Abstract

The novel thermoresponsive polycations poly(N-vinylbutyramide-co-vinylamide) (poly(NVBA-co-VAm)), with different mole ratios of poly(VAm) (PVAm):poly(NVBA) (PNVBA), were synthesized as a biomaterial by free radical copolymerization of poly(N-vinylbutyramide-co-N-vinylformamide) (poly(NVBA-co-NVF), followed by acid hydrolysis. Such poly(N-vinylamide)s do not generate toxic low-molecular-weight amine compounds by hydrolysis, although the poly(acrylamide) structural isomers do. The mole ratio of PVAm and PNVBA was varied by adjusting the NVF:NVBA mol% feeding ratio used in the copolymerization. The lower critical solution temperature (LCST) of the obtained copolymers was investigated and compared with that of PNVBA. PNVBA showed an LCST of 32 °C, while that for poly(NVBA-co-VAm) increased as the VAm mole ratio increased (due to the increasing hydrophilicity), and the more physiologically relevant temperature (for humans) of 36.5 °C was obtained at a VAm mole ratio of 5%. Furthermore, the LCST of these copolymers not only depended on the VAm mole ratios but also on the pH, the concentration of the copolymer solution and ionic strength. Variation in the copolymer LCST could lead to several applications, especially for copolymers with an LCST value around physiological temperature that would potentially be of merit for a controlled drug or biomolecule delivery system.

Similar content being viewed by others

Introduction

A thermosensitive polymer is a polymer that undergoes a conformational transition in response to changes in the external temperature. With respect to the temperature-induced conformational transition of a given thermosensitive polymer, it can lead to specific applications across a diverse array of applications, such as chromatography,1 surface modifier2 and, especially, in biomedical application for the controllable delivery of bioactive substances.3 The controllable delivery of a bioactive substance requires a polymeric carrier that is stable and protects the payload (bioactive compound) when out of the target environment (for example, body), but must allow the controlled release of the payload to deliver the drug into/onto the body or target site under relevant physiological (temperature) circumstances. Therefore, it is our interest to synthesize novel thermosensitive polycations that exhibit temperature-induced conformational transitions at around the physiological temperature of humans.

Thermosensitive synthetic polymers have been widely researched for decades. Poly(N-isopropylacrylamide) (PNIPAm)4, 5 is one of the most intensively researched synthetic thermosensitive polymers, and shows a lower critical solution temperature (LCST) at 32 °C, somewhat below the physiological temperature of humans and most veterinary animals. A fairly extensive range of graft polymers and block copolymers with PNIPAm have been reported, such as poly(methyl methacrylate) for micelle preparation,6 poly(acrylamide) with ionic surfactants,7 poly(lactide)s,8 poly(ɛ-caprolactone),9 chitosan,10 poly(ethylene oxide)11, 12 and polystyrene.13 These all take advantage of the thermosensitive characteristics of PNIPAm. To obtain additional functionality, polyelectrolytes have been fabricated as a copolymer with PNIPAm so as to yield thermosensitive and pH-sensitive polymers, using alginate,14 varying amounts of acrylamide derivatives bearing carboxylic groups,15 propylacrylic acid16 and acrylic acid.17 The chain-end structure18 and hydrogel structure19, 20 have also been modified for PNIPAm.

Among these, cationic copolymers with PNIPAm are useful because they possess electrostatic interactions with polyanions, such as DNA. Several cationic copolymers with PNIPAm have been investigated, such as copolymers with poly(vinylpyridine) to yield a colloidal microgel.21 For example, the use of poly(dimethylamino)ethylmethacrylate was found to be an efficient stationary phase for the separation of biomolecules,22 while the hetero-arm star polymer between poly(ethylene glycol) and poly(L-lysine) formed thermoresponsive micelles,23 and grafting with poly(ethylene imine) has been reported for a potential thermosensitive gene delivery vehicle.24

Indeed, gene delivery using PNIPAm with a copolymer,25, 26, 27, 28, 29, 30 star polymer31 or as a graft copolymer32, 33, 34, 35 have been reported. However, the structure of the polymer main chain is different, resulting in the cationic moieties locating separately in the polymer chain. In other words, the acrylamide backbone of PNIPAm cannot contribute to the random copolymer structure. Importantly, poly(acrylamide)s produce toxic low-molecular-weight amino compounds by hydrolysis. Therefore, from the view point of the safety of the material, it is expected that non-secondary amides as substituent thermosensitive cationic polymers would be more suitable (less toxic) for biomedical applications.

