Abstract

The rheological behavior of aminosaccharide-based glycopolymers prepared through the chemical modification of ethylene-vinyl alcohol copolymers was evaluated in bulk and in aqueous solution. The viscoelastic response of the polymers was assessed by conducting dynamic mechanical thermal analyses and taking rheology measurements, and information on the stiffness and relaxation mechanisms of the glycopolymers in bulk was obtained. Moreover, the development of reversible networks was observed by performing isochronal and isothermal experiments.

Similar content being viewed by others

Introduction

Recently, the synthesis of polymers containing carbohydrate groups pendant to the main chain,1, 2 also known as glycopolymers, has been studied extensively. Glycopolymers are of significant interest because they show strong interactions with lectins because of their high concentration of carbohydrate moieties (the glyco-cluster effect). Thus, glycopolymers can be used as tools to understand the specificity of interactions between saccharides and cell surface receptor lectins.3, 4 The lectin recognition abilities of synthetic glycopolymers are a favorable aspect for their suitability as biocompatible materials. For instance, glycopolymers can be used in diverse applications such as macromolecular drugs,5, 6, 7 drug delivery systems,8, 9, 10 matrices for encapsulation, stabilization and release of active ingredients,11, 12, 13, 14, 15 enhancement of food additives,14 biocatalytic hydrogels,15 surface modifiers16, 17 and artificial tissue and synthetic organ substrates.18

Because of their gelling and thickening abilities, polysaccharides have been used in sauces, salad dressings and ice cream in the food industry and in diverse applications in cosmetic and pharmaceutical industries.19 Moreover, polysaccharides are low in cost and non-toxic to humans and have a limited impact on the environment. In aqueous solution, polysaccharides display associative properties by increasing the viscosity of the solution through non-covalent crosslinks. Gelation in water is primarily due to the development of hydrogen bonds between branched chains, leading to the formation of three-dimensional structures called physical gels, which can be produced from both natural and synthetic polymers.20

Poly(vinyl alcohol) (PVOH) is a water-soluble, biocompatible and biodegradable polymer that is widely used in medical, cosmetic and packaging applications.21, 22 PVOH forms a gel in aqueous solution, dimethyl sulfoxide (DMSO)23, 24 and water/DMSO mixtures25, 26, 27 by undergoing freeze–thaw cycles that lead to the formation of hydrogen bonds between PVOH interchains.23 Incorporation of low concentrations of ethylene units leads to the formation of ethylene-vinyl alcohol (EVOH) copolymers, which display enhanced thermal stability and processability compared with those exhibited by PVOH homopolymer. Moreover, EVOH retains the satisfactory mechanical response, excellent barrier properties and good blood compatibility of PVOH. Nevertheless, the chemical and physical properties of EVOH copolymers are dependent on their composition.22 EVOH copolymers do not develop gels in aqueous solution because only a small amount is able to dissolve in water; however, EVOH copolymers form gels in mixtures of DMSO and H2O.28 The formation of hydrogen bonds between the hydroxyl groups of the vinyl alcohols of EVOH copolymers and hydrophobic interactions between methylenic groups contributes to gel formation. The formation of gels is attributed to differences between the intermolecular interactions of DMSO–EVOH networks and H2O–EVOH networks.28

The preparation of novel glycopolymers through the chemical modification of EVOH copolymers derived from three commercial monosaccharides (D-(+)-glucosamine, EVOHxF-Gl, D-(+)-galactosamine, EVOHxF-Ga and D-(+)-mannosamine, EVOHxF-Ma) has been described in a recent article.29 The thermal behavior of the copolymers was analyzed, and results revealed that crystallite development was prevented when the hydroxyl groups were substituted with carbohydrates.30 The lack of these crystallites and their reinforcement effect are replaced by strong interactions, ascribed to hydrogen bonds, between hydroxyl groups existing in the carbohydrate moieties. Therefore, similar glass transition temperatures are observed. In addition, the lectin recognition capabilities of the polymers were satisfactory because the synthetic glycopolymers were water soluble. The rheological response of a material is an important aspect of glycopolymer systems. Namely, the rheological response affects the applicability of glycopolymers and allows for the configuration of the entire spectra of structure–property applications exhibited by these materials. Therefore, the aim of this study was to examine the rheological behavior of glycopolymers in bulk and in aqueous solution. Dynamic mechanical thermal analyses (DMTA) were performed to elucidate the viscoelastic relaxation processes that occur within each carbohydrate derivative and the effect of the saccharide structure on the stiffness of the bulk material. Finally, rheology measurements on the water glycopolymer solutions were taken to determine their ability to develop reversible networks.

