Abstract

Urethane-crosslinked β-cyclodextrin polymers are prepared by crosslinking heptakis(2,6-di-O-methyl)-β-cyclodextrin (DM-β-CD) with various diisocyanate linkers, such as 4,4′-methylenebis(phenyl isocyanate) (MDI), 1,4-phenylene diisocyanate (PDI) and hexamethylene diisocyanate (HMDI), in DMF. Among these polymers, MDI- and PDI-crosslinked polymers have high adsorption capabilities toward polychlorobiphenyls (PCBs), such as tetra, penta and hexachlorobiphenyl, in isooctane. Toward hexachlorobiphenyl in insulating oil, the adsorption capability of the MDI-crosslinked polymer increases with the adsorption temperature. In addition, using acetone as a washing solvent gives the highest recovery percentage of the PCB from the PCB-adsorbed polymer.

Similar content being viewed by others

Introduction

Porous adsorbent materials with high adsorption properties have attracted much attention for diverse industrial applications, such as removing organic pollutants from air, soil and water environments. Cyclodextrins (CDs) are a class of cyclic oligosaccharides with subnanometer-sized cavities in which guest molecules with the appropriate size and shape can be incorporated.1 CDs and their derivatives have been applied as adsorbent materials to capture organic guest molecules in water.2, 3, 4, 5, 6 Among them, CD-based polymers which are prepared by the reaction of CD with various types of crosslinking agents (for example, epichlorohydrin,7, 8 dibasic acid dichlorides9, 10 and diisocyanates11, 12, 13, 14, 15, 16) can be used as an effective adsorbent for harmful compounds in aqueous systems. For instance, urethane-crosslinked CD polymers prepared by reacting CD with diisocyanate crosslinkers at an appropriate feed ratio have been used to effectively remove organic pollutants (for example, aromatic amines,12 phenol13 and chlorophenol16) in water. On the other hand, these CD polymers are yet to be applied to oil systems.

Recently, we found that 6-O-modified β-CDs (for example, heptakis(6-O-tert-butyldimethylsilyl)-β-CD (TBDMS-β-CD)) effectively form inclusion complexes with chlorinated benzenes,17 pyrene18 and naphthalene derivatives19 in nonpolar solvents including benzene and cyclohexane. Moreover, we successfully removed lower chlorinated biphenyls (mono, di and trichlorobiphenyls) in oil with channel-type γ-CD assemblies20 and completely removed polychlorobiphenyls (PCBs) in insulating oil with terephthaloyl-crosslinked γ-CD polymers.21

PCBs, which are a class of persistent organic pollutants comprised of chlorinated biphenyls, were widely used as insulating fluids in electric equipment (for example, capacitors and transformers),22 but many countries have prohibited both their manufacturing and commercial use due to their strong toxicity, environmental persistence and bioaccumulation.23, 24, 25, 26 However, large amounts of insulating oils contaminated with PCBs are still stored without the appropriate treatment in many countries, including Japan.27, 28, 29 This lack of treatment is due to the high chemical stability of PCBs and the risk of generating highly toxic dioxins on incineration at low temperatures. Thus, the efficient and safe treatment of large amounts of PCB-contaminated insulating oils is an important global issue.

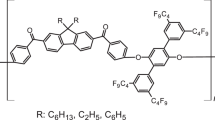

Under these backgrounds, we focused on new β-CD-based polymer adsorbents, which can be prepared by crosslinking heptakis(2,6-di-O-methyl)-β-CD (DM-β-CD) with diisocyanate linkers. Because the C-6 primary hydroxyl groups and the C-2 secondary hydroxyl groups of β-CD are protected with methyl groups in DM-β-CD, only the C-3 secondary hydroxyl groups serve as crosslinking points. Unlike the case of native β-CD where reaction control with the reactive diisocyanate crosslinkers is normally difficult, which results in a solid bulk gel, the moderate reactivity of these C-3 hydroxyl groups will make it possible to control the reaction with such crosslinkers. The resulting urethane-crosslinked DM-β-CD polymers can be expected to show a unique adsorption capability for PCBs in nonpolar solvents. A preliminary study on PCB removal using urethane-crosslinked CD polymers was reported by us in the proceedings of Dioxin 2012.30 Herein we describe a comprehensive study of urethane-crosslinked DM-β-CD polymers as an adsorbent toward PCBs in isooctane and insulating oil.

