Abstract

The structure, thermal properties and surface wettability of a novel alternating poly(VCN-alt-FAVE8) copolymer based on vinylidene cyanide (VCN) and perfluorooctyl ethyl vinyl ether (FAVE8) were investigated via both temperature-variable wide-angle X-ray powder diffraction (WAXD) and thin-film WAXD using a small angle incidence synchrotron radiation source, differential scanning calorimetry and contact angle measurements, respectively. The results of the WAXD and thin-film WAXD indicated that the alternating copolymer possessed a smectic liquid-crystalline phase at ambient temperature with a couple of fluoroalkyl side chains forming a bilayer with a 3.24 nm spacing and that the fluoroalkyl side chains in a thin-film on a Si wafer align perpendicularly to the surface. The isotropization temperature of the alternating copolymer was 150 °C, which was higher than the 29.5 °C for the poly(FAVE8) homopolymer. The spin-coated poly(VCN-alt-FAVE8) copolymer thin-film yielded high static contact angles for both water and oil similar to those for poly(perfluorooctyl ethyl acrylate), which is known as a superhydrophobic polymer. Dynamic contact angle and X-ray photoelectron spectroscopy measurements in both the dry and hydrated states suggested that the polar cyano and ether groups are enriched at the surface in the wet state, and this reorganization of the surface polar groups caused a large hysteresis of the contact angle.

Similar content being viewed by others

Introduction

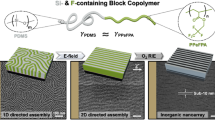

Fluorinated polymers1, 2, 3, 4, 5 are interesting materials thanks to their outstanding properties, such as their thermal stability, chemical inertness (to solvents, oils, water, acids and bases), low refractive index, permittivity, dissipation factor and water absorptivity, in addition to their excellent weatherability, durability and resistance to oxidation. Actually, two families of fluorinated polymers can be considered: (i) those where the fluorinated groups are located in the polymer backbone, which are chemically inert, thermally stable and have low refractive index and low dielectric constant, and (ii) those containing a fluorinated dangling group that enhances the surface properties. Of these exceptional characteristics, the surface properties are featured prominently. It is generally claimed that fluorinated side groups such as C8F17 have the optimal surface properties/price ratio, although some compounds that contain C8F17, for example, perfluorooctanoic acid, perfluorooctane sulfonic acid and their derivatives, are now criticized as environmental and health risks.6 Of the numerous homopolymers based on methacrylates,7, 8, 9, 10, 11, 12, 13 vinyl ethers14, 15, 16, 17 and styrenes18, 19, 20, 21 bearing such a group, polyacrylates with a perfluorooctyl ethyl side chain, poly(FA-C8), possess excellent surface properties because the side chains form a highly ordered lamellar phase with the C8F17 chains aligned perpendicular to the surface.22, 23, 24, 25, 26 However, their thermal stabilities are not high. In general, copolymerization methods have been used to combine the advantages of two or more monomers and improve the properties of a polymer. Thus, it was of interest to synthesize original copolymers bearing such a fluorinated group. The cationic polymerization of a fluorinated vinyl ether, such as 1H,1H,2H,2H-perfluorooctyl vinyl ether, was reported by Vandooren et al.16, 17 This reaction was initiated using a HI/ZnI2 system, which formed living poly(ether)s that bore fluoroalkyl side groups. A few copolymers based on perfluorooctyl ethyl vinyl ether (FAVE8) and ethylene,27 tert-butyl 2-trifluoromethyl acrylate,28 vinylidene cyanide (VCN)29 or chlorotrifluoroethylene30 have been reported. These last two copolymers are alternated with the last one showing remarkable thermal and superhydrophobic properties.

The objective of this study was to underline the unique structure, thermal properties and surface properties of an alternating VCN and FAVE8 copolymer, designated as the poly(VCN-alt-FAVE8) copolymer. To reach this objective, synchrotron variable-temperature wide-angle X-ray diffraction (WAXD), thin-film WAXD, differential scanning calorimetry (DSC), contact angle and X-ray photoelectron spectroscopy (XPS) measurements were performed.