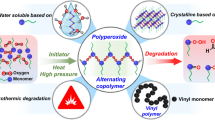

Along these lines, there is a series of poly(N-vinylamide)s whose carbonyl groups and nitrogen atom are positioned reversely.36, 37 For example, poly(N-vinylbutyramide) (PNVBA),38 the copolymer with poly(N-vinylacetamide) (PNVA) and poly(vinylacetate) (PNVAc),39 as well as poly(N-vinylisobutyramide) (PNVIBA) are thermosensitive polymers. PNVIBA corresponds to the structural isomer of PNIPAm and possesses an LCST of 39 °C. Such poly(N-vinylamide)s yield the cationic poly(vinylamine) (PVAm) after hydrolysis of the side-chain amide groups,40 which enables the preparation of thermal- and pH-responsive polymers.41 It is worth noting that the hydrolysis of poly(N-vinylamide)s does not generate low-molecular-weight amino compounds, because the nitrogen atom is directly connected to the polymer backbone. In addition, it is possible to prepare random copolymers with polycations because of the same polymer main chain backbone.

In this study, PNVBA with an LCST of 32 °C was selected to introduce cationic groups, because the introduction of the VAm moiety into poly(N-vinylamide)s results in increased polymer hydrophilicity and so shifts the LCST to a higher temperature. Accordingly, we sought to make a thermoresponsive copolymer of NVBA and VAm with an LCST close to the physiological temperature of humans (37 °C). Thus, we avoided PNVIBA, as it already has an LCST of 39 °C. The radical polymerization of NVBA and N-vinylformamide (NVF) at different molar ratios and their subsequent acid hydrolysis were performed to introduce potentially various controlled levels of cationic moieties. The thermosensitivity and pH sensitivity of each obtained copolymer were then investigated.

Experimental procedure

Materials

Azobisisobutyronitrile and n-butyramide were bought from Tokyo Chemical Industry Co. Ltd (Tokyo, Japan). Concentrated sulfuric acid, 2-propanol, acetaldehyde, sodium hydroxide and chloroform were purchased from Wako Pure Chemical Industries Ltd. (Osaka, Japan). NVF and anhydrous toluene were supplied from Sigma-Aldrich (Tokyo, Japan). Dialysis tube (MWCO 500Da) was provided from Spectrum Laboratories Inc. (Rancho Dominguez, USA). Most reagents were used as received, except for NVF that was purified under distillation before use.

Synthesis of N-(α-isopropoxyethyl)-n-butyramide)

N-(α-isopropoxyethyl)-n-butyramide) (IPEBA)38 was synthesized as follows: n-butyramide (50 g; 0.574 mol), 440 ml (5.75 mol) of 2-propanol and 3.06 ml (0.0574 mol) of concentrated sulfuric acid were added into a 1-liter three-necked flask equipped with a thermometer and circulating (5 °C) condenser. Then, 320 ml (5.74 mol) of acetaldehyde was gradually added to the reaction flask and subsequently stirred at room temperature to avoid excess localized exothermic heat, before refluxing the mixture at 90 °C for 2 h. The reaction mixture was then neutralized with 5 N NaOH and the unreacted acetaldehyde and 2-propanal was removed by evaporation. The condensed mixture was poured into 200 ml of distilled water, mixed and allowed to phase separate. The product and by-products were mainly partitioned in the upper oily organic layer that was harvested. However, the lower aqueous layer was extracted three times each with 100 ml of chloroform. The oily organic layer and three chloroform extractions were then pooled together and evaporated to remove the chloroform. The resulting IPEBA product was purified by distillation (107–108 °C at 7.0 mm Hg) to yield 37.2 g (37.4 mole%). The IPEBA was characterized by proton nuclear magnetic resonance (1H-NMR) spectroscopy (JEOL, Tokyo, Japan, ECS-400). 1H-NMR (CDCl3, p.p.m.) of IPEBA: 5.7 (br, 1H, –CONH), 5.4 (m, 1H, –NH–CH(CH3)–O–), 3.8 (m, 1H, –O–CH(CH3)2), 2.1 (t, 2H, –CH2CH2CH3), 1.6 (m, 2H, –CH2CH2CH3), 1.3 (d, 3H, –O–CH(CH3)–NH), 1.1 (dd, 6H, –O–CH(CH3)2) and 0.9 (t, 3H, –CH2CH2CH3). Underline represents the position of H (proton) in the chemical structure corresponding to that specific NMR peak.

Synthesis of NVBA

NVBA38 was synthesized as follows: a 200-ml three-necked flask was equipped with a dropping funnel and a quartz fiber-filled quartz pyrolysis tube. The flask was heated to 170 °C in an oil bath, whereas the pyrolysis tube was heated to 500 °C with an electric furnace. The other side of the pyrolysis tube was connected to a vacuum pump via two liquid nitrogen traps in series, the first being used to trap the product vapor and the second to trap volatiles before the vacuum pump, and the system was operated at 0.1–0.5 mm Hg. IPEBA (37.2 g; 0.2 mol) solvated in 170 ml 2-propanol was added dropwise into the flask at a rate of 1–1.5 ml min−1. The mixture in the first trap was condensed by evaporation and the resulting NVBA was obtained after purification by distillation under reduced pressure (101–102 °C at 6.0 mm Hg), yielding 3.49 g (14.4 mol%), and characterized by 1H-NMR (JEOL, ECS-400). 1H-NMR (CD3CN, p.p.m.) of NVBA: 8.2 (br, 1H, –CONH), 6.9 (m, 1H, CH2=CH), 4.6 (d, 1H, cis CH2=CH), 4.3 (d, 1H, trans CH2=CH), 2.1 (t, 2H, –CH2CH2CH3), 1.6 (m, 2H, –CH2CH2CH3) and 0.9 (t, 3H, –CH2CH2CH3).