Experimental procedure

Materials

β-CD was purchased from Wako Pure Chemical Industries (Tokyo, Japan). DM-β-CD was purchased from Nacalai Tesque (Kyoto, Japan). The CDs were vacuum dried at 80 °C overnight before use. Anhydrous N,N-dimethylformamide (DMF) was purchased from Wako Pure Chemical Industries. The crosslinker, MDI, was purchased from Wako Pure Chemical Industries. PDI and hexamethylene diisocyanate (HMDI) were purchased from Tokyo Chemical Industries, Ltd. (Tokyo, Japan) and Sigma-Aldrich (St Louis, MO, USA), respectively. Insulating oil was purchased from JX Nippon Oil and Energy (Tokyo, Japan). An isooctane solution of EC-5433 (75p.p.m., 1.2 ml) was supplied from CIL (Tewksbury, MA, USA). The EC-5433 solution was diluted a 100-fold with isooctane for the adsorption experiment. The composition and content of each PCB in EC-5433 is shown in the Supporting Information (Supplementary Table S1). 2,2′,3,3′,5,5′-Hexachlorobiphenyl (2,2′,3,3′,5,5′-HeCB) was purchased from AccuStandard, Inc. (USA). 2,2′,3,3′,5,5′-HeCB was dissolved in insulating oil at a prescribed concentration to prepare the 2,2′,3,3′,5,5′-HeCB-contaminated insulating oil.

Characterization and analysis

Scanning electron microscope (SEM) observations were performed with a JSM-6710F (JEOL, Tokyo, Japan). Fourier-transform infrared (FT-IR) spectra were recorded using Spectrum One (Perkin Elmer, Waltham, MA, USA). The contents (wt%) of carbon (C), hydrogen (H) and nitrogen (N) in the prepared CD polymers were measured by elemental analysis with CHN Corder MT-2 (Yanako, Kyoto, Japan), while the CD content was estimated on the basis of these values. Quantitative analyses of the PCBs in isooctane or insulating oil were carried out with a gas chromatography–tandem mass spectrometer [GC(450-GC)-MS/MS (320-MS, triple stage quadrupole spectrometer), Bruker Daltonics, Japan branch of Bruker, Billerica, MA, USA] equipped with a 30-m BGB172 capillary column (0.25 mm id, BGB Analytik AG, Böckten, Switzerland). The temperature program was 15 °C min−1 from 120 to 180 °C, 2 °C min−1 from 180 to 260 °C, 8 °C min−1 from 260 to 300 °C and held at 300 °C for 5 min. Helium and argon were used as the carrier and collision-induced dissociation gases, respectively. Both the injector and transfer line temperatures were maintained at 200 °C.

Synthesis of urethane-crosslinked CD polymers

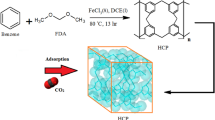

DM-β-CD was crosslinked with three types of diisocyanates (MDI, PDI and HMDI) at various molar feed ratios (molar ratio of crosslinker to DM-β-CD=3.0, 5.0 and 10) (Figure 1). Dried DM-β-CD (1 g, 0.752 mmol) was reacted with the crosslinker in dry DMF (10 ml) at 70 °C for 12 h under a nitrogen atmosphere. The reaction mixture was dropped into water (a poor solvent). The resulting solid was separated from the supernatant by centrifugation. To remove the unreacted starting materials, it was washed initially with water, followed by DMF and finally with water. Then the aqueous dispersion was lyophilized for 3 days to give a white powder as a urethane-crosslinked DM-β-CD polymer.

Adsorption and recovery experiments

The adsorption capabilities of the CD polymers toward PCBs in isooctane and insulating oil were investigated by two column methods. For the adsorption experiment in isooctane (Method 1), 180 mg of the CD polymer was loaded into a PP syringe-type column (diameter: 8.0 mm, length: 50 mm). Isooctane solutions of EC-5433 (PCB mixture, 0.75 p.p.m., 50 μl) and then isooctane (3.0 ml, 2074 mg) were passed through a column packed with each CD copolymer at 25 °C. In the other method (Method 2), 200 mg of the CD polymer was loaded into a stainless column (diameter: 4.6 mm, length: 100 mm). PCB-contaminated insulating oil (10 p.p.m., 400 mg) was passed through the column at a prescribed temperature (25, 40, 60, 80 or 110 °C) and N2 flow pressure (0.15 MPa). The concentrations of PCBs in the eluate were measured by GC/MS/MS. To recover the PCBs from the PCB-adsorbed CD polymer, the polymer was washed with various organic solvents (2 g) by passing these solvents through the column packed with the PCB-adsorbed CD polymer. The PCB concentrations in the resulting eluents were determined by GC/MS/MS.

