Abstract

Pd complexes with diimine ligands promoted the controlled cyclopolymerization of 1,6-dienes and 1,6,11-trienes to afford polymers containing 1,2-trans-cyclopentane groups with well-regulated stereochemistry. The polymerization proceeded with quantitative cyclization of the monomer, even under bulk conditions or in copolymerization reactions with ethylene and α-olefins. The polymerization of monomers with oligomethylene spacers yielded polymers with five-membered rings that are accurately distributed along the polymer chain. 4-Alkylcyclopentenes and alkenylcyclohexanes were also polymerized by Pd–diimine complexes to afford polymers with 1,3-trans-cyclopentane groups and 1,4-trans-cyclohexane groups, respectively. Pd complexes with a C2 symmetrical structure promoted the isospecific polymerization of 4-alkylcyclopentenes, and the resultant isotactic polymers showed liquid crystalline properties. The mechanism of the polymerization reaction has been revealed.

Similar content being viewed by others

Introduction

Recently, hydrocarbon polymers with cycloalkane groups along the polymer chain have attracted a considerable amount of attention because they exhibit high thermal stability and optical transparency.1 Addition polymerization of cyclic alkenes2, 3 and metathesis polymerization of norbornenes4, 5, 6 have been used to synthesize these polymers (Scheme 1). Cyclic groups on the monomer can be introduced into the polymer as cis-fused cycloalkane groups.7, 8, 9, 10, 11 The polymerization of non-conjugated dienes can also be used to synthesize polymers with cycloalkane groups because chain growth is accompanied by monomer ring closure.12 Early transition metal complexes have been extensively used in cyclopolymerization reactions.13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24 The polymers produced via cyclopolymerization often contain both cis- and trans-isomeric repeating units. Owing to the high oxophilicity of early transition metals, cyclopolymerization reactions of non-conjugated dienes with polar functional groups are relatively scarce.25

Compared with the corresponding homopolymers, the copolymerization of cyclic alkenes with ethylene or α-olefins produces polymers with cycloalkane groups in a relatively low density.26, 27, 28, 29, 30, 31, 32, 33, 34 The average density of cyclic units along the polymer chain can be controlled by changing the molar ratio of monomers, and the polymer properties also vary accordingly. However, the accurate control of the distribution of cyclic units in the polymer chain has not been achieved. The copolymerization of non-conjugated dienes with ethylene or α-olefins often produces polymers with uncyclized units, because the reactivity of ethylene and α-olefins is greater than that of non-conjugated dienes, which results in the preferential insertion of monomers over the cyclization of the diene unit at the end of the growing chain.35, 36, 37, 38, 39, 40, 41, 42, 43, 44, 45, 46

In contrast to early transition metal complexes, late transition metal complexes are highly active for the oligomerization of ethylene but are not suitable for polymerization. However, in 1995, Brookhart reported that Pd and Ni complexes with diimine ligands show high catalytic activity for the polymerization of ethylene, propylene and α-olefins.47 Since the discovery of Brookhart’s catalyst, many complexes based on late transition metals have been reported.48, 49 Although many studies on ethylene polymerization by late transition metal catalysts have been published, only limited examples of propylene or α-olefin polymerization have been presented.50 In contrast, Pd and Ni complexes with diimine ligands are effective for α-olefin polymerization.51

Conventional catalysts such as zirconocenes produce linear polyethylene and polyolefins with alkyl side chains in the polymerization of ethylene and α-olefins, respectively. In contrast, Pd- and Ni-diimine catalysts afford polyethylenes with highly branched structures and poly(α-olefin)s containing non-branched polymethylene repeating units, respectively (Scheme 2 (I)).47, 52, 53, 54, 55, 56, 57 The production of these polymers can be attributed to the occurrence of chain-walking reactions, in which alkylpalladium and alkylnickel species at the growing ends of the polymer undergo repetitive β-hydrogen elimination of vinyl-terminated polyolefins followed by reinsertion of the coordinated olefin into the metal-hydrogen bond (Scheme 2 (II)).

The copolymerization of ethylene or α-olefins with polar monomers such as acrylates has been difficult to achieve because most catalysts are composed of early transition metal complexes.58 In contrast, Pd catalysts promote the copolymerization of ethylene with polar monomers to give functionalized polyethylene.59, 60, 61

Recently, we demonstrated that late transition metal complexes are effective for stereoselective cycloolefin polymerization and diene cyclopolymerization reactions.62, 63 The resulting polymers contain 1,2- or 1,3-disubstituted trans-fused cyclopentane rings, which have been difficult to synthesize in a controlled manner by using conventional polymerization catalysts. Various functionalities can be incorporated into cyclopentane rings. The present article describes the scope and limitations of the controlled polymerization of cyclopentenes, dienes and trienes by late transition metal complexes.

