Abstract

The immobilization of poly(N-isopropylacrylamide) (PNIPAM) onto the surface of silica beads via hyperbranched polysiloxysilane (HBPS) was studied to develop a new material for cell cultivation. HBPS terminated with a vinyl functional group was synthesized by self-polymerization of an AB2 monomer. The terminal vinyl group was converted into a chain-transfer agent for reversible addition fragmentation chain transfer (RAFT) polymerization. The obtained HBPS was immobilized on the silica surface by mixing silica beads and HBPS in hexane. The graft polymerization of PNIPAM onto the silica surface was achieved using RAFT polymerization. The molecular weights of the grafted polymers obtained by cleavage from the surface of silica beads using NaOH aqueous solution were in the range of 6000–23 000 and the polydispersity index values were 1.4–1.6. The grafted silica beads have been tested for cell cultivation. Silica-HBPS-g-PNIPAM with a higher molecular weight (Mn) of PNIPAM (cleaved PNIPAM Mn=14 800 and 23 700) showed a thermo-reversible phase transition at approximately 34 °C, and controlled cell adhesion and detachment was demonstrated with these beads.

Similar content being viewed by others

Introduction

The controlled adhesion and detachment of cells on substrate surfaces is important for various biomedical and biomaterial applications, such as tissue engineering.1 For a well-controlled cell culture, ‘smart’ surfaces that exhibit reversible bioadhesion in response to various environmental stimuli are important.2, 3, 4 Poly(N-isopropylacrylamide) (PNIPAM) is the best known of the thermo-responsive polymers and has received a great deal of attention for a wide range of biomedical applications.5, 6, 7 PNIPAM-modified surfaces exhibit surface wettability and biomolecule adhesion properties that vary with temperature because of the reversible expanded/collapsed conformational transition of the polymer chains at the lower critical solution temperature (LCST), 32 °C. Because of their unique properties, PNIPAM-modified surfaces have been developed for the controlled adsorption or adhesion of proteins,8, 9 platelets10, 11 and steroids.12 In addition, cell cultures utilizing PNIPAM substrates that enable reversible adhesion and detachment of cells have also been developed.13, 14, 15, 16, 17

Currently, the demand for cell culture in biomaterial research is increasing. In 1990, Okano’s group developed temperature-responsive cell-culture surfaces by modifying tissue-culture-polystyrene dishes with PNIPAM.18 However, such planar substrates are limited in large-scale applications from the viewpoint of chemical engineering. Materials that are applicable in three-dimensional reactors, such as batch stirred-tank reactors and continuous stirred-tank reactors, are preferable. Silica beads, which have a large specific surface area compared with the planar substrates, could be useful materials for these purposes.

We previously reported the immobilization of PNIPAM onto silica beads using hyperbranched polysiloxysilane (HBPS), which worked as a linker and a functional group in living radical polymerization.19 The advantage of hyperbranched polymers in this type of immobilization is not only to maximize the number of the chain-transfer agent (CTA) molecules introduced onto a surface with a limited surface area but also to enable strong adhesion to a silica surface. We report the synthesis of PNIPAM-modified silica beads with a hyperbranched polymer and the results of preliminary cell-adhesion experiments.

Experimental Procedure

Measurements

Nuclear magnetic resonance (NMR) (1H, 300 MHz) spectra were obtained for samples dissolved in CDCl3 using a JEOL JNM-AL 300 NMR spectrometer (Jeol, Tokyo, Japan). Infrared (IR) spectra were recorded on a JASCO FT/IR 4100 spectrometer in diffuse-reflectance mode (Jasco, Tokyo, Japan). The molecular weights of the prepared HBPS were determined by gel permeation chromatography (GPC) using a Shodex GPC-101 system with an refractive index detector and a Shodex LF-804 column (Showa Denko, Yokohama, Japan) using tetrahydrofuran (THF) as the eluent; the GPC was calibrated with the polystyrene standards The molecular weight of PNIPAM was determined using the GPC based on poly(methyl methacrylate) calibration using a Viscotek TDA 302 system (Malvern Instruments Ltd, Worcestershire, UK) with an refractive index detector and a Shodex LF-804 column with N,N′-dimethylformamide (DMF) as the eluent. Thermogravimetric analysis (TGA) was performed under air using a SII TGA 7300 system (SII Nano Technology Inc., Chiba, Japan) at a heating rate of 20 °C min−1. The light transmittance of polymer solutions (2 wt% in water) was measured at 500 nm using a JASCO V-550 spectrophotometer at a heating rate of 0.3 °C min−1.