Results and discussion

Preparation and characterization of urethane-crosslinked DM-β-CD polymers

DM-β-CD, which has seven secondary hydroxyl groups at the C-3 position that can serve as crosslinking points, was reacted with MDI as a crosslinker. On completion of the reaction, dropping the reaction mixture into water (a poor solvent) gives a precipitate. Washing the precipitate with water followed by DMF and subsequent lyophilization gives MDI-crosslinked DM-β-CD polymers.

These polymers were characterized with FT-IR and SEM. Figure 2 shows the FT-IR spectra of DM-β-CD, MDI and the MDI-crosslinked DM-β-CD polymer (MDI/DM-β-CD ratio=4.3). The complete disappearance of the N=C=O stretching bands of MDI (2270 cm−1) and the appearance of the C=O stretching bands of the urethane (1703 cm−1) confirm that the urethane-crosslinked polymer is formed. Based on elemental analyses of the N content in the resulting polymers, the MDI/CD ratios in the polymers were estimated (Table 1). The MDI/CD ratio is higher than the molar feed ratio. Due to the high water solubility of DM-β-CD, the resulting urethane-crosslinked DM-β-CD polymers with low crosslinker/CD ratios may be removed during the purification process (reprecipitation in water). The SEM images of the DM-β-CD/MDI4.3 polymers show the formation of spherical nanoparticles with sizes ranging from 100 to 300 nm (Figure 3a). The particle size increases as the MDI/DM-β-CD ratio increases (Supplementary Figure S2a–c). This increase in the particle size with an increase in the MDI content can be explained by an increase in the polymer–polymer association in water through the hydrophobic interactions.

As a control polymer, a β-CD/MDI polymer was prepared by crosslinking β-CD with MDI in a similar manner as the DM-β-CD/MDI polymer. The crosslinking reaction of β-CD with MDI rapidly progresses within 1 h to form a bulk gel. The MDI-crosslinked β-CD polymer forms a continuous network structure with small voids (~100 nm) (Figure 3b); this structure clearly differs from that of the MDI-crosslinked DM-β-CD polymer. The native DM-β-CD forms 100 μm-sized microcrystals (Supplementary Figure S2g).

DM-β-CD/urethane polymers with other types of crosslinkers, such as PDI and HMDI, were also prepared in a similar manner where the crosslinker/DM-β-CD feed ratio was varied from 3 to 10. The resulting polymers were purified by reprecipitation in water, except for the DM-β-CD/PDI3.0 polymer. The DM-β-CD/PDI3.0 polymer was purified by dialysis for 3 days using a dialysis membrane (3 kDa molecular weight cutoff) because the DM-β-CD/PDI3.0 polymer did not precipitate in the reprecipitation process in water. Table 1 summarizes the crosslinker/DM-β-CD ratios in the resulting polymers. Supplementary Figure S1 of the Supporting Information shows the FT-IR spectra of the DM-β-CD polymers (see also Supplementary Table S2 for the wavenumbers of carbonyl stretching bands of the polymers).

The SEM images of these DM-β-CD polymers show that both the type of crosslinker and the crosslinker/DM-β-CD ratio affect the morphology (Supplementary Figure S2). The DM-β-CD/PDI3.0 polymer, which is water soluble, forms a stick-like structure (Supplementary Figure S2d). On the other hand, the DM-β-CD/PDI5.5 polymer forms particulate structures with sizes ranging from 90 to 200 nm (Supplementary Figure S2e). The DM-β-CD/HMDI10 polymer forms a particulate structure with almost the same size as the DM-β-CD/MDI4.3 polymer particles (Supplementary Figure S2f).