Cyclopolymerization of non-conjugated dienes by Pd complexes

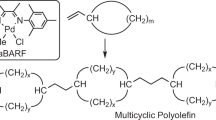

1,6-Heptadienes undergo cyclopolymerization in the presence of Pd–diimine complexes and NaBARF (BARF=B(C6H3(CF3)2-3,5)4).64, 65 The cyclopolymerization reaction proceeds with quantitative cyclization to afford polymers with high molecular weights, even under bulk conditions. In contrast, conventional catalysts frequently afford polymers with uncyclized repeating units and/or cross-linked repeating units as a result of their insufficient cyclization efficiency, especially under bulk conditions.66, 67, 68

Scheme 3 shows representative monomers that can be polymerized by Pd complexes. These monomers can be readily synthesized through bis-allylation of active methylene compounds such as malonates (I-a, I-b) or diketones (I-f, I-g). Pd catalysis is compatible with polar functional groups such as barbiturates (I-c, d) and sulfonamides (I-j, I-k, I-l). The stereochemistry of the cyclopentane ring of the polymer is controlled in a trans-configuration, as confirmed by the corresponding 13C(1H) nuclear magnetic resonance (NMR) spectra (Figure 1). Dienes with indanedione groups (I-f) and cyclic acetal groups (I-h) lead to polymers with sufficient molecular weights and narrow molecular weight distributions, even at lower temperatures. Polymer growth resumes as a result of monomer re-addition after polymerization, and polymers with higher molecular weights are produced, indicating that living cyclopolymerization occurs at low temperatures.

In contrast to the aforementioned monomers, the dienes shown in Scheme 4, including diallyl ether, diallyldimethylsilane, and 4,4-dicyano-1,6-heptadiene, do not afford high mass polymers. Unsubstituted 1,6-heptadiene is not suitable for cyclopolymerization because of the formation of stable π-allyl palladium species that do not promote further polymer growth.48

Complexes 1a and 1b, which possess a C2v symmetrical structure, produce atactic polymers of Ia, whereas C2 symmetrical complexes 1c and 1d afford threo-diisotactic polymers with a rr of 83% and 66%, respectively (Scheme 5). Recently, Kinbara and Aida69 demonstrated that 1e, a Pd complex containing a cyclic diimine ligand, was effective for the synthesis of threo-disyndiotactic diallylmalonates polymers (Scheme 5). In addition, the resulting polymer has been shown to adopt ordered aggregates.

Derivatives of Meldrum’s acid are known to undergo unique reactions.70 Baxter reported that the pyrolysis of 2,2-dimethyl-1,3-dioxane-4,6-dione-5-spirocyclopropane at 500 °C (0.05 mm Hg) produces ketenes and promotes the release of CO2 and acetone, which are converted to ketene dimer dispiro-(2.1.2.1)-octane-4,8-dione.71 Similar reactions of polymers containing Meltrum's acid moieties have been reported by Hawker.72, 73 Poly-I-a obtained using 1e as a catalyst undergoes a similar thermolysis reaction to afford cross-linked nanofibers.74

Copolymerization of non-conjugated dienes with olefins by Pd complexes

Pd–diimine complexes also catalyze the copolymerization of dienes with ethylene or α-olefins (Scheme 6). The diene undergoes quantitative cyclization during the copolymerization reaction to afford polymers with cyclopentane structures. Functionalized cyclopentane rings originating from the diene are located in the main chain of the copolymer. In contrast, in the copolymerization of ethylene with acrylate by Pd–diimine complexes, the produced polymer adopts a branched structure, and ester groups originating from the acrylate are located at the termini of the branches. Ye reported that copolymers of ethylene and diene adopt a less-branched structure than homopolyethylene produced under similar conditions, owing to the introduction of repeating units from the diene in the copolymer.75 Chain-walking reactions across the repeating unit from the diene are suppressed by the presence of trans-fused 1,2-cyclopentane rings in the polymer chain.

Synthesis of telechelic polyolefin and formation of a thermoreversible gel

Reaction of equimolar amounts of the Pd complex and monomer in the presence of NaBARF and subsequent recrystallization of the products yields 1a–I-a, a complex containing a five-membered C,O-chelating ring, as revealed by X-ray crystal structure and NMR analysis (Figure 2).

The isolated chelate complex initiates the cyclopolymerization of non-conjugated dienes and the polymerization of α-olefins with quantitative initiation efficiency. The resulting polymer contains the functional group from the chelate complex on the initiating end of the polymer chain. The polymerization of 1-hexene proceeds in living fashion, and another functional groups can be introduced on the terminating end of the polymer by adding functionalized olefin as the terminating reagent.

Thus, polyhexene with barbiturate groups on both termini (II) was synthesized by the polymerization of 1-hexene using 1a-I-c as the initiator and I-c and triethylsilane as the terminator (Scheme 7). Barbiturates form triple hydrogen bonds with melamine or 2,4,6-triaminopyrimidine, which have been employed to induce gel formation.76, 77 For instance, solutions of toluene containing telechelic polymer and melamine or 2,4,6-triaminopyrimidine form thermoreversible gels (Figure 3).

Isomerization cyclopolymerization of monoalkyl-substituted dienes by Pd complexes

Palladium-diimine complexes promote the polymerization of alkyl-substituted 1,6-dienes to produce polymers with alternating repeating units containing trans-1,2-disubstituted cyclopentane rings and oligomethylene spacers (Scheme 8).78 The polymers do not show 1H NMR signals that would arise from the presence of branches. Quantitative cyclopolymerizations of dienes with inner olefins are rare due to their poor reactivity.

