Abstract

N,N,N’,N’-(tetrakis-2-pyridylmethyl)ethylenediamine (TPEN) derivatives bearing a polymerizable double bond in the substituent structure of the pyridine ring were synthesized and subjected to copolymerization with N-isopropylacrylamide in the presence of azobisisobutyronitrile. The obtained poly(TPEN–NIPA) gels show thermoresponsive swelling/shrinking behaviors, and are used for the extraction of cadmium(II) (CdII) ions from an aqueous solution to examine the relationship between gel characteristics and extraction performance. Polymer gels composed of TPEN derivatives bearing C3, C4, C10 and branched C3 spacer chains were synthesized, and the temperature-dependent Cd ion extraction behaviors of the gels were compared. The gels extracted CdII ions efficiently from the aqueous solution in a swelling state at 5 °C, whereas little extraction was observed at 45 °C in the shrinking state. Poly(TPEN–NIPA) gel with branched C3 spacers (C3b) shows excellent thermoresponsive extraction performance.

Similar content being viewed by others

Introduction

Functionality design based on outside stimuli has attracted considerable attention in a wide range of fields. A polymer gel composed of poly(N-isopropyl acrylamide) (poly-NIPA), which reversibly switches between swelling and shrinking corresponding to temperature changes, is therefore intriguing as a thermoresponsive functional material.1, 2, 3, 4 We have recently shown that poly(N,N,N’,N’-(tetrakis-2-pyridylmethyl)ethylenediamine (TPEN)–NIPA) gel effectively extracts soft metal ions such as cadmium(II) (CdII), and its extraction behavior is thermally dependent in various pH regions. The gel was shown to extract CdII at low temperatures, whereas little extraction was observed at elevated temperatures.5, 6, 7, 8 N,N,N’,N’-(tetrakis-2-pyridylmethyl)ethylenediamine is recognized as a hexadentate ligand with six nitrogen donors and has been shown to chelate a variety of soft metal ions such as Hg, Cd, Au and Pd.9, 10, 11, 12, 13 It was also shown to be effective for the chelation of f-block metals; the separation of minor actinides from high-level radioactive waste is a pressing issue.14, 15, 16, 17, 18, 19, 20, 21, 22, 23 Derivatives of TPEN have been used as extracting agents for a variety of metal ions in organic solvents. However, it is possible to extract metal ions from aqueous solutions without organic solvent if the TPEN moiety is incorporated into a polymer gel. Because poly-NIPA gel has been shown to swell at low temperatures in water and shrink at temperatures higher than the lower critical solution temperature,1 this thermoresponsive swelling/shrinking can function as a conformational change that induces temperature-dependent changes in TPEN extraction behavior when a TPEN moiety such as 1a is used as a crosslinker in poly-NIPA gel.

In a recent report, we used the temperature-dependent extraction of CdII ions to study the relationship between the number of polymerizable double bonds in the pyridine ring and the structure of the ethylenediamine moiety on TPEN derivatives.7, 8, 24, 25, 26, 27, 28, 29 It was shown that poly(TPEN–NIPA) gel must be prepared from TPEN derivatives bearing at least three double-bond moieties to form a stable polymer gel and to show temperature-dependent changes in extraction behaviors. Accordingly, our concern centers on the relationship between the chain length and the branched structure of the spacer moiety between the polymer main chain and TPEN moiety. In this study, we report the synthesis of several TPEN derivatives bearing four polymerizable double bonds in the substituent on the pyridine ring with different methylene spacer lengths and branched structures. We also study the temperature-dependent Cd ion extraction behaviors of poly(TPEN–NIPA) gels with different spacer structures (Scheme 1).

Experimental procedure

General

NMR (500 MHz for 1H, 125 MHz for 13C) spectra were acquired using a Bruker Avance 500 spectrometer (Bruker BioSpin, Yokohama, Japan) at the Center for the Support of Research and Education Activities, Kobe University. Chemical shifts are expressed in p.p.m. using tetramethylsilane as an internal standard (0 p.p.m.). Coupling constants (J) are shown in hertz (Hz). Infrared (attenuated total reflectance ) spectra were measured with a Bruker Optics (Tokyo, Japan) Alpha spectrometer with Ge. TLC analyses were performed on analytical TLC plates coated with 60 F254 (E Merck, Tokyo, Japan) silica gel or alumina on aluminum foil. Column chromatography was performed using silica gel Wakogel C200 (Wako Chemicals, Kanagawa, Japan) or basic alumina (Wako Chemicals or Merck). High-resolution mass spectra were measured at the Nara Institute of Science and Technology with a JEOL JMS-700 (JEOL, Tokyo, Japan). ICP-AES analysis was carried out with a SII SPS3100 (SII, Chiba, Japan) at the Center for the Support of Research and Education Activities of Kobe University.

