Abstract

Heteroarm star-shaped polymers containing independent stimuli-responsive moieties were synthesized by a one-pot arm-linking reaction based on base-assisting living cationic polymerization. Mixing two or more kinds of living polymers followed by the linking reaction with a divinyl compound successfully produced a heteroarm star-shaped polymer containing a number of arm chains with a narrow molecular weight distribution (Mw/Mn=1.14–1.48) and high yield. For example, four kinds of linear poly(vinyl ether)s containing oxyethylene and alicyclic pendants were linked quantitatively to give a star polymer without any deactivation of the starting polymers. The heteroarm star-shaped polymers exhibited their unique stimuli-responsive behaviors in water or their film surfaces. Furthermore, linear living poly(2-methoxyethyl vinyl ether) and poly(2-phthalimidoethyl vinyl ether) were linked efficiently despite their different reactivities, producing a heteroarm star-shaped polymer with amino-containing and thermosensitive arms. The obtained star polymer exhibited unique aggregation behaviors in response to both pH and temperature in water. This report demonstrates that this one-pot arm-linking reaction is a facile and effective methodology for synthesis of heteroarm star polymers with various combinations of stimuli-responsive arm chains.

Similar content being viewed by others

Introduction

Construction of intelligent self-assembly systems based on the precise design and synthesis of functional polymers has been investigated extensively because of both academic interests and a number of potential applications.1, 2, 3, 4, 5, 6 To elaborate polymer assembly systems with multistep stimuli-responsive transitions, more than two stimuli-responsive chains are required, which independently change their conformations on each stimulus. To this end, branched polymers may offer suitable structures. Because heteroarm (or miktoarm) star-shaped polymers have independent sets of arm chains attached to a single core, the stimuli-responsive arm chains would transform the shapes of the whole polymer molecules to change their properties in response to each stimulus.7 Furthermore, star polymers with spherical shapes and dense structures are expected to provide unique properties and functions compared with their linear counterparts.8, 9

For the synthesis of heteroarm star polymers, especially with many arm chains, a sequential arm extension method has typically been utilized (Scheme 1a). Sequential living polymerization from living growing sites in the core of a star polymer with homoarm chains, prepared via a polymer-linking reaction, efficiently yields a heteroarm star polymer.10, 11, 12, 13, 14, 15 However, in general, there are some drawbacks to this method, for example, a limitation to only having two kinds of arm chains and difficulty in conducting efficient second-stage polymerization from the congested core living sites. An alternative method is the ‘one-pot arm-linking method,’ which involves the reaction of a bifunctional monomer with mixed living polymers (Scheme 1b). An advantage of this method is that any ratio of two or more types of arm polymers can be set simply by varying the feed ratio of the living polymers. Very recently, Gao and Matyjaszewski16 reported the synthesis of heteroarm star polymers in high yield using the one-pot arm-linking method in living radical polymerization.

The mixing method would require a stable living polymerization system because reaction mixtures should be transferred into another vessel during the reaction. In cationic polymerization, base-assisting living polymerization has proved more robust than other methods. In addition, this system allows quantitative synthesis of star polymers with narrow molecular weight distributions (MWDs) via an arm-linking reaction.17 In this study, therefore, we investigated the feasibility of the one-pot arm-linking method for preparing heteroarm star polymers with various combinations of living polymers of vinyl ethers listed in Chart 1, followed by the addition of a small amount of bifunctional vinyl ether (1,4-cyclohexanedimethanol divinyl ether (DVE)). Property independence of arm chains in the obtained star polymers was demonstrated by their stimuli-responsive behaviors.