Experimental procedure

Materials

Triethylamine (Scharlau, Barcelona, Spain), ethyl chloroformate (Merck, Hohenbrunn, Germany) and pyridine (Scharlau) were distilled before use, and p-dimethylamino pyridine (Fluka, Steinheim, Germany) and phthalic anhydride (Fluka) were used as received. DMSO (Scharlau), N-methyl-2-pirrolidone (Fluka) and N,N-dimethylformamide (DMF, Scharlau) were distilled before use, and D-(+)-glucosamine hydrochloride (99%, Fluka), D-(+)-galactosamine hydrochloride (99%, Fluka) and D-(+)-mannosamine hydrochloride (98%, Fluka) were used as received. Concanavalin A (Con A, Fluka) and Ricinus communis agglutinin (RCA120, Vector, Burlingame, CA, USA) were used as received, and Trizma-HCl (Aldrich, Steinheim, Germany), sodium chloride (NaCl, Panreac, Barcelona, Spain), manganese chloride tetrahydrate (MnCl·4H2O, 99%, Fluka), anhydrous calcium chloride (CaCl·2H2O, 99.5%, Fluka), sodium azide (NaN3, 99%, Fluka), phosphate monosodium (NaH2PO4, Panreac) and disodium phosphate (Na2HPO4, Panreac) were used without further purification.

Glycopolymers based on three commercial monosaccharides (D-(+)-glucosamine, D-(+)-galactosamine and D-(+)-mannosamine) were obtained through the chemical modification of EVOH copolymers29 with nominal vinyl alcohol compositions of 68 and 56% (supplied by Kuraray (Tokyo, Japan) and Dupont (Wilminton, DE, USA), respectively). The glycopolymers were labeled as EVOHxF-Gl, EVOHxF-Ga and EVOHxF-Ma, where x indicates the vinyl alcohol content of the polymer. The following two-stage procedure was used to synthesize the glycopolymers.

Reaction of EVOH copolymers with phthalic anhydride

The reactions were carried out in a Pyrex double-walled reactor that was isolated from the external environment to avoid contact with humidity. DMSO was used as a solvent, and triethylamine/p-dimethylamino pyridine was used as a catalyst system. The dissolution of the polymers was achieved at 75 °C; however, the solution was maintained at 60 °C throughout the reaction. Once the desired temperature was attained, the required amount of catalyst and anhydride was added, and the polymer remained soluble throughout the entire process. After 6 h, the resulting modified EVOH copolymer was isolated by precipitation from a distilled water/chloride acid mixture (100/1 v/v; 10:1 solution: copolymer) and the samples were purified by reprecipitation. Namely, methanol/acetone (1:1, v/v) was used as a solvent, and distilled water/chloride acid (100:1, v/v) was used as a precipitant. The material was dried under vacuum at room temperature in the presence of phosphorus pentoxide until a constant weight was attained.

The resulting intermediate compounds were characterized by nuclear magnetic resonance (NMR). In the 1H-NMR spectra, the peaks between 7.0 and 8.0 p.p.m. were attributed to the phthalic ring protons, and the peaks between 1.0 and 2.4 p.p.m. were assigned to the methylene protons on the main chain of the polymer. In the 13C-NMR spectra, peaks between 38.2 and 19.0 p.p.m. were attributed to the methylene carbons of the main chain, and peaks between 63.0 and 76.0 p.p.m. were ascribed to methynic carbons. The carbons associated with the aromatic ring appeared at 133.7–126.4 p.p.m., and the peak at 167.0 p.p.m. corresponded to the carboxylic acid. Finally, the peak at 168.0 p.p.m. was attributed to the C=O of the ester.

Reaction of aminosaccharides with carboxylic acid-modified EVOH copolymers activated with ethyl chloroformate

EVOH copolymers with carboxylic acid groups were dissolved in DMF at room temperature, and the solution was cooled to −8 °C using a Pyrex double-walled reactor. Subsequently, the calculated amounts of triethylamine and ethyl chloroformate were successively added to the reaction mixture. After 1 hour of agitation at −8 °C, a cooled solution of the corresponding aminosaccharide in DMF was added, and stirring was continued at −8 °C for 1 hour and at ambient temperature for 18 h. Triethylamine hydrochloride was removed by filtration, and the filtrate was precipitated in isopropanol to isolate glycopolymers. The glycopolymers were purified by reprecipitation from DMF in water and were dried under vacuum at room temperature in the presence of phosphorus pentoxide until a constant weight was attained.

The glycopolymers were characterized by NMR. In the 1H-NMR spectra, the peaks between 2.0 and 0.9 p.p.m. were assigned to the methylene protons of the main chain, and the peaks between 5.3 and 3.0 p.p.m. were attributed to the carbohydrate and methyne protons of the main chain. The proton of the NH- group appeared at 6.5–6.0 p.p.m., and the peaks of the aromatic ring were observed at 8.0–7.0 p.p.m. In the 13C-NMR spectra, the peaks between 53.0 and 80.0 p.p.m. were ascribed to the methynic carbons of modified and unmodified phthalic acid groups. Similarly, the carbons associated with modified or unmodified aromatic rings were observed at 139.5–120.0 p.p.m., and the peaks at 167.0 and 169.0 p.p.m. were attributed to the carboxylic acid and the C=O of the ester, respectively. Moreover, the intensity of the peak at 167.0 p.p.m. was diminished compared with that of the original EVOH copolymer. Finally, the carbon associated with the amide bond appeared at 162.0 p.p.m.