Synthesis of poly(NVBA-co-NVF)

Synthesis of poly(NVBA-co-NVF) was performed in toluene at 60 °C for 24 h through free radical polymerization between the NVBA and NVF monomers in the presence of azobisisobutyronitrile as an initiator. The net monomer (NVBA plus NVF) and azobisisobutyronitrile concentrations were fixed at 2 M and 2.5% (w/w), respectively, whereas within the 2 M net monomer concentration, the proportion of NVF to NVBA was varied at a molar ratio of 1:99, 5:95 and 10:90. PNVBA was synthesized by the same method, except using the NVBA monomer only without any NVF.

Preparation of poly(NVBA-co-VAm)

Poly(NVBA-co-VAm) was prepared by the hydrolysis of poly(NVBA-co-NVF) under acidic conditions.40 Poly(NVBA-co-NVF) (120 mg) was dissolved in 6 ml 2 N HCl to a polymer concentration of 2% (w/v). The polymer solution was heated to 80 °C for 100 min, cooled and neutralized with 2 N NaOH before being dialyzed against distilled water over 2 days. The hydrolyzed products were recovered by lyophilization.

Measurements

The 1H-NMR spectra were recorded on JEOL ECS-400 (400 MHz) instrument. The composition ratios of NVF in each poly(NVBA-co-NVF) copolymer was determined from the 1H-NMR spectra using the ratio of the integrated area of the –CH2 (2.2–1.2 p.p.m.) and –CH3 (0.9–0.6 p.p.m.) peaks. Likewise, the mole ratio of VAm in each obtained poly(NVBA-co-VAm) copolymer was determined from the integrated peak area of the –CH2 (2.2–1.2 p.p.m.) and –CH3 (0.9–0.6 p.p.m.) regions.

The molecular weights of PNVBA, poly(NVBA-co-NVF) and poly(NVBA-co-VAm) were characterized by size-exclusion chromatography using a TOSOH HLC-8120GPC instrument (TOSOH Corporation, Tokyo, Japan) with a TSK Super H-L guard column and a Super H3000 and Super H4000 column in tandem. Dimethylformamide was used as the mobile phase eluent at a flow rate of 0.2 ml min−1, and poly(methyl methacrylate) was used as a calibration standard. The elemental composition of each polymer or copolymer was measured on a CHN/O elemental analyzer (Yanaco CHN corder, MT-5, Kyoto, Japan) using acetanilide as the standard.

LCST and thermal-responsive reversibility

The LCST of each polymer or copolymer was analyzed as a 0.2% (w/v) aqueous solution with a UV spectrophotometer (Jasco Model V-550, Jasco Corporation, Tokyo, Japan) coupled with an ETC-505T temperature controller to determine the turbidity of the polymer solution as a function of the temperature, using a fixed wavelength of 500 nm. The heating and cooling rate of the sample cell was fixed at 1.0 °C min−1, corrected every 0.5 °C. The LCST was taken when the transmittance was reduced to 50% of the original level. The transmittance profiles of the first and second heating/cooling cycle were measured to evaluate the thermal-responsive reversibility.

Effect of pH and polymer or copolymer concentration on the LCST

To evaluate the effect of pH upon the LCST, polymers were dissolved to 0.2% (w/v) in an aqueous solution adjusted to the desired pH (range 4–12) using 0.01 M HCl or 0.01 M NaOH, as appropriate, at a constant ionic strength of 0.01 M. The LCST of each polymer was then evaluated under the different pH values as detailed above.

To evaluate the effect of the polymer concentration on the LCST, polymers were dissolved in distilled water and evaluated as above, but at a concentration of 0.05, 0.1 and 0.2% (w/v).

LCST of the copolymer under physiological conditions

With a potential biomedical application, the change in the LCST of the polymers under more physiological conditions (ionic strength of the media) was also investigated. Polymers were dissolved to 0.2% (w/v) in 0.9% (w/v) sodium chloride (normal saline) or phosphate-buffered saline (PBS) and then evaluated as above.

