Abstract

CaCO3/chitin-whisker hybrids were prepared using the liquid-crystalline suspension of the chitin whisker. Suspensions of chitin nanowhiskers were obtained by acid hydrolysis of chitin powder. The suspension containing about 5 wt% of whiskers exhibited lyotropic liquid-crystalline behavior. The suspension was converted to a gel form when it was exposed to ammonium carbonate vapor. CaCO3 crystals were formed for 30 days in chitin gels as templates. The nucleation of CaCO3 occurred in the liquid-crystalline chitin matrix and the CaCO3 crystals deposited in the chitin gels to form hybrids with an interpenetrated three-dimensional structure. Scanning electron microscopy image of the fractured sample of the hybrid showed that the gel matrix was filled with CaCO3 crystals. Thermogravimetric analysis revealed that the composition of CaCO3/polymer/H2O is about 2:6:2 in weight. This approach inspired by biomineralization may be useful for the development of inorganic/organic hybrid materials.

Similar content being viewed by others

Introduction

The process used by living organisms to produce inorganic/organic hybrids is called biomineralization.1, 2, 3 Natural biominerals such as bone, teeth and the nacre of the shell have high mechanical strength and optical properties. In these biominerals, the properties are closely related to their hierarchically ordered structures. For instance, the nacre of the shell has a layered structure composed of about 95 wt% CaCO3 and about 5 wt % organic matrices.4, 5, 6 The layered structure induces high mechanical strength and pearl luster. Another type of biomineral that is softer than the nacre of the shell is the exoskeleton of the crayfish.7 It is composed of about 50 wt% CaCO3 and about 50 wt% organic macromolecules such as chitin and proteins. In the exoskeleton, chitin fibers have a helical structure8, 9 that is analogous to the cholesteric liquid-crystalline order. These chitin fibers are complexed with proteins and CaCO3. These natural biominerals offer ideas for new inorganic/organic hybrid materials.10, 11, 12, 13, 14, 15, 16 A variety of calcium-based hybrid materials have been reported.17, 18, 19, 20, 21, 22, 23, 24, 25, 26 We previously reported that CaCO3 thin-film crystals were formed on chitin matrices in the presence of acidic polymers.17, 18, 19, 20, 21 Moreover, oriented CaCO3 crystals were obtained in an oriented chitin matrix.27 This result shows that the ordered matrix is important for further structure control of inorganic/organic hybrid materials. Our intention here is to use ordered chitin whiskers for the formation of hybrids. Herein, we report on the formation of CaCO3 crystals/chitin-whisker hybrids using the liquid-crystalline suspension of the chitin whisker.

Experimental procedure

Chitin purification

Chitin (α-chitin from crab) was stirred at room temperature in 5% KOH solution for several hours to remove the residual protein. Thereafter, the chitin sample was bleached with NaClO2 aqueous containing sodium acetate buffer for 6 h at 80 °C. The bleached sample was collected by centrifugation and washed several times with deionized water.

Disintegration of chitin

Purified chitin was suspended in water at 0.1–0.3% concentrations. The chitin slurry was adjusted to the pH value of 3 by the addition of several drops of dilute hydrochloric acid. Ultrasonication was applied to the slurry for 2 min using an ultrasonic homogenizer at 19.5 kHz and 300 W output power (7 mm in the probe tip diameter, US-300T, Nihon seiki, Tokyo, Japan). The disintegrated chitin was collected by filtration.

Acid hydrolysis of chitin

Suspensions of chitin nanowhiskers were prepared by acid hydrolysis of the resultant chitin. The disintegrated chitin (5 g) was treated with 100 ml of 4 M HCl solution at 104 °C for 90 min. The sample was then washed with distilled water until the pH value of the supernatant solution increased to around 2. The obtained suspension was then dialyzed against distilled water to adjust the pH value of 3. The suspension was then concentrated by dialysis against saturated polyethylene glycol (Mw=20 000) solution.

Crystallization of CaCO3

Purified water obtained from an Auto pure WT100 purification system (Yamato, Tokyo, Japan, relative resistivity: maximum 1.8 × 107 Ωcm) was used for the crystallization of CaCO3. Poly(acrylic acid) (Mw=5000, 2.0 × 10−2 wt%) was added to an aqueous solution of calcium chloride ([Ca2+]=24 mM). The solution was transferred to a vessel containing the chitin gel matrix. The vessel was then placed in a closed desiccator, together with a vial of ammonium carbonate for 30 days. The crystallization solution was changed every 3 days to maintain the concentration of Ca2+ ion. An incubator (Fukushima, Osaka, Japan) was used to maintain a constant crystallization temperature (5 °C).