The degree of modification of the functionalized copolymers was calculated by determining the ratio between the peaks of the methylene protons and those of the aromatic ring in the 1H-NMR spectra. The extent of glycopolymer modification was determined by calculating the ratio between the peaks attributed to methylene protons of the main chain and the peaks located at 5.3–4.0 p.p.m., which were assigned to the methylene protons of the main chain, to C1 and C5 of the carbohydrate and to the C6 carbohydrate methylene. The aforementioned peaks were used to determine the degree of modification to avoid interferences from the contribution of absorbed water within the glycopolymer.

Macromolecular characterization

The 1H- and 13C-NMR spectra were recorded at 70 °C in DMSO-d6 with a Bruker Advance spectrometer (Bruker, Madison, WI, USA) operating at 300 MHz. The proton spectra were used to determine the extent of EVOH copolymer modification. The relative intensities of the signals were determined from the integrated peak area, which was calculated with an electronic integrator. Fourier transform infrared spectroscopy was performed on a FT-IR 1720 X from Perkin-Elmer (Waltham, MA, USA) using KBr pellets. The number-average molecular weight (Mn) and polydispersity index (Mw/Mn) were measured by size exclusion chromatography (SEC), and a chromatographic system (Waters Division Millipore, Milford, MA, USA) equipped with a Waters model 410 refractive-index detector was used. DMF (99.9%, Aldrich) containing 0.1% LiBr at 50 °C and a flow rate of 1 cm3 min−1 was used as the eluent. Styragel packed columns (HR2, HR3 and HR4, Waters Division Millipore) were used to separate polymers, and poly(methyl methacrylate) standards (Polymer Laboratories, Shropshire, UK) with molecular weights between 2.4 × 106 and 9.7 × 102 g mol−1 were used to calibrate the columns.

Sample preparation

Cast films derived from the glycopolymers were prepared from 8% (w/v) solutions of the polymer in DMF to perform DMTA. The films were dried at room temperature and atmospheric pressure for 4 months to avoid undesirable bubble formation.

Dynamic mechanical thermal analysis

The viscoelastic properties of the bulk material were determined with a Polymer Laboratories MK II dynamic mechanical thermal analyzer operating in tensile mode. The complex modulus and loss tangent (tan δ) of each sample were determined on rectangular strips with a width, thickness and length of 3.5, 0.40 and 16 mm, respectively. The apparent activation energies were calculated according to an Arrhenius-type equation, and the experiments were conducted from −150 to 110 °C at 3, 10, 30 and 50 Hz. A heating rate of 1.5 was applied, and an accuracy of ±0.5 °C was used in the temperature assignment of the loss modulus maxima E″. Although relaxation is ascribed to cooperative motion, the dependence of the glass transition temperature on frequency was considered to follow Arrhenius behavior.31 This approximation can be made without introducing a significant amount of error because the range of analyzed frequencies was short enough to display linear behavior, as previously mentioned.

Rheological behavior of aqueous solutions

The rheological behavior of aqueous solutions of the glycopolymers was determined with a controlled stress rheometer (TA Instruments, New Castle, DE, USA, AR1000N) equipped with parallel plate geometry. Plates with a diameter of 40 mm were used, and the gap between parallel plates was adjusted to 0.4 mm. Briefly, 10 wt% glycopolymer solutions were prepared by adding the glycopolymer to ultrafiltered, distilled, deionized water at 23 °C, and allowing the solution to equilibrate for 24 h. Dynamic mechanical experiments were conducted in shear deformation mode to investigate the behavior of viscosity (η*), storage modulus (G′, elastic contribution) and loss modulus (G″, viscous component) under appropriate thermal and mechanical conditions. An initial stress sweep was performed at 25 °C, and different frequencies were applied to determine the linear viscoelastic range of the glycopolymers.

The temperature of gelation was determined by heating the samples from 20 to 50 °C at a rate of 1 °C min−1. The temperature of gelation and the viscoelastic properties subsequent to reversible network formation were tested by applying three thermal cycles, and the results were reproducible.

Lectin interactions

Interactions between the glycopolymer and Con A were measured in a buffered solution (pH 7.4) containing Trizma solution, 1 mM MnCl2, 1 mM CaCl2 and 0.1 M NaCl. To evaluate glycopolymer–RCA120 interactions, a buffered solution (pH 7.8) was prepared from doubly distilled water, 0.87 mM monosodium phosphate, 9.13 mM disodium phosphate and 0.15 M NaCl. Sodium azide (0.08%) was added for antimicrobial purposes.

To evaluate interactions between glycopolymers, Con A lectin and RCA120 lectin, the turbidity of the solutions was measured at a wavelength of 360 and 500 nm, respectively, with a UV–VIS spectrophotometer (Perkin-Elmer Lambda 16 Spectrometer, Perkin-Elmer).