Experimental Procedure

Materials

2-Methoxyethyl vinyl ether (MOVE; Maruzen Petrochemical, Tokyo, Japan), 2-ethoxyethyl vinyl ether (EOVE; Maruzen Petrochemical), 2-(2-ethoxy)ethoxyethyl vinyl ether (EOEOVE; Maruzen Petrochemical) and cyclohexyl vinyl ether (CHVE; TCI; >95.5%) were washed with 10% aqueous sodium hydroxide solution and then with water, dried overnight over potassium hydroxide pellets and distilled twice over metallic sodium before use. Isobutyl vinyl ether (IBVE; TCI, Tokyo, Japan; >99.0%), DVE (Aldrich, Tokyo, Japan; 98%), ethyl acetate (Wako, Osaka, Japan; >99.5%), dichloromethane (Nacalai Tesque, Tokyo, Japan; 99%) and 2,6-di-tert-butylpyridine (DTBP) (Aldrich; >97%) were distilled twice over calcium hydride. 2-Phthalimidoethyl vinyl ether (PIVE) was prepared by the reaction of 2-chloroethyl vinyl ether with potassium phthalimide.18 This monomer was purified by recrystallization from methanol twice and then from ethyl acetate, and vacuum-dried for over 3 h prior to use. 1,4-Dioxane (Wako; >99.5%) was distilled over calcium hydride and then lithium aluminum hydride. Hexane (Wako; >96.0%) was washed with 10% aqueous sodium hydroxide solution and then with water, dried overnight over calcium chloride and distilled at least twice over calcium hydride and metallic sodium just before use. 1-(Isobutoxy)ethyl acetate (IBEA; CH3CH(OiBu)OCOCH3) was prepared from IBVE and acetic acid as previously reported.19 Commercial Et1.5AlCl1.5 (Nippon Aluminum Alkyls, Tokyo, Japan; 1.0 M solution in toluene), EtAlCl2 (Wako; 1.0 M solution in hexane), and TiCl4 (Aldrich; 1.0 M solution in toluene) were used without further purification. All materials except for PIVE, hexane and toluene were stored in brown ampules under dry nitrogen.

Synthesis of heteroarm star-shaped polymers

Polymerization was carried out under dry nitrogen atmosphere in a glass tube with a three-way stopcock baked over 300 °C for 10 min before use. A typical example for the synthesis of the heteroarm star polymer of IBVE and PIVE is as follows. Living polymers of IBVE and PIVE were prepared separately in toluene and CH2Cl2, respectively. The polymerization of IBVE (or PIVE) was initiated by the addition of a prechilled Et1.5AlCl1.5 solution in toluene (or CH2Cl2 for PIVE) (200 mM) into a mixture of 1,4-dioxane, IBVE (or PIVE) and IBEA in toluene (or CH2Cl2 for PIVE) using a dry medical syringe at 0 °C. When both IBVE and PIVE had been consumed almost quantitatively, these polymerization solutions were mixed at a given ratio, and then DVE in toluene (1.0 M) was added to the mixture at 0 °C (r=[DVE]0/[living ends]=10). The polymerization was terminated with prechilled methanol containing a small amount of an aqueous ammonia solution (0.3 wt%). The quenched reaction mixture was washed with dilute hydrochloric acid to remove initiator residue and was neutralized, evaporated to dryness under reduced pressure and then vacuum-dried overnight.

Film preparation

The film of a heteroarm star-shaped polymer ((CHVE100)-(MOVE100)-(EOEOVE100)-star) was prepared by the solution casting method. A 1 wt% water/ethanol (1:1 wt:wt) solution of the polymer was deposited onto a glass plate and dried in a solvent atmosphere for 1 day and then under vacuum for 3 h at room temperature.

Deprotection procedures

To remove the pendant phthalimide groups, the phthalimide-containing polymer ((PIVE40)-star-(MOVE100)) was dissolved in a mixture of 1,4-dioxane/methanol (2:1 v:v) and hydrazine monohydrate was added. The solution was refluxed with stirring for 3 h. After the volume of solvent and unreacted hydrazine was decreased under vacuum, a white powder (polymeric ammonium salt of phthalylhydrazine) precipitated. Next, 0.5 M hydrochloric acid was added to the residue. The mixture was refluxed for 15 min with vigorous stirring. The solution was diluted with water and heated for an additional 45 min. The resulting insoluble byproduct (phthalylhydrazide) was removed by filtration. The filtrate was neutralized with 1.0 M aqueous sodium hydroxide (equivalent to the hydrochloric acid employed) and the polymer product was purified by dialysis against distilled water for at least 2 days and then Milli-Q water for a day (molecular weight cut off (MWCO) of dialysis tube is 12,000).