Experimental Procedures

Materials

The synthetic schemes for three polymers with fluoroalkyl (Rf) side-chain group, a poly(FAVE8) homopolymer14 an alternating poly(VCN-alt-FAVE8) copolymer,28 and a poly(FA-C8) homopolymer,22 have been reported elsewhere, and their chemical structures are shown in Scheme 1.

Methylene iodide (CH2I2), hexadecane (C16H34) and dimethylformamide were purchased from Tokyo Chemical Industry Co., Ltd, Tokyo, Japan, and AK-225, a mixture of 1,1-dichloro-2,2,3,3,3-pentafluoropropane and 1,3-dichloro-1,1,2,2,3-pentafluoropropane, was purchased from Asahi Glass Co., Tokyo, Japan. These materials were used as received. The water for the contact angle measurement was purified using a NanoPure Water system (Millipore, Inc., Billerica, MA, USA).

Measurements

DSC was performed using a Diamond DSC (PerkinElmer Inc., Waltham, MA, USA) under a nitrogen flow at a scanning rate of 10 °C min–1 to estimate the glass transition temperature (Tg) and the transition temperatures for the alternating poly(VCN-alt-FAVE8) copolymer and poly(FAVE8) homopolymer. Thermograms from the second heating and cooling cycle were used to estimate these values.

X-ray photoelectron spectroscopy (XPS) measurements were conducted using an XPS-APEX (Physical Electronics Inc., Chanhassen, MN, USA) at ∼10−9 Pa with a monochromatic Al Kα X-ray source operated at 300 W. All of the XPS data were collected using a take-off-angle of 45° and a low-energy (25 eV) electron flood gun to minimize the sample charging. The survey spectra (0–1000 eV) and high-resolution spectra for the C1s, O1s, N1s and F1s regions were acquired using pass energies of 100 and 25 eV for the analyzer, respectively. An X-ray beam was focused on an area with a diameter of ca. 1.2 mm. In the hydrated state, the samples were immersed in pure water for 2 h, dried under vacuum in an auxiliary deaeration chamber of the XPS machine and then immediately measured.

The contact angles for water, methylene iodide (CH2I2) and hexadecane (C16H34) (each droplet had a 2 μl volume) at 25 °C were recorded using the drop shape analysis system DSA 10 Mk2 (KRÜSS Inc., Hamburg, Germany) and Theta T-200 Auto 3 (Biolin Scientific Inc., Västra Frölunda, Sweden) equipped with a video camera. A sample on an inclinable plane stage was tilted until a 50 μl water droplet began to slide down the sample surface, and the advancing contact angle (θA), receding contact angle (θR) and sliding angle (θS) were determined.

The molecular aggregation states were investigated via synchrotron WAXD measurements for powdered samples using a large Debye–Scherrer camera and imaging plate detector with a BL02B2 beamline from JASRI/SPring-8, Hyogo, Japan. The wavelength (λ) of the incident X-rays was 0.100 nm, and the exposure time was 300 s. The scattering vector, q, is defined as 2π(s1–s0): where s0 is a vector parallel to the incident X-ray, s1 is parallel to the diffracted X-ray and |s0|=|s1|=1/λ. Therefore, the q value, i.e., the norm of q, is equal to (4π/λ) sinθ, where θ is the Bragg angle.

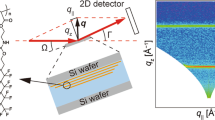

Thin film WAXD with small incidence angle (thin-film WAXD) measurements of thin-films on a Si wafer were performed on the BL13XU and BL03XU beamlines at the SPring-8 synchrotron facility (Japan Synchrotron Radiation Research Institute) using an incident X-ray with a wavelength λ of 0.1 nm and an incident angle, αi, of 0.16°. Both in-plane and out-of-plane diffractions from the sample were detected using a scintillation counter. The data were collected at 0.1° intervals, and the irradiation time at each point was 3.0 s. The sample cell was wrapped with a polyimide (KAPTON) dome filled with helium gas to prevent the oxidation of the sample during the measurements. The data were collected by subtracting the intensity of the background Si wafer from the sample intensity and then analyzed. All of the thin-film WAXD measurements were performed at room temperature. For thin-film WAXD, the scattering vector, q, is defined using the same equation as the usual WAXD configuration. Therefore, the components of the scattering vector q in both the vertical direction (out-of-plane direction) and horizontal direction (in-plane) are represented by qz=(2π/λ)sin(αf+αi) and qxy=(2π/λ)sinθxy, respectively. Herein, the αf and θxy are defined as the angles between the diffraction beam and substrate surface and between the projections of the incident and diffraction beams on the substrate, respectively.

