support of the existing viscous joint synovia.

Anti-fouling characteristics of polymer brushes

Because the adhesion of foreign substances involves various factors, each parameter must be separated to obtain further insight into the anti-fouling mechanisms. The polymer brush, that is, a surface-tethered polymer layer, is a proper model interface of polymeric soft materials. Recent developments in controlled radical polymerization techniques allow the preparation of high-density polymer brushes, where the polymer chains are densely grafted onto the substrate, to make the so called ‘high-density polymer brushes’.25 The simultaneous initiation and controlled growth from surface-immobilized initiators afford high-density surface-tethered polymer chains with controlled molecular weight and molecular weight distribution to yield a highly homogeneous polymer layer without serious defects. Because the chain end is covalently bound to the substrate, the surface-tethered polymer chains do not fall off by friction or washing, and they stay on the substrate even under good solvent.

Because of their stretched chain conformation, high-density brushes in solvent, in particular, exhibit unique surface properties compared with low-density brushes. The thickness depends on the balance between the osmotic pressure induced by the neighboring chains and the elastic restoring force of the polymer chains. High-density chain grafting promotes chain stretching due to the large osmotic pressure. Therefore, the high-density polymer brushes on Si substrates can be regarded as a model interface for the polymeric material to be applied to precise structural and spectroscopic analysis, while they contain their own features derived from the high-density grafting. For precise interface characterization, well-defined polymer brushes without serious defects are required because the irregularities of the polymer interface induced by the molecular weight distribution and topological defects obscure the interface structure and dynamics. Fabrication of polymer brushes onto resin and/or coating surfaces have been reported, and the similar performance can be introduced into the material surfaces.26, 27, 28, 29, 30

There are many reports of anti-fouling polymer brush surfaces for proteins, cells and organisms.31, 32, 33, 34, 35 The adsorption processes are diverse, but there are common principles for the non-fouling performance of hydrophilic polymer brushes. In the following sections, some of the principles are introduced.

Wettability and oil repellency of polyelectrolyte brushes in aqueous solution

One of the most attractive aspects of polymer brushes is the simple modification of their surface characteristics by choosing the chemical structure of the surface-grafted polymers. For instance, water and hexadecane droplets on fluorinated polymer brushes show high contact angles, while water-soluble or hydrophilic polymer brushes afford the hydrophilic surfaces without any change in the bulk performance of the substrates.36 Particularly, polyelectrolyte brushes, such as poly(methacrylic acid sodium salt) (PMANa), poly(2-methacryloyloxyethyl)trimethylammonium chloride) (PMTAC) and poly[3-(2-methacryloyloxyethyl-N,N-dimethyl)ammonatopropanesulfonate] (PMAPS) showed low water contact angles of ~10°. Poly(3-sulfopropyl methacrylate potassium salt) (PSPMK) and poly(2-methacryloyloxyethyl phosphorylcholine) (PMPC) wet the water especially well to generate extremely low contact angles of <3°. The chemical structures and abbreviations of the non-ionic and ionic polymer brushes described in this paper are shown in Figure 1. Excellent hydrophilicity is maintained over long periods by grafting the ionic polymers, although surface modifications by corona discharge treatment or plasma treatment immediately lose their effects. It is particularly difficult to maintain the hydrophilicity of the materials with a low glass transition temperature (Tg), for example, polyolefins, because of the surface rearrangement. Kobayashi et al.26 reported preparation of the zwitterionic PMPC brushes on bromo-functionalized polyolefine sheets by surface-initiated atom transfer radical polymerization. They found that the PMPC brush immobilized sheets retained a low water contact angle of <10° under atmospheric conditions over 3 years after surface modification.

Although polyelectrolyte brushes exhibit extremely low water contact angles, a water droplet does not wet the surface completely. Partial wetting with a finite contact angle is usually observed, even if the brushes are water-soluble polymers. The wetting of water on the polyelectrolyte brushes cannot be simply explained by the local equilibrium at the three-phase contact line but, instead, involves the hydration enthalpy of the polyelectrolyte brushes37 as well as a thin hydrated layer existing beneath and around the water droplet. High spatial resolution microscopic infrared (IR) spectroscopy demonstrated that water molecules outside the droplet were confined to the thin hydrated brush layer with a highly ordered hydrogen-bonding network, that is, ice-like structured water, which is discussed again in the following section.38 The hydrated thin film with structured water changes the surface and interfacial free energies of polyelectrolyte brushes, thus preventing the complete wetting of water. Therefore, the accurate surface free energy of the polyelectrolyte brushes cannot be simply obtained by the contact angles of probe liquids. The surface free energies of the polymer brushes were tentatively estimated by a three-liquid acid−base method proposed by van Oss, Chaudhury and Good.