Results and discussion

Synthesis of poly(NVBA-co-NVF)

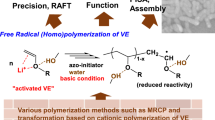

Synthesis of poly(NVBA-co-NVF) was performed by free radical polymerization, using azobisisobutyronitrile as the initiator, between NVBA and NVF monomers at NVF:NVBA molar ratios at 1:99, 5:95 and 10:90 at a constant concentration of 2 M. PNVBA was also synthesized in the same manner. The synthesis pathway is represented as the first step of the reaction in Scheme 1. The synthesized poly(NVBA-co-NVF) was coded as N series. The mole ratio of NVF and NVBA in each of the three different poly(NVBA-co-NVF) copolymers derived from different NVF:NVBA feed molar ratios, as calculated from 1H-NMR, and their molecular weight, as estimated by size-exclusion chromatography, is summarized in Table 1. The NVF ratios in the poly(NVBA-co-NVF) products were a bit higher than the NVF feed ratios. This likely reflects that NVF had a higher reactivity than NVBA as the NVBA monomer is more bulky and hydrophobic than that of the NVF monomers. The elemental analysis of the obtained PNVBA and different poly(NVBA-co-NVF) copolymers were in good agreement with the calculated values (Table 2). A representative 1H-NMR spectrum of poly(NVBA-co-NVF) (for that with a 18% NVF molar content) is shown in Figure 1a, and the corresponding data are as follows: 1H-NMR (CD3CN, p.p.m.) of poly(NVBA-co-NVF)—8.6–7.6 (br, 1H, HCO–), 3.8–3.4 (br, 2H, –CH2–CH–), 2.2–1.8 (br, 2H, –CH2CH2CH3), 1.8–1.2 (m, 6H, –CH2CH2CH3 and –CH2–CH– ) and 0.9 (t, 3H, –CH2CH2CH3).

Preparation of poly(NVBA-co-VAm)

Poly(NVBA-co-VAm) was prepared by acid (2 N HCl) hydrolysis of poly(NVBA-co-NVF) at 80 °C for 100 min, and is shown in the second step of the reaction in Scheme 1. The synthesized poly(NVBA-co-VAm) was coded as H series. The mol% of VAm and NVBA in the each poly(NVBA-co-VAm) copolymer, as calculated from the 1H-NMR spectra, is summarized in Table 3. In accordance with Yamamoto et al.,40 PNVF was completely hydrolyzed to PVAm in 2 N HCl at 80 °C for 100 min. A representative 1H-NMR spectrum of poly(NVBA-co-VAm) (for that with a 18% VAm molar content) is shown in Figure 1b, and the corresponding data are as follows: 1H-NMR (CD3CN, p.p.m.) of poly(NVBA-co-VAm)—3.8–3.4 (br, 2H, –CH2–CH–), 3.0–2.6 (m, 2H, –NH2), 2.2–1.8 (br, 2H, –CH2CH2CH3), 1.8–1.2 (m, 6H, –CH2CH2CH3 and –CH2–CH–) and 0.9 (t, 3H, –CH2CH2CH3).

Thermoresponsive property of poly(NVBA-co-NVF)

The light transmittance of a 0.2% (w/v) aqueous solution of the different poly(NVBA-co-NVF) copolymers at different temperatures is shown in Figure 2a. The LCST was taken as the temperature at which the transmittance was reduced to 50%, so that for PNVBA it was 32 °C. For the different poly(NVBA-co-NVF) copolymers, the LCST increased with increasing mol% proportions of NVF and so likely depended on the hydrophobic–hydrophilic balance of their side chains, with an LCST of 32, 33, 36.5 and 39.5 °C for poly(NVBA-co-NVF) copolymers with NVF mol% levels of 0% (PNVBA), 4%, 12% and 18%, respectively. The incorporation of increasing levels of the hydrophilic NVF comonomer led to a higher LCST, and also indicated that the molecular structure and side-chain length directly influenced the LCST. Regardless, poly(NVBA-co-NVF) with an NVF mol% composition from 0 to 18% provide a range of LCST values of 33–39.5 °C, including those around the human and veterinary animal physiological temperatures.

Temperature-dependent light transmittance of a 0.2% (w/v) aqueous solution of (a) poly(N-vinylbutyramide-co-N-vinylformamide) (poly(NVBA-co-NVF)) copolymers with a mol% NVF content of (▪) 0% (PNVBA), (•) 4%, (▴) 12% and (▾) 18%, and (b) poly(N-vinylbutyramide-co-vinylamide) (poly(NVBA-co-VAm)) copolymers with a mole % VAm content of (▪) 0% (PNVBA), (•) 5%, (▴) 12% and (▾) 18%.

The thermal responsiveness of a 0.2% (w/v) aqueous solution of the poly(NVBA-co-NVF) with a 4 mol% NVF content, as a representative example, is shown in Figure 3a. This poly(NVBA-co-NVF) exhibited a LCST value of 33 °C in both the first and second heating cycles, whereas it showed a slightly lower LCST at 32 °C in both corresponding cooling cycles. Theoretically, a coil-to-globule transition involves an intramolecular condensation between monomers of a single polymer molecule in an aqueous solution,42 while coacervation involves intermolecular condensation between polymer–solvent molecules with their subsequent aggregation.43 Both processes are completely reversible as a function of the temperature, and so the coil–globule transition regions of both heating and cooling are almost identical.44 The thermal responsiveness of the poly(NVBA-co-NVF) copolymers was reversible around the physiological temperature. The results indicate a coacervate structure rather than a coil–globule transition,45 although it is known that PNVIBA homopolymers obey a coil–globule transition. As we obtained thermosensitive poly(N-vinylamide) copolymers with LCST values below the known human physiological temperature, including the poly(NVBA-co-NVF) copolymers, we next analyzed the ability of the hydrolyzed poly(N-vinylamide)s to produce thermosensitive polycations.