Materials

A silica gel intended for column chromatography (TCI, spherical, 100 μm) was used for the silica beads in this study. The beads were dried under vacuum at 80 °C for 3 h before use. Chlorodimethylvinylsilane, dichloromethylsilane, 0.1 M solution of platinum(0) 1,3-divinyl-1,1,3,3-tetramethyldisiloxane complex in xylene and 2-mercaptoethanol were purchased from Sigma Aldrich Japan (Tokyo, Japan). 3-Aminopropyltriethoxysilane was purchased from TCI (Tokyo, Japan). 4-Dimethylaminopyridine, N,N′-dicyclohexyl carbodiimide, dehydrated dichloromethane and dehydrated toluene were purchased from Wako (Osaka, Japan). Diethyl ether was stirred over CaH2 and subsequently distilled. THF was used after distillation from sodium. N-Isopropylacrylamide (NIPAM) (TCI) was recrystallized twice from hexane. 2,2′-Azobis(isobutyronitrile) (AIBN) (TCI) was recrystallized from methanol. The S-1-dodecyl-S′-(α,α′-dimethyl-α′′-acetic acid) trithiocarbonate CTA (carboxyl-terminated CTA) was synthesized and purified according to a procedure literature.20 Chinese hamster ovary cell and Ham’s F-12 with L-glutamine and phenol red were used as a cell and culture medium, respectively.

Vinyl-terminated HBPS (HBPS-vinyl) (P1)

According to a previously reported procedure,19 vinyl-terminated hyperbranched poly(siloxysilane) (P1) was prepared by hydrosilylation of 1,3,5,5-pentamethyl-1,5-divinyltrisiloxane (AB2 type monomer) at 0 °C for 3 h in the presence of 0.1 mol% platinum(0) 1,3-divinyl-1,1,3,3-tetramethyldisiloxane complex in the bulk. The obtained P1 was a colorless viscous liquid (23.41 g, 47%). 1H NMR (CDCl3, δ, p.p.m.): −0.13 (br, Si(CH3)CHSi), −0.09 (br, O2Si(CH3)C), 0.12 (br, OSi(CH3)2C), 0.28 (br, SiC2H4Si), 0.87 (d, SiCH(CH3)), 5.50–5.79 (m, CH=CH2) and 5.91–6.03 (m, CH=CH2). IR (KBr, cm−1): 782 (C-Si-C, stretching), 1047 (Si-O, stretching), 1255 (Si-CH3, stretching) and 1595 (Si-CH=CH2, stretching). Mn=4100, Mw/Mn=1.53.

Hydroxyl-terminated HBPS (HBPS-OH) (P2)

In a 100 ml flask, vinyl-terminated HBPS (23.41 g, 95 mmol) was dissolved in 15 ml of toluene under nitrogen. 2-Mercaptoethanol (9.27 g, 119 mmol) and AIBN (0.99 g, 6 mmol) solution in 62 ml of toluene were subsequently added. The reaction mixture was stirred at 80 °C for 18 h. The solution was concentrated and dissolved in a small amount of diethyl ether and then precipitated twice from acetonitrile. After the solvent was removed, the product (P2) was obtained as a yellowish viscous liquid (13.23 g, 40%). 1H NMR (CDCl3, δ, p.p.m.): −0.24 (m, Si(CH3)CHSi), −0.04 (br, O2Si(CH3)C), 0.00 (br, OSi(CH3)2C), 0.32 (br, SiC2H4Si), 0.82 (m, Si(CH3)CHSi), 0.90 (m, SiCH2CH2S), 2.35 (s, CH2CH2OH), 2.48 (t, SiCH2CH2s), 2.63 (t, SCH2CH2OH) and 3.63 (s, CH2OH). IR (KBr, cm−1): 783 (C-Si-C, stretching), 1047 (Si-O, stretching), 1255 (Si-CH3, stretching) and 3382 (-OH, stretching). Mn=6200 and Mw/Mn=1.55.