Chemicals were used as purchased, without further purification.

Chloromethylpyridine derivatives were prepared in the manner described previously. The spectroscopic characteristics and physical properties are given below.

2-Chloromethyl-4-(buta-3-en-1-yloxy)pyridine (6b)

1H NMR (CDCl3) δ 8.35 (d, J=5.8, 1H), 6.98 (d, J=2.4, 1H), 6.72 (dd, J=5.8, 2.4, 1H), 5.81-5.91 (m, 1H), 5.10-5.19 (m, 2H), 4.60 (s, 2H), 4.07 (t, J=6.7, 2H), 2.52-2.57 (m, 2H); 13C NMR (CDCl3) 165.87, 158.03, 150.43, 133.54, 117.58, 109.50, 109.24, 67.25, 46.54, 33.11; IR 1595, 1568, 1308, 1295, 1034, 991, 919 cm−1; HRMS (EI+) calculated for C10H12ClNO [M]+: 197.0607; found: 197.0604.

2-Chloromethyl-4-(deca-9-en-1-yloxy)pyridine (6c)

1H NMR (CDCl3) δ 8.35 (d, J=5.8, 1H), 6.97 (d, J=2.4, 1H), 6.72 (dd, J=5.8, 2.4, 1H), 5.80 (ddt, J=17.2, 10.1, 6.7, 1H), 4.99 (dd, J=17.2, 1.7, 1H), 4.93 (dd, J=10.1, 1.0, 1H), 4.61 (s, 2H), 4.01 (t, J=6.6, 2H), 2.04 (dt, J=6.7, 6.6, 2H), 1.79 (quin, J=6.6, 2H), 1.31-1.48 (m, 10H); 13C NMR (CDCl3) 165.93, 157.99, 150.47, 138.94, 114.07, 109.39, 109.11, 68.00, 46.64, 33.63, 29.21, 29.10, 28.88, 28.75, 28.72, 25.76; IR 2925, 2854, 1596, 1568, 1467, 1308, 1296, 1025, 992, 909 cm−1; HRMS (EI+) calcd. for C16H24ClNO [M]+: 281.1546; found: 281.1541.

2-Chloromethyl-4-(2-methylprop-2-en-1-yloxy)pyridine (6d)

1H NMR (CDCl3) δ 8.37 (d, J=5.9, 1H), 7.01 (d, J=2.2, 1H), 6.75 (dd, J=5.9, 2.2, 1H), 5.08 (s, 1H), 5.03 (s, 1H), 4.61 (s, 2H), 4.49 (s, 2H), 1.82 (s, 3H); 13C NMR (CDCl3) 165.71, 158.15, 150.61, 139.48, 113.70, 109.73, 109.47, 71.64, 46.68, 19.27; IR 1594, 1568, 1478, 1311, 1241, 1177, 1018, 903 cm−1; HRMS (EI+) calcd. for C10H12ClNO [M]+: 197.0607; found: 197.0607.

N,N,N’,N’-Tetrakis[4-(buta-3-en-1-yloxy)pyridin-2-ylmethyl]ethylenediamine (1b)