Light transmittance of a 0.2% (w/v) aqueous solution of (a) poly(N-vinylbutyramide-co-N-vinylformamide) (poly(NVBA-co-NVF)) (4 mol% NVF) and (b) poly(N-vinylbutyramide-co-vinylamide) (poly(NVBA-co-VAm)) (5 mol% VAm), during the first round of (▪) heating and (□) cooling, and during the second round of (•) heating and (○) cooling.

Thermoresponsive property of poly(NVBA-co-VAm)

The light transmittance of a 0.2% (w/v) aqueous solution of the poly(NVBA-co-VAm) copolymers with different mol% VAm levels was found to be dependent on the temperature (Figure 2b). The PNVBA homopolymer after treatment with the same acidic conditions used to hydrolyze the poly(NVBA-co-NVF) to poly(NVBA-co-VAm) still showed the same LCST (32 °C) as without the treatment, indicating that the propyl group side chains are not hydrolyzed. In contrast, the LCST of poly(NVBA-co-VAm) copolymers increased with increasing VAm contents from 32 °C at 0% VAm (that is, PNVBA) to 36.5 and 49 °C at 5 and 12 mol% VAm, respectively. Thus, the hydrolysis of NVF to VAm changed the copolymers thermal-responsive properties to a higher temperature, presumably because of the cationic property. It is worth noting that the LCST changed from 33 °C (4 mol% NVF) to the more physiologically relevant (for humans) temperature of 36.5 °C (5 mol% VAm) after hydrolysis, which is due to the amino groups (–NH3+) being more hydrophilic than the –NHCOH groups. Thus, we obtained a thermosensitive polycation at a physiological temperature.

The thermal responsiveness of a 0.2% (w/v) aqueous solution of the poly(NVBA-co-VAm) copolymer with a 5 mol% VAm content, as a representative example, revealed an LCST of 36.5 °C in both the first and second heating cycles, and a slightly lower temperature of 33 °C in both corresponding cooling cycles (Figure 3b). This then supports that the thermal responsiveness of the poly(NVBA-co-VAm) copolymers, like that of the poly(NVBA-co-NVF) copolymers, was reversible with a coacervate structure rather than a coil–globule transition.45

Effect of pH on the LCST

To further clarify the effect of pH on the LCST of the hydrolyzed PNVBA and the different poly(NVBA-co-VAm) copolymers with 5, 12 or 18 mol% VAm contents, the LCST of the samples were measured in a 0.2% (w/v) aqueous solution over the pH range of 4–12. The LCST of the hydrolyzed PNVBA was not pH responsive, in that the LCST remained unchanged at 32 °C over the pH range of 4–12 (Figure 4). This supports that the –NHCO(CH2)2CH3 group of PNVBA cannot be hydrolyzed to –NH3+Cl−. In contrast, the poly(NVBA-co-VAm) copolymers all showed a pH dependence upon their LCST, with a biphasic decrease in the LCST with increasing pH (Figure 4). The LCST slightly decreased from that at pH 4.0 up to the pKa of VAm (pKa=10), and then decreased abruptly thereafter. The rate of decrease in the LCST between pH 4.0 and pH 10 increased with increasing mol% VAm contents. Surprisingly, whatever the LCST value was at pH 4–10 (below the pKa of VAm), the LCST value was then dramatically reduced to be close to that of the hydrolyzed PNVBA at pH 12. The reason why the LCST of the poly(NVBA-co-VAm) copolymers was reduced to almost that of the hydrolyzed PNVBA might be because of the neutralization of the ammonium groups (NH3+Cl−) in alkaline solution.

The pH dependence of the lower critical solution temperature (LCST) of a 0.2% (w/v) aqueous solutions of the poly(N-vinylbutyramide-co-vinylamide) (poly(NVBA-co-VAm)) copolymers with a VAm mol% contents of (▪) 0%, (•) 5%, (▴) 12% and (▾) 18%. The ionic strength of the polymer aqueous solution was 0.01 M.

Effect of the poly(NVBA-co-VAm) concentration on the LCST

To further clarify the thermosensitivity of poly(NVBA-co-VAm) copolymers, the effect of their aqueous solution concentration on the LCST was evaluated for those with a 5 and 12 mol% VAm composition. The LCST of these two poly(NVBA-co-VAm) copolymers decreased with increasing polymer concentrations (Figure 5), and the higher VAm content showed a more significant polymer concentration dependence, in accord with coacervation. The single polymer chain dissolved in water undergoes a sharp collapse transition from coil-to-compact globule as the temperature is raised. However, it has been difficult to observe this transition experimentally because the point of intramolecular condensation proved to be rather close to the point of intermolecular condensation at which the polymer aggregates. The coil-to-globule collapse, however, was followed by aggregation (coacervation) at increasing polymer concentrations.

