Abstract

The effects of the ligand used for fabricating palladium (Pd)-incorporated porous polymer composites on their catalytic performances were examined from the perspective of catalysis sustainability. To perform this research, poly(amidoamine) (PAMAM) dendrimers, which were generation zero (G0) and higher, up to G6, the breakdown structure of G0 (that is, the half (G0h) and quarter (G0q)) and a typical small molecule (that is, N,N-dimethyl ethylenediamine (DMEn)) were utilized as ligands. The catalytic performances of the polymer composites were investigated using the aqueous Suzuki–Miyaura carbon cross-coupling reaction as a model reaction. Concerning the efficiency, recyclability and Pd-leaching behavior of the catalytic reaction, polymer composites that were fabricated with PAMAM dendrimers (that is, G1 and higher generations) proved to possess the potential for application as sustainable heterogeneous catalysts.

Similar content being viewed by others

Introduction

For catalyst sustainability, metal nanoparticles have become the focus of much research because most catalysts consist of precious metals (for example, Pt, Au and Pd) that are rare. Furthermore, the demand for these precious metal catalysts by the automotive, pharmaceutical and chemical industries continues to increase. A sustainable catalyst needs to be easily reusable without loss of activity. In addition, the catalyst should not result in contamination, such as metal residues that appear because of leaching. Catalysts that meet these two requirements are interesting and scientifically important for use in green and sustainable industrial applications. Palladium (Pd) nanoparticles (PdNPs) are widely studied because of their large surface to volume ratio and the intrinsic versatility of Pd as a catalyst.1, 2, 3, 4, 5 Several fabrication approaches for supported PdNPs have been reported.6, 7, 8, 9, 10, 11, 12, 13 In addition, preparation of these materials that can also be easily recycled have been reported. However, some of the supported PdNPs still result in Pd leaching,10, 11, 14, 15, 16, 17 and this needs to be solved in a rapid manner.

We previously reported a strategy for fabricating PdNPs that are incorporated in insoluble porous polymers.18, 19, 20 This method utilizes a polymerization-induced phase separation (PIPS) technique,21, 22, 23 whereby the PIPS could play two roles. The first is in producing porous polymer platforms and the second is in reducing Pd ions to zero-valent nanoparticles because of the action of radicals on the growing polymer chains.24, 25, 26, 27 The outline of the PIPS technique is shown in Scheme 1. An important part of the fabrication of supported PdNP catalysts using this strategy is the use of poly(amidoamine) (PAMAM) dendrimers (Gn; n, number of generation) as a ligand to stabilize the prepared PdNPs. When G3 and G4 were used, the morphology of the PdNPs was well tuned and intriguing catalysts were produced that were easily recycled with low Pd leaching.18, 20 In contrast, the use of a small ligand, such as N,N-dimethyl ethylenediamine (DMEn), resulted in the formation of a composite with aggregated PdNPs that exhibited considerable Pd leaching.20 From this comparison, the template effect of the PAMAM dendrimer was proposed for the solid composite systems.

The PdNPs in the composites prepared with generation 3 (G3) and generation 4 (G4) appear to interact with multiple dendrimer assemblies that are covalently tethered to the polymer network. This proposed structure is similar to that of the well-established dendrimer-stabilized nanoparticles.14, 15, 28, 29, 30 Here, questions are raised as to the origin of the behavior of the PAMAM dendrimers. For example, from a structural perspective, does using larger dendrimers, such as generation 5 or 6 (G5 or G6), follow the dendrimer-stabilized nanoparticle mechanism or that of the dendrimer-encapsulated nanoparticles?1, 2, 3, 4, 5, 31, 32, 33, 34, 35 In addition, does using smaller dendrimers, such as G1 or generation zero (G0), result in aggregated PdNPs? From the perspective of strict suppression of Pd leaching, what is the critical condition for the G3 or G4 ligand? To answer these questions, PAMAM dendrimers that are G0 and higher, up to G6, were used in this study. In addition, two mid-sized ligands (that is, half (G0h) and quarter (G0q)), which have a size that is in between that of G0 and DMEn, were investigated to provide deeper insight into the dendrimer template effect. Finally, by studying the effects of the ligand structure, we propose an approach for the fabrication of a sustainable metal nanoparticle catalyst that exhibits low metal leaching and high recyclability.

Experimental Procedure

Materials

The solvents used for the polymer syntheses (that is, N,N-dimethylformamide (DMF), methanol and diethyleneglycol dimethylether) were purchased from Kanto Chemical, Tokyo, Japan. Ethyleneglycol dimethacrylate, which is a crosslinkable monomer, was obtained from Kyoeisha (Osaka, Japan) and used as received. 2,2′-Azobisisobutyronitrile, which was used as a polymerization initiator, was purchased from Wako Pure Chemical Industries (Osaka, Japan) and used after recrystallization from an ethanol/water mixed solvent. 2-Methacryloyloxyethyl isocyanate was obtained from Showa Denko (Tokyo, Japan). The PAMAM dendrimers (Gn: generation n, from 0 to 6) in methanol solution, DMEn and palladium acetate (Pd(OAc)2) were purchased from Aldrich (St Louis, MO, USA).