Similar to the cyclopolymerization of 1,6-heptadienes, alkyl-substituted 1,6-dienes with various functional groups such as malonate, cyclic imide, tosylamide and cyclic acetal groups also undergo cyclopolymerization. The polymerization of dienes with acetal groups proceeds in a living fashion at –20 °C to produce polymers with narrow molecular weight distributions (Mw/Mn=1.20). The polymerization of 1,6-heptadiene followed by 1,6-octadiene affords the corresponding block copolymer. This material possesses a glass transition temperature of 80 °C, which is in between the glass transition temperature of the homopolymers (90 °C and 72 °C, respectively). Diene monomers with isopropyl or isobutyl groups can also be used, and the resulting polymers possess methyl branches at regular intervals.79 However, the polymerization of dienes with sec-butyl groups displays insufficient cyclization efficiency.

Mechanism of cyclopolymerization

Scheme 9 depicts the proposed mechanism of cyclopolymerization. 2,1-Insertion of the olefinic group of the diene results in the formation of 5-hexenylpalladium intermediates (A), which undergo subsequent intramolecular 1,2-insertion of the remaining alkenyl group to form cyclopentylmethylpalladium intermediate B. The cyclization occurs in a trans-selective manner. Similar trans-selective cyclizations of 1,6-diene have also been observed in Pd-catalyzed cyclization hydrosilylation reactions.80, 81 Intermediate B may react with another monomer in a similar manner, resulting in chain growth; however, intermediate B also undergoes chain-walking reactions to produce cyclopentylpalladium intermediate C.

Although intermediates B and C are in equilibrium, the equilibrium resides largely toward the formation of C. However, dienes and olefins cannot insert into the CH-Pd bond of intermediate C, and insertion occurs only after the isomerization of C to B. In the polymerization of alkyl-substituted 1,6-diene, the new monomer inserts exclusively into the CH2-Pd bond of intermediate B′, which results in the formation of polymers with controlled repeating sequences.

Double cyclopolymerization of non-conjugated trienes by Pd complexes

In contrast to the cyclopolymerization of non-conjugated dienes, cyclopolymerizations of trienes are rare.82 The ordered and quantitative reaction of three C=C double bonds during chain growth is required for the formation of polymers with controlled structures. Recently, we found that Pd–diimine complexes are effective for the polymerization of 1,6,11-dodecatrienes with functional groups such as cyclic acetals and cyclic esters (Scheme 10).83 Double cyclization occurs quantitatively during polymerization. The resulting polymers contain two trans-1,2-cyclopentane rings in each repeating unit, and the relative stereochemistry between the two five-membered rings is controlled in the racemic structure.

The polymerization of trienes with acetal groups produces polymers with narrow molecular weight distributions. The polymer obtained using 1a is rich in racemo-syndiotactic sequences (91%). The acetal group of the polymer can be easily hydrolyzed in the presence of trifluoroacetic acid. In contrast to these monomers, trienes with sulfonamide or fluorenylidene groups do not undergo polymerization; however, cyclopolymerization reactions of dienes with the same functional groups proceed smoothly.

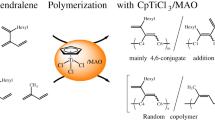

Isomerization polymerization of 4-alkylcyclopentene

The polymerization of cyclopentene by zirconocenes or Pd- and Ni-diimine catalysts affords polymers with cis-fused 1,3-cyclopentane rings. Reports on the polymerization of substituted cyclopentanes are relatively rare.84 We found that Pd-catalyzed polymerization of 4-alkylcyclopentenes is an efficient method for synthesis of polymers with trans-fused 1,3-cyclopentane rings (Scheme 11 (I)).85 Isomerization occurs during chain growth, and polymers with oligomethylene-1,3-trans-cyclopentane repeating units are produced. The length of the oligomethylene spacer is determined by the length of the alkyl group on the monomer.

A plausible mechanism for the polymerization reaction includes face-selective coordination and insertion of the monomer into the Pd-alkyl intermediate to form a cyclopentylpalladium species and selective insertion of a new monomer into the Pd-CH2 bond of the intermediate that forms after chain walking (Scheme 11 (II)).

Pd complex 1c, which contains a C2 symmetric diimine ligand, promotes isospecific polymerization reactions. The highly threo-diisotactic polymer shows liquid crystalline properties, as analyzed by polarizing microscopy and differential scanning calorimetry (DSC), whereas atactic polymers do not show such properties. The temperature of the transition between the liquid crystalline phase and solid phase or isotropic phase can be controlled by the length of the oligomethylene spacer of the polymer (Figure 4). Examples of liquid crystalline polyolefins are very limited.86, 87 The presence of stereo-regular five-membered rings may order the alignment of the polymer chain, which produces a material with liquid crystalline properties.