The thin polymer films were prepared on Si wafers by spin coating from the AK-225 (Asahi Glass CO., Tokyo, Japan) solutions of both the poly(FAVE8) and poly(FA-C8) and simple solvent casting from the dimethylformamide solution of the poly(VCN-alt-FAVE8) copolymer before drying in vacuo.

Results and discussion

Thermal properties assessed by DSC and WAXD

The DSC thermograms for the poly(FAVE8) homopolymer and poly(VCN-alt-FAVE8) copolymer are shown in Figure 1a. Interestingly, poly(VCN-alt-FAVE8) possessed a much higher transition temperature than both poly(FAVE8) and poly(FA-C8). The isotropization temperatures (Ti) of poly(FAVE8) and poly(FA-C8) homopolymer are 29.5 and 79.0 °C, respectively, while that of the poly(VCN-alt-FAVE8) copolymer is 178 °C. These values were assessed based on the peak position of the endothermic curve. The thermogram of the poly(FAVE8) homopolymer only possessed one peak in both the cooling and heating processes. By contrast, the thermograms of the alternating copolymer are complex; only two exothermic peaks appeared during the cooling process at 170.8 (T1C) and 111.0 °C (T2C), while an endothermic step corresponding to a glass transition (Tg) at 60.7 °C and three endothermic peaks at 103.6 (T1H), 147.0 (T2H) and 178.0 °C (T3H) appeared in the subsequent heating process. The transition enthalpy at T3H (ΔH3H=1.78 kJ mol–1) corresponded to that at T1C (ΔH1C=1.80 kJ mol–1). However, the sum of ΔH1H (1.07 kJ mol–1) at T1H and ΔH2H (2.78 kJ mol–1) at T2H was not equal to ΔH1C (1.81 kJ mol–1) at T1C, that is, ΔH1H+ΔH2H>ΔH1C. This result indicates that an exothermic transition (crystallization) occurred between T1H and T2H. Figure 1b shows the DSC thermogram for the heating process of an annealed alternating copolymer that had been cooled from 200 to 120 °C, where it was maintained for 2 h. This DSC thermogram displays only two endothermic peaks: a broad peak at 139 °C (ΔH=5.19 kJ mol–1) and a sharp one at 177.8 °C (ΔH=1.78 kJ mol–1). These findings also demonstrate that crystallization occurs at 120 °C during the annealing process and that the phase below T1C when cooled at a rate of 10 °C min–1 is metastable and yields a Tg of 60.7 °C. These thermodynamic data are summarized in Table 1.

(a) Differential scanning calorimetry (DSC) thermograms of poly(FAVE8) (perfluorooctyl ethyl vinyl ether polymer; dotted lines (1) and (2)) and the poly(VCN-alt-FAVE8) (alternating vinylidene cyanide (VCN) and perfluorooctyl ethyl vinyl ether (FAVE8)) copolymer (solid lines (3) and (4)) from the second heating and cooling cycle. The left and right arrows attached to each thermogram represent the cooling and heating process, respectively; (b) DSC thermogram (curve (5)) of the thermally annealed poly(VCN-alt-FAVE8) copolymer, which was cooled from 190 to 120 °C and kept at 120 °C for 2 h.

WAXD intensity profiles for powdered poly(VCN-alt-FAVE8) copolymer samples obtained during the heating process are shown in Figure 2. These samples were prepared by cooling isotropic melts at a rate of 10 °C min–1 to form the metastable phase observed in the DSC measurement. In small q regions, several sharp diffractions appear at q=1.94, 3.90 and 5.90 nm−1, while a broad diffraction appears at approximately q=12 nm−1 in large q regions. The d-spacings of these sharp diffractions are 3.24, 1.61 and 1.07 nm, while that of the broad one is 0.53 nm. These data indicate that the poly(VCN-alt-FAVE8) copolymer forms a smectic liquid-crystal (SX1) as the metastable phase. The sharp diffractions can be assigned to the smectic layer, and the broad diffraction corresponds to the average lateral distance between neighboring Rf mesogens with lateral, liquid-like packing in the smectic layer. The layer spacing, 3.24 nm, is approximately twice as wide as the side-chain length and acts as both a mesogen and spacer, which indicates that the smectic layer was formed from a couple of fluoroalkyl (Rf) side-chain groups, that is, bilayer of the Rf side chains. This layered structure is similar to that observed for other polymers with the same Rf group as reported previously.22, 23, 24, 25, 26 In this bilayer, it is reasonable to assume that the Rf side chain aligns almost parallel to the layer normal, and the main chains are segregated between bilayers similarly to the smectic phases observed for other side-chain liquid-crystalline polymers.31, 32