Compound 6b (395.3 mg, 2.0 mmol), hexadecyltrimethylammonium chloride (3.2 mg, 0.01 mmol) and ethylenediamine (33.6 μl, 0.5 mmol) in H2O (0.2 ml) were added to a 25-ml round-bottom flask under nitrogen atmosphere. To those compounds, 5-M NaOH aq. (0.5 ml, 2.5 mmol) was added, and the resulting mixture was stirred vigorously at room temperature for 72 h. The reaction mixture was extracted with CH2Cl2, and the extract was washed with water, dried over anhydrous Na2SO4 and concentrated in vacuo. The residue was purified by column chromatography on aluminum oxide (EtOAc:MeOH 100:0–10:1) to afford 1b as pale brown oil in 64% yield. 1H NMR (CDCl3) δ 8.24 (d, J=5.8, 4H), 6.98 (d, J=2.4, 4H), 6.60 (dd, J=5.8, 2.4, 4H), 5.76-5.89 (m, 4H), 5.07-5.16 (m, 8H), 4.60 (s, 2H), 3.94 (t, J=6.6, 8H), 3.72 (s, 8H), 2.77 (s, 4H), 2.45-2.52 (m, 8H); 13C NMR (CDCl3) 165.62, 161.72, 150.19, 133.95, 117.57, 109.14, 108.61, 67.05, 60.88, 52.63, 33.39; IR 1595, 1567, 1305, 1033, 993, 918, 829 cm−1; HRMS (EI+) calcd. for C42H52N6O4 [M]+: 704.4050; found: 704.4051.

N,N,N’,N’-Tetrakis[4-(deca-9-en-1-yloxy)pyridin-2-ylmethyl]ethylenediamine (1c)

To a solution of ethylenediamine (4.20 μl, 0.063 mmol) in tetrahydrofuran/toluene (1:1, 0.5 ml), 6c (71.5 mg, 0.25 mmol), potassium carbonate (35.1 mg, 0.254 mmol) and NaI (19 mg, 0.127 mmol) under nitrogen atmosphere were successively added. The reaction mixture was stirred for 19 h at 50 °C. The suspension was filtered through a Celite pad. The filtrate was evaporated, and the resulting oil was purified by chromatography on alumina (EtOAc:MeOH 100:0–20:1) to afford 1c (49.5 mg, 76%) as a pale yellow oil. 1H NMR (CDCl3) δ 8.23 (d, J=5.8, 4H), 6.98 (d, J=2.4, 4H), 6.59 (dd, J=5.8, 2.4, 4H), 5.78 (ddt, J=17.2, 10.1, 6.7, 4H), 4.96 (dd, J=17.2, 1.7, 4H), 4.90 (dd, J=10.1, 1.0, 4H), 3.87 (t, J=6.6, 8H), 3.72 (s, 8H) 2.79 (s, 8H), 2.04 (dt, J=6.7, 6.6, 8H), 1.72 (quin, J=6.6, 8H), 1.29-1.40 (m, 40H); 13C NMR (CDCl3) 165.83, 160.94, 149.74, 139.02, 114.14, 109.11, 108.69, 67.88, 60.32, 52.27, 33.71, 29.34, 29.28, 29.00, 28.91, 28.85, 25.90; IR 2925, 2853, 1594, 1567, 1467, 1305, 1024, 993, 908 cm−1; HRMS (FAB+) calculated for C66H100N6O4 [M+H]+: 1041.7884; found: 1041.7894.

N,N,N’,N’-Tetrakis[4-(2-methylprop-2-en-1-yloxy)pyridin-2-ylmethyl]ethylenediamine (1d)

To a solution of ethylenediamine (4.02 μl, 0.06 mmol) in tetrahydrfuran (0.482 ml), 6d (47.1 mg, 0.241 mmol), potassium carbonate (33.3 mg, 0.24 mmol), N-hexadecyltrimethylammonium chloride (7.7 mg) and NaI (18.1 mg, 0.12 mmol) under nitrogen atmosphere were successively added. The reaction mixture was stirred for 22 h at 50 °C. The suspension was filtered through a Celite pad. The filtrate was evaporated, and the resulting oil was purified by chromatography on alumina (EtOAc) to afford 1d (29.5 mg, 70%) as a pale yellow oil. 1H NMR (CDCl3) δ 8.37 (d, J=5.9, 1H), 7.01 (d, J=2.2, 1H), 6.75 (dd, J=5.9, 2.2, 1H), 5.08 (s, 1H), 5.03 (s, 1H), 4.61 (s, 2H), 4.49 (s, 2H), 1.82 (s, 3H); 13C NMR (CDCl3) 165.12, 161.42, 149.85, 139.54, 113.14, 108.89, 108.53, 71.06, 60.58, 52.36, 19.05; IR 1593, 1567, 1481, 1307, 1241, 1166, 1019, 903, 748 cm−1; HRMS (EI+) calcd. for C42H52N6O4 [M]+: 704.4050; found: 704.4044.

