Abstract

In this review, the development of low-molecular-weight gelators and polymer-based gelators is described. The driving forces for physical gelation are non-covalent bonds, such as hydrogen bonds, electrostatic interactions, van der Waals interactions and π–π interactions. When gelation occurs, the gelator molecules self-assemble into macromolecule-like aggregates through non-covalent intermolecular interactions. The close relationship between crystallization and gelation is discussed. Crystallization is a phenomenon in which crystals are separated from solution by the formation of a three-dimensional arrangement of solute through intermolecular interactions. Conversely, physical gelation is caused by the trapping of solvent in fibrous networks that are formed by gelator molecules through intermolecular interactions. Amino acid derivatives and cyclic dipeptides are introduced as typical gelators. To develop gelators that form semipermanent stable gels, a new concept termed ‘gelation-driving segments’ is proposed. Polymer-based gelators that can form semipermanent stable gels are synthesized by connecting gelation-driving segments to polymers or oligomers.

Similar content being viewed by others

Introduction

Low-molecular-weight gelators that form physical gels have recently been extensively studied. The physical gelation of low-molecular-weight compounds results from non-covalent bonds, such as hydrogen bonds. During a gelation process, gelator molecules are first self-assembled during the cooling process, producing fibrous assemblies. Then, these fibrous assemblies form a three-dimensional network structure, and gelation occurs by trapping solvent in the networks. A large number of gelators with different structures have been reported,1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 and some of these agents have been used as gelators for used cooking oils, crude oil spills, cosmetics, aromatics, ink-thickeners and greases. For example, 12-hydroxystearic acid12 is used to gel cooking oil and is practically used as a gelator. The (1,3:2,4)-dibenzylidene sorbitol13 and the α,γ-bis-n-butylamide of N-lauroyl-L-glutamic acid are used as ingredients of antiperspirants. Aromatic diureas are used as materials for synthetic grease.

However, gels composed of low-molecular-weight gelators are metastable and crystallize during prolonged storage. This crystallization process may occur within a few hours or within a few years, and the period until stabilization (that is, crystallization) occurs varies depending on the gel. In industrial applications for gelators, crystallization corresponds to a breakdown of gels and is a critical disadvantage. Unlike low-molecular-weight compounds, polymers and oligomers are never separated from a solution as crystals because of their molecular weight distributions and entanglement of their chains. We focused on the non-crystallizable characteristic of polymers and developed polymer-based gelators that produce semipermanent stable gels. Because gelation-driving segments covalently attached to a polymer chain can move in solution and aggregate during the cooling process, it is logical to anticipate that polymers that contain gelation-driving compounds can function as polymer-based gelators. Here, we present both low-molecular-weight gelators and polymer-based gelators.

Characteristics of low-molecular-weight gelators

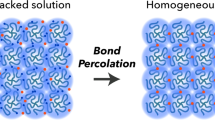

Figure 1 compares the molecular behavior of a low-weight compound during gelation and during crystallization. When crystals are heated in an appropriate solvent, a homogenous solution is formed. When the homogeneous solution is cooled, crystallization occurs in response to the differences in the solubility (the left half of Figure 1). However, in rare cases, gelation may occur rather than crystallization (the right half of Figure 1). When the formed gel is heated, it transforms back into the original homogeneous solution. Crystallization occurs because the molecules are condensed and arranged in an ordered three-dimensional pattern. In contrast, gelation occurs because the molecules are arranged in fibrous assemblies and form three-dimensional networks. Both crystallization and gelation are the result of non-covalent interactions, such as hydrogen bonds, van der Waals forces, π–π interactions and electrostatic interactions.

The characteristics of low-molecular-weight gelators are listed as follows.

-

1)

They are characterized by good solubility upon heating and induce the smooth gelation of fluids.

-

2)

Gelation generally occurs with a low concentration of gelator: less than 50 g l−1.

-

3)

The formed gels show a thermally reversible sol-to-gel phase transition.

-

4)

The driving forces of gelation are non-covalent interactions, such as hydrogen bonds, van der Waals forces, π–π interactions and electrostatic interactions.

The process of gel formation by a low-molecular-weight gelator is extremely simple. First, a mixture containing a gelator and a solvent is heated to obtain an isotropic solution, and then the hot solution is allowed to stand at room temperature. Gelation occurs as the solution cools. The characteristics of the formed gels, namely transparent, translucent or opaque, depend on the types of gelator and solvent.

Amino acid derivatives as gelators

The series of amino acid compounds shown in Figure 2, such as L-isoleucine derivative (1)14 and L-valine derivative (2),15 have a strong gelation ability. In particular, 1 is easily produced through a two-step reaction using L-isoleucine as a starting material.