Ligand monomers

PAMAM dendrimers (Gn) and DMEn were directly used as ligands. In addition, the G0q and G0h ligands were synthesized according to the reaction schemes shown in Supplementary Figure S1.36 The assignment of the chemical structures of G0q and G0h was confirmed by proton nuclear magnetic resonance analysis, as shown in Supplementary Figure S2. The proton nuclear magnetic resonance spectra were measured in CD3OD on a JOEL (Tokyo, Japan) JNM-LA300 instrument at 300 MHz. The ligand monomers, which have methacryloyl functional groups that can be polymerized, were synthesized according to a previously published procedure.18, 19, 20 In brief, a specific amount of the ligand (containing 497 μmol tertiary amine) was modified by 2-methacryloyloxyethyl isocyanate (equimolecular with the amino groups in the ligand) in 1 ml of DMF for 5 h at room temperature.

Synthesis of polymer composites

A Pd(OAc)2 solution in DMF (0.2 M, 3.3 ml) was added to a solution of the ligand monomer (containing 497 μmol tertiary amines) in DMF (1.0 ml), and the mixture was stirred for 30 min at room temperature. Then, this mixture was combined with the crosslinkable monomer ethyleneglycol dimethacrylate (adjusting the theoretical weight of resulted composites to 2.0 g), additional DMF (4.7 ml), methanol (2.3 ml), diethyleneglycol dimethylether (4.0 ml), and 2,2′-azobisisobutyronitrile (20 mg) in a medium-walled Pyrex polymerization tube. After nitrogen gas bubbling (30 min) of the resulting mixture, the tube was placed in an oil bath at 70 °C for 12 h. The obtained polymer composites were crushed in a mortar followed by Soxhlet extraction with tetrahydrofuran (2 h) and methanol (2 h). The collected extracts were analyzed to determine the loss of Pd by inductively coupled plasma atomic emission spectroscopy. The results suggested that there is almost no Pd content in the extracts, indicating that nearly all of the Pd ions were reduced to PdNPs. The remaining solid was dried in a vacuum oven (50 °C, 12 h) and then grinded and sized using a sieve. The 50–200 mesh (75–300 μm) particles were used in further studies.

Characterization of polymer composites

Field emission scanning electron microscopy was performed on a JEOL JSM-7500TFE. The polymer composites were immobilized on graphite paste, they were coated with a vacuum-deposited thin layer of Pt (thickness 0.5 nm) and were imaged using a 1.0 kV accelerating voltage. Transmission electron microscopy images of the Pd nanoparticles were obtained using a JEOL JEM-2200FS. The polymer composites were further ground in a mortar, and the ground materials were applied onto micro grids with a carbon membrane and imaged using 200 kV accelerating voltage. Nitrogen sorption analysis was carried out at 77 K using a BEL Japan (Osaka, Japan) Belsorp-mini instrument. The polymers were degassed for >7 h before measurement. Carbon monoxide adsorption analysis was performed using the dynamic pulse method with a BEL Japan BEL-METAL-3SP instrument.

Aqueous Suzuki–Miyaura carbon cross-coupling reactions

The catalytic performance of the polymers was investigated using the heterogeneous aqueous Suzuki–Miyaura coupling reaction. 4′-Bromoacetophenone (0.65 mmol), phenylboronic acid (0.86 mmol, 1.3 equiv.), potassium carbonate (2.0 mmol, 3.1 equiv.), the polymer composites as the catalyst (20.2 mg, ∼10−2 equiv. Pd) and water (12 ml) were added to a glass vial. The vial was capped with sealing tape and placed in a water bath (80 °C) with shaking. After 2 h, 20 ml of water (room temperature) was added to the mixture in the vial. Then, the catalyst was collected by filtration and sequentially washed with diethyl ether (10 ml × 5) and water (10 ml × 5). The combined filtrate was washed with water 3 times in a separatory funnel. Next, the organic phase was separated and dried with MgSO4, followed by concentrating in vacuo, yielding a solid that was analyzed to confirm the reaction yield by gas chromatography (GC). GC was performed on a Shimadzu gas chromatograph GC-2014 (Kyoto, Japan) equipped with a capillary column (30 m, 0.32 mm id., J&W Scientific DB-5, Santa Clara, CA, USA). The reaction yield was evaluated as the average value from at least three independent experiments.

Recycle test

After the aqueous Suzuki–Miyaura reaction was performed, the polymer composite was collected, washed, dried and reused for the next cycle. Each cycle followed the general procedure for the aqueous Suzuki–Miyaura coupling reactions described above.