General procedure for the radical polymerization of NIPA with TPEN derivatives

To a 25-ml sealed tube, equipped with a magnetic stirring bar, N-isopropylacrylamide (170 mg, 1.5 mmol) and TPEN derivative (0.019 mmol) were added. The mixture was dissolved in 0.13 ml of DMF, and azobisisobutyronitrile (1.25 mol % or 2.50 mol %) was added in one portion. The resulting mixture was heated at 60 °C for 18 h. The mixture was then cooled to room temperature and repeatedly washed with water. Poly(TPEN-NIPA) gels (C3, C4, C10 and C3b; see Scheme 3) obtained were found to swell in water at room temperature and shrink when the mixture was heated to 45 °C.

Extraction of cadmium(II) ion by poly(TPEN–NIPA) gel

An aliquot of poly(TPEN-NIPA) gel swollen in water was placed in a flask, and water was removed by heating at 50 °C under reduced pressure to leave a colorless solid, which was used for the extraction. A 1-mM aqueous Cd(NO3)2 solution was prepared. The pH values of the solutions were adjusted to 1.9, 2.0, 5.3 and 5.9 by controlled addition of 1-M aqueous NH4NO3 and 1-M HNO3. Poly(TPEN–NIPA) gel (2.5 mol% concentration of TPEN contents at the polymerization reaction) with a controlled TPEN moiety concentration of 1.5 μmol was added to 0.75 ml of the aqueous solution. Vigorous stirring of the mixture was continued for 60 min at 0 or 45 °C. An aliquot of the solution (0.2 ml) was taken, passed through a membrane filter (0.2 μm), and diluted with distilled water to 4 ml; it was then subjected to ICP-AES analysis. The amounts of CdII absorbed by poly(TPEN-NIPA) dry gels (mmol per g dry gel) are summarized in Table 1.

Results and Discussion

The synthetic pathways of TPEN derivatives with different side-chain lengths (1a-c) and branched structures (1d) are summarized in Scheme 2. Syntheses of pyridine derivatives bearing allyloxy moieties 3a-6a and TPEN derivative 1a were previously reported.5, 6, 7 Reactions affording 3b-d, 4b-d, 5b-d and 6b-d were conducted in similar manners. Although the reaction of 2-methyl-4-nitropyridine-1-oxide with allylic alcohol 2a or 2d proceeded smoothly, harsh conditions were necessary to afford 3b and 3c. Other reactions involving the introduction of the OAc group, hydrolysis of the acetoxy group and chlorination proceeded similarly. The obtained chloromethyl pyridine derivatives 6 were subjected to reaction with 1,2-ethylenediamine to afford the corresponding TPEN derivatives with substituents 1b–d. TPEN derivative 1b, which bears a 3-butenyloxy group at the 4-position of the pyridine ring, is a homologated derivative of 1a, whereas 1c (R=9-decen-1-yl) involves longer methylene groups. Derivative 1d possesses a methyl group at the C-2 carbon atom as a branched structure.

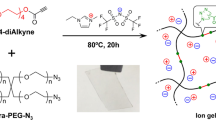

The TPEN derivatives, thus obtained, were subjected to radical copolymerization, leading to poly(TPEN–NIPA) gel (Scheme 3). The reaction was performed with NIPA and TPEN derivatives 1a–d in the presence of azobisisobutyronitrile as a radical initiator in DMF. All of the polymerizations were carried out at 60 °C for 18 h. When 1.25 mol% concentrations of TPEN derivatives 1a, 1b and 1d were used, the obtained polymer gels were insoluble in water (C3, C4 and C3b, respectively). In contrast, polymerization with 1c resulted in insufficient gel formation, and product C10 mostly dissolved after being placed in water for 2 days. Improved gel formation was observed with 2.50 mol% 1c, but slow leaching into the water was still found to be inevitable. The obtained polymer gels were found to be insoluble in any organic solvent or water; spectroscopic analyses of the chemical structures of the gels were therefore totally unsuccessful. Figure 1 shows poly(TPEN-NIPA) gels C3, C4, C3b and C10 in water in a swollen state.