Characterization

The MWD of the polymers was measured using gel permeation chromatography (GPC) in chloroform at 40 °C with three polystyrene gel columns (Tosoh, Tokyo, Japan; TSK gel G-4000HXL, G-3000HXL, and G-2000HXL; exclusion limit molecular weight=4 × 105, 6 × 104 and 1 × 104, respectively; column size=7.8 mm (internal diameter)× 300 mm; flow rate=1.0 ml min−1) connected to a Tosoh DP-8020 pump, a CO-8020 column oven, a UV-8020 ultraviolet detector and an RI-8020 refractive-index detector. The number−average molecular weight (Mn) and polydispersity ratio [weight−average molecular weight/number−average molecular weight (Mw/Mn)] were calculated from the chromatographs with respect to 16 polystyrene standards (Tosoh; Mn=577−1.09 × 106, Mw/Mn<1.1). The weight−average molecular weight (Mw) of the star polymers was determined by GPC coupled with multi-angled laser light scattering (GPC-MALLS) in chloroform at 40 °C on a Dawn E instrument (Wyatt Technology, Santa Barbara, CA, USA; Ga-As laser, λ=690 nm). Nuclear magnetic resonance (NMR) spectra of the polymer products were recorded using a JEOL JNM-ECA 500 spectrometer (JEOL, Tokyo, Japan) or a JEOL JNM-LA 500 spectrometer (JEOL) at 500 MHz. The transmittance of the polymer aqueous solutions was measured at 500 nm at various pH values using a JASCO V-550 UV-vis spectrometer equipped with a Peltier-type thermostatic cell holder ETC-505. Static contact angle measurements were conducted using a contact angle system (DM 100; Kyowa Interface Science, Saitama, Japan) with a thermostated circulator. The contact angle was measured at 30 s after the droplet was placed on the film. The average contact angle value was determined from values obtained at a minimum of two different positions. The hydrodynamic diameter (Dh) was determined by dynamic light scattering (FPAR-1000 (Otsuka Electronics, Osaka, Japan); λ=632.8 nm, scattering angle=90°).

Results and Discussion

Synthesis of heteroarm star-shaped polymers by one-pot linking reaction

To examine the feasibility of the proposed facile one-pot linking method for heteroarm star polymers, linear living (poly(IBVE)s) with different degrees of polymerization were treated with DVE. Polymerizations of IBVE with degrees of polymerization 50 and 200 were carried out separately using an adduct of IBVE with acetic acid (IBEA; CH3CH(OiBu)OCOCH3) as an initiator with EtAlCl2 in the presence of ethyl acetate in hexane at 0 °C ([IBVE]0=0.50 or 2.0 M, [IBEA]0=10 mM, [EtAlCl2]0=20 mM and [ethyl acetate]=1.0 M). After each linear living polymer had been consumed by almost 95%, the two reaction solutions were mixed and then DVE in hexane was added (r=[DVE]0/[living ends]=10). The reaction conditions examined here are typical for the quantitative star polymer synthesis of IBVE in base-assisting living cationic polymerization.17 Subsequent linking reactions at 0 °C yielded a soluble star polymer quantitatively with high molecular weight relative to that of the starting linear polymer and very narrow MWD (Figure 1a: Mn=18.1 × 104, Mw/Mn=1.19 and yield∼100%). This result indicated that the one-pot linking method would be efficient for the quantitative synthesis of heteroarm star-shaped polymers.

MWDs of the obtained polymers from the linking reaction of living poly(IBVE)s with different degrees of polymerization (a) and poly(EOVE) and poly(MOVE) (b). For the linking reaction: r=[DVE]0/[living ends]=10. For the linear arms polymerization: [monomer]0=0.50 or 2.0 M, [IBEA]0=10 mM, [EtAlCl2 (for a) or TiCl4 (for b)]0=20 mM and [ethyl acetate]=1.0 M in hexane (for a) or toluene (for b) at 0 °C. The Mn values shown here are based on a polystyrene calibration.