Filtration test

The polymer composites (20.2 mg, 10−2 equiv.) were placed in a glass vial with 4′-bromoacetophenone (0.65 mmol), phenylboronic acid (0.86 mmol, 1.3 equiv.), potassium carbonate (2.0 mmol, 3.1 equiv.) and water (12 ml). The vial was capped with sealing tape and placed in a water bath (80 °C) with shaking for 6 min (5% of 2 h). Next, the composite, 4′-bromoacetophenone and the product (that is, 4-acetylbiphenyl (yield, up to 30%)) were removed by filtration. Based on GC analysis, the obtained filtrate did not contain 4′-bromoacetophenone or the product. The filtrate was added to a heated vial with 4′-bromoacetophenone (0.65 mmol) and phenylboronic acid (0.86 mmol) to perform the aqueous Suzuki–Miyaura reaction at 80 °C in a water bath for 2 h. After completion of the reaction, the same procedure mentioned in the general procedure for aqueous Suzuki–Miyaura reaction was performed. The pending particle size of filter papers is 1 μm. During the filtration, two pieces of filter paper were simultaneously used to prevent the small particles of the composites from remaining in the filtrate.

Results and discussion

PdNP morphology

The structures of the ligand monomers produced from each ligand in this study are shown in Scheme 2. Different generations of PAMAM dendrimers were selected as ligands. The Gn (n: from 0 to 6) PAMAM-based dendritic ligand monomer contains 2n+2−2 tertiary amines in the internal region and 2n+2 peripheral methacrylate functions tethered by 2n+2 urea linkages in the spherical molecule. Inspired by the fact that the PAMAM dendrimer template is effective at suppressing Pd aggregation and Pd leaching during catalytic use, which were not observed for the DMEn ligand,19, 20 small-molecule ligands (that is, G0h and G0q) were also studied. Because they are designed by reducing G0 to G0h and G0q structures, these structures are a bridging concept between dendrimers and a small molecule, such as DMEn. The chemical structure of G0q is the same as the peripheral branch of dendrimers, with only one additional amide group compared with DMEn. The ligand monomer G0h-m, which has the same structure as half of G0-m, has one tertiary amine and two methacrylate functions, whereas G0q-m (half of G0h-m) and DMEn-m have only one each of these two functional units.

The preparation of PdNP-porous polymer composites was accomplished using the same procedure as that described in a previous report,18, 19, 20 except that different ligands were used. After premixing with 662 μmol of Pd(OAc)2 in DMF, the ligand monomer (497 μmol, based on the tertiary amine unit), which was obtained from the equimolar reaction between terminal primary amines of the ligand and 2-methacryloyloxyethyl isocyanate, was copolymerized with a large excess of monomer (ethyleneglycol dimethacrylate that adjusts the theoretical weight of the resulting composite to 2.0 g) in a PIPS setup at 70 °C to produce PdNPs supported on a porous network polymer in which the Pd weight ratio was fixed at 3.5%. The resulting composite solids were sized to 75–300 μm after drying and used for subsequent structural analysis and catalytic studies.

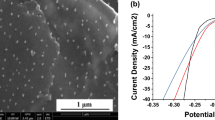

All of the resulting composites (that is, Gn-p (n: 0–6), G0h-p, G0q-p and DMEn-p) were confirmed to have highly porous structures (an advantage for use as a catalyst support) by nitrogen adsorption–desorption analysis and field emission scanning electron microscopy images (Table 1 and Supplementary Figure S3). The morphology of the embedded PdNPs in these composites is shown in Figure 1. The results indicate that size-tuned (5~10 nm in diameter) PdNPs were observed in G0h-p and G0q-p as well as in the dendrimer series composite Gn-p. However, DMEn-p exhibited an aggregation phenomenon. From G6-p to G0-p, the diameter of the PdNPs decreased slightly as the dendrimer generation decreased. The particles in G0h-p and G0q-p are slightly smaller than those in G0-p but still discrete. In the PAMAM dendrimer series composites, some nanoparticles that are <2 nm were observed and may correspond to a single encapsulated dendrimer.20

Transmission electron microscopy (TEM) images of palladium nanoparticles (PdNPs) in the polymer composites: (a) G6-p, (b) G5-p, (c) G2-p, (d) G1-p, (e) G0-p, (f) G0h-p, (g) G0q-p and (h) DMEn-p. The composites were applied onto micro-grids with the carbon membrane and imaged using 200 kV accelerating voltage.

Based on our preliminary understanding that comes from a comparison of the results for G4-p and DMEn-p reported previously,20 the aggregation of PdNPs during fabrication using the one-pot PIPS process can be better suppressed because of the special spherically steric structure of the dendrimer template rather than the small-molecule DMEn. However, the ligand monomers G0h-m and G0q-m also unexpectedly controlled the particle size. The interesting point of these two ligand monomers is that although they are not dendrimers, the molecular size of these two ligand monomers is more similar to DMEn-m, and their chemical constituents are the same as those in the G0-m fragment. This comparison reveals the most meaningful difference between G0q-p and DMEn-p. More important than the PAMAM dendrimers template, the transmission electron microscopy results suggest that the ligand containing -HN-CO-NH-, -CO-NH- and tertiary amine in one molecule appears to be important for suppressing PdNP aggregation for the fabrication of composites using our PIPS method. These exciting results might be helpful for an atomic-level understanding of the interaction between PdNPs and ligands.