The obtained gels were dried by heating at 50 °C under reduced pressure to afford colorless powders. In aqueous solutions, the gels showed repeated swelling at room temperature and shrinking when heated. The volume changes between swollen and shrinking states were found to be 25 (C3) and 18% (C10), respectively. Figure 2 shows the representative thermoresponsive change of C4.

Toughness of the obtained gel C4 was mostly similar to that of C3. Among poly(TPEN–NIPA) gels, C3b was found to form the strongest gel, probably because of the improved reactivity brought about by the introduction of an electron-donating methyl substituent into the double bond. In contrast, the performance of poly(TPEN–NIPA) gel C10 was inferior to other gels, partially dissolving in water on standing. This could be due to the longer, more flexible methylene chains, which inhibit stiff crosslinking.

Extraction studies were carried out on poly(TPEN-NIPA) gels using CdII ion. Temperature-dependent extraction behavior was examined in the swollen state (5 °C) and in the shrinking state (45 °C) at pH values of ∼2.0 and 6.5, respectively. A 1-mM solution of Cd(NO3)2 was prepared, and the pH values were adjusted to 1.9 and 5.3 (at 5 °C) for the swollen-state gels and to 2.0 and 5.9 (45 °C) for the shrinking-state gels by the addition of NH4NO3. Extraction was performed by the addition of dried poly(TPEN–NIPA) gel to 0.2 ml of 1-mM Cd(NO3)2 solution. The amount of CdII ion incorporated into the gel was estimated by ICP-AES analysis of the remaining amount of Cd ion. Figure 3 summarizes the results.

As reported previously, C3 extracted Cd ion efficiently at 5 °C (7.91 × 10−2 mmol-Cd per g dry gel) when the extraction was performed at pH 6.5, whereas at 45 °C, it extracted hardly any CdII (0.08 × 10−2). Such behavior was also observed at pH ≈2, although the extraction performance was slightly lower (3.20 × 10−2 at 5 °C, 1.07 × 10−2 at 45 °C). C4 was found to show slightly superior performance to C3 in both the amount of CdII extracted and the thermoresponsive difference (for pH ≈2, 4.64 × 10−2 at 5 °C, 0.48 × 10−2 at 45 °C). This improvement in performance could be due to the homologation of the side chain, which would increase the hydrophobicity of the TPEN moiety.16 C10 also showed improved extraction performance for both pH levels near 2 and 4.5 (5 °C; 5.50 × 10−2, 9.13 × 10−2). This could also be due to the increased hydrophobicity of long methylene chains. However, extraction performance in the shrinking state at 45 °C unexpectedly improved, leading to an inferior thermoresponsive change at pH values of 2 and 4.5 (1.64 × 10−2, 4.62 × 10−2). Poly(TPEN–NIPA) gel bearing a branched structure was found to show remarkable extraction performance in the swelling state and a thermoresponsive change at pH 6.5, resulting in the highest extraction at 5 °C and low extraction at 45 °C. Also noteworthy was its remarkably high extraction at pH 2 and at 5 °C (6.40 × 10−2), and its excellent thermoresponsive change (6.40 × 10−2 to 0.26 × 10−2). This could be due to the formation of a stiff gel as well as the increased hydrophobicity.

Conclusion

In summary, we have synthesized TPEN derivatives bearing side chains with varying chain length and branched structures. The prepared derivatives were used to form poly(TPEN–NIPA) gels. The temperature-dependent change in the CdII ion extraction behavior of poly(TPEN–NIPA) gels was highly influenced by the side-chain structures. The excellent thermoresponsive changes observed, particularly under highly acidic conditions (pH≈2), could potentially be used for the chromatographic separation of metal ions, specifically for thermal swing chromatography, which could be applied toward the separation of minor actinides from high-level radioactive wastes. The high performance of TPEN-NIPA gel C3b is noteworthy.

TPEN derivatives.

Synthesis of TPEN derivatives.

Synthesis of poly(TPEN–NIPA) gel.

References

Tanaka, T., Nishio, I., Sun, S.- T. & Ueno-Nishio, S. Collapse of gels in an electric field. Science 218, 467–469 (1982).