As mentioned in the section above, hydrophilic surfaces in nature achieve their own self-cleaning system, which is applicable to artificial hydrophilic polymer brush surfaces. The anionic PSPMK and zwitterionic PMPC brushes show extremely low contact angles (<3°) for both water and hexadecane in air, indicating that super-hydrophilic surfaces receive oily foulant adhesion under dry conditions. In contrast, hydrophilic polymer brushes repel oils in de-ionized water, indicating excellent anti-fouling in wet conditions. The polyelectrolyte brushes were wet with water to reduce the interfacial free energy to yield a hydrated polyelectrolyte brush layer. The silicone oil that was spread on the polyelectrolyte brush surfaces in air quickly beaded up and detached from the brushes once they were immersed in water, as shown in Figure 2. The work of adhesion (WOWS) in water for the silicone oil on the hydrated polyelectrolyte brushes, such as PSPMK and PMPC, was calculated to be <0.06 mN m−1 using the contact angle of the oil (>173°). The low adhesion force between the hydrated polyelectrolyte brushes and oils is attributed to the conformational mobility and lower volume fraction of solid components in the swollen brush layers. The stable hydration shell prevents foreign objects from approaching the polymer chains, and the defect-free fluid layer blocks the attachment of foulants.

Droplet images with contact angle (θ) and work of adhesion (WOWS) in silicone oil (5.0 μl, KF-96-100CS, Shin-Etsu Chemical Co., Tokyo, Japan) on (a) PSPMK and (b) PFA-C8 brushes in water, and (c) schematic representation for the definition of surface and interfacial free energies of an oil droplet on polymer brushes in water. The interfacial free energies for oil–water, water–solid and solid–oil are described as γOW, γSW and γSO, respectively.

In contrast, the fluorinated polymer brush, poly(2-perfluorooctylethyl acrylate) (PFA-C8) exhibited a large contact angle of water and oil in air, indicating that it repels both hydrophilic and oleophilic foreign substances. However, air bubbles and oil droplets attached on the PFA-C8 brushes under water (Figure 2b). Therefore, hydrophobic foulants are likely to adhere to the fluorinated polymer brushes in water. Oil detachment was not observed on the PFA-C8 brushes, most likely due to the large WOWS (14.3 mN m−1) in water for the silicone oils.

Swollen state and network structure of hydrated water in polyelectrolyte brushes

The swollen state of the polyelectrolyte chains and the hydrogen-bonding network structure of hydrated water are striking factors not only for bio/blood compatibility but also for anti-fouling in wet conditions. As mentioned above, the swollen thickness and chain conformation of the solvated polymer brushes are essentially determined by the balance between the osmotic pressure and the elastic restoring force of the polymer chains. However, in the case of polyelectrolyte brushes, the ionic strength of aqueous solution and the electrostatic inter- and intra-molecular interactions complicate the swollen structures of polyelectrolyte brushes in aqueous media. The hydrated chain dimension of PMTAC as well as zwitterionic PMPC and PMAPS brushes in aqueous solutions at various ionic strengths were characterized by neutron reflectivity39, 40 and small angle X-ray scattering41, 42, 43, 44 measurements. The hydration state and the salt concentration dependence clearly depend on the chemical structure of the charged polyelectrolyte chains. PMTAC brushes adopt a two-phase structure that consists a shrunken region at the Si substrate interface and a diffuse region at the solution interface in de-ionized water.45 The diffuse swollen chain collapsed in a sodium chloride solution due to the charge shielding effect. In contrast, PMAPS brushes collapse in de-ionized water because of the strong attractive interaction of the sulfobetaine groups, whereas their aggregation is dissociated by the addition of sodium chloride to obtain a diffuse swollen layer. The hydration state of PMPC brushes is stable and inert to the ionic strength of the solution. The unique ionic strength-dependent hydration state of the polyelectrolyte brushes plays a significant role in anti-fouling properties.

The structure of hydrated water involves both the hydrogen-bonded network of water and the local orientation (rotational rearrangement) of water around the polymer chains. It is becoming recognized that the water structure is an important cast member in the bio/blood compatibility and anti-fouling characters.7, 8, 9, 10, 11, 12 For the past few decades, considerable experimental and theoretical efforts have been devoted to the dynamics and structures of hydrated water. Vibrational spectroscopy, including Raman and IR spectroscopy, have been applied to show the hydrogen-bonded network structure and the rotational rearrangement of water molecules because the observation time scale is much shorter than the relaxation time scale of these structures. Alternatively, differential scanning calorimetry,9 X-ray diffraction/scattering,46 dielectric relaxation47, 48 and nuclear magnetic resonance49 measurements provide diffusion-averaged structures of the water molecules. Tanaka et al.9, 10 proposed a unique hydration model to describe a common principle found in the bio/blood compatible polymeric materials. They found a freezing-bound water molecule that exhibits cold crystallization in the heating process of differential scanning calorimetry <0 °C and presents a strong peak at 3400 cm−1 in an IR spectrum, a so called ‘intermediated water’. The hydrated water structure is roughly categorized into three discrete states: free water (or freezing water), freezing-bound water (or intermediate water) and non-freezing water (or non-freezing-bound water). The bio/blood compatible polymers commonly involve ‘intermediate water’ that interacts weakly with the polymer chains, indicating that the excellent bio/blood compatibility is derived from the existence of intermediated water on the polymer surfaces.

The structure of hydrated water in polyelectrolyte brushes was investigated by high-spatial resolution microscopic IR spectroscopy using an IR beam from synchrotron radiation.38 A microscopic film of hydrated polyelectrolyte brushes exists outside the water droplet. The hydrated PMTAC brushes contain highly ordered, amorphous, solid-like water. Similar hydrogen-bonded network structures were observed in anionic and zwitterionic polyelectrolytes, indicating that the water-soluble polyelectrolyte brushes adopt the hydrated water ice-like structured state regardless of the surface charge.