Alternate soaking method

A chitin gel was alternatively soaked in two aqueous solutions containing calcium chloride (24 mM) and sodium carbonate (24 mM). Each solution contained poly(acrylic acid) (Mw=5000) at a concentration of 2.0 × 10−2 wt%. The chitin gel matrix was immersed in 100 ml of CaCl2 aqueous solution at 5 °C for 1 day, followed by rinsing with deionized water. The swollen chitin gel containing Ca2+ ion was then immersed in Na2CO3 solution at 5 °C for 1 day and washed with deionized water. The alternate soaking process was repeated 10 times to form CaCO3 crystals.

Characterization

Polarizing optical microscopy images were taken with an Olympus BX51 polarizing optical microscope (Olympus, Tokyo, Japan). Scanning electron microscopy (SEM) images were obtained using a Hitachi S-4700 field-emission SEM (Hitachi, Tokyo, Japan) operated at 2 kV. Samples were coated with platinum using a Hitachi E-1030 ion sputter. Energy dispersive X-ray analysis was conducted with an EMAX-7000 energy dispersive X-ray spectroscope (Horiba, Kyoto, Japan). Fourier transform infrared spectra were recorded on a Jasco FT/IR-660Plus spectrometer (Jasco, Tokyo, Japan). Thermogravimetric analysis was conducted with Thermo Plus TG 8120 thermogravimetic equipment (Rigaku, Tokyo, Japan).

Results and Discussion

Liquid-crystalline chitin suspensions were prepared by acid hydrolysis of α-chitin according to the procedure proposed by Revol and Marchessault.28, 29, 30 The isotropic and liquid-crystalline phases coexisted in the resultant suspension if the amount of the suspension was 5.3 wt%. The region of the liquid-crystalline phase increased with an increase in the amount of suspensions. The suspension became completely liquid crystalline when the amount was above 11.3 wt%. The suspension was adjusted to the pH value of 3 to protonate the amino groups on the surface of the chitin whiskers.

A fingerprint texture was observed with the polarizing optical microscope at a concentration of 6.8 wt% (Supplementary Figure S1), suggesting that the chitin suspension formed the chiral nematic structure spontaneously. The spacing of the fringes that corresponds to the half-pitch of cholesteric structure was approximately 20–30 μm. The rod-like character of the chitin crystallites was observed by TEM analysis of the diluted chitin suspension (0.01 wt%). The length of the rods ranged from 200 to 500 nm, with a width of 5–20 nm, giving average aspect ratios of 15–20 (Supplementary Figure S1).

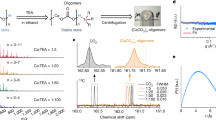

The suspension was converted to a gel form (Figure 1a), which was used as a template for CaCO3 crystallization. When the casted suspension was exposed to ammonium carbonate vapor, the sample immediately converted to gel. The polarizing optical micrograph image of the gel (Figure 1b) shows the fingerprint texture, indicating that the cholesteric structure was preserved even after the suspension was converted to gel.

The CaCO3 crystallization was induced by the slow diffusion of ammonium carbonate vapor into calcium chloride solution. The gel matrix was immersed in an aqueous solution of CaCl2 in the presence of polyacrylic acid. We observed that spherical CaCO3 crystals were formed in the matrix after 3 days. The laser Raman spectra of the sample show that the spherical CaCO3 crystals were crystalline calcite and no amorphous CaCO3 existed in this stage (Supplementary Figure S2). These crystals gradually increased their sizes until the gel matrix was filled with CaCO3 crystals. Figure 2 shows a photograph (a) and a SEM image (b) of the fractured sample of the CaCO3/chitin gel hybrid formed after immersing for 30 days, in which the crystals deposited until the gel matrix was filled. The hybrid sample became turbid because of the formation of CaCO3 crystals. The polarizing optical microscope image of the sample shows that the crystals in the matrix were polycrystalline. In the energy dispersive X-ray analysis mapping and spectrum for calcium element on the cross-sectional fractured surface of the obtained hybrid (Figure 3 and Supplementary Figure S3), the color indicating the existence of calcium displays a uniform spatial distribution on the cross-section, indicating that CaCO3 filled the gel.