Thus, the method was expanded to the synthesis of star polymers containing two arm species. A heteroarm star polymer with two kinds of thermosensitive segments, poly(EOVE) and poly(MOVE) arms,20 was prepared by the linking reaction using TiCl4 in toluene ([EOVE]0=0.50M or [MOVE]0=2.0 M, [IBEA]0=10 mM, [TiCl4]0=20 mM and [ethyl acetate]=1.0 M) under optimal conditions for homoarm star polymers of EOVE and MOVE.17 Although two kinds of linear polymers were just mixed during polymerization, selective synthesis of the heteroarm star polymer was achieved without deactivating the starting polymers (Figure 1b: Mn=9.79 × 104, Mw/Mn=1.41 and yield∼100%). The thermosensitive behaviors of the obtained star polymer will be described later.

To further investigate the one-pot linking reaction, we prepared a heteroarm star-shaped polymer using MOVE and CHVE, which has a higher reactivity21 compared with IBVE and MOVE, using Et1.5AlCl1.5 in toluene ([CHVE]0=0.5 M or [MOVE]0=1.0 M, [IBEA]0=10 mM, [Et1.5AlCl1.5]0=20 mM, [1,4-dioxane]=1.2 M, [DTBP (proton trap)]=4.0 mM (for CHVE) or 0 mM (for MOVE)). The obtained MWD curves at 20 and 40 min after addition of DVE indicated that these two kinds of living polymers were consumed almost simultaneously despite of their differences in reactivity (Figure 2, Supplementary Information). After 4 h, the linking reaction was completed, yielding a star polymer with a narrow MWD (Mw/Mn=1.24) and yield∼100%. These results suggested that a heteroarm star-shaped polymer was successfully prepared even using MOVE and CHVE.

MWDs of the obtained polymers from the linking reaction of living poly(CHVE) and poly(MOVE). For the linking reaction: [living ends]=9.1 mM, r=10. For the linear arms polymerization: [CHVE]0=0.5M or [MOVE]0=1.0 M, [IBEA]0=10 mM, [Et1.5AlCl1.5]0=20 mM, [1,4-dioxane]=1.2 M and [DTBP]=4.0 mM (for CHVE) or 0 mM (for MOVE) in toluene at 0 °C. The Mn values shown here are based on a polystyrene calibration.

Synthesis of heteroarm star-shaped polymers containing three or four kinds of arms

One advantage of the proposed one-pot linking method is that any ratio of two or more kinds of arm polymers can be incorporated into a star polymer by simply mixing the living polymers. Thus, we examined the synthesis of heteroarm star-shaped polymers containing three or four kinds of arms (poly(CHVE), poly(MOVE), poly-(EOEOVE) and/or poly(EOVE)) by the one-pot linking method (Figure 3). The linking reaction of three kinds of living polymers, poly(CHVE), poly(MOVE) and poly(EOEOVE) (mixing ratio: 2/1/1), with DVE proceeded quantitatively in 8 h and yielded a star polymer with a narrow MWD (Figure 3a: Mn=6.42 × 104, Mw/Mn=1.29 and yield∼100%). Furthermore, even with four kinds of arm chains, poly(CHVE), poly(MOVE), poly(EOVE) and poly(EOEOVE) (mixing ratio: 2/0.7/0.7/0.7), selective synthesis of the star polymer was achieved (Figure 3b: Mn=8.19 × 104, Mw/Mn=1.14 and yield∼100%). These results demonstrate that this facile synthetic methodology is highly effective for the quantitative synthesis of heteroarm star-shaped polymers containing two or more kinds of arm chains. The weight−average molecular weight (Mw) of the polymers containing three and four kinds of arm chains were 1.11 × 106 and 7.23 × 105, respectively, as determined by GPC coupled with multi-angled laser light scattering (GPC-MALLS) in chloroform at 40 °C. The average number (f) of arms calculated from Mw and the composition was 75 and 49, respectively.

MWDs for the heteroarm star-shaped polymers of CHVE100, MOVE100, EOEOVE100 (a), and EOVE100 (b). For the linking reaction: [living ends]=9.1 mM, r=10. For the linear arms polymerization: [monomers]0=1.0 M, [IBEA]0=10 mM, [Et1.5AlCl1.5]0=20 mM, [1,4-dioxane]=1.2 M and [DTBP]=4.0 mM (for CHVE) or 0 mM (for others) in toluene at 0 °C. The Mn values shown here are based on a polystyrene calibration.