Fluid lubrication of hydrated polyelectrolyte brushes

Polymer brushes made from water-soluble hydrophilic polymers and charged polyelectrolytes show efficient lubrication under aqueous environments.39, 50, 51, 52, 53, 54, 55 Densely grafted polyelectrolyte chains stretch away from the substrate through hydration to avoid chain overlap due to electrostatic repulsion and the osmotic pressure of hydrated counter-ions around the charged chains. The conformational entropy and the excluded volume effect of hydrated chains prevent compression by vertical loading to cause repulsive force. The fluidity of the hydrated bound water also promotes lubrication. Klein et al.52, 53 demonstrated that polyelectrolyte chain grafting reduces friction in aqueous media using a surface force apparatus. The macroscopic friction coefficient and wear resistance of a series of polyelectrolyte brushes were investigated by a ball-on-plate reciprocating tribometer.50, 51 The sliding velocity dependence of the friction coefficient in the polyelectrolyte brushes is in accordance with a Stribeck curve.56, 57 While the sliding probe and substrate directly contact and slide at a low sliding velocity, inducing a high friction coefficient (boundary lubrication state), a fluid lubrication film separates the surfaces to cause drastic friction coefficient reduction at a high sliding velocity (EHL).24 Although polymer brush-assisted lubrication is not entirely explained by conventional EHL theory, the pseudo-EHL appears to have relatively low sliding velocity because the hydrated polyelectrolyte brush layer stabilizes the fluid film. This mechanism is commonly found in cartilage lubrication.1, 58 The polymer brush-assisted water lubrication mechanism was further investigated by direct measurement of the lubrication layer thickness at the sliding interface using double-spacer-layer ultra-thin-film interferometry.59 The gap between the PMTAC brushes and a spherical glass probe increased with increasing sliding velocity to be 130 nm at 2 × 10−2 m s−1, and the friction coefficient simultaneously decreased to 0.01−0.02. The lubrication effect of polyelectrolyte brushes is surely related to the weak adhesive force of foreign substances in aqueous media.

Anti-fouling of polymer brushes for marine fouling organisms

Various non-toxic, anti-fouling marine coatings including silicone and fluorinated polymer-based fouling release and self-peeling coatings have been proposed; however, multipurpose non-toxic coatings that are long-lasting and effective on diverse marine organisms have never been developed.2, 3, 4 The anti-fouling performance of polymer brushes for marine fouling organisms has been investigated to obtain effective polymer interfaces for preventing marine organism settlement.60, 61, 62, 63, 64 Either micro-organisms, such as marine bacteria, diatoms and algae spores, or macro-organisms, such as barnacle cypris larvae, tube worms, mussel larvae and algae, have been examined. Jiang et al.61, 62, 63, 64 demonstrated versatile marine organism settlement inhibition by zwitterionic poly(sulfobetaine)s and poly(carboxy betaine)s in a wide variety of settlement tests; however, insight into the anti-fouling mechanisms has not yet been clarified. The hydration state and neutral surface charge of the polyelectrolyte chains are commonly attributed to the anti-fouling mechanism. Although the settlement mechanisms of marine fouling organisms have diversity, the anti-fouling properties of polymer substrates are hardly explained by any correlation between the physical characteristics of polymer surfaces and the individual settlement mechanisms.

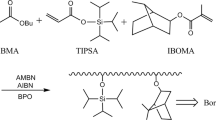

We carried out comprehensive anti-fouling research on a wide variety of polymer brushes with three marine fouling organisms, barnacle cypris larvae, mussel larvae in their adhesion period, and marine bacteria, using filtered natural sea water.65 The settlement tests were performed using artificially cultivated larvae to ensure the reproducibility of the examinations.66 A variety of polymer brushes including zwitterionic polyelectrolytes PMPC and PMAPS, cationic polyelectrolyte PMTAC, a hydrophobic glassy polymer (poly(methyl methacrylate), PMMA), a hydrophobic aliphatic polymer (poly(butyl acrylate), PBA) and silicone containing polymer (poly(3-[tris(trimethylsiloxy)silyl]propylmethacrylate), PTMSM) were examined. Zwitterionic polyelectrolyte brushes showed versatile anti-fouling behavior for all examined marine organisms, whereas all hydrophobic polymer brushes allowed marine fouling organism settlement (Figure 3). Moreover, we found organism-selective anti-fouling of cationic PMTAC brushes. Positively charged PMTAC brushes showed excellent anti-fouling performance with barnacle cypris larvae, similar to the zwitterionic polyelectrolytes, but mussel larvae and marine bacteria settled on PMTAC brushes in a manner similar to hydrophobic polymer brushes.

The ratio of (a) ‘settled’ barnacle cypris larvae to the initial population of cypris larvae after 10 days and (b) ‘settled’ mussel larvae to the initial population of mussel larvae after a 6-day settlement test period on the polymer brushes. Reproduced from the study by Higaki et al.65 with permission.