LCST of copolymers under physiological conditions

The LCST of poly(NVBA-co-VAm) copolymers with a VAm mol% content of 5% and 12%, respectively, under more physiological conditions was investigated in 0.9% (w/v) NaCl and PBS (Figure 6). The LCST of these two poly(NVBA-co-VAm) copolymers decreased from 36.5 °C in aqueous solution to around 33 °C in 0.9% (w/v) NaCl or PBS for poly(NVBA-co-VAm) copolymers with a VAm mol% contents of 5%, and from 49 °C in aqueous solution to around 37.5 °C in 0.9% (w/v) NaCl or PBS for the copolymer with a VAm mol% contents of 12%. Thus, the LCST of the poly(NVBA-co-VAm) copolymer in 0.9% (w/v) NaCl or PBS (approximately 0.15 M ionic strength) was shifted to a lower temperature than in the salt-free aqueous solution.

Light transmittance of a 0.2% (w/v) aqueous solution of poly(N-vinylbutyramide-co-vinylamide) (poly(NVBA-co-VAm)) copolymers with a VAm mol% content of (•, o) 5% or (▴, Δ) 12%, where the closed symbols represent poly(NVBA-co-VAm) copolymers in 0.9% (w/v) NaCl and opened symbols represent poly(NVBA-co-VAm) copolymers in phosphate-buffered saline (PBS).

Therefore, of relevance to potential biomedical applications, it should be noted that the conformational transition of poly(NVBA-co-VAm) was not only dependent on the pH and concentration of the copolymers but also upon the ionic strength of the solution.

Conclusion

Novel thermal- and pH-responsive poly(NVBA-co-VAm) copolymers with different VAm:NVBA mol% ratios were synthesized though radical copolymerization of NVBA and NVF, followed by acidic hydrolysis. The LCST of the obtained poly(NVBA-co-VAm) copolymers was dependent on the pH and copolymer concentration, ionic strength and the mol% proportion of the cationic VAm. Thermosensitive cationic copolymers with an LCST close to the human physiological temperature were obtained and they could possibly be of use in biomedical applications, due to the biocompatibility of the poly(N-vinylamide) structure that does not generate toxic low–molecular-weight amino compounds during acid hydrolysis, as the nitrogen atoms are directly connected to the polymer backbone.

Synthesis pathway of poly(N-vinylbutyramide-co-N-vinylformamide) (poly(NVBA-co-NVF)) and poly(N-vinylbutyramide-co-vinylamide) (poly(NVBA-co-VAm)).

References

Kanazawa, H. & Okano, T. Temperature-responsive chromatography for the separation of biomolecules. J. Chromatogr. A 1218, 8738–8747 (2011).

Kanazawa, H., Nishikawa, M., Mizutani, A., Sakamoto, C., Morita-Murase, Y., Nagata, Y., Kikuchi, A. & Okano, T. Aqueous chromatographic system for separation of bimolecules using thermoresponsive polymer modified stationary phase. J. Chromatogr. A 1191, 157–161 (2008).

Coughlan, D. C. & Corrigan, O. I. Drug–polymer interactions and their effect on thermoresponsive poly(N-isopropylacrylamide) drug delivery systems. Int. J. Pharm. 313, 163–174 (2006).

Okano, T., Bae, Y. H. & Kim, S. W. Thermally on–off switching polymers for drug permeation and release. J. Control. Rel. 11, 255–265 (1990).

Takai, Y. G., Aoki, T., Sanui, K., Ogata, N., Okano, T. & Sakurai, Y. Temperature-responsive bioconjugates. 2. molecular design for temperature-modulated bioseperations. Bioconjugate Chem. 4, 341–348 (1993).

Wei, H., Zhang, X. Z., Zhou, Y., Cheng, S. X. & Zhuo, R. X. Self-assembled thermoresponsive micelles of poly(N-isopropylacrylamide-b-methyl methacrylate). Biomaterials 27, 2028–2034 (2006).

Caykara, T., Kiper, S. & Demirel, G. Thermosensitive poly(N-isopropylacrylamide-co-acrylamide) hydrogels: synthesis, swelling and interaction with ionic surfactants. Eur. Polym. J. 42, 348–355 (2006).

Liu, S. Q., Tong, Y. W. & Yang, Y. Y. Incorporation and in vitro release of doxorubicin in thermally sensitive micelles made from poly(N-isopropylacrylamide-co-N,N-dimethylacrylamide)-b-poly(D,L-lactide-co-glycolide) with varying compositions. Biomaterials 26, 5064–5074 (2005).

Choi, C., Chae, S. Y. & Nah, J. W. Thermosensitive poly(N-isopropylacrylamide)-b-poly(ɛ-caprolactone) nanoparticles for efficient drug delivery system. Polymer 47, 4571–4580 (2006).

Cho, J. H., Kim, S. H., Park, K. D., Jung, M. C., Yang, W. I., Han, S. W., Noh, J. Y. & Lee, J. W. Chondrogenic differentiation of human mesenchymal stem cells using a thermosensitive poly(N-isopropylacrylamide) and water-soluble chitosan copolymer. Biomaterials 25, 5743–5751 (2004).