The profile changed drastically on increasing the temperature to 130 °C. Some broad diffractions overlapped with the sharp layer diffraction at both q=3.9 nm–1 and q=ca.12 nm–1. Above 160 °C, these overlapping diffractions disappeared, while the sharp layer diffractions shifted to the wide-angle region and decreased in intensity. Finally, the sharp diffractions disappeared completely at 190 °C. These changes agree well with those observed in the DSC heating thermogram shown in Figure 1a. The overlapping diffractions can be assigned to the crystal phases that appear upon thermal annealing. Both the sharp diffraction in the small angle region (2.98 nm) and the broad diffraction in the wide angle region (0.57 nm) were observed above 160 °C, which indicates that a smectic phase appears during the heating process between 160 and 170 °C. When compared with the DSC thermograms, this phase corresponded to both the one present between 160 and 175 °C during the heating process and the one observed upon cooling from 170 to 140 °C. This phase gradually transformed into the SX1 phase during the cooling process from 140 °C as observed in the DSC thermogram. Therefore, the smectic phase can be identified as a stable smectic phase (SX2) that differs from SX1. It was also observed that the metastable SX1 and stable SX2 are rather unusual because the layer spacing decreased with the transition from SX1 to SX2 (that is, 3.24–2.98 nm) upon heating. In addition, the layer spacing continuously increases in typical stable smectic liquid-crystals and, in some cases, discontinuously increased at a transition, for example, those observed in the smectic C phase and the smectic C to A transition.33

Thin-film WAXD with small-angle incidence (thin-film WAXD) measurements

The bulk structures of the poly(FAVE8), poly(VCN-alt-FAVE8) and poly(FA-C8) thin-films were investigated via both the in-plane and out-of-plane thin-film WAXD measurements with an incident angle, αi, of 0.16.34 Figure 3 shows the thin-film WAXD profiles for the thin-films of these three polymers. The poly(FAVE8) and poly(FA-C8) exhibit similar profiles with sharp diffractions for the out-of-plane geometry at qz=1.98, 3.94, 5.91 and 9.84 nm–1 for poly(FA-C8) and qz=2.29 and 4.54 nm–1 for poly(FAVE8) and a broader diffraction at qxy=12.5 nm–1 for the in-plane geometry. These statements indicate that both polymers form smectic B (SB) or crystalline B phases and that the layers align almost perfectly parallel to the substrate. Moreover, the fact that poly(FAVE8) exhibited only first- and second-order layer diffractions, while poly(FA-C8) showed first-, second-, third- and fifth-order diffractions (We could not find the fourth-order diffraction in our experiments. It can be attributed to an extinction rule. In other words, the structure factor of this bilayer structure becomes zero around the position of the fourth-order diffraction.) indicates that the layer order is lower for poly(FAVE8) than for poly(FA-C8).

Thin film wide-angle X-ray diffraction intensity profiles for poly(FA-C8) (polyacrylates with a perfluorooctyl ethyl side chain; lower), poly(FAVE8) (perfluorooctyl ethyl vinyl ether polymer; middle) and the poly(VCN-alt-FAVE8) (alternating vinylidene cyanide (VCN) and perfluorooctyl ethyl vinyl ether (FAVE8)) copolymer (upper) for the (a) in-plane and (b) out-of-plane geometry.

However, the alternating copolymer thin-film possessed three sharp peaks at qz=1.97, 3.94 and 5.93 nm–1 for the out-of-plane geometry and a broad diffraction at qxy=ca. 12 nm–1 for the in-plane geometry. These diffractions were assigned to those observed for the SX1 phase in the powdered samples. The geometry of both the layer diffraction and the outer broad diffraction demonstrates that the normal of the smectic layer and the Rf side chains both align perpendicular to the substrate.