For the barnacle cypris larvae, enthusiastic searching action was observed and the majority of them settled after 10 days on the hydrophobic polymer brushes, while both zwitterionic and cationic polymer brushes refused their exploration to achieve complete settlement inhibition. In contrast, the mussel larvae crept on all polymer brushes, but only zwitterionic polyelectrolyte brushes inhibited their permanent settlement. The mussel larvae attempted to settle on the surface by secreting adhesive proteins from the tip of their byssus. However, their settlement failed on the zwitterionic polyelectrolyte brushes, whereas it worked on the cationic polyelectrolyte surface. In the marine bacteria colonization test, the population of bacterial colonies was less in the zwitterionic polyelectrolyte brushes than the other polymer brushes. Cationic PMTAC brushes accept a large amount of bacterial colonies even after washing.

These interesting contrasts in anti-fouling performance of polyelectrolyte brushes were explained by the bio-adhesion mechanism of fouling organisms as well as the hydration state and surface charge of the polymer brushes. Barnacle cypris larvae crept onto a surface by the attachment of splitting cuticular villi at the antennal tip through van der Waals interaction and capillary adhesion of the non-polar viscous glycoproteins at the antennular secretion.66 The adhesion force is relatively weak to repeat cyclic adhesion. The mussel foot adhesive protein (mfp) consists of amino acids with post-translationally modified side chains, including 3,4-dihydroxy-L-phenylalanine (DOPA), and shows strong adhesive forces in ocean reefs.67 The mussel byssus has a suction pad at the tip and removes water prior to the secretion of adhesive proteins. Negatively charged marine bacteria attach through polysaccharide-based extracellular polymeric substances to achieve unspecific adhesion. As described in the section above, zwitterionic polyelectrolytes are well hydrated in a sodium chloride solution and are supposed to maintain the strongly bound water, whereas cationic PMTAC collapses in sodium chloride solution, losing part of the hydrated water under high ionic strength. Although the weak cyclic adhesion by the cuticular villi of barnacle larvae is prevented by moderate hydrophilic surfaces, the hydration state in saline water could be crucial for mussel adhesion because of the water suction process and the strong adhesive force of the mfp. Positive surface charge is a disadvantage in marine bacteria adhesion. In addition, PMTAC brushes lost the hydration shell that prevents bacterial attachment by fluid lubrication and the washing out properties through water penetration at the adhesion interface.

Anti-fouling of polymer brushes for asphaltene deposition

Crude oil includes a component that aggregates and deposits, asphaltene, and it is the principal source of pipeline blocking.5 Asphaltenes consist of heterogeneous macromolecules with high degrees of aromaticity and polarity. Genzer and colleagues68 reported asphaltene adsorption studies for self-assembled monolayers. They concluded that the surface energy of the monolayer is not the leading factor for asphaltene adsorption, instead the thickness of the self-assembled monolayers is most important. Sjöblom and colleagues69 monitored the adsorption quantity of asphaltenes to surface-modified silica particles. Hydrophilic particles received more asphaltenes than hydrophobic particles, indicating that the shielding interaction by the hydrophobic organic layer is effective for separating the underlying polar substrate. We examined the adsorption behavior of an asphaltene model compound (C5Pe) and the detachment behavior of asphaltene deposit films on polymer brushes.70 Zwitterionic PMAPS, a water insoluble but weakly hydrophobic glassy polymer, PMMA and hydrophobic aliphatic polymer, poly(hexyl methacrylate) (PHMA) were examined. The polymer brushes were immersed in a 0.2 mg ml−1 toluene solution of C5Pe for 24 h; subsequently, the polymer brushes were lifted from the solution and dried. While the PMMA brushes were covered with C5Pe, the PMAPS and PHMA brushes exhibited only small amounts of C5Pe adsorption (Figure 4a). The weakly adsorbed C5Pe was removed by sonication, and the adsorption amount was measured by ultraviolet–visible absorption spectroscopy (Figure 4b). Both the PMAPS and PHMA brushes clearly prevented the C5Pe adsorption, whereas the PMMA brushes received a large amount of C5Pe adsorption. The detachability of the asphaltene deposit was evaluated by detachment test in solvent. A 1.0 wt% toluene solution of an extracted natural asphaltene was deposited on the polymer brushes and dried in air. The asphaltene films were immersed in model oil (1/4 (vol/vol) toluene/n-heptane) or de-ionized water and shaken for 20 min. The asphaltene films on the PHMA brush detached in the model oil, whereas the asphaltene films remained adhered to the PMAPS and PMMA brushes, as shown in Figure 5. In contrast, the asphaltene films on the PMAPS brush detached in water, whereas the asphaltene films remained adhered to the PHMA and PMMA brushes. The C5Pe adsorption and detachment behavior of the asphaltene deposits were explained by the interfacial free energies for the polymer brush/asphaltene (γSA) and polymer brush/toluene (γSO) interfaces. For the PHMA brush, the γSO is smaller than the other polymer brushes and is similar in magnitude to γSA. In this case, the solvent (toluene) wets the PHMA brush, leading to effective suppression of C5Pe adsorption. For the PMMA and PMAPS brushes, γSO>γSA, indicating that C5Pe adsorption is preferred over solvent wetting. The γSA in the PMAPS brushes is much higher than the other polymer brushes, and the electromagnetic interaction of the charged sulfobetaine groups is supposed to promote C5Pe adsorption. However, the C5Pe adsorption quantity is lowest in PMAPS brushes. This behavior is attributed to the hydrated layer formation at the interface. Because of the low interfacial free energy for the PMAPS/water interface (γSW), a slight amount of water in toluene immediately adsorbs to PMAPS and the hydration layer prevents C5Pe contact. The liquid penetration into the asphaltene deposit/polymer brush interface is driven by thermodynamic interfacial free energy reduction due to the low polymer brush/liquid interfacial free energy. The solvated polymer brushes repel the adsorbent to maintain a low interfacial free energy.