Adsorption capability of urethane-crosslinked DM-β-CD polymers toward PCBs in isooctane

First, we examined the adsorption capabilities of DM-β-CD/urethane polymers toward PCBs in isooctane. The β-CD/urethane polymer and native DM-β-CD were used as controls. EC-5433, which is a mixture of 66 kinds of PCBs (mono to decachlorobiphenyls), was used as PCBs. The adsorption capability of the DM-β-CD/urethane polymers toward the EC-5433 in isooctane was examined by passing the EC-5433/isooctane solution through a column packed with the DM-β-CD/urethane polymers (isooctane/polymers weight ratio=11.5) at 25 °C. The PCBs concentrations in the isooctane solution emerging from the column end were measured by GC/MS/MS to determine the percentage of PCBs removed from isooctane by the DM-β-CD/urethane polymer.

Because actual PCB-contaminated insulating oils, such as Kanechlor 500-contaminated insulating oil, mainly contain tetra, penta and hexachlorinated biphenyls,31 we highlighted the adsorption capability of DM-β-CD/urethane polymers toward these three chlorobiphenyls in EC-5433, which are abbreviated as TeCBs, PeCBs and HeCBs, respectively (Supplementary Figure S3 shows the removal percentages against the 66 kinds of mono to decachlorobiphenyls). Figure 4 shows the removal percentages of TeCBs, PeCBs and HeCBs in isooctane with the DM-β-CD/MDI4.3 polymer, native DM-β-CD and the β-CD/MDI3.4 polymer, respectively. The DM-β-CD/MDI4.3 polymer shows a higher adsorption capability toward the PCBs than native DM-β-CD, indicating that polymerization with a MDI crosslinker improves the adsorption capability of DM-β-CD toward PCBs. The DM-β-CD/MDI4.3 polymer also shows a higher adsorption capability than the β-CD/MDI3.4 polymer, which can be explained by considering the difference in the affinity for isooctane and/or the surface to volume ratio between the DM-β-CD/MDI4.3 and the β-CD/MDI3.4 polymers.

Removal percentages of tetrachlorobiphenyls (TeCBs), pentachlorobyphenyls (PeCBs) and hexachlorobiphenyls (HeCBs) in isooctane using the DM-β-CD/MDI4.3 polymer, DM-β-CD and the β-CD/MDI3.4 polymer, respectively. DM-β-CD, heptakis(2,6-di-O-methyl)-β-CD. A full color version of this figure is available at Polymer Journal online.

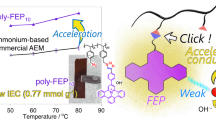

Figure 5 shows the removal percentages of TeCBs, PeCBs and HeCBs in isooctane using various DM-β-CD/urethane polymers with different types of crosslinkers and crosslinker/DM-β-CD ratios. The DM-β-CD/MDI polymers exhibit a high adsorption capability toward these PCBs regardless of the ratio of MDI to DM-β-CD in the range of 4.3 to 10. On the other hand, for the DM-β-CD/PDI polymers, the polymer with a crosslinker/DM-β-CD ratio of 5.5 (DM-β-CD/PDI5.5) shows a higher adsorption capability than that with a crosslinker/DM-β-CD ratio of 3.0 (DM-β-CD/PDI3.0). These results may suggest that the lipophilicity of the polymer has an important role in the adsorption of PCBs in isooctane. Interestingly, the DM-β-CD/PDI3.0 polymer shows a higher adsorption capability toward HeCBs than toward TeCBs and PeCBs, suggesting that cooperative binding by plural DM-β-CD cavities effectively captures bulky HeCBs. The DM-β-CD/HMDI10 polymer has a lower adsorption capability than the DM-β-CD/MDI4.3 and DM-β-CD/PDI5.5 polymers, indicating that the choice of crosslinker is important when designing a DM-β-CD polymer with a high PCB adsorption capability. Thus, employing an appropriate amount of an aromatic crosslinker is required to attain a high adsorption of PCBs in nonpolar organic media by the DM-β-CD polymer.

Removal percentages of tetrachlorobiphenyls (TeCBs), pentachlorobyphenyls (PeCBs) and hexachlorobiphenyls (HeCBs) in isooctane using various DM-β-CD/urethane polymers at ambient temperature. DM-β-CD, heptakis(2,6-di-O-methyl)-β-CD. A full color version of this figure is available at Polymer Journal online.