The reason that the cast thin-films of the poly(VCN-alt-FAVE8) copolymer did not form a higher-ordered smectic phase (SB phase) could be because of the low mobility in the main chain due to the bulkiness and/or strong dipole–dipole interactions of the cyano groups, which also produces a higher isotropization temperature. In fact, the bulkiness of any side group attached to the main chain increases the isotropization temperature as reported for a methacrylate polymer with the same Rf, where the methyl group also reduced the chain mobility.22 Furthermore, strong cooperative interactions between CN dipoles were indicated by the dielectric relaxation measurements for similar alternated copolymers of VCN and vinyl acetate35 and may also decrease the chain mobility.

Contact angle measurements

The water repellency of the poly(VCN-alt-FAVE8) thin-film can be observed from the contact angles of several droplets. Table 2 lists the water, CH2I2 and C16H34 static contact angles and the surface-free energies for the poly(VCN-alt-FAVE8) thin-film and poly(FA-C8) spin-coated thin-film. Figure 4 shows the pictures of the water, CH2I2 and C16H34 static contact angles for the poly(VCN-alt-FAVE8) copolymer thin-film. The static water contact angle was 110°, which is larger than 90° but slightly smaller than the 119° for poly(FA-C8). In other words, the hydrophobicity of the poly(VCN-alt-FAVE8) thin-film surface is sufficiently high but is still slightly lower than that of poly(FA-C8). The same situation occurred when using C16H34 as the probing liquid. In addition, the surface-free energy of the poly(VCN-alt-FAVE8) thin-film, as estimated by the Owens–Wendt equation (see equation below) from water and CH2I2,36 was slightly higher than that of the spin-coated poly(FA-C8) thin-film.

Herein, θL is the static contact angle while both γsd and γsp and both γLd and γLp represent the disperse and polar components of the surface free energy for the polymers and each contacting liquid, respectively. γs is defined as γsd+γsp. The values for γsd and γsp are listed in Table 2. The value of γs for the poly(VCN-alt-FAVE8) copolymer is 2.9 mN m–1 higher than that of the poly(FA-C8) homopolymer, where the contributions of the disperse and polar components are ca. 60% and 40%, respectively. The contribution of the polar component is relatively large compared with the disperse component. Therefore, the increase in γs can be attributed to the strong dipole–dipole interactions between the CN groups and the lower-ordered smectic structure and lower orientation of the Rf group in the poly(VCN-alt-FAVE8) copolymer compared with the SB phase of poly(FA-C8).13, 25, 26

The dynamic contact angles of both poly(VCN-alt-FAVE8) and poly(FA-C8) thin-films (the latter being regarded as the reference) are summarized in Table 3 and shown in Figure 5. A sliding water droplet on the poly(VCN-alt-FAVE8) copolymer thin-film formed an asymmetric shape with a high θA and low θR. By contrast, a water droplet on the poly(FA-C8) spin-coated thin-film started sliding and maintained both high θA and θR when the film was tilted to θS=12°. The contact angle hysteresis, expressed as θA−θR for the water droplets was quite different. In the case of the poly(FA-C8) spin-coated thin-film, the value was 25° whereas that of the poly(VCN-alt-FAVE8) spin-coated thin-film it was 84°. These results suggest that the outermost surface structure changed after exposure to water.37, 38, 39, 40, 41

Photographs of the water droplets on spin-cast films of the poly(FA-C8) (polyacrylates with a perfluorooctyl ethyl side chain) homopolymer (left) and poly(VCN-alt-FAVE8) (alternating vinylidene cyanide (VCN) and perfluorooctyl ethyl vinyl ether (FAVE8)) copolymer (right) for the dynamic contact angle and sliding angle measurements.

The atomic composition at the surface of the spin cast films measured by XPS in both the dry and pseudo-hydrated states also supported this model (Figure 6). From the XPS characterization, the surface atomic ratios for C1s/O1s/F1s/N1s in the poly(VCN-alt-FAVE8) copolymer under dry conditions were estimated at 0.46/0.06/0.45/0.04, which corresponds to the theoretical atomic composition of the copolymer (C/O/F/N=0.45/0.03/0.46/0.06). However, the ratio of the F1s peaks significantly decreased, while the ratios of the N1s and O1s spectra increased after immersion in pure water for 2 h. The C/O/F/N ratio in the wet state was 0.59/0.14/0.14/0.13. These XPS results show that the O and N atom compositions increased after contacting water, which suggests that a reorientation of the polar groups (cyano and ether group) occurred in the outermost surface.