(a) Fluorescence microscopy images of the polymer brush surfaces after C5Pe adsorption test. (b) Relative amount of C5Pe adsorption onto the polymer brush surfaces. Reproduced from the study by Higaki et al.70 with permission.

Appearances of asphaltene deposit films on the polymer brushes after immersing and shaking in (a) a model oil (1/4 (vol/vol) toluene/n-heptane) and (b) water. Reproduced from the study by Higaki et al.70 with permission.

Future perspectives

This review summarizes the recent research on the anti-fouling of polymer brushes. Polymer brushes are one of the most appropriate model interfaces for the investigation of the polymer/water interfacial structure. The wetting, lubrication, hydration state of the polymer chains and network structure of hydrated water play inter-related, essential roles in anti-fouling. The versatile anti-fouling potential of zwitterionic polyelectrolyte brushes for bio-macromolecules, marine fouling organisms and asphaltene deposition has been demonstrated, and the mechanism behind the anti-fouling has been considered based on the physical states in hydrated polymer brushes. However, there are more complicated structures, including electrolytes in solution71 and discrete local hydrogen-bonded network structures of water.72 Further insights regarding the hydration structure through cutting-edge interface-sensitive analysis will define the essential mechanism of anti-fouling, and this could lead to novel material design for advanced polymeric anti-fouling materials.

References

Ishihara, K. Highly lubricated polymer interfaces for advanced artificial hip joints through biomimetic design. Polym. J. 47, 585–597 (2015).

Lejars, M., Margaillan, A. & Bressy, C. Fouling release coatings: a nontoxic alternative to biocidal antifouling coatings. Chem. Rev. 112, 4347–4390 (2012).

Callow, J. A. & Callow, M. E. Trends in the development of environmentally friendly fouling-resistant marine coatings. Nat. Commun. 2, 244–210 (2011).

Ciriminna, R., Bright, F. V. & Pagliaro, M. Ecofriendly antifouling marine coatings. ACS Sustainable Chem. Eng. 3, 559–565 (2015).

Takanohashi, T., Sato, S., Saito, I. & Tanaka, R. Molecular dynamics simulation of the heat-induced relaxation of asphaltene aggregates. Energy Fuels 17, 135–139 (2003).

Brady, J., Robert, F. & Singer, I. L. Mechanical factors favoring release from fouling release coatings. Biofouling 15, 73–81 (2000).

Ishihara, K., Nomura, H., Mihara, T., Kurita, K., Iwasaki, Y. & Nakabayashi, N. Why do phospholipid polymers reduce protein adsorption? J. Biomed. Mater. Res. 39, 323–330 (1998).

Kitano, H., Imai, M., Mori, T., Gemmei-Ide, M., Yokoyama, Y. & Ishihara, K. Structure of water in the vicinity of phospholipid analogue copolymers as studied by vibrational spectroscopy. Langmuir 19, 10260–10266 (2003).

Tanaka, M., Hayashi, T. & Morita, S. The roles of water molecules at the biointerface of medical polymers. Polym. J. 45, 701–710 (2013).

Morita, S., Tanaka, M. & Ozaki, Y. Time-resolved in situ ATR-IR observations of the process of sorption of water into a poly(2-methoxyethyl acrylate) film. Langmuir 23, 3750–3761 (2007).

Hirata, T., Matsuno, H., Kawaguchi, D., Hirai, T., Yamada, N. L., Tanaka, M. & keiiji, T. Effect of local chain dynamics on a bioinert interface. Langmuir 31, 3661–3667 (2015).

Kitano, H. Characterization of polymer materials based on structure analyses of vicinal water. Polym. J. 48, 15–24 (2016).

Wong, T.-S., Kang, S. H., Tang, S. K. Y., Smythe, E. J., Hatton, B. D., Grinthal, A. & Aizenberg, J. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity. Nature 477, 443–447 (2011).

Bhushan, B. Bioinspired structured surfaces. Langmuir 28, 1698–1714 (2012).

Koch, K., Bhushan, B. & Barthlott, W. Multifunctional surface structures of plants: an inspiration for biomimetics. Prog. Mater. Sci. 54, 137–178 (2009).

Koch, K., Bohn, H. F. & Barthlott, W. Hierarchically sculptured plant surfaces and superhydrophobicity. Langmuir 25, 14116–14120 (2009).

Schumacher, J. F., Aldred, N., Callow, M. E., Finlay, J. A., Callow, J. A., Clare, A. S. & Brennan, A. B. Species-specific engineered antifouling topographies: correlations between the settlement of algal zoospores and barnacle cyprids. Biofouling 23, 307–317 (2007).