Isomerization polymerization of alkenylcyclohexane

Although Pd catalysts are effective for the isomerization polymerization of alkylcyclopentenes, the polymerization of 3-methylcyclohexene does not proceed in the presence of the catalysts. In contrast, alkenylcyclohexanes undergo smooth isomerization polymerization to afford polymers containing trans-fused 1,4-cyclohexane rings (Scheme 12 (I)).88 The intervals between adjacent cyclohexane rings in the polymer are determined by the length of the oligomethylene spacer between the vinyl and cyclohexyl group of the monomer. The active species in the polymerization reaction is a cyclohexyl Pd complex, which undergoes selective 2,1-insertion of the monomer followed by chain walking of the resulting intermediate. In contrast to the isomerization polymerization of alkyl-substituted dienes and 4-alkylcyclopentene, intermediates containing a Pd-CH2 bond do not form in the polymerization of alkenylcyclohexane. The insertion of another monomer into an intermediate containing a 4-alkylcyclohexyl-Pd bond occurs selectively to yield a polymer with trans-fused 1,4-disubstituted six-membered rings (Scheme 12 (II)).

Summary

We have shown that Pd-catalyzed cyclopolymerizations of dienes and trienes and isomerization polymerizations of alkylcyclopentenes and alkenylcyclohexanes are effective methods for the synthesis of polymers with trans-fused cycloalkane groups. In the cyclopolymerization of dienes and trienes, various functional groups such as cyclic esters, acetals and imides can be incorporated into the cyclopentane group of the polymer. Further modification of the functional groups in the polymer is also possible. Through the chain-walking isomerization of growing termini, polymers containing a regular distribution of cyclopentane or cyclohexane groups can be synthesized.

The melting temperature and/or glass transition temperature of polymers with trans-fused five-membered rings are comparable to those that of polymers with cis-fused rings.89, 90 In addition, stereo-regular polymers with trans-1,3-cyclopentane rings show liquid crystalline properties. Further design of novel monomers will allow the synthesis of polymers with unique cyclic structures.

Synthesis of polyolefins with cycloalkane groups.

(i) Polymerization of ethylene and 1-hexene by Pd–diimine complexes and (ii) the mechanism of chain walking.

Cyclopolymerization of 1,6-heptadienes by Pd–diimine complexes.

Monomers that do not undergo smooth cyclopolymerization.

Stereospecific polymerization of diallylmalonate (I-a).

Copolymerization of ethylene with I-a and thermolysis of poly(I-a-co-ethylene).

Synthesis of telechelic polyhexene.

Isomerization cyclopolymerization of alkyl-substituted 1,6-dienes.

Mechanism of cyclopolymerization of (i) 1,6-heptadienes and (ii) alkyl-substituted 1,6-dienes.

Double cyclopolymerization of 1,6,11-trienes and hydrolysis.

(i) Polymerization of 4-alkylcyclopentenes by Pd complexes and (ii) the mechanism of polymerization.

(i) Polymerization of alkenylcyclohexanes by Pd complexes and (ii) the mechanism of polymerization.

References

Yamazaki, M. Industrialization and application development of cyclo-olefin polymer. J. Mol. Catal. A: Chem. 213, 81–87 (2004).

Janiak, C. & Lassahn, P. G. The vinyl homopolymerization of norbornene. Macromol. Rapid Commun. 22, 479–492 (2001).

Li, X. & Hou, Z. Organometallic catalysts for copolymerization of cyclic olefins. Coord. Chem. Rev. 252, 1842–1869 (2008).

Bielawski, C. W. & Grubbs, R. H. Living ring-opening metathesis polymerization. Prog. Polym. Sci. 32, 1–29 (2007).

Slugovc, C. The ring opening metathesis polymerisation toolbox. Macromol. Rapid Commun. 25, 1283–1297 (2004).

Frenzel, U. & Nuyken, O. Ruthenium-based metathesis initiators: development and use in ring-opening metathesis polymerization. J. Polym. Sci. Part A Polym. Chem. 40, 2895–2916 (2002).

Collins, S. & Kelly, W. M. The microstructure of poly(cyclopentene) produced by polymerization of cyclopentene with homogeneous Ziegler-Natta catalysts. Macromolecules 25, 233–237 (1992).

Kelly, W. M., Taylor, N. J. & Collins, S. Polymerization of cyclopentene using metallocene catalysts: polymer tacticity and properties. Macromolecules 27, 4477–4485 (1994).

Arndt, M. & Kaminsky, W. Polymerization with metallocene catalysts. hydrooligomerization and NMR investigations concerning the microstructure of poly(cyclopentenes). Macromol. Symp. 95, 167–183 (1995).

Kelly, W. M., Wang, S. & Collins, S. Polymerization of cyclopentene using metallocene catalysts: competitive cis- and trans-1,3 insertion mechanisms. Macromolecules 30, 3151–3158 (1997).

McLain, S. J., Feldman, J., McCord, E. F., Gardner, K. H., Teasley, M. F., Coughlin, E. B., Sweetman, K. J., Johnson, L. K. & Brookhart, M. Addition polymerization of cyclopentene with nickel and palladium catalysts. Macromolecules 31, 6705–6707 (1998).

Butler, G. B. Cyclopolymerization. J. Polym. Sci. Part A Polym. Chem. 38, 3451–3461 (2002).

Resconi, L. & Waymouth, R. M. Diastereoselectivity in the homogeneous cyclopolymerization of 1,5-hexadiene. J. Am. Chem. Soc. 112, 4953–4954 (1990).