Results and Discussion

The synthetic procedure used to obtain the glycopolymers is described in the experimental section of this paper and is summarized in Scheme 1. As shown in the figure, before the aminosaccharides could be incorporated into the polymer, an initial activation stage was required. The first reaction involved the preliminary activation of hydroxyl groups in EVOH copolymers, which show low reactivity toward saccharides similar to that in PVOH homopolymers.32 However, the hydroxyl groups in EVOH copolymers could be transformed into highly reactive functional groups, which were reacted with the saccharides. Namely, the reactivity of the hydroxyl groups of the EVOH copolymers was enhanced by incorporating carboxylic acids. Subsequently, aminosaccharides were added to a solution of modified copolymers, and glycopolymers were isolated from isopropanol and dried under vacuum until a constant weight was reached. The product was purified by reprecipitation from a mixture of DMF and water to eliminate unreacted aminosaccharides.

Interactions of isolated carbohydrate ligands with carbohydrate-binding proteins (lectins) are characterized by low affinity and broad specificity.33 However, carbohydrate signals in biological systems are often amplified by the multivalency of carbohydrates, also known as the glyco-cluster effect.34, 35 Thus, as previously mentioned, glycopolymers are an exciting scaffold that may display glyco-cluster effects because of their multiple binding sites36, 37 and cooperativity.38, 39 Moreover, the glycopolymers used in this study displayed specific molecular recognition capabilities.29 In this investigation, EVOHxF glycopolymers with glucosyl and mannosyl residues were evaluated by UV–VIS spectroscopy, and the results revealed that glycopolymers displayed selective affinities toward Con A, as shown in Figure 1a. Alternatively, glycopolymers that contained terminal β-D-galactosyl residues within their architecture displayed selective binding affinities toward RCA120, as depicted in Figure 1b.

As shown in Figure 1, at a constant lectin concentration, the behavior of glycopolymers was dependent on the type of aminosaccharide moiety and the specific interactions between glycopolymers and lectins. Nevertheless, the molecular recognition response of both lectins was independent of the initial hydroxyl composition of the EVOH copolymer because of the analogous global content of aminosaccharide incorporated into both sets of glycopolymers. The results shown in Figure 1a demonstrate that strong interactions were obtained at low glycopolymer concentrations. However, as the glycopolymer concentration increased, constant values were achieved, and stronger interactions were not observed. Alternatively, at a constant Con A concentration, the specificity of the glycopolymers increased. As a result, high absorbance values were observed when glucosyl residues were located along the backbone of the polymer.

At a given Ricinus communis agglutinin concentration, the glycopolymer content had a significant effect on intermolecular interactions, as observed in Figure 1b. For instance, as the glycopolymer concentration increased, a rapid increase in lectin–glycopolymer interactions was observed until a maximum value was achieved. However, when the glycopolymer content was further increased, a decrease in lectin–glycopolymer interactions was observed because of protein–glycopolymer aggregation and precipitation.40, 41 Maximum absorbance values were observed at a glycopolymer concentration of 0.1 mg ml−1.

The capacity for molecular recognition is a fundamental feature of glycopolymers; however, several mechanical and rheological requirements must be attained to use the materials in a variety of applications. Accordingly, the rheological behavior of a polymer in aqueous solution and in the solid phase is an important aspect that must be examined. Thus, a DMTA was conducted to evaluate the viscoelastic response of the polymer; the experiments were conducted on bulk material to analyze the response of the polymer over a wide temperature range. The determination of viscoelastic response provides information on relaxation processes related to glass transitions or local motions. Moreover, information on macromolecular stiffness can be achieved if the real component of the complex modulus is considered.

As shown in Figure 2, two clear relaxation processes were exhibited by glycopolymers derived from EVOH56. Specifically, at −75 °C, a secondary relaxation process involving local motions associated with hydroxyl groups within the saccharide architecture was observed. In addition, another relaxation mechanism was observed at 70–100 °C and was ascribed to the generalized mobility that occurs during glass transition. The viscoelastic response of the modified copolymers was dissimilar to that exhibited by pristine EVOH68 and EVOH56 copolymers. Dried films of EVOH68 copolymer processed by means of compression show three main relaxation mechanisms between −150 and 150 °C. Namely, as the temperature increases, β, α and α′ relaxations were observed.42 The former relaxation was a very broad process that consisted of two main contributions. Similar to the relaxation mechanism observed in PVOH at an analogous temperature, a low temperature contribution related to the local torsional movement of hydroxyl groups around the main chain was observed in the modified copolymer.43 The second contribution to β relaxation was ascribed to motions within EVOH interfacial regions. Alternatively, the α process was associated with cooperative movements that occur during the glass transition. Finally, α′ relaxation, which occurred at temperatures greater than that of the α process, was attributed to motions within the crystalline phase because of the relaxation of hydrogen bonds connecting hydroxyl groups within the phase or to movements close to the crystal lamella surface.44, 45 Moreover, in EVOH56, the copolymer with the highest ethylene content, an additional mechanism was observed at very low temperatures (approximately −120 °C). This process was only observed in EVOH56 because at least three methylenic units in the amorphous region are required for this process to occur,42 and the likelihood of attaining the necessary sequences was higher in the EVOH56 copolymer than in the EVOH68 copolymer because of the high ethylene content. This mechanism was called γ, and its molecular origin is analogous to the γ relaxation of polyethylene, which is associated with restricted conformational transitions within amorphous regions.46