In addition, the size of the PdNPs is ∼10 nm in diameter for G6-p and G5-p (Figure 1a and b). Because G6 and G5 are 6.7 and 5.4 nm in diameter, respectively (Table 2), because of their spherical spatial structure,1, 37 the obtained PdNPs are slightly too large to be stabilized by a single dendrimer molecule, the same also occurring for G4-p.20 This result indicates that even for higher-generation dendrimers (G6-p and G5-p), multiple distorted dendrimer molecules should work together to stabilize these PdNPs in the surrounding network polymer matrices. Based on the multiple dendrimer-stabilized nanoparticle concept,14, 15, 28, 29, 30 other generations of small dendrimers can also stabilize PdNPs after assembly in G3-p, G2-p, G1-p and G0-p. For G0h-p and G0q-p, the PdNPs are only surrounded by a small-molecule ligand.

Next, we studied the catalytic performance of these PdNPs. As a preliminary characterization, carbon monoxide adsorption analysis was performed on the polymer composites to detect the amount of Pd atoms that can adsorb carbon monoxide,38, 39 because the surface-exposed Pd atoms are closely related to the catalytic ability of the composites. As shown in Table 3, the results for all of the composites except DMEn-p were similar, ranging between 10 and 15%, enabling a simple comparison of their catalytic performances. For DMEn-p, 20% of the Pd atoms are exposed, slightly more than that in other composites. This result is reasonable because larger aggregated PdNPs are more difficult to be surrounded by the polymer network that consists of bicontinuous polymer fibers of a certain width.

Pd-leaching behavior

The use of this type of composite as a heterogeneous Pd catalyst for the aqueous Suzuki–Miyaura coupling reaction is important in the field of green and sustainable chemistry.40, 41, 42, 43 The reaction of phenylboronic acid and 4′-bromoacetophenone was selected as a model reaction. In previous studies, small-angle X-ray scattering data and scanning transmission electron microscopy–high-angle annular dark field observations confirmed the existence of two PdNP size distributions in a PAMAM dendrimer composite series that were located at ∼1 and 10 nm.18, 20 Here, a similar result was observed in the transmission electron microscopy images (for example, see Figure 1d). The composites that only contained small PdNPs encapsulated in a single dendrimer and were fabricated by controlling the Pd/ligand molar ratio are inactive for the Suzuki–Miyaura coupling reaction, and the composites barely adsorbed any carbon monoxide, consistent with previous results.20 This result is also consistent with that of the composites in this study. This result indicates that the reaction is primarily catalyzed by dendrimer-stabilized nanoparticles with a diameter of 5–10 nm that are partially exposed in the polymer network. All of the composites in this study are active catalysts, and their catalytic ability is shown in Figure 2, in which most of the reaction yields (purple cross) are >90%.

Catalytic performances of the polymer composites. Catalytic reaction (purple cross) conditions: 4′-bromoacetophenone (0.65 mmol), phenylboronic acid (0.86 mmol), composite (20.2 mg), K2CO3 (2.0 mmol) and water (12 ml), 80 °C, 2 h. For the detailed procedure of the filtration test (green triangle), see the main text. The reaction yields were evaluated as average values from at least three independent experiments. DMEn, N,N-dimethyl ethylenediamine. A full color version of this figure is available at Polymer Journal online.

Next, we determined whether these composites are strictly heterogeneous catalysts.44, 45, 46, 47 In other words, are there any leached catalytically active Pd atoms observed during the reaction process? To answer this question, we performed a filtration test to detect Pd leaching during the Suzuki–Miyaura coupling reaction. This test is a brief Pd-leaching test48, 49 whereby the catalytic reaction was performed in the filtrate that was obtained from the catalytic reaction with the composites for a short period of time (80 °C, 6 min). In the early stage of the prior reactions, a certain amount of products was generated, and their conversion yields were as high as 30% depending on the composite used. After the catalyst was filtered, the filtrate was agitated with the newly added substrate for 2 h at 80 °C.50 If there are leached Pd atoms in the filtrate, a reaction should occur. However, if no reaction is observed, no Pd has leached into the reaction medium. The results of the filtration test (green triangle) for these composites are also shown in Figure 2. When the G1 or larger dendrimers was used as a ligand, almost no reaction was observed with the filtrates. However, a reaction was observed with the filtrates when relatively small ligand monomers (that is, from G0-m to DMEn-m) were used for the composites, and the reaction yields decreased from G0q-p to G1-p.