Kesti, M. R. & Waymouth, R. M. Highly chemo- and stereoselective cyclopolymerization of 2-methyl-1,5-hexadiene: chain transfer via β-CH3 elimination. J. Am. Chem. Soc. 114, 3565–3567 (1992).

Mogstad, A.-L. & Waymouth, R. M. Chain transfer to aluminum in the homogeneous cyclopolymerization of 1,5-hexadiene. Macromolecules 25, 2282–2284 (1992).

Coates, G. W. & Waymouth, R. M. Chiral polymers via cyclopolymerization. J. Mol. Catal. 76, 189–194 (1992).

Coates, G. W. & Waymouth, R. M. Enantioselective cyclopolymerization of 1,5-hexadiene catalyzed by chiral zirconocenes: a novel strategy for the synthesis of optically active polymers with chirality in the main chain. J. Am. Chem. Soc. 115, 91–98 (1993).

Sernetz, F. G., Mülhaupt, R. & Waymouth, R. M. Homo-, co-, and terpolymerization of 1,5-hexadiene using a methylalumoxane activated mono-Cp-amido-complex. Polym. Bull. 38, 141–148 (1997).

Naga, N., Shiono, T. & Ikeda, T. Copolymerization of propene and nonconjugated diene involving intramolecular cyclization with metallocene/methylaluminoxane. Macromolecules 32, 1348–1355 (1999).

Jayaratne, K. C., Keaton, R. J., Henningsen, D. A. & Sita, L. R. Living Ziegler-Natta cyclopolymerization of nonconjugated dienes: new classes of microphase-separated polyolefin block copolymers via a tandem polymerization/cyclopolymerization strategy. J. Am. Chem. Soc. 122, 10490–10491 (2000).

Kim, I., Shin, Y. S., Lee, J. K. & Won, M.-S. Cyclopolymerization of 1,5-hexadiene catalyzed by various stereospecific metallocene compounds. J. Polym. Sci. Part A Polym. Chem. 38, 1520–1527 (2000).

Imanishi, Y., Naga, N. & Tsubooka, M. Synthesis of polyolefins with unique properties by using metallocene-type catalysts. Macromol. Symp. 195, 45–62 (2003).

Napoli, M., Costabile, C., Pragliola, S. & Longo, P. Closing cycles with C2-Symmetric Ziegler-Natta polymerization catalysts. Macromolecules 38, 5493–5497 (2005).

Yeori, A., Goldberg, I. & Kol, M. Cyclopolymerization of 1,5-hexadiene by enantiomerically-pure zirconium salan complexes. polymer optical activity reveals α-olefin face preference. Macromolecules 40, 8521–8523 (2007).

Kesti, M. R., Coates, G. W. & Waymouth, R. M. Homogeneous Ziegler-Natta polymerization of functionalized monomers catalyzed by cationic group IV metallocenes. J. Am. Chem. Soc. 114, 9679–9680 (1992).

Jerschow, A., Ernst, E., Hermann, W. & Müller, N. NMR evidence for a new microstructure in ethylene-cyclopentene copolymers. Macromolecules 28, 7095–7099 (1995).

Fujita, M. & Coates, G. W. Synthesis and characterization of alternating and multiblock copolymers from ethylene and cyclopentene. Macromolecules 35, 9640–9647 (2002).

Naga, N. & Imanishi, Y. Copolymerization of ethylene cyclopentene with zirconocene catalysts: effect of ligand structure of zirconocenes. Macromol. Chem. Phys. 203, 159–165 (2002).

Lavoie, A. R., Ho, M. H. & Waymouth, R. M. Alternating stereospecific copolymerization of cyclopentene and ethylene with constrained geometry catalysts. Chem. Commun. 864–865 (2003).

Tang, L.-M., Duan, Y.-Q., Pan, L. & Li, Y.-S. Copolymerization of ethylene and cyclopentene with bis(β-enaminoketonato) titanium complexes. J. Polym. Sci. Part A Polym. Chem. 43, 1681–1689 (2005).

Wang, W., Fujiki, M. & Nomura, K. Copolymerization of ethylene with cyclohexene (CHE) catalyzed by nonbridged half-titanocenes containing aryloxo ligand: notable effect of both cyclopentadienyl and anionic donor ligand for efficient CHE incorporation. J. Am. Chem. Soc. 127, 4582–4583 (2005).

Liu, J. & Nomura, K. Highly efficient ethylene/cyclopentene copolymerization with exclusive 1,2-cyclopentene incorporation by (cyclopentadienyl)(ketimide)titanium(IV) Complex-MAO catalysts. Adv. Synth. Catal. 349, 2235–2240 (2007).

Zou, H., Zhu, F. & Wu, Q. Synthesis of novel branched ethylene/cyclopentene copolymers with only cis-1,3-enchained cyclopentene units using α-diimine nickel(II) complexes in the presence of methylaluminoxane. J. Polym. Sci. Part A Polym. Chem. 46, 2186–2192 (2008).