Tokuyama, H. & Kanehara, A. Temperature swing adsorption of gold(III) ions on poly(N-isopropylacrylamide) gel. React. Funct. Polym. 67, 136–143 (2007).

Kohri, M., Sato, K., Ide, K., Inoue, Y. & Okouchi, H. Solid phase extraction for the speciation of organotin compounds in shellfish samples. Anal. Sci. 13, 141–143 (1997).

Takeshita, K., Tanaka, M., Nakano, Y. & Seida, Y. Thermal-swing extraction of Cd(II) by thermosensitive gel crosslinked with nitrogen-donor ligands. J. Chem. Eng. Japan. 36, 1253–1258 (1993).

Takeshita, K., Matsumura, T. & Nakano, Y. Separation of Americium(III) and Europium(III) by thermal-swing extraction using thermosensitive polymer gel. Prog. Nucl. Energy. 50, 466–469 (2008).

Takeshita, K., Ishida, K., Nakano, Y. & Matsumura, T. Thermal-swing extraction of cadmium(II) by thermosensitive polymer gel crosslinked with encapsulating hexadentate ligand. Chem. Lett. 36, 1032–1033 (2007).

Fukuoka, S., Kida, T., Nakajima, Y., Watanabe, W., Tsumagari, T., Inaba, Y., Mori, A., Matsumura, T., Nakano, Y. & Takeshita, K. Thermo-responsive extraction of cadmium(II) ion with TPEN-NIPA gel. Effect of the number of polymerizable double bond toward gel formation and the extracting behavior. Tetrahedron 66, 1721–1727 (2010).

Maekawa, T., Kida, T., Miyazaki, Y., Watanabe, W., Inaba, Y., Takeshita, K. & Mori, A. Temperature-dependent change of extraction performance of soft Cadmium(II) ion with TPEN-NIPA gel. Studies on the effect of the ethylenediamine skeleton. Bull. Chem. Soc. Japan. 84, 122–124 (2011).

Jensen, M. P., Morss, L. R., Beitz, J. V. & Ensor, D. D. Aqueous complexation of trivalent lanthanide and actinide cations by N,N,N’,N’-tetrakis(2-pyridylmethyl)ethylenediamine. J. Alloys. Compd. 303–304, 137–141 (2000).

Cukrowski, I., Cukrowska, E., Hancock, R. D. & Anderegg, G. The effect of chelate ring size on metal ion size-based selectivity in polyamine ligands containing pyridyl and saturated nitrogen donor groups. Anal. Chim. Acta 312, 307–321 (1995).

Hirayama, N., Iimuro, S., Kubono, K., Kokusen, H. & Honjo, T. Formation of dinuclear copper(II) complex with N,N,N’,N’-tetrakis(2-pyridylmethyl)-1,2-ethanediamine in aqueous solution. Talanta 43, 621–626 (1996).

Watanabe, M., Mirvaliev, R., Tachimori, S., Takeshita, K., Nakano, Y., Morikawa, K. & Mori, R. Separation of Americium(III) from lanthanide by encapsulating hexadentate-ligand. Chem. Lett. 31, 1230–1231 (2002).

Mirvaliev, R., Watanabe, M., Matsumura, T., Tachimori, S. & Takeshita, K. Selective separation of Am(III) from Ln(III) with a novel synergistic extraction system, N,N,N’,N’-tetrakis(2-methylpyridyl)ethylenediamine (TPEN) and carboxylic acid in 1-octanol. J. Nucl. Sci. Technol. 41, 1122–1124 (2004).

Kolarik, Z. Complexation and separation of lanthanides(III) and actinides(III) by heterocyclic N-donors in solutions. Chem. Rev. 108, 4208–4252 (2008).

Blindauer, C. A., Razi, M. T., Parsons, S. & Sadler, P. J. Metal complexes of N,N,N’,N’-tetrakis(2-pyridylmethyl)ethylenediamine (TPEN): variable coordination numbers and geometries. Polyhedron 25, 513–520 (2006).

Ogata, T., Takeshita, K., Fugate, G. A. & Mori, A. Extraction of soft metals from acidic media with nitrogen-donor ligand TPEN and its analogs. Sep. Sci. Technol. 43, 2630–2640 (2008).