Adsorption capability of urethane-crosslinked DM-β-CD polymers toward 2,2′,3,3′,5,5′-HeCB in insulating oil

To study the adsorption capability of DM-β-CD/urethane polymers toward PCBs in insulating oil, the DM-β-CD/MDI4.3 polymer, which exhibits high adsorption capabilities toward PCBs in isooctane, were used as adsorbents for PCBs in insulating oil (10 p.p.m.). Here, 2,2′,3,3′,5,5′-HeCB, which is one of the bulkiest HeCBs, was chosen as the PCB to study the cooperation of plural β-CD cavities in the capture of PCBs, based on our previous results.21 The adsorption experiments were performed by passing HeCB-contaminated insulating oil through a column packed with the DM-β-CD/MDI4.3 polymer (insulating oil/polymer weight ratio=2.0) under N2 flow (0.15 MPa).

Figure 6a shows the effects of temperature on the adsorption capability of the DM-β-CD/MDI4.3 polymer toward 2,2′,3,3′,5,5′-HeCB in insulating oil and the recovery yield of purified insulating oil. When the adsorption experiment was carried out at ambient temperature, the insulating oil was not eluted from the column due to its high viscosity. The yield of purified insulating oil gradually increases as the temperature increases. At 110 °C, the yield of purified insulating oil is 86%. As the temperature increases, the viscosity of the insulating oil decreases, and the intramolecular hydrogen bonds of the DM-β-CD/MDI4.3 polymer are weakened, resulting in an enhanced mass transfer of the insulating oil and the PCB molecules through the DM-β-CD/MDI4.3 polymer network. When the DM-β-CD/MDI4.3 polymer is used at 60 °C, 99% of 2,2′,3,3′,5,5′-HeCB is removed from the insulating oil. An increase in the temperature to 80 °C enhances the adsorption capability, resulting that 2,2′,3,3′,5,5′-HeCB is completely removed. This result may suggest the capture of 2,2′,3,3′,5,5′-HeCB by the cooperation of plural β-CD cavities, which should be promoted by an increase in the penetration of insulating oil inside the DM-β-CD/MDI4.3 polymer network via the cleavage of the intramolecular hydrogen bonds between the β-CD units as the temperature increases.21 On the other hand, the adsorption capability of the DM-β-CD/MDI4.3 polymer toward 2,2′,3,3′,5,5′-HeCB appears to decrease slightly as the temperature increases further. At 110 °C, the removal percentage of 2,2′,3,3′,5,5′-HeCB is 94%. Thus, to obtain purified insulating oil in a high yield, the temperature at which PCB-contaminated oil is treated must be optimized.

(a) Removal percentage of 2,2′,3,3′,5,5′-HeCB by the DM-β-CD/MDI4.3 polymer (50 wt%) and the recovery yield of insulating oil (n=2) as a function of temperature. (b) Removal percentage of 2,2′,3,3′,5,5′-HeCB in insulating oil as a function of the added amount of the DM-β-CD/MDI4.3 polymer at 80 °C. DM-β-CD, heptakis(2,6-di-O-methyl)-β-CD; HeCB, hexachlorobiphenyl. A full color version of this figure is available at Polymer Journal online.

Figure 6b shows the effect of the addition amount of the DM-β-CD/MDI4.3 polymer on the removal percentage of 2,2′,3,3′,5,5′-HeCB in insulating oil. The removal percentage of 2,2′,3,3′,5,5′-HeCB increases as the amount of added polymer increases. A polymer concentration of 50 wt% completely removes 2,2′,3,3′,5,5′-HeCB from the insulating oil.

Recovery of PCB adsorbed on urethane-crosslinked DM-β-CD polymer using a washing solvent

We examined the recovery of 2,2′,3,3′,5,5′-HeCB adsorbed on the DM-β-CD/MDI4.3 polymer on washing with various organic solvents (Table 2). Of the washing solvents tested, acetone is the most effective to recover 2,2′,3,3′,5,5′-HeCB adsorbed on the DM-β-CD/MDI4.3 polymer, consistent with the case of the terephthaloyl-crosslinked γ-CD polymer reported previously.21 This result suggests that the DM-β-CD/MDI4.3 polymer can be easily regenerated and possibly recycled in the future process. Further studies on the complete recovery of PCB adsorbed on the polymer are now in progress.