Itagaki, K. & Nomura, K. Efficient synthesis of functionalized polyolefin by incorporation of 4-vinylcyclohexene in ethylene copolymerization using half-titanocene catalysts. Macromolecules 42, 5097–5103 (2009).

Doi, Y., Tokuhiro, N. & Soga, K. Synthesis and structure of a ‘living’ copolymer of propylene and 1,5-hexadiene. Makromol. Chem. 190, 643–651 (1989).

Bergemann, C., Cropp, R. & Luft, G. Copolymerization of ethylene and 1,5-hexadiene under high pressure catalyzed by a metallocene. J. Mol. Catal. A Chem. 116, 317–322 (1997).

Naga, N., Shiono, T. & Ikeda, T. Copolymerization of propene and nonconjugated diene involving intramolecular cyclization with metallocene/methylaluminoxane. Macromolecules 32, 1348–1355 (1999).

Pietikäinen, P., Väänänen, T. & Seppälä, J. V. Copolymerization of ethylene and non-conjugated dienes with Cp2ZrCl2/MAO catalyst system. Eur. Polym. J. 35, 1047–1055 (1047).

Kim, I., Shin, Y. S. & Lee, J. K. Copolymerization of propylene and 1,5-hexadiene with stereospecific metallocene/Al(iBu)3/[Ph3C][B(C6F5)4]. J. Polym. Sci, Part A Polym. Chem. 38, 1590–1598 (2000).

Pietikäinen, P., Seppälä, J. V., Ahjopalo, L. & Pietilä, L.-O. Copolymerization of ethylene and non-conjugated dienes with Cp2ZrCl2/MAO catalyst system: effect of polymerization temperature on the copolymer structure. Eur. Polym. J. 36, 183–192 (2000).

Kokko, E., Pietkäinen, P., Koivunen, J. & Seppälä, J. V. Long-chain-branched polyethene by the copolymerization of ethene and nonconjugated α,ω-dienes. J. Polym. Sci. Part A Polym. Chem. 39, 3805–3817 (2001).

Kono, H., Mori, H. & Terano, M. Novel olefin block copolymer, polypropene-block-poly(methylene-1,3-cyclopentane-co-propene), synthesized from propene and 1,5-Hexadiene by a modified stopped-flow method. Macromol. Chem. Phys. 202, 1319–1326 (2001).

Kono, H., Ichiki, T., Mori, H., Nakatani, H. & Terano, M. Basic characterization of polypropene-block-poly(methylene-1,3-cyclopentane-co-propene) synthesized from propene and 1,5-hexadiene with modified stopped-flow method. Polym. Int. 50, 568–571 (2001).

Kim, I., Shin, Y. S., Lee, J.-K., Cho, N. J., Lee, J.-O. & Won, M.-S. Copolymerization of ethylene and 1,5-hexadiene by stereospecific metallocenes in the presence of Al(iBu)3/[Ph3C][B(C6F5)4]. Polymer 42, 9393–9403 (2001).

Choo, T. N. & Waymouth, R. M. Cyclopolymerization: a mechanistic probe for dual-site alternating copolymerization of ethylene and α-olefins. J. Am. Chem. Soc. 124, 4188–4189 (2002).

Naga, N. & Imanishi, Y. Copolymerization of ethylene and 1,5-hexadiene with zircononcene catalysts. Macromol. Chem. Phys. 203, 771–777 (2002).

Johnson, L. K., Killian, C. M. & Brookhart, M. New Pd(II) and Ni(II)-based catalysts for polymerization of ethylene and α-olefins. J. Am. Chem. Soc. 117, 6414–6415 (1995).

Ittel, S. D., Johnson, L. K. & Brookhart, M. Late-metal catalysts for ethylene homo- and copolymerization. Chem. Rev. 100, 1169–1203 (2000).

Gibson, V. C. & Spitzmesser, S. K. Advances in non-metallocene olefin polymerization catalysis. Chem. Rev. 103, 283–315 (2003).

Takeuchi, D. Recent progress in olefin polymerization catalyzed by transition metal complexes: new catalysts and new reactions. Dalton Trans. 39, 311–328 (2010).

Camacho, D. H. & Guan, Z. Desiging late-transition metal catalysts for olefin insertion polymerization and copolymerization. Chem. Commun. 46, 7879–7893 (2010).

Killian, C. M., Tempel, D. J., Johnson, L. K. & Brookhart, M. Living polymerization of α-olefins using Ni(II)-α-diimine catalysts. synthesis of new block polymers based on α-olefins. J. Am. Chem. Soc. 118, 11664–11665 (1996).

Guan, Z., Cotts, P. M., McCord, E. F. & McLain, S. J. Chain walking: a new strategy to control polymer topology. Science 283, 2059–2062 (1999).

Tempel, D. J., Johnson, L. K., Huff, R. L., White, P. S. & Brookhart, M. Mechanistic studies of Pd(II)-α-diimine-catalyzed olefin polymerizations. J. Am. Chem. Soc. 122, 6686–6700 (2000).

Gates, D. P., Svejda, S. A., Oñate, E., Killian, C. M., Johnson, L. K., White, P. S. & Brookhart, M. Synthesis of branched polyethylene using (α-diimine)nickel(II) catalysts: influence of temperature, ethylene pressure, and ligand structure on polymer properties. Macromolecules 33, 2320–2334 (2000).