Ogata, T., Takeshita, K., Tsuda, K. & Mori, A. Solvent extraction of perrhenate ions with podand-type nitrogen donor ligands. Sep. Purif. Technol. 68, 288–290 (2009).

Shimojo, K., Naganawa, H., Noro, J., Kubota, F. & Goto, M. Extraction behavior and separation of lanthanides with a diglycolamic acid derivative and a nitrogen-donor ligand. Anal. Sci. 23, 1427–1430 (2007).

Mikata, Y., Yamanaka, A., Yamashita, A. & Yano, S. Isoquinoline-based TQEN family as TPEN-derived fluorescent zinc sensors. Inorg. Chem. 47, 7295–7301 (2008).

Heitzmann, M., Bravard, F., Gateau, C., Boubals, N., Berthon, C., Pecaut, J., Charbonnel, M. C. & Delangle, P. Comparison of two tetrapodal N,O ligands: impact of the softness of the heterocyclic N-donors pyridine and pyrazine on the selectivity for Am(III) over Eu(III). Inorg. Chem. 48, 246–256 (2009).

Ekberg, C., Fermvik, A., Retegan, T., Skarnemark, G., Foreman, M. R. S., Hudson, M. J., Englund, S. & Nilsson, M. An overview and historical look back at the solvent extraction using nitrogen donor ligands to extract and separate An(III) from Ln(III). Radiochimica. Acta. 96, 225–233 (2008).

Takeshita, K., Watanabe, K., Nakano, Y. & Watanabe, M. Solvent extraction separation of Cd(II) and Zn(II) with the organophosphorus extractant D2EHPA and the aqueous nitrogen-donor ligand TPEN. Hydrometallurgy 70, 63–71 (2003).

Takeshita, K., Watanabe, K., Nakano, Y. & Watanabe, M. Extraction of Cd(II) and Zn(II) with dialkylthiophosphinic acid and hexadentate nitrogen-donor ligand. Chem. Lett. 32, 96–97 (2003).

Cavus, S., Gurdag, G., Sozgen, K. & Gurkaynak, M. A. The preparation and characterization of poly(acrylic acid-co-methacrylamide) gel and its use in the non-competitive heavy metal removal. Polym. Adv. Technol. 20, 165–172 (2009).

Cavus, S. & Gurdag, G. Competitive heavy metal removal by poly(2-acrylamido-2-methyl-1-propane sulfonic acid-co-itaconic acid). Polym. Adv. Technol. 19, 1209–1217 (2008).

Rathore, N. S., Leopold, A., Pabby, A. K., Fortuny, A., Coll, M. T. & Sastre, A. M. Extraction and permeation studies of Cd(II) in acidic and neutral chloride media using Cyanex 923 on supported liquid membrane. Hydrometallurgy 96, 81–87 (2009).

Huang, J., Zeng, G., Fang, Y., Qu, Y. & Li, X. Removal of cadmium ions using micellar-enhanced ultrafiltration with mixed anionic-nonionic surfactants. J. Membr. Sci. 326, 303–309 (2009).

Quintelas, C., Rocha, Z., Silva, B., Fonseca, B., Figueiredo, H. & Tavares, T. Removal of Cd(II), Cr(VI), Fe(III) and Ni(II) from aqueous solutions by an E. coli biofilm supported on kaolin. Chem. Eng. J. 149, 319–324 (2009).

Perez-Quintanilla, D., del Hierro, I., Fajardo, M. & Sierra, I. Adsorption of cadmium(II) from aqueous media onto a mesoporous silica chemically modified with 2-mercaptopyrimidine. J. Mater. Chem. 16, 1757–1764 (2006).

Acknowledgements

This work was partially supported by the Innovative Nuclear Research and Development Program of the Ministry of Education, Sports, Culture, Science, and Technology (MEXT), Japan. We thank the Support Network for Nanotechnology Research of the Nara Institute of Science and Technology supported by MEXT for the measurement of high-resolution mass spectra.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Inaba, Y., Tsumagari, T., Kida, T. et al. Thermoresponsive extraction of cadmium(II) ions by poly(TPEN–NIPA) gels. Effect of chain length and branched spacer structure on gel formation and extraction behavior. Polym J 43, 630–634 (2011). https://doi.org/10.1038/pj.2011.38

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2011.38