Compared with the effect of the ligand structure on particle morphology (size) control or aggregation suppression during fabrication, the effect of the ligands on Pd leaching during the catalytic reaction is different. The obtained results suggest that the molecular size of the ligand is more important for stabilizing PdNPs and preventing Pd leaching during the catalytic event than the characteristics of the electron-donating group on the ligand. To understand this trend, the PdNPs may serve as a reservoir for delivering catalytically active Pd species to the reaction medium.51, 52, 53, 54, 55 As proposed by the Astruc group,14 after oxidative addition of ArX (Ar, aryl group; X, halogen atom) to the PdNP surface in the Suzuki–Miyaura reaction, ArPdnX, which is an extremely catalytically reactive Pd species, could escape from the parent PdNPs into the solution. Based on the multiple dendrimer-stabilized PdNP system described above, when the PAMAM dendrimers were used as a ligand, the PdNPs may have been surrounded by an extended thick layer consisting of electron-donating groups because of the assembly of the dendrimers (Figure 3a). This configuration creates a special zone where the leached Pd species could interact with the electron-donating groups and return to their mother PdNP.56 In contrast, the stabilization provided by the small ligands might act as points or a thin intermittent layer around the PdNPs. Therefore, the ability to trap the leached Pd would be reduced, resulting in irreversible Pd leaching to the reaction medium (Figure 3b). The spherically steric macromolecule dendrimers (G1 and the larger ones), which provide better fabrication of sustainable catalysts, are better at preventing Pd leaching compared with small-molecule ligands.

Catalysis recyclability

Based on the results discussed in the previous section, the Gn-p (n⩾1) composites are heterogeneous catalysts that exhibit almost no Pd leaching. However, the reaction with the catalysts using other small-molecule ligands, including G0-p, was significantly assisted by the action of the leached Pd species. In this section, catalytic recyclability of the composites was studied using the same model reaction described above (that is, the Suzuki–Miyaura reaction of 4′-bromoacetophenone and phenylboronic acid in water).

As shown in Table 4, all of the polymer composites exhibited durable catalyst properties. In the first 5 runs, the reaction yields were always >80% for all of the composites. For G0-p, G0h-p and G0q-p, the leached Pd species may assist the reaction to some extent, consistent with the previously reported results for DMEn-p.20 Therefore, their catalytic abilities may decrease after dozens or hundreds of runs. It is important to note that Pd leaching appears to be compatible with catalytic recyclability.14, 55 However, the heterogeneous catalysts based on the composites with the PAMAM dendrimer (G1 or the larger ones), which exhibited less leaching, are more important because these catalysts exhibit the potential for reuse over more catalytic runs without the loss of activity.

Conclusion

In this study, the choice of ligand for the fabrication of PdNP-incorporated porous polymer composites using a PIPS procedure was studied. The ligand is one of the most important factors for obtaining sustainable supported catalysts. The effects of the ligand structure on the catalytic performance (that is, efficiency, recyclability and Pd-leaching behavior) of the polymer composites were systematically investigated using the Suzuki–Miyaura reaction of 4′-bromoacetophenone and phenylboronic acid in water as a model reaction. The major results are described below.

-

1

During polymer fabrication using a one-pot PIPS process, all of the studied PAMAM dendrimers were able to stabilize the prepared PdNPs (5–10 nm) according to the multiple dendrimer stabilization mechanism despite a tiny fraction of the PdNPs (<2 nm) being encapsulated in a single dendrimer. These ligands are capable of suppressing aggregation of PdNPs during fabrication.

-

2

The G0h and G0q ligands are considered intermediate ones that bridge the structure gap between the PAMAM dendrimers and DMEn, which is a small molecule. The ligand monomers G0h-m and G0q-m (containing one -HN-CO-NH-, one -CO-NH- and one tertiary amine orderly within one molecule) were also capable of controlling the size of the PdNPs during fabrication.

-

3

However, different structural factors are required for the ligand with regard to the Pd-leaching behavior of the catalyst. PAMAM dendrimers (that is, G1 and larger ones) effectively suppressed the release of Pd atoms into the medium, whereas G0 and small ligands, including G0h and G0q, allowed Pd leaching to occur. The larger ligands may provide a thick layer containing many electron-donating groups surrounding the PdNPs after assembly. In contrast, the small ligands might afford only point-like or thin intermittent layers that have a reduced ability to trap the leached Pd, leading to irreversible Pd leaching.

In this manner, the specific ligand integration effects on the control of the PdNP morphology during fabrication and the suppression of Pd leaching during the catalytic reaction were determined. In conclusion, the polymer composites fabricated with the PAMAM dendrimer (G1 or the higher generations) are sustainable heterogeneous catalysts. Work is now in progress to explore the potential applicability of these polymer composite catalysts.

Schematic outline of the preparation of the microporous network polymers that contain palladium nanoparticles (PdNPs). A full color version of this figure is available at Polymer Journal online.

Cartoon and the corresponding chemical structure of the polymerizable ligand molecules used in this study. A full color version of this figure is available at Polymer Journal online.

References

Scott, R. W. J., Wilson, O. M . & Crooks, R. M. Synthesis, characterization, and applications of dendrimer-encapsulated nanoparticles. J. Phys. Chem. B 109, 692–704 (2005).

Chandler, B. D . & Gilbertson, J. D. Dendrimer-encapsulated bimetallic nanoparticles: synthesis, characterization, and applications to homogeneous and heterogeneous catalysis. Top. Organomet. Chem. 20, 97–120 (2006).

Astruc, D., Boisselier, E . & Ornelas, C. Dendrimers designed for functions: from physical, photophysical, and supramolecular properties to applications in sensing, catalysis, molecular electronics, photonics, and nanomedicine. Chem. Rev. 110, 1857–1959 (2010).