Trithiocarbonate-terminated HBPS (HBPS-CTA) (P3)

In a 200 ml flask, P2 (2.0 g, 6.16 mmol), S-1-dodecyl-S′-(α,α′-dimethyl-α′′-acetic acid) trithiocarbonate (4.50 g, 12.33 mmol) and 4-dimethylaminopyridine (0.80 g, 6.16 mmol) was dissolved in 112 ml of dehydrated dichloromethane. The mixture was stirred for 30 min at 0 °C, and N,N′-dicyclohexyl carbodiimide (0.50 g, 2.37 mmol) dissolved in 5 ml of dehydrated dichloromethane was slowly added to the mixture. The resulting mixture was warmed to room temperature and stirred for 20 h. The solution was then filtered and the dehydrated dichloromethane was removed under vacuum. The crude product was precipitated into methanol. The obtained P3 was an orange, viscous liquid (3.64 g, 88%). 1H NMR (CDCl3, δ, p.p.m.): −0.21 (m, Si(CH3)CHSi), 0.05 (br, O2Si(CH3)2C), 0.12 (br, OSi(CH3)C), 0.36 (br, SiC2H4Si), 0.90 (m, S(CH2)11CH3), 0.95 (m, Si(CH3)CHSi), 1.29 (m, S(CH2)2(CH2)9C), 1.69 (m, SCCH3), 2.53 (t, SiCH2CH2S), 2.64 (t, SCH2CH2O), 3.19 (t, S-C=S-SCH2) and 4.17 (t, SCH2CH2O). IR (KBr, cm−1): 787 (C-Si-C, stretching), 1047 (Si-O, stretching), 1256 (Si-CH3, stretching) and 1736 (C=O, stretching). Mn=11000 and Mw/Mn=1.43.

Synthesis of silica-supported reversible addition fragmentation chain transfer (RAFT) agent (silica-HBPS-CTA) (P3-silica)

The prepared silica (5 g), P3 (0.62 g) and 60 ml of hexane were mixed in a 100-ml vial on a roller mixer at room temperature for 48 h.19 The product was filtered and washed overnight using a Soxhlet extractor. The sample was dried at 80 °C overnight under vacuum to give silica-HBPS-CTA.

Synthesis of silica-HBPS-g-PNIPAM

Silica-HBPS-CTA (0.7 g), NIPAM (1.13 g, 10 mmol) and 1 mg of AIBN in 3 ml of THF were added to a 20-ml tube. The tube was sealed under vacuum using a freeze-vacuum-thaw method. The tube was then placed in an oil bath at 65 °C, and the mixture was gently stirred for 18 h. The viscosity increased dramatically at the end of the reaction. The mixture was cooled to 0 °C and was immediately diluted with THF and filtered. The obtained silica beads were washed overnight using a Soxhlet extractor. The sample was dried at 80 °C overnight in vacuum to give silica-HBPS-g-PNIPAM.

Synthesis of silica-g-PNIPAM

The silica beads were treated with a 17% HCl aqueous solution. The silica beads (3 g) were dispersed in 60 ml of dry toluene, and 15 ml of 3-aminopropyltriethoxysilane was added. The solution was heated to 65 °C for 24 h. The mixture was filtered and washed with hexane and THF. The amino-functionalized particles were dispersed directly into 50 ml of THF and were reacted with CTA (1.50 g, 4.11 mmol) in the presence of N,N′-dicyclohexyl carbodiimide (0.908 g, 4.40 mmol) and 4-dimethylaminopyridine (0.013 g, 0.037 mmol) for 24 h at room temperature. The resulting mixture was poured into acetone. The precipitate was filtered and washed completely with acetone and ethanol to give silica-CTA. An ampoule that contained 0.7 g of silica-CTA, 1.13 g (10 mmol) of NIPAM and 1 mg AIBN in 3 ml of THF was sealed under vacuum using a freeze-vacuum-thaw method. The ampoule was heated at 65 °C for 18 h. The mixture was cooled to 0 °C, diluted with THF and filtered. The obtained silica beads were washed with THF using a Soxhlet extractor. The sample was dried at 80 °C overnight in vacuum to give silica-g-PNIPAM.