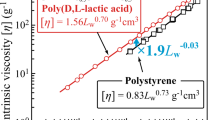

Two additional features were distinguished from the results shown in Figure 2. Specifically, the intensity of the secondary β mechanism was significantly lower than that of the α process because of differences in the mobility of the material. Moreover, the temperature of β relaxation was independent of the type of aminosaccharide (see Table 1), whereas the temperature of α relaxation was dependent on the nature of the sugar residue. However, because the degree of modification influences the amount of global hydroxyl groups and the strength of physical interactions between macrochains, the effect of the extent of modification was as important as the effect of the aminosaccharide content. Molecular weight and polydispersity can also affect the mechanical response of polymers in the solid phase and in solution. Nevertheless, the effect of molecular weight and polydispersity on the mechanical responses of glycopolymers seems to be less important than the changes provoked by the extent of modification and type of aminosaccharide, which may be because of the relatively high molecular weights and similar polydispersities of the polymers (see Table 1).

Figure 3 shows the relaxation processes observed in glycopolymers containing glucosyl moieties. As shown in the figure, significant differences between glucosyl-based glycopolymers were not observed. As previously mentioned, the temperature of β relaxation in both glycopolymers was similar, and the apparent activation energy values were analogous. Compared with EVOH68F-Gl, a shift in the temperature of the α mechanism to slightly higher temperatures was observed in the EVOH56F-Gl glycopolymer. The functionalization of EVOH hydroxyl groups leads to the incorporation of phthalic acid groups, and the presence of these bulky and rigid moieties reduces long-term segmental mobility. As a result, the α process occurs at higher temperatures in glycopolymers than in pristine EVOH copolymers. Accordingly, aminosaccharide-modified copolymers derived from EVOH68 or EVOH56 displayed α relaxation at higher temperatures, depending on the vinyl alcohol content, the extent of modification attained during the preparation of the glycopolymer and the ratio between the two parameters, as deduced from the results shown in Figure 3 and Table 1.

Knowledge of the rigidity of the copolymers is attained from the value of the storage modulus, E′, as shown in Figure 4. The value of the storage modulus, which is related to the stiffness of the material, is independent of the applied frequency until relaxation ascribed to the glass transition is near; that is, at ∼50 °C. The storage modulus decreases steadily because of thermal expansion; however, the dependence of the storage modulus on frequency varies in the proximity of the glass transition and is independent of the aminosaccharide content because of the cooperative nature of motions involved in the relaxation process.

The results shown in Figure 4 and Table 2 display the qualitative differences in the flexibility of glycopolymers at distinct temperatures. As shown in the figure, the stiffness of the polymers was dependent on several variables such as EVOH composition, extent of modification, type of aminosaccharide and the molecular weight of the polymer. However, quantitative conclusions could not be made because the glycopolymers displayed different degrees of modification and molecular weights. In general, glycopolymers derived from EVOH68 exhibited greater E′ values and were stiffer than homologous copolymers derived from EVOH56 because of their higher content of rigid phthalic acid groups. Moreover, when the degree of modification was similar (compare EVOH68F-Gl and EVOH68F-Ma), the incorporation of D-(+)-mannosamine led to greater E′ values than that of D-(+)-glucosamine. Alternatively, when the degree of modification was significantly different (compare EVOH56F-Gl and EVOH56F-Ga), intermolecular and intramolecular hydrogen interactions had a significant effect on rigidity, and the E′ values of the polymer increased.

As previously mentioned, the study of the rheological behavior of polymers in solution is of significant interest. Therefore, oscillatory isochronal shear experiments were conducted at a frequency of 1 Hz during the temperature sweeps. On heating, the glycopolymers can self-associate via intramolecular and intermolecular physical bonds. This self-association process may lead to the formation of physical and reversible networks, which present higher elastic modulus and viscosity values than those exhibited by the glycopolymer solution. If reversibility is observed, the aqueous glycopolymer solutions are recovered on cooling, and the rheological responses are reproducible. These are useful characteristics for applications in food, cosmetic and pharmaceutical industries. As previously mentioned, the development of gels is often reported in polysaccharides; however, gelation is rather unusual in glycopolymers.