The polymorph of CaCO3 crystals in the hybrid was examined with Fourier transform infrared spectroscopy. It is revealed that the crystals formed in the gel were calcite (Figure 4a). The X-ray diffraction measurement shows that the crystal was calcite (Supplementary Figure S4). The weight composition of the hybrid was analyzed by thermogravimetric analysis. The thermogravimetric curve of the hybrid shows a three-step weight loss (Figure 4b). The weight loss around 200 °C corresponded to dehydration. Organic components, chitin and polyacrylic acid decomposed between 300 and 600 °C. CaCO3 decomposed at 600 °C to form CaO. These results show the composition of CaCO3/polymer/H2O is 22:58:20 in weight.

To examine the effects of the gel matrix structure on crystallization, CaCO3 was crystallized in the isotropic chitin gel. The isotropic phase of the chitin suspension (1.9 wt%) was converted to a gel matrix as a template for hybrid formation. Although some spherical crystals deposited in the gel matrix, the matrix was not fully calcified. The surface of the chitin crystallites served as a platform for CaCO3 crystallization. The density of the chitin crystallite for this isotropic chitin gel was not enough for the CaCO3 crystallization.

We also attempted CaCO3 mineralization by an alternate soaking method.31 The formation of chitin/mineral composite was not confirmed by SEM observation, although the infrared spectrum indicates that some amounts of CaCO3 were formed (Figure 5). The SEM picture shows that inside the matrix, only chitin whiskers exist and CaCO3 crystals are not formed. The alternate soaking method requires a longer time for ion diffusion into three-dimensional matrix.

The differences between the results of the vapor diffusion method and the alternate soaking method can be explained on the basis of a hypothesis on the aggregation-mediated pathway. This hypothesis relates to the concept of amorphous calcium carbonate (ACC) nanoparticles.32 It was reported that colloidal ACC nanoparticles were generated in the solution by using the ammonium carbonate diffusion method in the presence of highly concentrated acidic polymers and calcium ion.33 The ACC nanoparticle is an effective vehicle for transportation of CaCO3 to construct three-dimensional interpenetrated hybrids.33 In recent years, it is widely recognized that the aggregation-mediated pathway of mineralization is important to understand biomineralization.34, 35 It has been proposed that living organisms also use ACC nanoparticles for storage, transportation and mineralization of CaCO3 in their systems.36, 37 In our present system, the colloidal ACC nanoparticles may be formed in the crystallization solution as previously reported.33 The ACC nanoparticles might diffuse into the gel matrix because of the capillary force, eventually transforming into calcite in the gel matrix to form three-dimensional interpenetrated hybrid materials. In contrast, for the alternate soaking method, it was insufficient to transport CaCO3 because only cation or anion was supplied to the gel matrix. Crystals were formed at the surface of the gel matrix, and the resultant crystals inhibited further diffusion of ions.

Conclusion

We prepared CaCO3/chitin-whisker hybrids using chitin gel matrices prepared from liquid-crystalline chitin suspensions. ACC nanoparticles infiltrated into the gel matrix to form a three-dimensional interpenetrated structure. This method may allow us to produce hybrids with hierarchical structures by using highly ordered organic templates. In the exoskeleton of the crayfish, the chitin has a helical order similar to a chiral nematic liquid crystal and the ordered structure contributes to its high mechanical strength. The hybrids obtained here did not exhibit high mechanical strength because they consisted of whiskers with length shorter than fibers in the natural exoskeleton. However, the concept shown in this study is beneficial for the design of mechanically stable hybrid material. This approach may also be useful for the development of highly functional materials such as hybrids containing transition metals.38

References

Mann, S. Biomineralization (eds. Compton R.G., Davies, S. G., Evans, J.) (Oxford University Press, Oxford, 2001).

Addadi, L. & Weiner, S. Control and design principles in biological mineralization. Angew. Chem. Int. Ed. Engl. 31, 153–169 (1992).

Bäuerlein, E., Behrens, P. & Epple, M. Handbook of Biomineralization (ed.) (Wiley-VCH, Weinheim, 2007).

Watabe, N. Studies on shell formation — XI. Crystal-matrix relationships in the inner layers of mollusk shells. J. Ultrastruct. Res. 12, 351–370 (1965).