Synthesis of heteroarm star-shaped polymers with amino groups

This synthetic method also permitted the efficient synthesis of heteroarm star polymers from functional monomers (Chart 1). Heteroarm star polymers containing phthalimide VE (PIVE) and IBVE were prepared via the arm-linking reaction. As described in a previous report, living polymerization of PIVE requires CH2Cl2 as a polymerization solvent because of its low solubility in hexane or toluene.22 Thus, after IBVE and PIVE were polymerized almost quantitatively in toluene and CH2Cl2, respectively ([IBVE]0=1.0 M or [PIVE]0=0.40 M, [IBEA]0=10 mM, [Et1.5AlCl1.5]0=20 mM and [1,4-dioxane]=1.2 M), the subsequent linking reaction was conducted in a mixture of toluene/CH2Cl2 (1:1 v:v) at 0 °C (r=[DVE]0/[living ends]=10). Despite the sudden change in polarity and the difference in reactivity between IBVE and PIVE (Supplementary Information), the linking reaction was well controlled, yielding a star polymer with a narrow MWD (Figure 4). The UV absorption peak from the phthalimide group of PIVE was nearly identical in shape and elution volume to the RI peak of the product star polymer, which indicated that poly(PIVE) was nearly homogeneously incorporated into the obtained star polymers. This result and the following solubility result indicate that the RI peak of the obtained star polymer did not represent a mixture of two homoarm star polymers but heteroarm star polymers. In contrast to the previous examples as shown in Figures 1, 2, 3, some PIVE arm polymers remained and the yield slightly decreased in this system. The main reason for this is the lower reactivity of PIVE relative to IBVE and DVE. Therefore, to achieve quantitative star polymer synthesis of polar monomers with low reactivity, the reaction conditions must be optimized.

MWDs for the heteroarm star polymer of PIVE40 and IBVE100. For the linking reaction: [living ends]=9.1 mM, r=10. For the linear arms polymerization: [IBVE]0=1.0 M or [PIVE]0=0.40 M, [IBEA]0=10 mM, [Et1.5AlCl1.5]0=20 mM and [1,4-dioxane]=1.2 M in toluene (for IBVE) or CH2Cl2 (for PIVE) at 0 °C. The Mn values shown here are based on a polystyrene calibration, †main peak. The obtained star-shaped polymer was denoted by (PIVE40)-star-(IBVE100).

1H NMR spectra showed that the composition of the arm chains in the star polymer, fractionated using preparatory GPC, was PIVE/IBVE=34/100 (the feed composition: 40/100) (Supplementary Information). This result suggested the incorporation of both polymer chains into the star polymer. Furthermore, the peaks derived from poly(DVE) were too broad and their integral areas were too weak to be detected (Supplementary Information), indicative of the formation of a very congested microgel core with tightly cross-linked structures. The Mw of the polymer was 1.41 × 106, as determined by GPC-MALLS in chloroform at 40 °C. The number (f) of arms calculated from Mw and the composition was 124 (Table 1).

The solubility of the products was investigated next (Table 2). (IBVE100)-star (1), (PIVE40)-star (2) and the obtained heteroarm star polymer (PIVE40)-star-(IBVE100) (3) were all soluble in chloroform but insoluble in DMSO and methanol. Interestingly, both samples 1 and 3 exhibited good solubility in toluene without any precipitation, whereas sample 2 was insoluble. Only sample 1 dissolved in hexane. These results indicated that the solubility of 3 shared features of both 1 and 2, indicative of the heteroarm structure of sample 3.

Synthesis of heteroarm star polymers using PIVE and thermosensitive monomer MOVE was also carried out under the same conditions as that using PIVE and IBVE (for the linking reaction: [living ends]=9.1 mM, r=10 and for the linear arms polymerization: [MOVE]0=1.0 M or [PIVE]0=0.40 M, [IBEA]0=10 mM, [Et1.5AlCl1.5]0=20 mM and [1,4-dioxane]=1.2 M in toluene (for MOVE) or CH2Cl2 (for PIVE)). Although controlled polymerization of MOVE in CH2Cl2 was difficult (Mw/Mn∼1.4),22 the arm-linking reaction yielded star polymers efficiently with narrow MWDs even in toluene/CH2Cl2 mixtures (Figure 5). In this one-pot arm-linking method, heteroarm star polymers with different arm compositions were obtained by simply changing the feed ratio of the two kinds of living polymer solutions. Synthesis of (PIVE40)-star-(MOVE100) with PIVE40/MOVE100=1/2, 1/1, 2/1 were all well controlled with relatively high yields (79–90%) regardless of the CH2Cl2/toluene ratio (1/2, 1/1, 2/1). Furthermore, increasing UV absorption with increasing proportion of poly(PIVE) confirmed the incorporation of poly(PIVE) into the star polymers. The compositions determined by 1H NMR, Mw (GPC-MALLS) and f (the number of arms) of the star polymers are listed in Table 1.