X-ray photoelectron spectroscopy spectra of the poly(VCN-alt-FAVE8) (alternating vinylidene cyanide (VCN) and perfluorooctyl ethyl vinyl ether (FAVE8)) copolymer in the (1) dry and (2) pseudo-hydrated states. (a) Survey scan spectrum and (b) high-resolution spectra around the C1s peak. The peak assignments for the C atoms are inserted in the spectra.

Conclusions

The structural and thermal properties of a novel alternating copolymer based on vinylidene cyanide and perfluorooctyl ethyl vinyl ether, the poly(VCN-alt-FAVE8) copolymer, were investigated via synchrotron WAXD, thin-film WAXD and DSC, and the surface properties of the spin-coated thin-film were measured using contact angle and XPS. Both temperature-variable WAXD and DSC measurements demonstrated that the alternating copolymer showed some evolution upon heating: metastable smectic (SX1) and stable smectic (SX2) phases formed during the heating process after first cooling from the isotropic phase at 10 °C min–1. These smectic phases had a bilayer structure with a d-spacing corresponding to the length of a pair of the Rf side-chain groups. Thin film WAXD measurements for the thin-film on a Si wafer indicated that the alternating copolymer produced the SX1 phase at ambient temperature and both the layers of the normal and Rf group aligned perpendicularly to the substrate similarly to poly(FAVE8) and poly(FA-C8). Static water and oil contact angles of the poly(VCN-alt-FAVE8) copolymer thin-films were ca. 110 and ca. 76°, respectively, and indicated that the surface was both hydrophobic and oleophilic. However, the receding contact angle and sliding angle in the dynamic contact angle measurements were 30 and >80°, respectively, which is clear evidence of a change in the surface state after contacting water. XPS spectroscopy in both the dry and hydrated state also suggested that the polar CN group gathered on the outermost surface of the thin-films upon contact with water, which created this large hysteresis in the dynamic contact angle.

Chemical structures of the fluoroalkyl side chain polymers used in this study.

References

Feiring, A. E. in Organofluorine Chemistry: Principles and Commercial Applications (eds Banks R. E., Smart B. E., Tatlow J. C., Ch. 15, 339–352 (Plenum Press, New York, NY, USA, 1994).

Chuvatkin, N. N. & Yu, I. in Modern Fluoropolymers ed. Scheirs J., Ch. 9, 191–207 (John Wiley and Sons Ltd., New York, NY, USA, 1997).

Thomas, R. R. in Fluoropolymers 2: Properties eds Hougham G., Cassidy P. E., Johns K., Davidson T., Ch. 4, 47–65 (Kluwer/Plenum, New York, NY, USA, 1999).

Ebnesajjad, S. in Fluoroplastics Vol. 1: Non-Melt Processible Fluoroplastics 23–31 (Plastics Design Library, Norwich, NY, USA, 2000).

Ameduri, B. & Boutevin, B. in Well-Architectured Fluoropolymers: Synthesis, Properties and Applications 187–222 (Elsevier, Amsterdam, the Netherlands, 2004).

Zaggia, A. & Ameduri, B. Recent advances on synthesis of potentially non-bioaccumulable fluorinated surfactants. Curr. Opin. Colloids Interface Sci. 17, 188–195 (2012).

Shimizu, T., Tanaka, Y., Kutsumizu, S. & Yano, S. Ordered structures of poly (1 H, 1 H,2H,2Hperfluorodecyloi-substituted acrylate)s. Macromol. Symp. 82, 173–184 (1994).

Castelvetro, V., Aglietto, M., Ciardelli, F., Chiantore, O. & Lazzari, M. Structure control, coating properties, and durability of fluorinated acrylic-based polymers. J. Coating Technol. 74, 57–66 (2001).

Belfield, K. D. & Abdel-Sadek, G. G. Synthesis and characterization of fluorinated terpolymers. Polym. Prepr. 43, 588–589 (2002).