Addadi, L., Joester, D., Nudelman, F. & Weiner, S. Mollusk shell formation: A source of new concepts for understanding biomineralization processes. Chem. Eur. J. 12, 980–987 (2006).

Suzuki, M., Saruwatari, K., Kogure, T., Yamamoto, Y., Nishimura, T., Kato, T. & Nagasawa, H. An Acidic matrix protein, Pif, is a key macromolecule for Nacre formation. Science 325, 1388–1390 (2009).

Travis, D. F. Structural features of mineralization from tissue to macromolecular levels of organization in the Decapod Crustacea. Ann. N.Y. Acad. Sci. 109, 177–245 (1963).

Raabe, D., Sachs, C. & Romano, P. The crustacean exoskeleton as an example of a structurally and mechanically graded biological nanocomposite material. Acta Mater. 53, 4281–4292 (2005).

Bouligand, Y. Twisted fibrous arrangements in biological materials and cholesteric mesophases. Tissue and Cell 4, 189–217 (1972).

Kato, T., Sakamoto, T. & Nishimura, T. Macromolecular templating for the formation of inorganic-organic hybrid structures. MRS Bulletin 35, 127–132 (2010).

Kato, T., Sugawara, A. & Hosoda, N. Calcium carbonate-organic hybrid materials. Adv. Mater. 14, 869–877 (2002).

Kato, T. Polymer/Calcium carbonate layered thin-film composites. Adv. Mater. 12, 1543–1546 (2000).

Imai, H. Self-organized formation of hierarchical structures. Top. Curr. Chem. 270, 43–72 (2007).

Naka, K. & Chujo, Y. Control of crystal nucleation and growth of calcium carbonate by synthetic substrates. Chem. Mater. 13, 3245–3259 (2001).

Arakaki, A., Nakazawa, H., Nemoto, M., Mori, T. & Matsunaga, T. Formation of magnetite by bacteria and its application. J.R. Soc. Interface 5, 977–999 (2008).

Ohtsuki, C., Kamitakahara, M. & Miyazaki, T. Coating bone-like apatite onto organic substrates using solutions mimicking body fluid. J. Tissue Eng. Regin. Med. 27, 1527–1533 (2007).

Sakamoto, T., Oichi, A., Nishimura, T., Sugawara, A. & Kato, T. Calcium carbonate/polymer thin-film hybrids: induction of the formation of patterned aragonite crystals by thermal treatment of a polymer matrix. Polym. J. 41, 522–523 (2009).

Hosoda, N., Sugawara, A. & Kato, T. Template effect of crystalline poly(vinyl alcohol) for selective formation of aragonite and vaterite CaCO3 thin films. Macromolecules 36, 6449–6452 (2003).

Sugawara, A. & Kato, T. Calcium carbonate/polymer composites: polymorph control for aragonite. Compos. Interfaces 11, 287–295 (2004).

Sugawara, A., Oichi, A., Suzuki, H., Shigesato, Y., Kogure, T. & Kato, T. Assembled structures of nanocrystals in polymer/calcium carbonate thin-film composites formed by cooperation of chitosan and poly(aspartate). J. Polym. Sci. Part A: Polym. Chem. 44, 5153–5160 (2006).

Sugawara, A., Ishii, T. & Kato, T. Self-organized calcium carbonate with regular surface-relief structures. Angew. Chem. Int. Ed. 42, 5299–5303 (2003).

Sugawara, A., Yamane, S. & Akiyoshi, K. Nanogel-templated mineralization: polymer-calcium phosphate hybrid nanomaterials. Macromol. Rapid Commun. 27, 441–446 (2006).

Tanahashi, M., Yao, T., Kokubo, T., Minoda, M., Miyamoto, T., Nakamura, T. & Yamamuro, T. Apatite coating on organic polymers by a biomimetic process. J. Am. Ceram. Soc. 77, 2805–2808 (1994).

Takaguchi, Y., Yanagimono, Y., Tajima, T., Ohta, K., Motoyoshiya, J. & Aoyama, H. Photodimerization of anthracene having dendritic substituent within the vaterite crystal of CaCO3 . Chem. Lett. 1102–1103 (2002).

Obara, S., Yamauchi, T. & Tsubokawa, N. Evaluation of the stimulus response of hydroxyapatite/calcium alginate composite gels. Polym. J. 42, 161–166 (2010).