Bronstein, L. M . & Shifrina, Z. B. Dendrimers as encapsulating, stabilizing, or directing agents for inorganic nanoparticles. Chem. Rev. 111, 5301–5344 (2011).

Myers, V. S., Weir, M. G., Carino, E. V., Yancey, D. F., Pande, S . & Crooks, R. M. Dendrimer-encapsulated nanoparticles: new synthetic and characterization methods and catalytic applications. Chem. Sci. 2, 1632–1646 (2011).

Scott, R. W. J., Wilson, O. M . & Crooks, R. M. Titania-supported Au and Pd composites synthesized from dendrimer-encapsulated metal nanoparticle precursors. Chem. Mater. 16, 5682–5688 (2004).

Kahat, T., Goren, K . & Portnoy, M. Dendrons on insoluble supports: synthesis and applications. New J. Chem. 31, 1218–1242 (2007).

Scott, R. W. J., Sivadinarayana, C., Wilson, O. M., Yan, Z., Goodman, D. W . & Crooks, R. M. Titania-supported PdAu bimetallic catalysts prepared from dendrimer-encapsulated nanoparticle precursors. J. Am. Chem. Soc. 127, 1380–1381 (2005).

Gil-Moltó, J., Karlström, S . & Nájera, C. Di(2-pyridyl)methylamine–palladium dichloride complex covalently anchored to a styrene-maleic anhydride co-polymer as recoverable catalyst for C–C cross-coupling reactions in water. Tetrahedron 61, 12168–12176 (2005).

Inasaki, T., Ueno, M., Miyamoto, S . & Kobayashi, S. Polymer-incarcerated palladium with active phosphine as recoverable and reusable Pd catalyst for the amination of aryl chlorides. Synlett. 20, 3209–3213 (2007).

Ranganath, K. V. S., Kloesges, J., Schäfer, A. H . & Glorius, F. Asymmetric nanocatalysis: N-heterocyclic carbenes as chiral modifiers of Fe3O4/Pd nanoparticles. Angew. Chem. Int. Ed. 49, 7786–7789 (2010).

Kong, L., Lu, X., Bian, X., Zhang, W . & Wang, C. Constructing carbon-coated Fe3O4 microspheres as antiacid and magnetic support for palladium nanoparticles for catalytic applications. ACS Appl. Mater. Interfaces 1, 35–42 (2011).

Jin, M.-J . & Lee, D.-H. A practical heterogeneous catalyst for the Suzuki, Sonogashira, and Stille coupling reactions of unreactive aryl chlorides. Angew. Chem. Int. Ed. 49, 1119–1122 (2010).

Diallo, A. K., Ornelas, C., Salmon, L., Ruiz Aranzaes, J . & Astruc, D. "Homeopathic" catalytic activity and atom-leaching mechanism in Miyaura-Suzuki reactions under ambient conditions with precise dendrimer-stabilized Pd nanoparticles. Angew. Chem. Int. Ed. 46, 8644–8648 (2007).

Esumi, K., Isono, R . & Yoshimura, T. Preparation of PAMAM- and PPI-metal (silver, platinum, and palladium) nanocomposites and their catalytic activities for reduction of 4-nitrophenol. Langmuir 20, 237–243 (2004).

Gaikwad, A. V., Holuigue, A., Thathagar, M. B., ten Elshof, J. E . & Rothenberg, G. Ion- and atom-leaching mechanisms from palladium nanoparticles in cross-coupling reactions. Chem. Eur. J. 13, 6908–6913 (2007).

Fang, P.-P., Jutand, A., Tian, Z.-Q . & Amatore, C. Au-Pd core-shell nanoparticles catalyze Suzuki–Miyaura reactions in water through Pd leaching. Angew. Chem. Int. Ed. 50, 12184–12188 (2011).

Ogasawara, S . & Kato, S. Palladium nanoparticles captured in microporous polymers: a tailor-made catalyst for heterogeneous carbon cross-coupling reactions. J. Am. Chem. Soc. 132, 4608–4613 (2010).

Yang, Y., Ogasawara, S., Li, G . & Kato, S. Water compatible Pd nanoparticle catalysts supported on microporous polymers: their controllable microstructure and extremely low Pd-leaching behaviour. J. Mater. Chem. A 1, 3700–3705 (2013).

Yang, Y., Ogasawara, S., Li, G . & Kato, S. Critical effects of ligand integration in creating palladium-incorporated porous polymer composites. J. Phys. Chem. C 118, 5872–5880 (2014).

O’Connor, N. A., Paisner, D. A., Huryn, D . & Shea, K. J. Screening of 5-HT1A receptor antagonists using molecularly imprinted polymers. J. Am. Chem. Soc. 129, 1680–1689 (2007).

Urraca, J. L., Aureliano, C. S. A., Schillinger, E., Esselmann, H., Wiltfang, J . & Sellergren, B. Polymeric complements to the Alzheimer's Disease biomarker β-amyloid isoforms A β 1-40 and A β 1-42 for blood serum analysis under denaturing conditions. J. Am. Chem. Soc. 133, 9220–9223 (2011).