Conclusion

Crosslinking DM-β-CD with various types of diisocyanates gives urethane-crosslinked DM-β-CD polymers. The MDI- and PDI-crosslinked DM-β-CD polymers show high adsorption capabilities toward PCBs (TeCBs, PeCBs and HeCBs) in isooctane. Similarly, the MDI-crosslinked DM-β-CD polymer shows a high adsorption capability toward 2,2′,3,3′,5,5′-HeCB in insulating oil. Washing the PCB-adsorbed MDI-crosslinked DM-β-CD polymer with acetone effectively recovers the PCB.

References

Szejtli, J. Introduction and general overview of cyclodextrin chemistry. Chem. Rev. 98, 1743–1754 (1998).

Murai, S., Imajo, S., Takasu, Y., Takahashi, K. & Hattori, K. Removal of phthalic acid esters from aqueous solution by inclusion and adsorption on β-cyclodextrin. Environ. Sci. Technol. 32, 782–787 (1998).

Crini, G. & Morcellet, M. Synthesis and applications of adsorbents containing cyclodextrins. J. Sep. Sci. 25, 789–813 (2002).

Bibby, A. & Mercier, L. Adsorption and separation of water-soluble aromatic molecules by cyclodextrin-functionalized mesoporous silica. Green Chem. 5, 15–19 (2003).

Chen, C. Y., Chen, C. C. & Chung, Y. C. Removal of phthalate esters by α-cyclodextrin-linked chitosan bead. Bioresour. Technol. 98, 2578–2583 (2007).

Kawano, S., Kida, T., Takemine, S., Matsumura, C., Nakano, T., Kuramitsu, M., Adachi, K. & Akashi, M. Efficient removal and recovery of perfluorinated compounds from water by surface-tethered β-cyclodextrins on polystyrene particles. Chem. Lett. 42, 392–394 (2013).

Crini, G., Bertini, S., Torri, G., Naggi, A., Sforzini, D., Vecchi, C., Janus, L. & Lekchiri, Y. Sorption of aromatic compounds in water using insoluble cyclodextrin polymers. J. Appl. Polym. Sci. 68, 1973–1978 (1998).

Garcia-Zubiri, I. X., Gonzalez-Gaitano, G. & Isasi, J. R. Sorption models in cyclodextrin polymers: Langmuir, Freundlich, and a dual-mode approach. J. Colloid Interface Sci. 337, 11–18 (2009).

Wilson, L. D. & Guo, R. Preparation and sorption studies of polyester microsphere copolymers containing β-Cyclodextrin. J. Colloid Interface Sci. 387, 250–261 (2012).

Mahamed, M. H., Wilson, L. D., Pratt, D. Y., Guo, R., Wu, C. & Headley, J. V. Evaluation of the accessible inclusion sites in copolymer materials containing β-cyclodextrin. Carbohydr. Polym. 87, 1241–1248 (2012).

Ma, M. & Li, D.-Q. New organic nanoporous polymers and their inclusion complexes. Chem. Mater. 11, 872–874 (1999).

Bhaskar, M., Aruna, P., Jeevan, R., Jeevan, G. & Radhakrishnan, G. β-Cyclodextrin-polyurethane polymer as solid phase extraction material for the analysis of carcinogenic aromatic amines. Anal. Chim. Acta 509, 39–45 (2004).

Yamasaki, H., Makihata, Y. & Fukunaga, K. Efficient phenol removal of wastewater from phenolic resin plants using crosslinked cyclodextrin particles. J. Chem. Technol. Biotechnol. 81, 1271–1276 (2006).

Mohamed, M. H., Wilson, L. D., Headley, J. V. & Peru, K. M. Investigation of the sorption properties of β-cyclodextrin-based polyurethanes with phenolic dyes and naphthenates. J. Colloid Interface Sci. 356, 217–226 (2011).

Wilson, L. D., Mohamed, M. H. & Headley, J. V. Surface area and pore structure properties of urethane-based copolymers containing β-cyclodextrin. J. Colloid Interface Sci. 357, 215–222 (2011).

Wilson, L. D., Mohamed, M. H. & Berhaut, C. L. Sorption of aromatic compounds with copolymer sorbent materials containing β-cyclodextrin. Materials 4, 1528–1542 (2011).