Cleavage of NIPAM from silica-HBPS-g-PNIPAM

In a typical experiment, silica-HBPS-g-PNIPAM (0.2 g), 1 ml of 3 M NaOH and 20 ml of MeOH were added to a 50-ml flask. The mixture was stirred and refluxed at 110 °C for 1 h. The silica was filtered out and the solution was concentrated. The crude product was dissolved in a small amount of THF and then precipitated in hexane. The precipitate was dried overnight at 60 °C under vacuum.

Cell-culture experiments

Chinese hamster ovary cells were cultured in a Nunc low cell-binding plate that contained 200 μg beads per well. The cell was incubated at 37 ° for 48 h. The cells over LCST were observed by taking photos with a microscope immediately after the incubation. The cells at room temperature were observed after cooling down the samples for 30 min. The photos were taken using an inverted microscope (U-PMTVC, Olympus, Tokyo, Japan) and a digital camera (C-300ZOOM (J), Olympus).

Results and Discussion

Synthesis and characterization of trithiocarbonate-terminated HBPS (HBPS-CTA) (P3)

Trithiocarbonate-terminated HBPS (HBPS-CTA) (P3) was synthesized according to Scheme 1. Vinyl-terminated HBPS (P1) was obtained via the self-hydrosilylation of 1,5-divyl-1,1,3,5,5-pentamethyltrisiloxane (AB2 monomer) in the presence of 0.1 mol% of platinum(0) 1,3-divinyl-1,1,3,3-tetramethyldisiloxane complex as a catalyst.19 Hydroxyl-terminated HBPS (P2) was obtained from the reaction of the vinyl groups in P1 and 2-mercaptomethanol. The absence of a vinyl peak in the 1H NMR spectrum of P2 suggested that the conversion from P1 to P2 was successful. Compound P3 was prepared by the esterification of the hydroxyl terminal group with carboxyl-terminated CTA. The 3.63-p.p.m. (s, CH2OH) peak in the 1H NMR of P2 disappeared, and the 4.17-p.p.m. (t, SCH2CH2O) peak of P3 emerged. This result indicated that the terminal group was converted almost quantitatively (Figure 1). The obtained P3 shows Mn=11 000 and Mw/Mn=1.43, as determined from GPC experiments. The chemical structure of P3 was characterized by NMR and IR spectroscopies (Figure 1).

Immobilization of trithiocarbonate-terminated HBPS (HBPS-CTA) (P3) on silica beads

The immobilization of P3 on the silica beads was performed by mixing P3 and silica beads in hexane at room temperature. Compared with whitish bare silica, the P3-immobilized beads exhibited a yellowish color. The P3-immobilized onto the silica surface was analyzed using fourier transform IR (FT-IR) (Figure 2b). For bare silica particles (Figure 2a), absorption bands at 1100 cm−1 (Si-O stretching) and 800 cm−1 (Si-O-Si bending) were observed. After the immobilization of P3, characteristic absorption bands were observed at 1739 cm−1, which was attributed to the stretching vibration of the ester C=O group, and at 2951 cm−1, which was attributed to the stretching vibration of C-H group (Figure 2b). Numerous groups have already reported that siloxane-based polymers exhibit good adhesion toward silica and silicon surfaces. We have also previously reported that the immobilized PNIPAM strongly adheres to silica beads via the hyperbranched polymer.19 From these results, P3 was assumed to have been connected to the silica surface by the interaction between the siloxane segment of P3 and the silanol group at the silica surface.

RAFT polymerization of PNIPAM onto P3-immobilized silica

The general preparation pathway for the modification of the silica beads with PNIPAM is shown in Scheme 2. RAFT polymerization of NIPAM on the silica surface was conducted in THF at 65 °C using AIBN as the initiator. The PNIPAM-modified silica surface was analyzed using FT-IR (Figure 2c). The resulting PNIPAM-modified silica showed an N-H stretching vibration and a bending vibration at 1554 and ca. 3700 cm−1, respectively. The C-H and C=O stretching vibrations also appear at 2936 and 1661 cm−1, respectively.