McCord, E. F., McLain, S. J., Nelson, L. T. J., Ittel, S. D., Tempel, D., Killian, C. M., Johnson, L. K. & Brookhart, M. 13C NMR analysis of α-olefin enchainment in poly(α-olefins) produced with nickel and palladium α-diimine catalysts. Macromolecules 40, 410–420 (2007).

Xu, Y., Xiang, P., Ye, Z. & Wang, W.-J. Hyperbranched-linear polyethylene block polymers constructed with chain blocks of hybrid chain topologies via one-pot stagewise chain walking ethylene ‘living’ polymerization. Macromolecules 43, 8026–8038 (2010).

Boffa, L. S. & Novak, B. M. Copolymerization of polar monomers with olefins using transition-metal complexes. Chem. Rev. 100, 1479–1493 (2000).

Nakamura, A., Ito, S. & Nozaki, K. Coordination-insertion copolymerization of fundamental polar monomers. Chem. Rev. 109, 5215–5244 (2009).

Johnson, L. K., Mecking, S. & Brookhart, M. Copolymerization of ethylene and propylene wth functionalized vinyl monomers by palladium(II) catalysts. J. Am. Chem. Soc. 118, 267–268 (1996).

Mecking, S., Johnson, L. K., Wang, L. & Brookhart, M. Mechanistic studies of the palladium-catalyzed copolymerization of ethylene and α-olefins with methyl acrylate. J. Am. Chem. Soc. 120, 888–899 (1998).

Takeuchi, D., Park, S. & Osakada, K. Controlled cyclopolymerization of dienes by late transition metal complexes. J. Synth. Org. Chem. Jpn. 66, 1049–1056 (2008).

Takeuchi, D. Novel controlled polymerization of cyclo-olefins, dienes, and trienes by utilizing reaction properties of late transition metals. Macromol. Chem. Phys. 212, 1545–1551 (2011).

Park, S., Takeuchi, D. & Osakada, K. Pd complex-promoted cyclopolymerization of functionalized α,ω-dienes and copolymerization with ethylene to afford polymers with cyclic repeating units. J. Am. Chem. Soc. 128, 3510–3511 (2006).

Park, S., Okada, T., Takeuchi, D. & Osakada, K. Cyclopolymerization and copolymerization of functionalized 1,6-heptadienes catalyzed by Pd complexes: mechanism and application to physical-gel formation. Chem. Eur. J. 16, 8662–8678 (2010).

Yeori, A., Goldberg, I., Shuster, M. & Kol, M. Diastereomerically-specific zirconium complexes of chiral salan ligands: isospecific polymerization of 1-hexene and 4-methyl-1-pentene and cyclopolymerization of 1,5-hexadiene. J. Am. Chem. Soc. 128, 13062–13063 (2006).

Nomura, K., Hatanaka, Y., Okumura, H., Fujiki, M. & Hasegawa, K. Polymerization of 1,5-hexadiene by the nonbridged half-titanocene complex-MAO catalyst system: remarkable difference in the selectivity of repeated 1,2-insertion. Macromolecules 37, 1693–1695 (2004).

Volkis, V., Averbuj, C. & Eisen, M. S. Reactivity of group 4 benzamidinate complexes towards mono- and bis-substituted silanes and 1,5-hexadiene. J. Organomet. Chem. 692, 1940–1950 (2007).

Miyamura, Y., Kinbara, K., Yamamoto, Y., Praveen, V. K., Kato, K., Takata, M., Takano, A., Matsushita, Y., Lee, E., Lee, M. & Aida, T. Shape-directed assembly of a ‘macromolecular barb’ into nanofibers: stereospecific cyclopolymerization of isopropylidene diallylmalonate. J. Am. Chem. Soc. 132, 3292–3294 (2010).

Chen, B.-C. Meldrum’s acid in organic synthesis. Heterocycles 32, 529–597 (1991).

Xiang, P., Ye, Z., Morgan, S., Xia, X. & Liu, W. Tuning polyethylene chain topology via ring incorporation in chain walking ethylene polymerization. Macromolecules 42, 4946–4949 (2009).

Baxter, G. J., Brown, R. F. C., Eastwood, F. W. & Harrington, K. J. Pyrolytic generation of carbonylcyclopropane (dimethylene ketene) and its dimerization to dispiro-[2,1,2,1]-octane-4,8-dione. Tetrahedron Lett. 48, 4283–4284 (1975).

Leibfarth, F. A., Kang, M., Ham, M., Kim, J., Campos, L. M., Gupta, N., Moon, B. & Hawker, C. J. A facile route to ketene-functioalized polymers for general materials applications. Nat. Chem. 2, 207–212 (2010).

Leibfarth, F. A., Schneider, Y., Lynd, N. A., Schultz, A., Moon, B., Kramer, E. J., Bazan, G. C. & Hawker, C. J Ketene functionalized polyethylene: control of cross-linked density and material properties. J. Am. Chem. Soc. 132, 14706–14709 (2010).