The value of the gelation temperature, Tgel, can be obtained from the G′–G″ crossover plot. At low temperatures, aqueous solutions exhibited viscous behavior; therefore, G″>G′. However, as the temperature increased, the G″ values and those related to the elastic component, G′, became similar because of the self-association of hydroxyl groups until a gel was formed and crossover occurred (G″=G′). At temperatures greater than Tgel, elastic behavior was observed, and G″ became <G′. Figure 5 depicts the rheological behavior of glycopolymers based on D-(+)-glucosamine. The Tgel of EVOH68F-Gl was located at slightly higher temperatures than that of EVOH56F-Gl (see Table 3), indicating greater hindrance for hydrophilic interactions responsible for network formation in the glycopolymer. These interactions within the macromolecular architectures are related to the overall hydroxyl content and their spatial orientation. The total saccharide content of both glycopolymers was similar; however, the polymers presented differences in the content of modified hydroxyl groups and phthalic acid groups. Namely, the phthalic acid group content in the EVOH68F-Gl glycopolymer was greater than that of other polymers, and the rigidity of the phthalic acid group delayed gel development (see Figure 5 and data in Table 3). Both networks were characterized by considerable strength, as indicated by the high values of their gel modulus (see Table 3).

The rheological behavior of glycopolymers derived from EVOH56 is shown in Figure 6. The gelation temperature of the copolymers was similar to those exhibited by EVOH68-based glycopolymers because their global aminosaccharide contents were similar. When estimating the overall aminosaccharide content, one must consider that the extent of modification is related to the initial content and position of the hydroxyl groups. Thus, the results shown in Figure 6 suggest that the position of the hydroxyl groups within the three isomers had a significant effect on gelation. Moreover, in the crossover plots of the three glycopolymers, a small shoulder was observed before the drastic change in the value of G″ and G′, and was more pronounced in the plot obtained from EVOH56F-Ga than that from other glycopolymers. The presence of shoulders has been observed in some methylcelluloses47 and is ascribed to the formation of a weak gel. At lower temperatures, the solution remained clear until a weak gel had formed, and became progressively turbid as the temperature was further increased.

The gel process is also dependent on the applied frequency. Figure 7 shows the moduli of EVOH56F-derived glycopolymers in isothermal experiments at 30 °C. At this temperature, the viscosities of the solutions were relatively low; however, the change in the moduli of the material was indicative of a rheological response, and a flow-to-rubbery transition was observed. Thus, these systems displayed appreciable intra- and intermolecular interactions due to hydrogen bonding. Although gel formation occurred at similar frequencies, minor differences in the gelation frequencies of the glycopolymers were observed. First, the flow-to-rubbery transition was delayed in EVOH68F derivatives because of their high bulky group content and slightly higher molecular weight than that of analogous EVOH56F copolymers. Second, the development of physical and reversible gels was favored in glycopolymers containing D-(+)-galactosamine, which indicates that the type of aminosaccharide has a significant effect on the physical properties of the polymers.

Conclusions

In the novel aminosaccharide-based glycopolymers synthesized in the present study, α relaxation, which is associated with motion that occurs during the glass transition, took place at higher temperatures compared with that of the initial EVOH copolymers because of the incorporation of a bulky and rigid spacer. The location of α relaxation was consistent with the results obtained from differential scanning calorimetry (DSC) measurements and was dependent on the extent of modification. Moreover, the location and apparent activation energy of the secondary relaxation processes were independent of the type of monosaccharide incorporated into the polymer.

The stiffness of the glycopolymers was examined by determining the storage modulus, E′. Although the E′ values of the glycopolymers were significantly lower than those observed in pristine EVOH copolymers because of the loss of crystalline structure, the E′ values were sufficient for many applications. Moreover, because of the presence of rigid phthalic acid groups and intermolecular and intramolecular hydrogen bonds, the bulk glycopolymers displayed satisfactory mechanical performance.

Water-soluble glycopolymers presented extraordinary rheological behavior in solution, and self-associated networks developed as the temperature and frequency increased. Gel formation was reversible on cooling, and the main rheological characteristics of the material were dependent on the type of aminodisaccharide.

Preparation of ethylene-vinyl alcohol (EVOH) copolymers functionalized with carboxylic acid groups and further glycopolymer formation.

References

Thoma, G., Patton, J. T., Magnani, J. L., Ernst, B., Ohrlein, R. & Duthaler, R. O. Versatile functionalization of polylysine: synthesis, characterization, and use of neoglycoconjugates. J. Am. Chem. Soc. 121, 5919–5929 (1999).

Okada, M. Molecular design and syntheses of glycopolymers. Prog. Polym. Sci. 26, 67–104 (2001).

Varki, A. Biological roles of oligosaccharides—all of the theories are correct. Glycobiology 3, 97–130 (1993).

Dwek, R. A. Glycobiology: toward understanding the function of sugars. Chem. Rev. 96, 683–720 (1996).

Choi, S. K., Mammen, M. & Whitesides, G. M. Generation and in situ evaluation of libraries of poly(acrylic acid) presenting sialosides as side chains as polyvalent inhibitors of influenza-mediated hemagglutination. J. Am. Chem. Soc. 119, 4103–4111 (1997).

Roy, R. & Baek, M. G. Glycodendrimers: novel glycotope isosteres unmasking sugar coding. Case study with T-antigen markers from breast cancer MUC1 glycoprotein. Rev. Mol. Biotechnol. 90, 291–309 (2002).