Schumacher, J. F., Carman, M. L., Estes, T. G., Feinberg, A. W., Wilson, L. H., Callow, M. E., Callow, J. A., Finlay, J. A. & Brennan, A. B. Engineered antifouling microtopographies—effect of feature size, geometry, and roughness on settlement of zoospores of the green alga Ulva. Biofouling 23, 55–62 (2007).

Bohn, H. F. & Federle, W. Insect aquaplaning: Nepenthes pitcher plants capture prey with the peristome, a fully wettable water-lubricated anisotropic surface. Proc. Natl Acad. Sci. USA 101, 14138–14143 (2004).

Ma, W., Wu, H., Higaki, Y., Otsuka, H. & Takahara, A. A ‘non-sticky’ superhydrophobic surface prepared by self-assembly of fluoroalkyl phosphonic acid on a hierarchically micro/nanostructured alumina gel film. Chem. Commun. 48, 6824–6826 (2012).

Ma, W., Higaki, Y., Otsuka, H. & Takahara, A. Perfluoropolyether-infused nano-texture: a versatile approach to omniphobic coatings with low hysteresis and high transparency. Chem. Commun. 49, 597–599 (2013).

Ma, W., Xu, H. & Takahara, A. Substrate-independent underwater superoleophobic surfaces inspired by fish-skin and mussel-adhesives. Adv. Mater. Interfaces 1, 1300092 (2014).

Cheng, D. F., Urata, C., Yagihashi, M. & Hozumi, A. A statically oleophilic but dynamically oleophobic smooth nonperfluorinated surface. Angew. Chem. Int. Ed. 51, 2956–2959 (2012).

Gelinck, E. & Schipper, D. J. Calculation of Stribeck curves for line contacts. Tribol. Int. 33, 175–181 (2000).

Edmondson, S., Osborne, V. L. & Huck, W. T. S. Polymer brushes via surface-initiated polymerizations. Chem. Soc. Rev. 33, 14 (2004).

Kobayashi, M., Matsugi, T., Saito, J., Imuta, J.-i., Kashiwa, N. & Takahara, A. Direct modification of polyolefin films by surface-initiated polymerization of a phosphobetaine monomer. Polym. Chem. 4, 731–739 (2013).

Kimura, T., Kobayashi, M., Morita, M. & Takahara, A. Preparation of poly(vinylidene fluoride-co-trifluoroethylene) film with a hydrophilic surface by direct surface-initiated atom transfer radical polymerization without pretreatment. Chem. Lett. 38, 446–447 (2009).

Yano, T., Yah, W. O., Yamaguchi, H., Terayama, Y., Nishihara, M., Kobayashi, M. & Takahara, A. Precise control of surface physicochemical properties for electrospun fiber mats by surface-initiated radical polymerization. Polym. J. 43, 838–848 (2011).

Higaki, Y., Kabayama, H., Tao, D. & Takahara, A. Surface functionalization of electrospun poly(butylene terephthalate) fibers by surface‐initiated radical polymerization. Macromol. Chem. Phys. 216, 1103–1108 (2015).

Shinohara, T., Higaki, Y., Nojima, S., Masunaga, H., Ogawa, H., Okamoto, Y., Aoki, T. & Takahara, A. Molecular aggregation states and wetting behavior of a poly {2-(perfluorooctyl) ethyl acrylate} brush-immobilized nano-imprinted surface. Polymer 69, 10–16 (2015).

Sin, M. C., Chen, S. H. & Chang, Y. Hemocompatibility of zwitterionic interfaces and membranes. Polym. J. 46, 436–443 (2014).

Xu, F. J., Neoh, K. G. & Kang, E. T. Bioactive surfaces and biomaterials via atom transfer radical polymerization. Prog. Polym. Sci. 34, 719–761 (2009).

Chang, Y., Liao, S.-C., Higuchi, A., Ruaan, R.-C., Chu, C.-W. & Chen, W.-Y. A Highly stable nonbiofouling surface with well-packed grafted zwitterionic polysulfobetaine for plasma protein repulsion. Langmuir 24, 5453–5458 (2008).

Zhang, Z., Chao, T., Chen, S. & Jiang, S. Superlow fouling sulfobetaine and carboxybetaine polymers on glass slides. Langmuir 22, 10072–10077 (2006).

Iwasaki, Y. & Saito, N. Immobilization of phosphorylcholine polymers to Ti-supported vinyldimethylsilyl monolayers and reduction of albumin adsorption. Colloids Surf. B 32, 77–84 (2003).

Kobayashi, M., Terayama, Y., Yamaguchi, H., Terada, M., Murakami, D., Ishihara, K. & Takahara, A. Wettability and antifouling behavior on the surfaces of superhydrophilic polymer brushes. Langmuir 28, 7212–7222 (2012).

Muller, P., Sudre, G. & Théodoly, O. Wetting transition on hydrophobic surfaces covered by polyelectrolyte brushes. Langmuir 24, 9541–9550 (2008).

Murakami, D., Kobayashi, M., Moriwaki, T., Ikemoto, Y., Jinnai, H. & Takahara, A. Spreading and structuring of water on superhydrophilic polyelectrolyte brush surfaces. Langmuir 29, 1148–1151 (2013).