Park, I. J., Lee, S. B. & Choi, C. K. Surface properties of the fluorine-containing graft copolymer of poly((perfluoroalkyl)ethyl methacrylate)-g-poly(methyl methacrylate). Macromolecules 31, 7555–7558 (1998).

Hayakawa, Y., Terasawa, N., Hayashi, E. & Abe, T. Synthesis of novel polymethacrylates bearing cyclic perfluoroalkyl groups. Polymer (Guildf) 39, 4151–4154 (1998).

de Crevoisier, G., Fabre, P., Liebler, L., Tencé-Girault, S. & Corpart, J. M. Structure of fluorinated side-chain smectic copolymers: role of the copolymerization statistics. Macromolecules 35, 3880–3888 (2002).

Honda, K., Morita, M., Sakata, O., Sasaki, S. & Takahara, A. Effect of surface molecular aggregation state and surface molecular motion on wetting behavior of water on poly(fluoroalkyl methacrylate) thin films. Macromolecules 43, 454–460 (2010).

Höpken, J., Möller, M., Lee, M. & Percec, V. Synthesis of poly(viny1 ether)s with perfluoroalkyl pendant groups. Makromol. Chem. 193, 275–284 (1992).

Choi, W. O., Sawamoto, M. & Higashimura, T. Living cationic homo- and copolymerizations of vinyl ethers bearing a perfluoroalkyl pendant. Polym. J. 20, 201–210 (1988).

Vandooren, C., Jérôme, R. & Teyssié, P. Coupling of living polystyryllithium anions and living polyethyl vinyl ether cations. Polym. Bull. 32, 387–393 (1994).

Vandooren, C. Cationic polymerization of fluorinated vinyl ethers, PhD Dissertation, (University of Liège,, Belgium, 1994).

Hirao, A., Koide, G. & Sugiyama, K. Synthesis of novel well-defined chain-end- and in-chain-functionalized polystyrenes with one, two, three, and four perfluorooctyl groups and their surface characterization. Macromolecules 35, 7642–7651 (2002).

Höpken, J. & Möller, M. Low surface energy polystyrene. Macromolecules 25, 1461–1467 (1992).

Bouteiller, V., Garnault, A. M., Teyssié, D., Boileau, S. & Möller, M. Synthesis, thermal and surface characterization of fluorinated polystyrenes. Polym. Int. 48, 765–772 (1999).

de Crevoisier, G., Fabre, P., Corpart, J. M. & Liebler, L. Switchable tackiness and wettability of a liquid crystalline polymer. Science 285, 1246–1249 (1999).

Volkov, V. V., Plate, N. A., Takahara, A., Kajiyama, T., Amaya, N. & Murata, Y. Aggregation state and mesophase structure of comb-shaped polymers with fluorocarbon side groups. Polymer (Guildf) 33, 1316–1320 (1992).

Honda, K., Morita, M., Otsuka, H. & Takahara, A. Molecular aggregation structure and surface properties of poly(fluoroalkyl acrylate) thin films. Macromolecules 38, 5699–5705 (2005).

Honda, K., Yakabe, H., Koga, T., Sono, S., Sakata, O. & Takahara, A. Molecular aggregation structure of poly(fluoroalkyl acrylate) thin films evaluated by synchrotron-sourced grazing-incidence X-ray diffraction. Chem. Lett. 34, 1024–1025 (2005).

Honda, K., Yamaguchi, H., Sakata, O., Sasaki, S., Takata, M., Morita, M. & Takahara, A. Influence of α-methyl group on molecular aggregation structure and surface physicochemical properties of fluoroalkyl side chain polymers. J. Phys. Conference Ser. 184, 012007 (2009).

Corpart, J. M., Girault, S. & Juhue, D. Structure and surface properties of liquid crystalline fluoroalkyl plyacrylates: role of the spacer. Langmuir 17, 7237–7244 (2001).

Patil, Y., Raspolli, A. M. R., Silly, G. & Ameduri, B. Copolymerization of ethylene with a vinyl ether bearing a fluorinated group. J. Fluorine Chem. 132, 1207–1212 (2011).