The results for the polymerization of NIPAM onto silica-HBPS at various monomer-to-solvent ratios are summarized in Table 1. PNIPAM grafted onto silica beads was cleaved by the hydrolysis of the ester group of CTA using an aqueous NaOH solution. The cleaved PNIPAM was isolated by filtration and precipitation into hexane, and the molecular weight (Mn) was determined using GPC. The molecular weight (Mn) of PNIPAM increases as the monomer/solvent ratio increases, as shown in Table 1. The Mw/Mn of the cleaved PNIPAM was slightly larger than that expected polydispersity index of general polymers prepared by RAFT polymerization. As reported regarding atom-transfer radical polymerization of NIPAM on a silica surface 21 and regarding RAFT polymerization using silica-immobilized CTA,22 the larger polydispersity of the cleaved NIPAM is probably due to the porous morphology of the silica beads used in the present study. The polymerization reaction inside the pores would be inhibited by the limited monomer transport compared with that at the surface. In addition, the reaction rate between chain radicals and the RAFT agent inside the pores would be slower in the pores compared with the rate of the reaction on the outer surfaces.

A comparison of the amount of polymer immobilized onto the silica beads was measured by TGA, as shown in Figure 3. The weight lost during the TGA measurement corresponds to the weight of organic polymer on the beads. As shown in the table, the polymer loading increases as the monomer/solvent ratio is increased. This increase in the polymer loading is probably due to the increase in the molecular weight of PNIPAM, as suggested by the GPC results. We conclude that polymer loading on the silica beads can be controlled by changing the RAFT polymerization conditions.

The advantage of hyperbranched polymers in this type of immobilization is to maximize the number of molecules of the CTA introduced onto a surface with a limited surface area because CTA is introduced at the terminal position of HBPS. To check the effect of a hyperbranched polymer, silica-HBPS-g-PNIPAM and silica-g-PNIPAM were compared. Silica-g-PNIPAM was prepared by graft polymerization of NIPAM from the silica surface treated with 3-aminopropyltriethoxysilane. TGA was conducted under air to evaluate the amount of polymer compound immobilized onto the silica. The polymer content of silica-g-PNIPAM and silica-HBPS-g-PNIPAM was 15.9% and 17.4% at 800 °C, respectively. These values indicate that the use of a hyperbranched polymer can introduce more PNIPAM onto a surface with a limited surface area.

Figure 4 shows the temperature dependence of the light transmittance of cleaved PNIPAM dissolved in water. Cleaved PNIPAM (Figure 4(3 and 4)) was soluble in water at low temperatures. The turbidity change occurred at approximately 34 °C in both cases, which indicates that cleaved PNIPAM (Figure 4(3 and 4)) has a LCST in aqueous solution. These findings indicate that grafted PNIPAM exhibits thermally reversible behavior at approximately 34 °C for temperature-responsive cell cultivation. However, the turbidity of the cleaved PNIPAM (Figure 4(1 and 2)) in aqueous solution was dramatically changed at 40 and 37 °C, respectively. These temperatures are higher than the corresponding temperature for linear PNIPAMs (32 °C).

Cell cultivation using silica-HBPS-g-PNIPAM

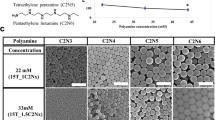

Silica-HBPS-g-PNIPAM was tested for cell culture using Chinese hamster ovary cells. Chinese hamster ovary cells were cultured in the presence of the silica-HBPS-g-PNIPAM and the samples were observed with an optical microscope. Figure 5 shows the results of the cell-culture experiments. In the optical microscopy images, the large spheres are silica-HBPS-g-PNIPAM. As shown in Figure 5c and d, silica-HBPS-g-PNIPAM has long chains of grafted PNIPAN (Mn=14 800 and 23 700, respectively), whereas silica-HBPS-g-PNIPAM (Figures 5a and b) has short lengths of grafted PNIPAM (Mn=6200 and 9100, respectively).