MWDs for the heteroarm star polymers of PIVE40 and MOVE100 with ratios of 1:2 (a), 1:1 (b) and 2:1 (c). For the linking reaction: [living ends]=9.1 mM, r=10. For the linear arms polymerization: [MOVE]0=1.0 M or [PIVE]0=0.40 M, [IBEA]0=10 mM, [Et1.5AlCl1.5]0=20 mM and [1,4-dioxane]=1.2 M in toluene (for MOVE) or CH2Cl2 (for PIVE) at 0 °C. The Mn values shown here are based on a polystyrene calibration, †main peak.

Unique characteristic features of heteroarm star polymers in water and their film surfaces: independent stimuli-responsiveness of arm chains

Because the heteroarm star polymer ((EOVE100)-star-(MOVE200)) has two independent thermosensitive arms, poly(EOVE) and poly(MOVE), which display lower critical solution temperature (LCST)-type phase separation in water at 20 and 63 °C, respectively,20 its double-thermosensitive behaviors were investigated. An aqueous solution of (EOVE100)-star-(MOVE200) exhibited a two-step transition in transmittance with increasing temperature, the transition temperatures of which corresponded to that of each homoarm star polymer ((EOVE100)-star and (MOVE200)-star) (Figure 6a). This result supports the notion that the obtained star polymer possesses features of both EOVE and MOVE. Furthermore, a concentrated solution (20 wt% aqueous solution) displayed a sol-gel transition upon heating (Figure 6b).

Next, thermosensitive behaviors of the heteroarm star-shaped polymers with three different kinds of arm chains were investigated. Because poly(VE)s with pendant alicyclic groups form free-standing films with Tgs higher than room temperature and high thermal stability,21, 23, 24 thermosensitive behaviors of a heteroarm star polymer film ((CHVE100)-(MOVE100)-(EOEOVE100)-star) were examined. The surface wettability against water showed a two-step transition in response to temperature (Figure 7). The surface exhibited high affinity for water below 43 °C (contact angles∼30°) and became hydrophobic at 46–56 °C (contact angles=41–56°). Upon increasing temperature, the surface became more hydrophobic and the polymers repelled water at over 60 °C (contact angles∼60°). These wettability transition temperatures were in agreement with the LCSTs of poly(EOEOVE) and poly(MOVE) (around 40 and 63 °C),20 which indicated that the obtained star polymer with three kinds of arms also demonstrated stimuli-responsiveness of each arm chain independently.

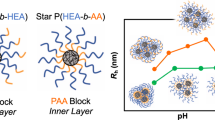

Finally, we examined the dual independent stimuli-responsiveness using a heteroarm star polymer with amino and oxyethylene pendants, (AEVE40)-star-(MOVE100) (precursor polymer: Table 1; Entry 2). The turbidity of 0.1 wt% aqueous solutions of (AEVE40)-star-(MOVE100) was measured with increasing temperature under acidic and basic conditions. At high pH (pH=11.0), a sharp phase separation was observed at approximately 60 °C, similar to homopolymers of MOVE and their block copolymers.20 In contrast, at low pH (pH=2.2), the transmittance remained nearly unchanged until 60 °C and then slightly decreased at higher temperatures as shown in Figure 8a. This behavior indicated that the protonation of amino functions dissolved the star polymer even above the LCST of the MOVE segment under acidic conditions, as in the case with the corresponding linear block copolymer.22 (The transmittance of 1.0 wt% aqueous solution of diblock copolymer MOVE200-b-AEVE50 was only slightly reduced at a low pH (pH=2) around 63 °C on increasing temperature, whereas clear phase separation was observed at a high pH (pH=12).) These stimuli-responsive behaviors were further examined using dynamic light scattering. The Dh values for the 0.01 wt% aqueous solutions of (AEVE40)-star-(MOVE100) were 167 nm at pH 2.7, 70 °C and 139 nm at pH 12.4, 40 °C (Figure 8b and ). It has previously been reported that the diameters for the star-shaped poly(IBVE)s (degrees of polymerization (arm)=50–300) ranged from ca. 5 to 40 nm in ethyl acetate.17 Therefore, the obtained sizes for (AEVE40)-star-(MOVE100) in this study suggest that the star polymers formed large aggregates.