Kida, T., Fujino, Y., Miyawaki, K., Kato, E. & Akashi, M. 6-O-Modified β-cyclodextrin enabling inclusion complex formation in nonpolar media. Org. Lett. 11, 5282–5285 (2009).

Kida, T., Iwamoto, T., Fujino, Y., Tohnai, N., Miyata, M. & Akashi, M. Strong guest binding by cyclodextrin hosts in competing nonpolar solvents and the unique crystalline structure. Org. Lett. 13, 4570–4573 (2011).

Kida, T., Iwamoto, T., Asahara, H., Hinoue, T. & Akashi, M. Chiral recognition and kinetic resolution of aromatic amines via supramolecular chiral nanocapsules in nonpolar solvents. J. Am. Chem. Soc. 135, 3371–3374 (2013).

Kida, T., Nakano, T., Fujino, Y., Matsumura, C., Miyawaki, K., Kato, E. & Akashi, M. Complete removal of chlorinated aromatic compounds from oils by channel-type γ-cyclodextrin assembly. Anal. Chem. 80, 317–320 (2008).

Kawano, S., Kida, T., Miyawaki, K., Noguchi, Y., Kato, E., Nakano, T. & Akashi, M. Cyclodextrin polymers as highly effective adsorbents for removal and recovery of polychlorobiphenyl (PCB) contaminants in insulating oil. Environ. Sci. Technol. 48, 8094–8100 (2014).

Rouse, T. O. Mineral insulating oil in transformers. IEEE Electr. Insul. M 14, 6–16 (1998).

Gustafson, C. G. PCB’s-prevalent and persistent. Intensified research is needed to minimize their dangers. Environ. Sci. Technol. 4, 814–819 (1970).

Risebrough, R. W., Rieche, P. D., Peakall, B., Herman, S. G. & Kirven, M. N. Polychlorinated biphenyls in the global ecosystem. Nature 220, 1098–1102 (1968).

Safe, S. H. Polychlorinated biphenyls (PCBs): environmental impact, biochemical and toxic responses, and implications for risk assessment. Crit. Rev. Toxicol. 4, 87–149 (1994).

Kelly, B. C., Ikonomou, M. G., Blair, J. D., Morin, A. E. & Gobas, F. A. P. C. Food web-specific biomagnification of persistent organic pollutants. Science 317, 236–239 (2007).

Kanbe, H. & Shibuya, M. Solvent cleaning of pole transformers containing PCB contaminated insulating oil. Waste Manage 21, 371–380 (2001).

Seok, J. & Hwang, K.-Y. Thermo-chemical destruction of polychlorinated biphenyls (PCBs) in waste insulating oil. J. Hazard. Mater. 124, 133–138 (2005).

Kaya, D., Imamoglu, I. & Sanin, F. D. Anaerobic mesophilic digestion of waste activated sludge in the presence of 2, 3′, 4, 4′, 5-pentachlorobiphenyl. Int. Biodeter. Biodegr. 83, 41–47 (2013).

Kawano, S., Nakano, T., Miyawaki, K., Kato, E., Kida, T. & Akashi, M. in Proceedings of Dioxin 2012 (International Symposium on Halogenated Persistent Organic Pollutants in Cairns), 1194–1197 (Cairns, Queensland, Australia, 2012).

Takasuga, T., Kumar, K. S., Noma, Y. & Sakai, S. Chemical characterization of polychlorinated biphenyls, -dibenzo-p-dioxins, and -dibenzofurans in technical Kanechlor PCB formulations in Japan. Arch. Environ. Contam. Toxicol. 49, 385–395 (2005).

Acknowledgements

This work was partially supported by the Funding Program for Next Generation World-Leading Researchers (GR067), a Grant-in-Aid for Scientific Research (No. 25288081) from the Japan Society of the Promotion of Science and the Risk-Taking Fund for Technology Development from the Japan Science and Technology Agency (JST).

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Kawano, S., Kida, T., Miyawaki, K. et al. Adsorption capability of urethane-crosslinked heptakis(2,6-di-O-methyl)-β-cyclodextrin polymers toward polychlorobiphenyls in nonpolar organic media. Polym J 47, 443–448 (2015). https://doi.org/10.1038/pj.2015.13

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2015.13