As shown in Table 1, in which solvents ranging from dimethyl sulfoxide to cyclohexane are listed in order of descending dielectric constant, 1 and 2 can gel a wide variety of fluids, including highly polar solvents, such as dimethyl sulfoxide and N,N-dimethylformamide and various alcohols, ketones, esters, aromatic compounds, carbon tetrachloride, silicon oils, mineral oils and vegetable oils. For example, 1 liter of acetone and silicon oil can be gelled by adding 7 and 5 g of 1, respectively. When the structure is limited to the N-octadecylamide of N-benzyloxycarbonyl-L-amino acid, not all amino acid derivatives have gelation ability. The corresponding compounds prepared from glycine, L-alanine, D,L-valine, L-phenylalanine and L-proline only crystallize rather than gel. In contrast, the compounds from L-leucine and L-tert-leucine are miscible in most solvents.

The gelation by amino acid derivatives results primarily from the formation of hydrogen bonds. The Fourier transformation-infrared spectrum of a kerosene gel with compound 2 shows the NH stretching vibration at 3269 cm−1, the urethane C=O stretching vibration at 1688 cm−1 and the amide stretching vibration at 1646 cm−1. This result indicates that hydrogen bonds form between NH and the C=O of urethane and that amide bonds, and few NH and C=O, are present as a non-hydrogen bond type. In contrast, compound 2 forms a homogeneous solution in chloroform as a result of solvation; therefore, the spectrum in chloroform is characterized by the NH stretching vibration at 3437 cm−1, the urethane C=O stretching vibration at 1714 cm−1 and the amide C=O stretching vibration at 1671 cm−1, indicating a non-hydrogen bond type.

When gelation occurs with low-molecular-weight compounds, molecules are self-assembled through non-covalent bonds, such as hydrogen bonds, and produce fibrous assemblies. Finally, three-dimensional networks are constructed, and solvent molecules are trapped in these networks. A nano-sized fibrous assembly is always produced during the initial stage of the gelation process. This fibrous assembly formed by a gelator can be easily observed with an electron microscope. In a transmission electron microscopy image of a tetrachloromethane gel formed by gelator 1, which was recorded with negative staining under osmium oxide vapor, a large assembly composed of fibrous assemblies with a minimum width of 10–30 nm was observed (see the Graphical Abstract). The gelling mechanism of amino acid-based compounds can be explained by considering the hierarchical structure of assemblies. The initial assemblies are formed by intermolecular hydrogen bonds between amide and urethane, and these assemblies grow into large assemblies. Subsequently, these assemblies are bundled through interactions of van der Waals forces or other forces, and then they are entangled to form a network structure. The trapping of solvent molecules in the network structure results in their low fluidity, and gelling finally occurs.

Cyclic dipeptides as gelators

To develop a low-molecular-weight gelator, it is necessary to find compounds that satisfy the following three requirements: (I) the compound forms a large assembly by intermolecular interactions through non-covalent bonds, (II) the assemblies are bundled by interactions of van der Waals forces or other forces to construct three-dimensional networks and (III) the compound is capable of stabilizing metastable gels and preventing crystallization.

It is reasonable to assume that cyclic dipeptides will satisfy the above requirements (I)–(III). Because a cyclic dipeptide, namely a 2,5-diketopiperazine derivative, is a six-membered ring with two amide bonds, it is hypothesized that it forms a molecular assembly through intermolecular hydrogen bonds (I). When a failure occurs in these hydrogen bonds, it triggers the three-dimensionalization of fibrous assemblies (II). A random arrangement of cyclic dipeptides prevents crystallization from occurring and consequently stabilizes a gel state, satisfying requirement (III).

In fact, cyclic dipeptide derivative 3 has gelation ability.16, 17, 18 All cyclic dipeptides that contain the same amino acid residue exhibit a high crystalline property and have no gelation ability. However, a cyclic dipeptide functions as a gelator when it contains two characteristically different amino acids: a neutral amino acid, such as L-valine, L-leucine or L-phenylalanine and an acidic amino acid, such as L-glutamic acid or L-aspartic acid. In particular, compound 3 composed of L-aspartic acid and L-phenylalanine, cyclo(L-Asp(OC10H21)-L-Phe), is characterized by a good gelation ability. Compound 3 can be easily prepared from the artificial sweetener Aspartame. The minimum gel concentrations of 3 for typical solvents are 44 g l−1 (methanol), 28 g l−1 (ethanol), 28 g l−1 (acetone), 23 g l−1 (ethyl acetate), 10 g l−1 (benzene), 3 g l−1 (toluene), 11 g l−1 (chlorobenzene), 15 g l−1 (triolein), 15 g l−1 (tricaprylin), 13 g l−1 (soybean oil) and 5 g l−1 (decamethylcyclopentasiloxane). Triolein, tricaprylin and decamethylcyclopentasiloxane are often used as cosmetic ingredients.