Ohtsuki, C., Kokubo, T. & Yamamuro, T. Mechanism of apatite formation on CaO-SiO2-P205 glasses in a simulated body fluid. J. Non-Cryst. Solids 143, 84–92 (1992).

Nishimura, T., Ito, T., Yamamoto, Y., Yoshio, M. & Kato, T. Macroscopically ordered polymer/CaCO3 hybrids prepared by using a liquid-crystalline template. Angew. Chem. Int. Ed. 47, 2800–2803 (2008).

Marchessault, R. H., Morehead, F. F. & Walter, N. M. Liquid crystal systems from fibrillar polysaccharides. Nature 184, 632–633 (1959).

Revol, J.- F., Bradford, H., Giasson, J., Marchessault, R. H. & Gray, D. G. Helicoidal self-ordering of cellulose microfibrils in aqueous suspension. Int. J. Biol. Macromol. 14, 170–172 (1992).

Revol, J.- F. & Marchessault, R. H. In vitro chiral nematic ordering of chitin crystallites. Int. J. Biol. Macromol. 15, 329–335 (1993).

Taguchi, T., Kishida, A. & Akashi, M. Apatite formation on/in hydrogel matrices using an alternate soaking process: II. Effect of swelling ratios of poly(vinyl alcohol) hydrogel matrices on apatite formation. J. Biomater. Sci., Polymer Ed. 10, 331–339 (1999).

Oaki, Y., Kajiyama, S., Nishimura, T., Imai, H. & Kato, T. Nanosegregated amorphous composites of calcium carbonate and an organic polymer. Adv. Mater. 20, 3633–3637 (2008).

Olszta, M. J., Douglas, E. P. & Gower, L. B. Scanning electron microscopic analysis of the mineralization of Type I collagen via a polymer-induced liquid-precursor (PILP) process. Calcif. Tissue Int. 72, 583–591 (2003).

Cölfen, H. & Mann, S. Higher-order organization by mesoscale self-assembly and transformation of hybrid nanostructures. Angew. Chem. Int. Ed. 42, 2350–2365 (2003).

Meldrum, F. C. & Cölfen, H. Controlling mineral morphologies and structures in biological and synthetic systems. Chem. Rev. 108, 4332–4432 (2008).

Addadi, L., Raz, S. & Weiner, S. Taking advantage of disorder: amorphous calcium carbonate and its roles in biomineralization. Adv. Mater. 15, 959–970 (2003).

Raz, S., Testeniere, O., Hecker, A., Weiner, S. & Luquet, G. Stable amorphous calcium carbonate is the main component of the calcium storage structures of the Crustacean orchestia cavimana. Biol. Bull. 203, 269–274 (2002).

Oaki, Y., Kajiyama, S., Nishimura, T. & Kato, T. Selective synthesis and thin-film formation of α-cobalt hydroxide through an approach inspired by biomineralization. J. Mater. Chem. 18, 4140–4142 (2008).

Acknowledgements

This study was partially supported by Grant-in-Aid for the Global COE Program ‘Chemistry Innovation through Cooperation of Science and Engineering’ (TK and YY), by Exploratory Research (no. 20655022) (TK) and by Encouragement of Young Scientists B (no. 19750106) (TN) from the Ministry of Education, Culture, Sports, Science and Technology. We are grateful to Dr Yuya Oaki for helpful discussion.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Yamamoto, Y., Nishimura, T., Saito, T. et al. CaCO3/chitin-whisker hybrids: formation of CaCO3 crystals in chitin-based liquid-crystalline suspension. Polym J 42, 583–586 (2010). https://doi.org/10.1038/pj.2010.32

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2010.32

Keywords

This article is cited by

-

Macromolecular templates for biomineralization-inspired crystallization of oriented layered zinc hydroxides

Polymer Journal (2017)

-

Polysaccharide nanocrystals as fillers for PLA based nanocomposites

Cellulose (2017)

-

Macromolecular templates for the development of organic/inorganic hybrid materials

Polymer Journal (2015)

-

Polymer-mediated dendritic growth of a transition metal salt crystal as a template for morphogenesis

Polymer Journal (2015)

-

Hydroxyapatite formation on oxidized cellulose nanofibers in a solution mimicking body fluid

Polymer Journal (2015)