Kobayashi, M., Terayama, Y., Kikuchi, M. & Takahara, A. Chain dimensions and surface characterization of superhydrophilic polymer brushes with zwitterion side groups. Soft Matter 9, 5138–5148 (2013).

Kobayashi, M., Ishihara, K. & Takahara, A. Neutron reflectivity study of the swollen structure of polyzwitterion and polyeletrolyte brushes in aqueous solution. J. Biomater. Sci. Polym. Ed. 25, 1673–1686 (2014).

Kikuchi, M., Terayama, Y., Ishikawa, T., Hoshino, T., Kobayashi, M., Ogawa, H., Masunaga, H., Koike, J.-i., Horigome, M., Ishihara, K. & Takahara, A. Chain dimension of polyampholytes in solution and immobilized brush states. Polym. J. 44, 121–130 (2012).

Ishikawa, T., Kikuchi, M., Kobayashi, M., Ohta, N. & Takahara, A. Chain conformation of poly[2-(methacryloyloxy)ethyltrimethylammonium chloride] in aqueous sodium chloride solutions. Macromolecules 46, 4081–4088 (2013).

Matsuda, Y., Kobayashi, M., Annaka, M., Ishihara, K. & Takahara, A. Dimensions of a free linear polymer and polymer immobilized on silica nanoparticles of a zwitterionic polymer in aqueous solutions with various ionic strengths. Langmuir 24, 8772–8778 (2008).

Kikuchi, M., Terayama, Y., Ishikawa, T., Hoshino, T., Kobayashi, M., Ohta, N., Jinnai, H. & Takahara, A. Salt dependence of the chain stiffness and excluded-volume strength for the polymethacrylate-type sulfopropylbetaine in aqueous NaCl solutions. Macromolecules 48, 7194–7204 (2015).

Murakami, D., Takenaka, A., Kobayashi, M., Jinnai, H. & Takahara, A. Measurement of the electrostatic interaction between polyelectrolyte brush surfaces by optical tweezers. Langmuir 29, 16093–16097 (2013).

Huang, C., Wikfeldt, K. T., Tokushima, T., Nordlund, D., Harada, Y., Bergmann, U., Niebuhr, M., Weiss, T. M., Horikawa, Y., Leetmaa, M., Ljungberg, M. P., Takahashi, O., Lenz, A., Ojamäe, L., Lyubartsev, A. P., Shin, S., Pettersson, L. G. M. & Nilsson, A. The inhomogeneous structure of water at ambient conditions. Proc. Natl Acad. Sci. USA 106, 15214–15218 (2009).

Mashimo, S., Kuwabara, S., Yagihara, S. & Higasi, K. Dielectric relaxation time and structure of bound water in biological materials. J. Phys. Chem. 91, 6337–6338 (1987).

Nandi, N., Bhattacharyya, K. & Bagchi, B. Dielectric relaxation and solvation dynamics of water in complex chemical and biological systems. Chem. Rev. 100, 2013–2046 (2000).

Yasunaga, H. & Ando, I. Hydrogen-bonded structure of water in crosslinked polymer gel as studied by 1H NMR chemical shift data. J. Mol. Struct. 301, 125–128 (1993).

Kobayashi, M., Terayama, Y., Hosaka, N., Kaido, M., Suzuki, A., Yamada, N., Torikai, N., Ishihara, K. & Takahara, A. Friction behavior of high-density poly(2-methacryloyloxyethyl phosphorylcholine) brush in aqueous media. Soft Matter 3, 740–746 (2007).

Kobayashi, M. & Takahara, A. Tribological properties of hydrophilic polymer brushes under wet conditions. Chem. Rec. 10, 208–216 (2010).

Klein, J., Kumacheva, E., Mahalu, D., Perahia, D. & Fetters, L. J. Reduction of frictional forces between solid surfaces bearing polymer brushes. Nature 370, 634–636 (1994).

Raviv, U., Giasson, S., Kampf, N., Gohy, J.-F., Jérôme, R. & Klein, J. Lubrication by charged polymers. Nature 425, 163–165 (2003).

Tairy, O., Kampf, N., Driver, M. J., Armes, S. P. & Klein, J. Dense, highly hydrated polymer brushes via modified atom-transfer-radical-polymerization: structure, surface interactions, and frictional dissipation. Macromolecules 48, 140–151 (2015).

Ishikawa, T., Kobayashi, M. & Takahara, A. Macroscopic frictional properties of poly(1-(2-methacryloyloxy)ethyl-3-butyl imidazolium bis(trifluoromethanesulfonyl)-imide) brush surfaces in an ionic liquid. ACS Appl. Mater. Interfaces 2, 1120–1128 (2010).

Jacobson, B. The Stribeck memorial lecture. Tribol. Int. 36, 781–789 (2003).

Luengo, G., Israelachvili, J. & Granick, S. Generalized effects in confined fluids: new friction map for boundary lubrication. Wear 200, 328–335 (1996).

Moro, T., Takatori, Y., Ishihara, K., Konno, T., Takigawa, Y., Matsushita, T., Chung, U.-i., Nakamura, K. & Kawaguchi, H. Surface grafting of artificial joints with a biocompatible polymer for preventing periprosthetic osteolysis. Nat. Mater. 3, 829–836 (2004).