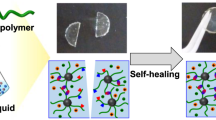

Development of a polymer-based gelator

A defect of gels formed by low-molecular-weight gelators is a breakdown of gels resulting from crystallization. Because a low-molecular-weight gelator is a single molecule, it forms a metastable gel and tends to crystallize. Therefore, when a gel is allowed to stand for a prolonged period of time, the gelator molecules in fibrous assemblies that form the gel are rearranged and transform into crystals. To develop a gelator capable of forming a semipermanently stable gel that does not crystallize, a factor that prevents the crystallization of gels is required to be included in the molecular design of a gelator. Polymers and oligomers, which are not single molecules, are never separated from solution as crystals due to the distribution of their molecular weights and entanglement of their chains. Non-crystallizability, which is an inherent characteristic of polymers and oligomers, can be utilized for the molecular design of a gelator. A low-molecular-weight gelator is adhered to a polymer as ‘a gelation-driving compound’ with a covalent bond. This process converts a low-molecular-weight gelator into ‘a polymer-based gelator’ that can form a stable gel. Flexible polysiloxanes, polyethers and polycarbonates are useful polymers for preventing crystallization.

Based on the variety of low-molecular-weight gelators that we have developed, we prepared compounds 4–6 as gelation-driving compounds, which include olefin at their termini (Figure 2). The terminal olefin segment is introduced for the hydrosilylation reaction. To function as a gelation-driving segment, the compound itself must possess gelation ability. In other words, the structure of gelators 1–3 must be changed while maintaining the potential capability for intermolecular interactions to form molecular assemblies. For example, gelator 1 requires an amino acid residue L-isoleucine segment as well as an amide bond and a urethane bond. Although the urethane bond in the gelator is modified to an amide bond in gelation-driving compound 4, the fundamental structure is the same. In the gelation-driving compound 6, an alkyl group in gelator 3 is simply replaced by an alkenyl group.

Based on examinations of the gelation abilities of compounds 4–6 prepared as gelation-driving compounds, although the gelation ability of compound 6 is somewhat lower than that of compounds 4 and 5, all of compounds 4–6 have gelation ability. The minimum gel concentrations of 4, 5 and 6 for toluene are 11, 16 and 6 g l−1, respectively. This result indicates that a partial replacement, such as the replacement of a urethane group with an amide group and the replacement of an alkyl group with an alkenyl group, does not result in a loss of their gelation ability.

Compounds 7–9 are commercially available as polymers or oligomers with a Si-H bond (Figure 3). Compound 7 is a 50–55% methylhydrosiloxane-dimethylsiloxane copolymer (Mw=1200, viscosity=10–15 cSt). Compound 8 is a hydride-terminated polydimethylsiloxane (Mw=6000, viscosity=100 cSt). Compound 9 is 1,1,2,2,3,3,4,4-octamethyltetrasiloxane. Figure 3 shows a typical preparation of polysiloxane-based gelator 10 through hydrosilylation between copolymer 7 and gelation-driving compound 4. Here, the gelation-driving segment in 10 forms the network structure through non-covalent bonds, and the polydimethylsiloxane backbone prevents crystallization.19

The polymer-based gelators 10–14 shown in Figure 4 were prepared through hydrosilylation between a terminal olefin within a gelation-driving compound and a Si-H bond in compounds 7–9.

The gelation abilities of polydimethylsiloxane-based gelators 10 and 12 are compared with those of original gelation-driving compounds 4 and 6. For example, the minimum gel concentrations of 4 and 10 for silicone oil are both equal to 2 g l−1. Gelator 12 has low solubility in solvents and can only gel a few type of solvents. In contrast, the gelation ability of gelator 10 is extremely high and is equal to that of gelation-driving compound 4. The strong gelation ability of polydimethylsiloxane-based gelator 10 indicates that polydimethylsiloxane being present on the backbone does not prevent self-aggregation between the attached gelation-driving segments. These results led us to conclude that polymer-based gelators can be synthesized by introducing a gelation-driving segment to polydimethylsiloxane as a side chain.