The apparent behavior of heteroarm star-shaped polymers (Scheme 2) is similar to that of the corresponding linear diblock copolymers,22 whereas polymer aggregates constructed with star polymers are different from simple micelle structures formed by diblock copolymers. Therefore, such heteroarm star polymers containing stimuli-responsive arm chains are expected to be unique materials displaying block copolymer-like behaviors at macroscopic levels. However, further investigation is needed for nanoparticles of uniform size at microscopic levels.

Conclusions

Highly efficient synthesis of heteroarm star-shaped polymers was demonstrated using the one-pot arm-linking reaction by base-assisting living cationic polymerization. Simple mixing of living polymers and subsequent linking reaction with a divinyl compound successfully yielded heteroarm star polymers with narrow MWDs. In particular, poly(VE)s with alkyl, oxyethylene and alicyclic pendants were linked quantitatively (yield∼100%). Heteroarm star polymers containing three or four arm species with these poly(VE)s were also successfully prepared. Furthermore, this methodology was expanded to polar functional monomers, for example, heteroarm star polymers with amino-containing arms were prepared efficiently. The features of two or three arm chains were clearly demonstrated in terms of their stimuli-responsive behaviors in water or their film surfaces.

Synthesis of heteroarm star-shaped polymers via cross-linking reaction by living polymerization. (a) Sequential arm-extension method and (b) one-pot arm-linking method.

Schematic illustrations for pH/temperature-responsive behavior of (AEVE40)-star-(MOVE100) in water.

References

Hoffman, A. S. ‘Intelligent’ polymers in medicine and biotechnology. Macromol. Symp. 98, 645–664 (1995).

Riess, G. Micellization of block copolymers. Prog. Polym. Sci. 28, 1107–1170 (2003).

Harada, A. & Kataoka, K. Supramolecular assemblies of block copolymers in aqueous media as nanocontainers relevant to biological applications. Prog. Polym. Sci. 31, 949–982 (2006).

Aoshima, S. & Kanaoka, S. Synthesis of stimuli-responsive polymers by living polymerization: poly(N-isopropylacrylamide) and poly(vnyl ether)s. Adv. Polym. Sci. 210, 169–208 (2008).

Blanazs, A., Armes, S. P. & Ryan, A. J. Self-assembled block copolymer aggregates: from micelle to vesicles and their biological applications. Macromol. Rapid Commun. 30, 267–277 (2009).

Smith, A. E., Xu, X. & McCormick, C. L. Stimuli-responsive amphiphilic (co)polymers via RAFT polymerization. Prog. Polym. Sci. 35, 45–93 (2010).

Zhang, Y., Liu, H., Hu, J., Li, C. & Liu, S. Synthesis and aggregation behavior of multi-responsive double hydrophilic ABC miktoarm star terpolymer. Macromol. Rapid Commun. 30, 941–947 (2009).

Hadjichristidis, N. Synthesis of miktoarm star (μ-star) polymers. J. Polym. Sci., Part A: Polym. Chem. 37, 875–871 (1999).

Li, Z., Hillmyer, M. A. & Lodge, T. P. Morphologies of multicompartment micelles formed by ABC miktoarm star terpolymers. Langmuir 22, 9409–9417 (2006).

Kanaoka, S., Omura, T., Sawamoto, M. & Higashimura, T. Star-shaped polymers by living cationic polymerization. 3. Synthesis of heteroarm amphiphilic star-shaped polymers of vinyl ethers with hydroxyl or carboxyl pendant groups. Macromolecules 25, 6407–6413 (1992).