Virtanen, J., Baron, C. & Tenhu, H. Grafting of poly(N-isopropylacrylamide) with poly(ethylene oxide) under various reaction conditions. Macromolecules 33, 336–341 (2000).

Qin, S., Gen, Y., Discher, D. E. & Yang, S. Temperature-controlled assembly and release from polymer vesicles of poly(ethylene oxide)-block-poly(N-isopropylacrylamide). Adv. Mater. 18, 2905–2909 (2006).

Nuopponen, M., Ojala, J. & Tenhu, H. Aggregation behaviour of well defined amphiphilic diblock copolymers with poly(N-isopropylacrylamide) and hydrophobic blocks. Polymer 45, 3643–3650 (2004).

Kim, J. H., Lee, S. B., Kim, S. J. & Lee, Y. M. Rapid temperature/pH response of porous alginate-g-poly(N-isopropylacrylamide) hydrogels. Polymer 43, 7549–7558 (2002).

Kuckling, D., Alder, H. J. P., Arndt, K. F., Ling, L. & Habicher, W. D. Temperature and pH dependent solubility of novel poly(N-isopropylacrylamide) copolymers. Macromol. Chem. Phys. 201, 273–280 (2000).

Yin, X., Hoffman, A. S. & Stayton, P. S. Poly(N-isopropylacrylamide-co-propylacrylic acid) copolymers that respond sharply to temperature and pH. Biomacromolecules 7, 1381–1385 (2006).

Schilli, C. M., Zhang, M., Rizzardo, E., Thang, S. H., Chong, Y. K., Edwards, K., Karlsson, G. & Mueller, A. H. E. A new double-responsive block copolymer synthesized via RAFT polymerization: poly(N-isopropylacrylamide)-block-poly(acrylic acid). Macromolecules 37, 7861–7866 (2004).

Li, M., De, P., Gondi, S. R. & Sumerlin, B. S. End group transformations of RAFT-generated polymers with bismaleimides: functional telechelics and modular block copolymers. J. Polym. Sci. Part A 46, 5093–5100 (2008).

Kratz, K., Hellweg, T. & Eimer, W. Influence of charge density on the swelling of colloidal poly(N-isopropylacrylamide-co-acrylic acid) microgels. Colloids Surf. 170, 137–149 (2000).

Zhang, J. & Peppas, N. A. Synthesis and characterization of pH- and temperature-sensitive poly(methacylic acid)/poly(N-isopropylacrylamide) interpenetrating polymeric networks. Macromolecules 33, 1102–1107 (2000).

Pinkrah, V. T., Snowden, M. J., Mitchell, J. C., Seidel, J., Chowdhry, B. Z. & Fern, G. R. Physicochemical properties of poly(N-isopropylacrylamide-co-4-vinylpyridine) cationic polyelectrolyte colloidal microgels. Langmuir 19, 585–590 (2003).

Nagase, K., Kobayashi, J., Kikuchi, A., Akiyama, Y., Kanazawa, H. & Okano, T. Preparation of thermoresponsive cationic copolymer brush surfaces and application of the surface to seperation of biomolecules. Biomacromolecules 9, 1340–1347 (2008).

Li, J., He, W. D., He, N., Han, S. C., Sun, X. L., Li, L. Y. & Zhang, B. Y. Synthesis of PEG-PNIPAM-PLys hetero-responsibility after the formation of polyelectrolyte complex micelles with PAA. J. Polym. Sci. Part A 47, 1450–1462 (2009).

Griffiths, P. C., Alexander, C., Nilmini, R., Pennadam, S. S., King, S. M. & Heenan, R. K. Physicochemical characterization of thermoresponsive poly(N-isopropylacrylamide)-poly(ethylene imine) graft copolymers. Biomacromolecules 9, 1170–1178 (2008).

Kurisawa, M., Yokoyama, M. & Okano, T. Gene expression control by temperature with thermo-responsive polymeric gene carriers. J. Control. Rel. 69, 127–137 (2000).

Oupický, D., Reschel, T., Koňák, Č. & Oupická, L. Temperature-controlled behavior of self-assembly gene delivery vectors based on complexes of DNA with poly(L-lysine)-graft-poly(N-isopropylacrylamide). Macromolecules 36, 6863–6872 (2003).

Twaites, B. R., Alarcón, C. H., Cunliffe, D., Lavigne, M., Pennadam, S., Smith, J. R., Górecki, D. C. & Alexander, C. Thermo and pH responsive polymers as gene delivery vectors: effect of polymer architecture on DNA complexation in vitro. J. Control. Rel. 97, 551–556 (2004).

Zintchenko, A., Ogris, M. & Wagner, E. Temperature dependent gene expression induced by PNIPAM-based copolymers: potential of hyperthermia in gene transfer. Bioconjugate Chem. 17, 766–772 (2006).