Kobayashi, M., Tanaka, H., Minn, M., Sugimura, J. & Takahara, A. Interferometry study of aqueous lubrication on the surface of polyelectrolyte brush. ACS Appl. Mater. Interfaces 6, 20365–20371 (2014).

Yang, W. J., Neoh, K.-G., Kang, E.-T., Lee, S. S. C., Teo, S. L.-M. & Rittschof, D. Functional polymer brushes via surface-initiated atom transfer radical graft polymerization for combating marine biofouling. Biofouling 28, 895–912 (2012).

Zhang, Z., Chen, S., Chang, Y. & Jiang, S. Surface grafted sulfobetaine polymers via atom transfer radical polymerization as superlow fouling coatings. J. Phys. Chem. B 110, 10799–10804 (2006).

Cheng, G., Zhang, Z., Chen, S., Bryers, J. D. & Jiang, S. Inhibition of bacterial adhesion and biofilm formation on zwitterionic surfaces. Biomaterials 28, 4192–4199 (2007).

Zhang, Z., Finlay, J. A., Wang, L., Gao, Y., Callow, J. A., Callow, M. E. & Jiang, S. Polysulfobetaine-grafted surfaces as environmentally benign ultralow fouling marine coatings. Langmuir 25, 13516–13521 (2009).

Aldred, N., Li, G., Gao, Y., Clare, A. S. & Jiang, S. Modulation of barnacle (Balanus amphitrite Darwin) cyprid settlement behavior by sulfobetaine and carboxybetaine methacrylate polymer coatings. Biofouling 26, 673–683 (2010).

Higaki, Y., Nishida, J., Takenaka, A., Yoshimatsu, R., Kobayashi, M. & Takahara, A. Versatile inhibition of marine organism settlement by zwitterionic polymer brushes. Polym. J. 47, 811–818 (2015).

Aldred, N., Clare, A. S. in Functional Surfaces in Biology, Vol. 2 (ed. Gorb S.N.) Ch. 2, 43–65 (Springer, Netherlands, 2009).

Lee, B. P., Messersmith, P. B., Israelachvili, J. N. & Waite, J. H. Mussel-inspired adhesives and coatings. Annu. Rev. Mater. Res. 41, 99–132 (2011).

Turgman-Cohen, S., Fischer, D. A., Kilpatrick, P. K. & Genzer, J. Asphaltene adsorption onto self-assembled monolayers of alkyltrichlorosilanes of varying chain length. ACS Appl. Mater. Interfaces 1, 1347–1357 (2009).

Hannisdal, A., Ese, M.-H., Hemmingsen, P. V. & Sjöblom, J. Particle-stabilized emulsions: effect of heavy crude oil components pre-adsorbed onto stabilizing solids. Colloids Surf. A 276, 45–58 (2006).

Higaki, Y., Hatae, K., Ishikawa, T., Takanohashi, T., Hayashi, J.-i. & Takahara, A. Adsorption and desorption behavior of asphaltene on polymer-brush-immobilized surfaces. ACS Appl. Mater. Interfaces 6, 20385–20389 (2014).

Abuillan, W., Schneck, E., Körner, A., Brandenburg, K., Gutsmann, T., Gill, T., Vorobiev, A., Konovalov, O. & Tanaka, M. Physical interactions of fish protamine and antisepsis peptide drugs with bacterial membranes revealed by combination of specular x-ray reflectivity and grazing-incidence x-ray fluorescence. Phys. Rev. E 88, 012705 (2013).

Tokushima, T., Harada, Y., Takahashi, O., Senba, Y., Ohashi, H., Pettersson, L. G. M., Nilsson, A. & Shin, S. High resolution X-ray emission spectroscopy of liquid water: The observation of two structural motifs. Chem. Phys. Lett. 460, 387–400 (2008).

Acknowledgements

This research is partially supported by the Adaptable and Seamless Technology Transfer Program through Target-driven R&D (No. AS2511206M) at the Japan Science and Technology Agency, JST. This work is also supported in part by the Photon and Quantum Basic Research Coordinated Development Program from the Ministry of Education, Culture, Sports, Science and Technology, Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Higaki, Y., Kobayashi, M., Murakami, D. et al. Anti-fouling behavior of polymer brush immobilized surfaces. Polym J 48, 325–331 (2016). https://doi.org/10.1038/pj.2015.137

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2015.137

This article is cited by

-

Surface zeta potential and protein adsorption on the coating surface of a heteroarm star polymer with a controlled hydrophilic/hydrophobic arm ratio

Polymer Journal (2024)

-

Design of functional soft interfaces with precise control of the polymer architecture

Polymer Journal (2024)

-

Cononsolvency of poly(carboxybetaine methacrylate) in water–ethanol mixed solvents

Polymer Journal (2023)

-

Negative interfacial energies of dynamic polymer brush interfaces: a discussion of the free energy balance

Polymer Journal (2023)

-

Controlling orientation, conformation, and biorecognition of proteins on silane monolayers, conjugate polymers, and thermo-responsive polymer brushes: investigations using TOF-SIMS and principal component analysis

Colloid and Polymer Science (2021)