In all cases, cells were cultivated at 37 °C for 48 h and then cooled to 25 °C (room temperature). As shown in Figure 5a, cells distributed around the silica beads were observed at room temperature and they did not appear to detach from the silica beads under LCST. As shown in Figure 5b, the cells did not exist on the surface of the silica-HBPS-g-PNIPAM at either 37 or 25 °C. According to the literature regarding PNIPAM-grafted-silicon substrates,23 cell adhesion onto and detachment from PNIPAM-modified substrates did not work well when the thickness of the grafted PNIPAM was insufficient. The short length of grafted PNIPAM forms into a dense film structure on the surface of the substrate. This structure leads to a restriction of water infiltration into grafted PNIPAM (including hydrophobic/hydrophilic properties), and they consequently show different behaviors with respect to cell adhesion onto and cell detachment from the modified substrate. These results reveal that PNIPAM with a low Mn (<10 000) was not sufficiently thick on silica beads to show controlled cell adhesion and detachment behavior on the surface of the silica-HBPS-g-PNIPAM, even though the cleaved PNIPAM showed LCST behavior. In contrast, Figure 5c and d show cells surrounding silica beads at 37 °C, and they appear to detach from the surface at 25 °C. These results suggest that PNIPAM with a sufficient molecular weight on the silica-HBPS-g-PNIPAM showed hydrophobic behavior at 37 °C followed by hydrophilic behavior at 25 °C. This result corroborates the light transmittance results for the cleaved PNIPAM dissolved in water.

Conclusions

Silica-HBPS-g-PNIPAM was synthesized by RAFT polymerization of NIPAM onto an HBPS-immobilized silica surface as a macro RAFT polymerization agent, and the prepared materials were tested for cell cultivation. The seeded cell successfully adhered to the silica-HBPS-g-PNIPAM at 37 ° (a temperature greater than the LCST of PNIPAM) and detached from the surface at 25 °C when the Mn of PNIPAM was sufficiently large. These results suggest that the silica-HBPS-g-PNIPAM is a promising material for three-dimensional cell culture. Further study is required to optimize the polymerization conditions and to clarify the details of cell cultivation on this type of material of grafted PNIPAM to consider its large-scale application in chemical engineering.

Synthesis of trithiocarbonate-terminated HBPS (HBPS-CTA) (P3).

Preparation of silica-HBPS-g-PNIPAM.

References

Chen, H., Chen, Y., Sheardown, H. & Brook, M. A. Immobilization of heparin on a silicone surface through a heterobifunctional PEG spacer. Biomaterials 26, 7418–7424 (2005).

Matsuda, N., Shimizu, T., Yamato, M. & Okano, T. Tissue engineering based on cell sheet technology. Adv. Mater. 19, 3089–3099 (2007).

Mendes, P. M. Stimuli-responsive surfaces for bio-applications. Chem. Soc. Rev. 37, 2512–2529 (2008).

Cole, M. A., Voelcker, N. H., Thissen, H. & Griesser, H. J. Stimuli-responsive interfaces and systems for the control of protein–surface and cell–surface interactions. Biomaterials 30, 1827–1850 (2009).

Rzaev, Z. M. O., Dincer, S. & Piskin, E. Functional copolymers of N-isopropylacrylamide for bioengineering applications. Prog. Polym. Sci. 32, 534–595 (2007).

Kikuchi, A. & Okano, T. Nanostructured designs of biomedical materials: applications of cell sheet engineering to functional regenerative tissues and organs. J. Control Release 101, 69–84 (2005).

Chilkoti, A., Dreher, M. R., Meyer, D. E. & Raucher, D. Targeted drug delivery by thermally responsive polymers. Adv. Drug Deliv. Rev. 54, 613–630 (2002).

Cheng, X., Canavan, H. E., Graham, D. J., Castner, D. G. & Ratner, B. D. Temperature dependent activity and structure of adsorbed proteins on plasma polymerized N-isopropyl acrylamide. Biointerphases 1, 61–72 (2006).

Huber, D. L., Manginell, R. P., Samara, M. A., Kim, B. I. & Bunker, B. C. Programmed adsorption and release of proteins in a microfluidic device. Science 301, 352–354 (2003).

Chen, L., Liu, M., Bai, H., Chen, P., Xia, F., Han, D. & Jiang, L. Antiplatelet and thermally responsive poly(N-isopropylacrylamide) surface with nanoscale topography. J. Am. Chem. Soc. 131, 10467–10472 (2009).