Fleming, C., Maldjian, A., Costa, D. D., Rullay, A. K., Haddleton, D. M., St John, J., Penny, P., Noble, R. C., Cameron, N. R. & Davis, B. G. A carbohydrate-antioxidant hybrid polymer reduces oxidative damage in spermatozoa and enhances fertility. Nat. Chem. Biol. 1, 270–274 (2005).

Garcia-Martin, M. G., Jimenez-Hidalgo, C., Al-Kass, S. S. J., Caraballo, I., De Paz, M. V. & Galbis, J. A. Synthesis and characterization of some new homo- and copoly(vinylsaccharides). Some preliminary studies as drug delivery. Polymer 41, 821–826 (2000).

Roche, A. C., Fajac, I., Grosse, S., Frison, N., Rondanino, C., Mayer, R. & Monsigny, M. Glycofection: facilitated gene transfer by cationic glycopolymers. Cell Mol. Life Sci. 60, 288–297 (2003).

Yun, Y. H., Goetz, D. J., Yellen, P. & Chen, W. Hyaluronan microspheres for sustained gene delivery and site-specific targeting. Biomaterials 25, 147–157 (2004).

Palomino, E. Carbohydrate handles as natural-resources in drug-delivery. Adv. Drug Deliv. Rev. 13, 311 (1994).

Wadhwa, M. S. & Rice, K. G. Receptor-mediated glycotargeting. J. Drug Target. 3, 111–127 (1995).

Sihorkar, V. & Vya, S. P. Potential of polysaccharide anchored liposomes in drug delivery, targeting and immunization. J. Pharm. Pharm. Sci. 4, 138–158 (2001).

Dickinson, E. & Bergenstahl, B. in Food Colloids: Proteins, Lipids and Polysaccharides Vol. 192, pp. 417 (The Royal Society of Chemistry, Cambridge, 1997).

Novick, S. J. & Dordick, J. S. Preparation of active and stable biocatalytic hydrogels for use in selective transformations. Chem. Mat. 10, 955–958 (1998).

Wulff, G., Zhu, L. & Schmidt, H. Investigations on surface-modified bulk polymers. 1. Copolymers of styrene with a styrene moiety containing a sugar monomer. Macromolecules 30, 4533–4539 (1997).

Wulff, G., Schmidt, H. & Zhu, L. Generating hydrophilic surfaces on standard polymers after copolymerization with low amounts of protected vinyl sugars. Macromol. Chem. Phys. 200, 774–782 (1999).

Karamuk, E., Mayer, J., Wintermantel, E. & Akaike, T. Partially degradable film/fabric composites: textile scaffolds for liver cell culture. Artif. Organs 23, 881–884 (1999).

Nitta, Y. & Nishinari, K. Gelation and gel properties of polysaccharides gellan gum and tamarind xyloglucan. J. Biol. Macromol. 5, 47–52 (2005).

Kavanagh, G. M. & Ross-Murphy, S. B. Rheological characterisation of polymer gels. Prog. Polym. Sci. 23, 533–562 (1998).

Peppas, N. A. Hydrogels in Medicine and Pharmacy Vol. 1 (CRC Press, Boca Raton, FL, 1986).

Dunn, A. S. in: Polyvinyl Alcohol-Developments (ed. Finch, C.A.) 217 (John Wiley and Sons, London, 1992).

Takahashi, A. & Hiramits, S. Melting temperature of a thermally reversible gel. 3. Poly(vinyl alcohol)-water gels. Polym. J. 6, 103–107 (1974).

Rogozhin, S. V., Lozinskii, V. I., Vainerman, E. S., Domotenko, L. V., Mamtsis, A. M., Ivanova, S. A., Shtilman, M. I. & Korshak, V. V. Non-covalent cryostructurization in polymer systems. Dokl Akad Nauk USSR 278, 129–133 (1984).

Yamaura, K., Itoh, M. & Matsuzawa, S. Properties of gels obtained by freezing-thawing of poly(vinyl-alcohol) water dimethyl-sulfoxide solutions. J. Appl. Polym. Sci. 37, 2709–2718 (1989).

Cha, W. I., Hyon, S. H. & Ikada, Y. Transparent poly(vinyl alcohol) hydrogel with high water-content and high-strength. Makromol. Chem. 193, 1913–1925 (1992).

Ohkura, M., Kanaya, T. & Kaji, K. Gels of poly(vinyl alcohol) from dimethyl-sulfoxide water solutions. Polymer 33, 3686–3690 (1992).

Kanekiyo, M., Kobayashi, M., Ando, I., Kurosu, H. & Amiya, S. Structural and dynamic study of ethylene-vinyl alcohol copolymer gels by H-1 pulse NMR and solid-state C-13 NMR. Macromolecules 33, 7971–7976 (2000).

Ruiz, C., Sánchez-Chaves, M., Cerrada, M. L. & Fernández-García, M. Glycopolymers resulting from ethylene-vinyl alcohol copolymers: synthetic approach, characterization and interactions with lectins. J. Polym. Sci. Part A Polym. Chem. 46, 7238–7248 (2008).