To determine the type of polymers and oligomers that are suitable as a backbone for the development of a polymer-based gelator, the gelation abilities of polymer-based gelators 11, 13 and 14 were compared, which were produced by introducing gelation-driving compounds 5 to 7, 8 and 9, respectively (Table 2). Table 2 shows that polydimethylsiloxane copolymer 7 and 1,1,2,2,3,3,4,4-octamethyltetrasiloxane 9 are suitable as a backbone for introducing a gelation-driving segment, whereas gelator 13 prepared from 8 is soluble in most solvents. We therefore may conclude that hydride-terminated polydimethylsiloxane 8 is not suitable as a gelator material. The degree of polycondensation of polydimethylsiloxane 8 is large, with a value of 80, and siloxane dominates most parts of gelator 13. The small ratio of gelation-driving segments in 13 is responsible for the reduced gelation ability. Although polydimethylsiloxane 8 is generally not suitable as a gelator material, note that polydimethylsiloxane 8 is the most appropriate material for the gelation of octamethylcyclotetrasiloxane and decamethylcyclopentasiloxane.

A notable and useful characteristic of polymer-based gelators is that they can form transparent gels. Unlike opaque and translucent gels formed by the gelation-driving compound 4, polymer-based gelator 10, which contains 4 at its side chain, forms transparent gels in most solvents, such as alcohols, ketones, esters, aromatic solvents, N,N-dimethylacetamide, dimethyl sulfoxide, hexane and kerosene. Because the gelation-driving compound is a single molecule with a low-molecular-weight, the orderliness of the self-assemblies is high, and thus, the assemblies form a large-scale network structure that disperses visible light. However, it is hypothesized that the polymer-based gelators produce transparent gels because the steric repulsion and flexibility of polysiloxane prevents their growth into a large-scale network structure with pores as large as the wavelength of visible light.

Another characteristic of a polymer-based gelator is the stability of the formed gels. Low-molecular-weight gelator 6 can form a gel with alcohols; however, the formed gel is decomposed and transforms into a crystal after 24 h. In contrast, polymer-based gelator 12 that contains gelation-driving compound 6 produces an extremely stable gel that remains as a transparent gel, which does not crystallize even after several years. This semipermanent stability is most likely due to the distribution of molecular weights and entanglement of flexible chains in polysiloxane prevent the rearrangement of gelator molecules and consequently prevent crystallization of the gelation-driving segment.

We focused on commercially available polyethers and polycarbonates with hydroxyl groups at the both termini as polymer materials and developed polymer-based gelators.20 Compound 15 with an isocyanate group was prepared as a gelation-driving compound. Polyether-based gelator 16 and polycarbonate-based gelator 17 were prepared by adding 15 to the hydroxyl groups of the polyether and polycarbonate (Figure 4). The gelation abilities of gelation-driving compound 15, polyether-based gelator 16 and polycarbonate-based gelator 17 are summarized in Table 3. The values in the table are the minimum amount (g l−1) of a gelator required for gelling at 25 °C. The results indicated that polymer-based gelators 16 and 17 have strong gelation abilities that are comparable with that of gelation-driving compound 15. One important characteristic of 16 and 17 is that both an acidic fluid, such as oleic acid and linoleic acid, and a polyether type fluid, such as polyethylene glycol and polypropylene glycol, can be gelled by adding these compounds in a few weight %. Polyethers, polycarbonates and polysiloxanes are excellent ingredients for developing polymer-based gelators.

Conclusions

The general characteristics of low-molecular-weight gelators and of the representative gelators that we developed were explained. The concept of a ‘gelation-driving compound’ was proposed on the basis of low-molecular-weight gelators. The introduction of gelation-driving compounds into polymers afforded polymer-based gelators. Polysiloxane-, polyether- and polycarbonate-based gelators exhibited strong gelation abilities, reflecting the properties of the gelation-driving compounds. Polymer-based gelators formed transparent and stable gels that do not transform into crystals. It is important to introduce a gelation-driving compound to highly miscible and flexible polymers such as polysiloxane, polyether and polycarbonate. Considering that polymer-based gelators are physiologically inert and safe, they are most likely useful as scaffolds for tissue engineering. In the future, by utilizing the transparency and safety of gels produced using polymer-based gelators, a variety of industrial applications are expected, such as cosmetics and an ink-thickener for an inkjet printer, among others.

References

Terech, P. & Weiss, R. G. Low molecular mass gelators of organic liquids and the properties of their gels. Chem. Rev. 97, 3133–3159 (1997).

van Esch, J. H. & Feringa, B. L. New functional materials based on self-assembling organogels: from serendipity towards design. Angew. Chem. Int. Ed. 39, 2263–2266 (2000).