Tsoukatos, T., Pispas, S. & Hadjichristidis, N. Star-branched polystyrenes by nitroxide living free-radical polymerization. J. Polym. Sci., Part A: Polym. Chem. 39, 320–325 (2001).

Gao, H., Tsarevsky, N. V. & Matyjaszewski, K. Synthesis of degradable miktoarm star copolymers via atom transfer radical polymerization. Macromolecules 38, 5995–6004 (2005).

Taromi, F. A. & Rempp, P. ‘Porcupine’ polymers and double-star polymers. Makromol. Chem. 190, 1791–1798 (1989).

Tsitsilianis, C., Chaumont, P. & Rempp, P. Synthesis and characterization of hetero-arm star copolymers. Makromol. Chem. 191, 2319–2328 (1990).

Tsitsilianis, C., Lutz, P., Graff, S., Lamps, J.-P. & Rempp, P. Core-first synthesis of star polymers with potentially ionogenic branches. Macromolecules 24, 5897–5902 (1991).

Gao, H. & Matyjaszewski, K. Arm-first method as a simple and general method for synthesis of miktoarm star copolymers. J. Am. Chem. Soc. 129, 11828–11834 (2007).

Shibata, T., Kanaoka, S. & Aoshima, S. Quantitative synthesis of star-shaped poly(vinyl ether)s with a narrow molecular weight distribution by living cationic polymerization. J. Am. Chem. Soc. 128, 7497–7504 (2006).

Hashimoto, T., Ibuki, H., Sawamoto, M. & Higashimura, T. Living cationic polymerization of 2-vinyloxyethyl phthalimide: synthesis of poly(vinyl ether) with pendant primary amino functions. J. Polym. Sci., Part A: Polym. Chem. 26, 3361–3374 (1988).

Aoshima, S. & Higashimura, T. Living cationic polymerization of vinyl monomers by organoaluminum halides. 3. Living polymerization of isobutyl vinyl ether by EtAlCl2 in the presence of ester additives. Macromolecules 22, 1009–1013 (1989).

Aoshima, S., Oda, H. & Kobayashi, E. Synthesis of thermally-induced phase separating polymer with well-defined polymer structure by living cationic polymerization. I. Synthesis of poly(vinyl ether)s with oxyethylene units in the pendant and its phase separation behavior in aqueous solution. J. Polym. Sci., Part A: Polym. Chem. 30, 2407–2413 (1992).

Cramail, H. & Deffieux, A. Living cationic polymerization of cyclohexyl vinyl ether. Macromol. Chem. Phys. 195, 217–227 (1994).

Oda, Y., Kanaoka, S. & Aoshima, S. Synthesis of dual pH/temperature-responsive polymers with amino groups by living cationic polymerization. J. Polym. Sci., Part A: Polym. Chem. 48, 1207–1213 (2010).

Tsujimoto, H., Kanaoka, S. & Aoshima, S. Smart films obtained from block copolymers of various vinyl ethers: primary structures of polymers and controlled surface responsiveness. Polym. Prepr. (Am. Chem. Soc., Div. Polym. Chem.) 50, 110 (2009).

Shiono, S., Kanaoka, S. & Aoshima, S. Thermo-responsive film prepared from block copolymers of vinyl ether with a polycyclic hydrocarbon substituent. Kobunshi Ronbunshu 62, 92–95 (2005).

Acknowledgements

This research was partially supported by a Grant-in-Aid for Scientific Research (No. 22107006) on Innovative Areas of ‘Fusion Materials: Creative Development of Materials and Exploration of Their Function through Molecular Control’ (no. 2206) from the Ministry of Education, Culture, Sports, Science and Technology, Japan (MEXT) and a Grant-in-Aid for Scientific Research (C) (No. 21550209) from the Japan Society for the Promotion of Science (JSPS).

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Oda, Y., Shibata, T., Tsujimoto, H. et al. Highly efficient synthesis of heteroarm star-shaped polymers using polymer-linking reaction and their characteristic stimuli-responsive behaviors. Polym J 44, 541–549 (2012). https://doi.org/10.1038/pj.2012.23

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.23