Hasegawa, G., Kanamori, K., Nakanishi, K . & Yamago, S. Fabrication of highly crosslinked methacrylate-based polymer monoliths with well-defined macropores via living radical polymerization. Polymer 52, 4644–4647 (2011).

Nakao, Y. Preparation and characterisation of noble metal solid sols in poly(methyl methacrylate). J. Chem. Soc. Chem. Commun. 826–828 (1993).

Yanagihara, N., Uchida, K., Wakabayashi, M., Uetake, Y . & Hara, T. Effect of radical initiators on the size and formation of silver nanoclusters in poly(methyl methacrylate). Langmuir 15, 3038–3041 (1999).

Zhang, Z . & Han, M. One-step preparation of size-selected and well-dispersed silver nanocrystals in polyacrylonitrile by simultaneous reduction and polymerization. J. Mater. Chem. 13, 641–643 (2003).

Aymonier, C., Bortzmeyer, D., Thomann, R . & Mülhaupt, R. Poly(methyl methacrylate)/palladium nanocomposites: synthesis and characterization of the morphological, thermomechanical, and thermal properties. Chem. Mater. 15, 4874–4878 (2003).

Gatard, S., Liang, L., Salmon, L., Ruiz, J., Astruc, D . & Bouquillon, S. Water-soluble glycodendrimers: synthesis and stabilization of catalytically active Pd and Pt nanoparticles. Tetrahedron Lett. 52, 1842–1846 (2011).

Ornela, C., Ruiz, J., Salmon, L . & Astruc, D. “Click” dendrimers: synthesis, redox sensing of Pd(OAc)2, and remarkable catalytic hydrogenation activity of precise Pd nanoparticles stabilized by 1,2,3-triazole-containing dendrimers. Chem. Eur. J. 14, 50–64 (2008).

Astruc, D., Ornelas, C., Diallo, A. K . & Ruiz, J. Extremely efficient catalysis of carbon-carbon bond formation using click dendrimer-stabilized palladium nanoparticles. Molecules 5, 4947–4960 (2010).

Zhao, M., Sun, L . & Crooks, R. M. Preparation of Cu nanoclusters within dendrimer templates. J. Am. Chem. Soc. 120, 4877–4878 (1998).

Balogh, L . & Tomalia, D. A. Poly(amidoamine) dendrimer-templated nanocomposites. 1. synthesis of zerovalent copper nanoclusters. J. Am. Chem. Soc. 120, 7355–7356 (1998).

Esumi, K., Suzuki, A., Aihara, N., Usui, K . & Torigoe, K. Preparation of gold colloids with UV irradiation using dendrimers as stabilizer. Langmuir 14, 3157–3159 (1998).

Yamamoto, K., Imaoka, T., Chun, W.-J., Enoki, O., Katoh, H., Takenaga, M . & Sonoi, A. Size-specific catalytic activity of platinum clusters enhances oxygen reduction reactions. Nat. Chem. 1, 397–402 (2009).

Kibata, T., Mitsudome, T., Mizugaki, T., Jitsukawa, K . & Kaneda, K. Investigation of size-dependent properties of sub-nanometer palladium clusters encapsulated within a polyamine dendrimer. Chem. Commun. 49, 167–169 (2013).

Tomalia, D. A., Baker, H., Dewald, J., Hall, M., Kallos, G., Martin, S., Roeck, J., Ryder, J . & Smith, P. A new class of polymers: starburst-dendritic macromolecules. Polym. J. 17, 117–132 (1985).

Heigl, N., Bachmann, S., Petter, C.H., Marchetti-Deschmann, M., Allmaier, G., Bonn, G.K . & Huck, C.W. Near-infrared spectroscopic study on guest-host interactions among G0-G7 amine-terminated poly(amidoamine) dendrimers and porous silica materials for simultaneously determining the molecular weight and particle diameter by multivariate calibration techniques. Anal. Chem. 81, 5655–5662 (2009).

Agostini, G., Pellegrini, R., Leofanti, G., Bertinetti, L., Bertarione, S., Groppo, E., Zecchina, A . & Lamberti, C. Determination of the particle size, available surface area, and nature of exposed sites for silica-alumina-supported Pd nanoparticles: a multitechnical approach. J. Phys. Chem. C 113, 10485–10492 (2009).

Agostini, G., Groppo, E., Piovano, A., Pellegrini, R., Leofanti, G . & Lamberti, C. Preparation of supported Pd catalysts: from the Pd precursor solution to the deposited Pd2+ phase. Langmuir 26, 11204–11211 (2010).

Yamada, Y. M. A., Sarkar, S. M . & Uozumi, Y. Self-assembled poly(imidazole-palladium): highly active, reusable catalyst at parts per million to parts per billion levels. J. Am. Chem. Soc. 134, 3190–3198 (2012).

Ornelas, C., Ruiz, J., Salmon, L . & Astruc, D. Sulphonated “click” dendrimer-stabilized palladium nanoparticles as highly efficient catalysts for olefin hydrogenation and Suzuki coupling reactions under ambient conditions in aqueous media. Adv. Synth. Catal. 350, 837–845 (2008).