Cheng, H., Zhu, J. L., Sun, Y. X., Cheng, S. X., Zhang, X. Z. & Zhuo, R. X. Novel thermoresponsive nonviral gene vector: P(NIPPAAm-co-NDAPM)-b-PEI with adjustable gene transfection efficiency. Bioconjugate Chem. 19, 1368–1374 (2008).

Ma, Y., Hou, S. H., Ji, B., Yao, Y. & Feng, X. A novel temperature-responsive polymer as a gene vector. Macromol. Biosci. 10, 202–210 (2010).

Zhou, Y. M., Ishikawa, A., Okahashi, R., Uchida, K., Nemoto, Y., Nakayama, M. & Nakayama, Y. Deposition transfection technology using a DNA complex with a thermoresponsive cationic star polymer. J. Control. Rel. 123, 239–246 (2007).

Mao, Z., Ma, L., Yan, J., Yan, M., Gao, C. & Shen, J. The gene transfection efficiency of thermoresponsive N,N,N-trimethyl chitosan chloride-g-poly(N-isopropylacrylaminde) copolymer. Biomaterials 28, 4488–4500 (2007).

Mori, T. & Maeda, M. Temperature-responsive formation of colloidal nanoparticles from poly(N-isopropylacrylamide) grafted with single-stranded DNA. Langmuir 20, 313–319 (2004).

Twaites, B. R., Alarcón, C. H., Lavigne, M., Saulnier, A., Pennadam, S. S., Cunliffe, D., Górecki, D. C. & Alexander, C. Thermoresponsive polymers as gene delivery vectors: cell viability, DNA transport and transfection studies. J. Control. Rel. 108, 472–483 (2005).

Bisht, H. S., Manickam, D. S., You, Y. & Oupicky, D. Temperature-controlled properties of DNA complexes with poly(ethylenimine)-graft-poly(N-isopropylacrylamide). Biomacromolecules 7, 1169–1178 (2006).

Akashi, M., Yashima, E., Yamashita, T., Miyauchi, N., Sugita, S. & Marumo, K. A novel synthetic procedure of vinylacetamide and its free radical polymerization. J. Polym. Sci. Part A 28, 3487–3497 (1990).

Akashi, M., Saihata, S., Yashima, E., Sugita, S. & Marumo, K. Novel nonionic and cationic hydrogels prepared from N-vinylacetamide. J. Polym. Sci. Part A 31, 1153–1160 (1993).

Suwa, K., Morishita, K., Kishida, A. & Akashi, M. Synthesis and functionalities of poly(N-vinylalkylamide). V. control of a lower critical solution temperature of poly(N-vinylalkylamide). J. Polym. Sci. Part A 35, 3087–3094 (1997).

Yamamoto, K., Serizawa, T. & Akashi, M. Systhesis and thermosensitive properties of poly[(N-vinylamide)-co-(vinyl acetate)]s and their hydrogels. Macromol. Chem. Phys. 204, 1027–1033 (2003).

Yamamoto, K., Serizawa, T., Muraoka, Y. & Akashi, M. Synthesis and functionalities of poly(N-vinylalkylamide). XII. Synthesis and thermosensitive property of poly(vinylamine) copolymer prepared from poly(N-vinylformamide-co-N-vinylisobutyramide). J. Polym. Sci. Part A 38, 3674–3681 (2000).

Yamamoto, K., Serizawa, T., Muraoka, Y. & Akashi, M. Synthesis and functionalities of poly(N-vinylalkylamide). 13. Synthesis and properties of thermal and pH stimuli-responsive poly(vinylamine) copolymers. Macromolecules 34, 8014–8020 (2001).

Graziano, G. On the temperature-induced coil to globule transition of poly-N-isopropylacrylamide in dilute aqueous solutions. Int. J. Biol. Macromol. 27, 89–97 (2000).

Miyazaki, H. & Kataoka, K. Preparation of polyacrylamide derivatives showing thermo-reversible coacervate formation and their potential application to two-phase separation processes. Polymer 37, 681–685 (1996).

Yang, H., Cheng, R. & Wang, Z. A quantitative analyses of the viscometric data of the coil-to-globule and globule-to-coil transition of poly(N-isopropylacrylamide) in water. Polymer 44, 7175–7180 (2003).

Ajiro, H., Takahashi, Y. & Akashi, M. Thermosensitive biodegradable homopolymer of trimethylene carbonate derivative at body temperature. Macromolecules 45, 2668–2674 (2012).

Acknowledgements

We would like to express our appreciation to The Hitachi Scholarship Foundation for the research fellowship to W Tachaboonyakiat. This work was also supported in part by Arai Scientific Technology Promoting Foundation and the MEXT project, ‘Creating Hybrid Organs of the future’ at Osaka University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tachaboonyakiat, W., Ajiro, H. & Akashi, M. Synthesis of a thermosensitive polycation by random copolymerization of N-vinylformamide and N-vinylbutyramide. Polym J 45, 971–978 (2013). https://doi.org/10.1038/pj.2013.12

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2013.12