Uchida, K., Sakai, K., Kwon, O. H., Ito, E., Aoyagi, T., Kikuchi, A., Yamato, M. & Okano, T. Temperature-sensitive poly(N-isopropylacrylamide)-grafted surfaces modulate blood platelet interactions. Macromol. Rapid Commun. 21, 169–173 (2000).

Idota, N., Kikuchi, A., Kobayashi, J., Akiyama, Y. & Okano, T. Thermal modulated interaction of aqueous steroids using polymer-grafted capillaries. Langmuir 22, 425–430 (2006).

Nagase, K., Kobayashi, J., Kikuchi, A., Akiyama, Y., Kanazawa, H. & Okano, T. Interfacial property modulation of thermoresponsive polymer brush surfaces and their interaction with biomolecules. Langmuir 23, 9409–9415 (2007).

Okano, T., Yamada, N., Okuhara, M., Sakai, H. & Sakurai, Y. Mechanism of cell detachment from temperature-modulated, hydrophilic-hydrophobic polymer surfaces. Biomaterials 16, 297–303 (1995).

da Silva, R. M. P., Mano, J. F. & Reis, R. L. Smart thermoresponsive coatings and surfaces for tissue engineering: switching cell-material boundaries. Trends Biotechnol. 25, 577–583 (2007).

Cooperstein, M. A. & Canavan, H. E. Biological cell detachment from poly(N-isopropyl acrylamide) and its applications. Langmuir 26, 7695–7707 (2010).

Yamato, M., Akiyama, Y., Kobayashi, J., Yang, J., Kikuchi, A. & Okano, T. Temperature-responsive cell culture surfaces for regenerative medicine with cell sheet engineering. Prog. Polym. Sci. 32, 1123–1133 (2007).

Yamada, N., Okano, T., Sakai, H., Karikusa, F., Sawasaki, Y. & Sakurai, Y. Thermo-responsive polymeric surfaces; control of attachment and detachment of cultured cells. Makromol. Chem. Rapid Commun. 11, 571–576 (1990).

Seino, M., Yokomachi, K., Hayakawa, T., Kikuchi, R., Kakimoto, M. & Horiuchi, S. Preparation of poly(N-isopropylacrylamide) grafted silica bead using hyperbranched polysiloxysilane as polymer brush and application to temperature-responsive HPLC. Polymer 47, 1946–1952 (2006).

Skey, J. & O’Reilly, R. K. Facile one spot synthesis of a range of reversible addition-fragmentation chain transfer (RAFT) agents. Chem. Commun. 35, 4183–4185 (2008).

Nagase, K., Kobayashi, J., Kikuchi, A., Akiyama, Y., Kanazawa, H. & Okano, T. Effects of graft densities and chain lengths on separation of bioactive compounds by nanolayered thermoresponsive polymer brush surfaces. Langmuir 24, 511–517 (2008).

Nguyen, D. H. & Vana, P. Silica-immobilized cumyl dithiobenzoate as mediating agent in reversible addition fragmentation chain transfer (RAFT) polymerization. Polym. Adv. Technol. 17, 625–633 (2006).

Li, L., Zhu, Y., Li, B. & Gao, C. Fabrication of thermoresponsive polymer gradients for study of cell adhesion and detachment. Langmuir 24, 13632–13639 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, B., Nabae, Y., Surapati, M. et al. Poly(N-isopropylacrylamide)-modified silica beads with hyperbranched polysiloxysilane for three-dimensional cell cultivation. Polym J 45, 210–215 (2013). https://doi.org/10.1038/pj.2012.124

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.124

Keywords

This article is cited by

-

Micro computed tomography with and without contrast enhancement for the characterization of microcarriers in dry and wet state

Scientific Reports (2021)

-

Synthesis of hyperbranched-linear poly(N-isopropylacrylamide) polymers with a poly(siloxysilane) hyperbranched macroinitiator, and their application to cell culture on glass substrates

Polymer Journal (2016)

-

Grafting of poly(lauryl acrylate) onto nano-silica by ‘click chemistry’

Chemical Research in Chinese Universities (2014)