Estroff, L. A. & Hamilton, A. D. Water gelation by small organic molecules. Chem. Rev. 104, 1201–1217 (2004).

Suzuki, M. & Hanabusa, K. L-Lysine-based low-molecular-weight gelators. Chem. Soc. Rev. 38, 967–975 (2009).

Suzuki, M. & Hanabusa, K. Polymer organogelators that make supramolecular organogels through physical cross-linking and self-assembly. Chem. Soc. Rev. 39, 455–463 (2010).

John, G., Shankar, B. V., Jadhav, S. R. & Vemula, P. K. Biorefinery: a design tool for molecular gelators. Langmuir 26, 17843–17851 (2010).

Svobodová, H., Noponen, V., Kolehmainen, E. & Sievänen, E. Recent advances in steroidal supramolecular gels. RSC Adv. 2, 4985–5007 (2012).

Tam, A. Y.-Y. & Yam, V. W.-W. Recent advances in metallogels. Chem. Soc. Rev. 42, 1540–1567 (2013).

Raeburn, J., Cardoso, A. Z. & Adams, D. J. The importance of the self-assembly process to control mechanical properties of low molecular weight hydrogels. Chem. Soc. Rev. 42, 5143–5156 (2013).

Yu, G., Yan, X., Han, C. & Huang, F. Characterization of supramolecular gels. Chem. Soc. Rev. 42, 6697–6722 (2013).

Segarra-Maset, M. D., Nebot, V. J., Miravet, J. F. & Escuder, B. Control of molecular gelation by chemical stimuli. Chem. Soc. Rev. 42, 7086–7098 (2013).

Tachibana, T., Mori, T. & Hori, K. Chiral mesophases of 12-hydroxyoctadecanoic acid in jelly and in the solid state. I. a new type of lyotropic mesophase in jelly with organic solvents. Bull. Chem. Soc. Jpn 53, 1714–1719 (1980).

Yamamoto, S. Sorbitol derivatives. III. Organogel formation by benzylidenesorbitol. J. Chem. Soc. Jpn. Ind. Chem. Soc. 46, 779–781 (1943) Chem. Abstr. 46, 7047i (1952).

Hanabusa, K., Hiratsuka, K. & Shirai, H. Easy preparation and useful character of organogel electrolytes based on low molecular weight gelator. Chem. Mater. 11, 649–655 (1999).

Hanabusa, K., Tange, J., Taguchi, Y., Koyama, T. & Shirai, H. Small molecular gelling agents to harden organic liquids. J. Chem. Soc. Chem. Commun. 390–392 (1993).

Hanabusa, K., Matsumoto, M., Kakehi, A. & Shirai, H. Low molecular weight gelators for organic fluids: gelation using a family of cyclo(dipeptide)s. J. Colloid Interface Sci. 224, 231–244 (2000).

Hanabusa, K., Fukui, H., Suzuki, M. & Shirai, H. Specialist gelator for ionic liquids. Langmuir 21, 10383–10390 (2005).

Hoshizawa, H., Minemura, Y., Yoshikawa, K., Suzuki, M. & Hanabusa, K. Thixotropic hydrogelators based on a cyclo(dipeptide) derivative. Langmuir 29, 14666–14673 (2013).

Okabe, S., Ando, K., Hanabusa, K. & Shibayama, M. Dynamic light scattering and small-angle neutron scattering studies on organogels formed with a gelator. J. Polym. Sci. B 42, 1841–1848 (2004).

Suzuki, M., Setoguchi, C., Shirai, H. & Hanabusa, K. Organogelation by novel polymer organogelators with L-lysine derivative: the formation of a three-dimensional network consisting of supramolecular polymer and conventional polymer. Chem. Eur. J. 13, 8193–8200 (2007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hanabusa, K., Suzuki, M. Development of low-molecular-weight gelators and polymer-based gelators. Polym J 46, 776–782 (2014). https://doi.org/10.1038/pj.2014.64

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2014.64

This article is cited by

-

Role of organogel chemistry on rheology and microstructure of molecular gels rationalized by Hansen solubility parameters

Colloid and Polymer Science (2023)

-

Supramolecular organogel of polyureas containing POSS units in the main chain: dependence on the POSS and comonomer structures

Polymer Journal (2022)

-

Study of oleogel as a frying medium for deep-fried chicken

Journal of Food Measurement and Characterization (2022)

-

Liquid-liquid phase separation and self-assembly of a lysine derivative Fmoc-L-lysine in water-DMSO mixtures

Polymer Journal (2021)

-

Intracellular self-assembly of supramolecular gelators to selectively kill cells of interest

Polymer Journal (2020)