Cerrada, M. L., Sánchez-Chaves, M., Ruiz, C. & Fernández-García, M. Glycopolymers resultant from ethylene-vinyl alcohol copolymers: degradation and rheological behavior in bulk. Eur. Polym. J. 44, 2194–2201 (2008).

Mc Crum, N. G., Read, B. E. & Williams, G. Anelastic and Dielectric Effects in Solid Polymers (Dover, New York, 1991).

Sánchez-Chaves, M., Ruiz, C., Cerrada, M. L. & Fernández-García, M. New glycopolymers containing aminosaccharide pendant groups by chemical modification of ethylene vinyl alcohol copolymers. Polymer 49, 2801–2807 (2008).

Lee, R. T., Ichikawa, Y., Fay, M., Drickamer, K., Shao, M. C. & Lee, Y. C. Ligand-binding characteristics of rat serum-type mannose-binding protein (mbp-a)-homology of binding-site architecture with mammalian and chicken hepatic lectins. J. Biol. Chem. 266, 4810–4815 (1991).

Lee, Y. C. & Lee, R. T. Carbohydrate-protein interactions: basis of glycobiology. Acc. Chem. Res. 28, 321–327 (1995).

Miura, Y., Ikeda, T., Wada, N., Sato, H. & Kobayashi, K. Chemoenzymatic synthesis of glycoconjugate polymers: greening the synthesis of biomaterials. Green Chem. 5, 610–614 (2003).

Matsuura, K., Hibino, M., Ikeda, T., Yamada, Y. & Kobayashi, K. Self-organized glycoclusters along DNA: effect of the spatial arrangement of galactoside residues on cooperative lectin recognition. Chemistry 10, 352–359 (2004).

Matsuura, K., Oda, R., Kitakoji, H., Kiso, M., Kitajima, K. & Kobayashi, K. Surface plasmon resonance study of carbohydrate-carbohydrate interaction between various gangliosides and Gg3-carrying polystyrene. Biomacromolecules 5, 937–941 (2004).

Kitov, P. I., Shimizu, H., Homans, S. W. & Bundle, D. R. Optimization of tether length in non-glycosidically linked bivalent ligands that target sites 2 and 1 of a Shiga-like toxin. J. Am. Chem. Soc. 125, 3284–3294 (2003).

Yung, A., Turnbull, W. B., Kalverda, A. P., Thomson, G. S., Homans, S. W., Kitov, P. & Bundle, D. R. Large-scale millisecond intersubunit dynamics in the B subunit homopentamer of the toxin derived from Escherichia coli O157. J. Am. Chem. Soc. 125, 3058–13062 (2003).

Sánchez-Chaves, M., Arranz, F. & Cortazar, M. Poly(vinyl alcohol) functionalized by monosuccinate groups. Coupling of bioactive amino compounds. Polymer 39, 2751–2757 (1998).

Takae, S., Akiyama, Y., Otsuka, H., Nakamura, T., Nagasaki, Y. & Kataoka, K. Ligand density effect on biorecognition by PEGylated gold nanoparticles: regulated interaction of RCA(120) lectin with lactose installed to the distal end of tethered PEG strands on gold surface. Biomacromolecules 6, 818–824 (2005).

Cerrada, M. L., Benavente, R., Pérez, E. & Pereña, J. M. The effect of annealing on the structure and relaxation processes of vinyl alcohol-ethylene copolymers. J. Polym. Sci. Part B Polym. Phys. 39, 1–12 (2001).

Cerrada, M. L., Pereña, J. M., Benavente, R. & Pérez, E. Viscoelastic processes in vinyl alcohol-ethylene copolymers. Influence of composition and thermal treatment. Polymer 41, 6655–6661 (2000).

Garrett, P. D. & Grubb, D. T. Effect of drawing on the alpha-relaxation of poly(vinyl-alcohol). J. Polym. Sci. Part B Polym. Phys. 26, 2509–2523 (1998).

Hong, P. D. & Miyasaka, K. Drawing of poly(vinyl alcohol) gel films. Polymer 32, 3140–3146 (1991).

Heaton, N. J., Benavente, R., Pérez, E., Bello, A. & Pereña, J. M. The gamma relaxation in polymers containing ether linkages: conformational dynamics in the amorphous phase for a series of polybibenzoates containing oxyethylene spacers. Polymer 37, 3791–3798 (1996).

Hirrien, M., Chevillard, C., Desbrières, J., Axelos, M. A. V. & Rinaudo, M. Thermogelation of methylcelluloses: new evidence for understanding the gelation mechanism. Polymer 39, 6251–6259 (1998).

Acknowledgements

The financial support of Ministerio de Ciencia e Innovación (Project MAT2007-60983) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cerrada, M., Ruiz, C., Sánchez-Chaves, M. et al. Rheological behavior of aminosaccharide-based glycopolymers obtained from ethylene-vinyl alcohol copolymers. Polym J 43, 205–213 (2011). https://doi.org/10.1038/pj.2010.128

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2010.128