Miyamura, Y., Park, C., Kinbara, K., Leibfarth, F. A., Hawker, C. J. & Aida, T. Controlling volume shrinkage in soft lithography through heat-induced cross-linking of patterned nanofibers. J. Am. Chem. Soc. 133, 2840–2843 (2011).

Hanabusa, K., Miki, T., Taguchi, Y., Koyama, T. & Shirai, H. Two-component, small molecule gelling agents. J. Chem. Soc. Chem. Commun. 1382–1384 (1993).

Yagai, S., Karatsu, T. & Kitamura, A. Melamine-barbiturate/cyanurate binary organogels possessing rigid azobenzene-tether moiety. Langmuir 21, 11048–11052 (2005).

Okada, T., Park, S., Takeuchi, D. & Osakada, K. Pd-catalyzed polymerization of dienes that involves chain-walking isomerization of the growing polymer end: synthesis of polymers composed of polymethylene and five-membered-ring units. Angew. Chem. Int. Ed. 46, 6141–6143 (2007).

Okada, T., Takeuchi, D. & Osakada, K. Cyclopolymerization of monoterminal 1,6-dienes catalyzed by Pd complexes. Macromolecules 43, 7998–8006 (2010).

Widenhoefer, R. A. Synthetic and mechanistic studies of the cycloisomerization and cyclization/hydrosilylation of functionalized dienes catalyzed by cationic palladium(II) complexes. Acc. Chem. Res. 35, 905–913 (2002).

Perch, N. S. & Widenhoefer, R. A. Mechanism of palladium-catalyzed diene cyclization/hydrosilylation: direct observation of intramolecular carbometalation. J. Am. Chem. Soc. 126, 6332–6346 (2004).

Butler, G. B. & Iachia, B. The fundamental basis for cyclopolymerization. I. unconjugated chromophoric interactions related to cyclopolymerization. J. Macromol. Sci.-Chem. A3, 803–819 (1969).

Motokuni, K., Okada, T., Takeuchi, D. & Osakada, K. Double cyclopolymerization of functionalized trienes catalyzed by palladium complexes. Macromolecules 44, 751–756 (2011).

McLain, S. J., McCord, E. F., Bennett, A. M. A., Ittel, S. D., Sweetman, K. J. & Teasley (DuPont), K. J. Polymers of substituted cyclopentenes. US Patent 6,258,908, WO 9950320 (1999).

Okada, T., Takeuchi, D., Shishido, A., Ikeda, T. & Osakada, K. Isomerization polymerization of 4-alkylcyclopentenes catalyzed by Pd complexes: hydrocarbon polymers with isotactic-type stereochemistry and liquid-crystalline properties. J. Am. Chem. Soc. 131, 10852–10853 (2009).

Naga, N., Yabe, T., Sawaguchi, A., Sone, M., Noguchi, K. & Murase, S. Liquid crystalline features in a polyolefin of poly(methylene-1,3-cyclopentane). Macromolecules 41, 7448–7452 (2008).

Naga, N., Shimura, H. & Sone, M. Liqiud crystalline features of optically active poly(methylene-1,3-cyclopentane). Macromolecules 42, 7631–7633 (2009).

Takeuchi, D. Precise isomerization polymerization of alkenylcyclohexanes: stereoregular polymers containing six-membered rings along the polymer chain. J. Am. Chem. Soc. 133, 11106–11109 (2011).

Takeuchi, D., Matsuura, R., Park, S. & Osakada, K. Cyclopolymerization of 1,6-heptadienes catalyzed by iron and cobalt complexes: synthesis of polymers with trans- and cis-fused 1,2-cyclopentanediyl groups depending on the catalyst. J. Am. Chem. Soc. 129, 7002–7003 (2007).

Takeuchi, D., Matsuura, R., Fukuda, Y. & Osakada, K. Selective cyclopolymerization of α,ω-dienes and copolymerization with ethylene catalyzed by Fe and Co complexes. Dalton Trans. 8955–8962 (2009).

Acknowledgements

I am grateful to Professor Kohtaro Osakada of the Tokyo Institute of Technology for helpful suggestions and discussion. This work was supported by a Grant-in-Aid for Young Scientists (No. 22685012) for Scientific Research from the Ministry of Education, Science, Sports and Culture, Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Takeuchi, D. Stereo-controlled synthesis of polyolefins with cycloalkane groups by using late transition metals. Polym J 44, 919–928 (2012). https://doi.org/10.1038/pj.2012.27

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.27

Keywords

This article is cited by

-

Synthesis of polycyclic polyolefins by a Pd-catalyzed isomerization polymerization of vinylcycloalkanes

Polymer Journal (2020)

-

Synthesis and thermal properties of poly(oligomethylene-cycloalkylene)s with regulated regio- and stereochemistry

Polymer Journal (2018)

-

Ligand steric effects on naphthyl-α-diimine nickel catalyzed α-olefin polymerization

Chinese Journal of Polymer Science (2018)

-

Ethylene polymerization by salicylaldimine Nickel(II) complexes derived from arylnaphthylamine

Journal of Polymer Research (2017)

-

Cyclopolymerization of a bisacrylate through selective formation of a 19-membered ring

Polymer Journal (2016)