Mejías, N., Pleixats, R., Shafir, A., Medio-Simón, M . & Asensio, G. Water-soluble palladium nanoparticles: click synthesis and applications as a recyclable catalyst in Suzuki cross-couplings in aqueous media. Eur. J. Org. Chem. 2010, 5090–5099 (2010).

Fujii, S., Matsuzawa, S., Nakamura, Y., Ohtaka, A., Teratani, T., Akamatsu, K., Tsuruoka, T . & Nawafune, H. Synthesis and characterization of polypyrrole-palladium nanocomposite-coated latex particles and their use as a catalyst for Suzuki coupling reaction in aqueous media. Langmuir 26, 6230–6239 (2010).

Balanta, A., Godard, C . & Claver, C. Pd nanoparticles for C-C coupling reactions. Chem. Soc. Rev. 40, 4973–4985 (2011).

Astruc, D. Palladium nanoparticles as efficient green homogeneous and heterogeneous carbon-carbon coupling precatalysts: a unifying view. Inorg. Chem. 46, 1884–1894 (2007).

Cho, J. K., Najman, R., Dean, T. W., Ichihara, O., Muller, C . & Bradley, M. Captured and cross-linked palladium nanoparticles. J. Am. Chem. Soc. 128, 6276–6277 (2006).

Shin, J. Y., Lee, B. S., Jung, Y., Kim, S. J . & Lee, S. Palladium nanoparticles captured onto spherical silica particles using a urea cross-linked imidazolium molecular band. Chem. Commun. 2007, 5238–5240 (2007).

Okamoto, K., Akiyama, R., Yoshida, H., Yoshida, T . & Kobayashi, S. Formation of nanoarchitectures including subnanometer palladium clusters and their use as highly active catalysts. J. Am. Chem. Soc. 127, 2125–2135 (2005).

Wang, S., Zhao, Q., Wei, H., Wang, J.-Q., Cho, M., Cho, H. S., Terasaki, O . & Wan, Y. Aggregation-free gold nanoparticles in ordered mesoporous carbons: toward highly active and stable heterogeneous catalysts. J. Am. Chem. Soc. 135, 11849–11860 (2013).

GC analysis for the filtrates indicated that the water-insoluble substances and the reaction product could also be filtered out completely

Davies, I. W., Matty, L., Hughes, D. L . & Reider, P. J. Are heterogeneous catalysts precursors to homogeneous catalysts? J. Am. Chem. Soc. 123, 10139–10140 (2001).

Cassol, C. C., Umpierre, A. P., Machado, G., Wolke, S. I . & Dupont, J. The role of Pd nanoparticles in ionic liquid in the Heck reaction. J. Am. Chem. Soc. 127, 3298–3299 (2005).

Phan, N. T. S., Van der Sluys, M . & Jones, C. W. On the nature of the active species in palladium catalyzed Mizoroki-Heck and Suzuki-Miyaura couplings-homogeneous or heterogeneous catalysis, a critical review. Adv. Synth. Catal. 348, 609–679 (2006).

Durand, J., Teuma, E . & Gómez, M. An overview of palladium nanocatalysts: surface and molecular reactivity. Eur. J. Inorg. Chem. 2008, 3577–3586 (2008).

de Vries, J. G. A unifying mechanism for all high-temperature Heck reactions. The role of palladium colloids and anionic species. Dalton Trans. 2006, 421–429 (2006).

Bernechea, M., de Jesús, E., López-Mardomingo, C . & Terreros, P. Dendrimer-encapsulated Pd nanoparticles versus palladium acetate as catalytic precursors in the Stille reaction in water. Inorg. Chem. 48, 4491–4496 (2009).

Acknowledgements

Some of the transmission electron microscopy (TEM) images were obtained at the Graduate School of Materials Science, Nara Institute of Science and Technology, with the support of Kyoto-Advanced Nanotechnology Network. We thank Professor Atsushi Ikeda for helpful discussions. We also thank Dr Masafumi Uota for helpful discussions and technical support. We gratefully acknowledge analytical support from the Analysis Center at the DIC Corporation. This research was partially supported by a Grant-in-Aid for Scientific Research (C) (No. 23550172) from the Ministry of Education, Culture, Sports, Science and Technology, Japan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Yang, Y., Ogasawara, S., Li, G. et al. Dendrimer-stabilized Pd polymer composites: drastic suppression of Pd leaching and fine catalysis sustainability. Polym J 47, 340–347 (2015). https://doi.org/10.1038/pj.2014.133

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2014.133

This article is cited by

-

Visualization of Nanomechanical Properties of Polymer Composites Using Atomic Force Microscopy

Polymer Journal (2023)

-

Preparation of metal-polymer nanocomposites by chemical reduction of metal ions: functions of polymer matrices

Journal of Polymer Research (2018)

-

Thermo-responsive Ruthenium Dendrimer-based Catalysts for Hydrogenation of the Aromatic Compounds and Phenols

Journal of Inorganic and Organometallic Polymers and Materials (2016)