Cracowski, J. M., Montembault, V., Odobel, F., Ameduri, B. & Fontaine, L. Synthesis and characterization of poly(fluorinated vinyl ether-alt-tert-butyl a-trifluoromethacrylate) copolymers. J. Polym. Sci. Polym. Chem 47, 6116–6123 (2009).

Meskini, A., Raihane, M. & Ameduri, B. Unexpected alternated radical copolymerization of vinylidene cyanide with a vinyl ether for superhydrophobic and highly oleophobic films. Macromolecules 42, 3532–3539 (2009).

Couture, G., Campagne, B., Alaaeddine, A. & Améduri, B. Synthesis and characterizations of alternating co- and terpolymers based on vinyl ethers and chlorotrifluoroethylene. Polym. Chem. 4, 1960–1968 (2013).

Noirez, L., Keller, P. & Cotton, J. P. On the structure and the chain conformation of side-chain liquid crystal polymers. Liquid Crystals 18, 129–148 (1995).

Noirez, L., Davidson, P., Schwarz, W. & Pépy, G. Side-chain liquid crystal polymers. A study by neutron diffraction of the backbone distribution profile in the smectic A phase. Liquid Crystals 16, 1081–1092 (1994).

de Gennes, P. G. & Prost, J. in The Physics of Liquid Crystals, 2nd edn, (International Series of Monographs on Physics) eds de Gennes P. G., Prost J., Ch. 10, 527–540 (Oxford University Press, New York, NY, USA, 1995).

Russell, T. P. X-ray and neutron reflectivity for the investigation of polymers. Mater. Sci. Rep. 5, 171–271 (1990).

Wang, T. T. & Takase, Y. Ferroelectriclike dielectric behavior in the piezoelectric amorphous copolymer of vinylidenecyanide and vinyl acetate. J. Appl. Phys. 62, 3466–3469 (1987).

Owens, D. K. & Wendt, R. C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 13, 1741 (1969).

Whitesides, G. M. & Laibinis, P. E. Wet chemical approaches to the characterization of organic surfaces: self-assembled monolayers, wetting, and the Physical-Organic Chemistry of the solid-liquid interface. Langmuir 6, 87–96 (1990).

Teraya, T., Takahara, A. & Kajiyama, T. Surface chemical composition and surface molecular mobility of diblock and random copolymers with hydrophobic and hydrophilic segments. Polymer (Guildf) 31, 1149–1153 (1990).

Tretinnikovt, O. N. & Ikada, Y. Dynamic wetting and contact angle hysteresis of polymer surfaces studied with the modified Wilhelmy balance method. Langmuir 10, 1606–1614 (1994).

Bongiovanni, R., Lombardi, V. & Priola, A. in Contact Angles, Wettability, and Adhesion Vol. 2 ed. Mittal K. L., 101–108 (CRC Press, 2002).

Bongiovanni, R., Di Meo, A., Pollicino, A., Priola, A., Tonelli, C. & Di Meo, A. New perfluoropolyether urethane methacrylates as surface modifiers: effect of molecular weight and end group structure. React. Funct. Polym. 68, 189–200 (2008).

Acknowledgements

The present work was supported by a Grant-in-Aid for the Global COE Program, ‘Science for Future Molecular Systems’ from the Ministry of Education, Culture, Science, Sports and Technology of Japan. HY acknowledges financial support from a Grant-in-Aid for JSPS Fellows. The synchrotron WAXD and thin-film WAXD measurements were performed on BL02B2, BL03XU and BL13XU beamlines at SPring-8 with the approval of the Japan Synchrotron Radiation Research Institute (JASRI), proposals 2011A1467, 2012A7219 and 2011B1427, respectively. We thank Dr Jungeun Kim, Dr Hiroki Ogawa and Dr Hiroo Tajiri for their assistance in the experiments on BL02B2, BL03XU and BL13XU, respectively. Dr Kazuki Mita (Mitsui Chemicals, Inc.) is also gratefully acknowledged for kindly providing the opportunity to conduct the thin-film WAXD measurements on the BL03XU. BA and MR also thank CNRS and CNRST for funding.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ishige, R., Yamaguchi, H., Shinohara, T. et al. Structural analysis and surface wettability of a novel alternated vinylidene cyanide with fluorinated vinyl ether copolymer. Polym J 45, 1041–1046 (2013). https://doi.org/10.1038/pj.2013.32

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2013.32