Abstract

Fluoroalkyl end-capped N-(1,1-dimethyl-3-oxobutyl)acrylamide oligomer [RF-(DOBAA)n-RF] in silica nanocomposite can exhibit a nonflammability, even after calcination at 800 °C, through the formation of ammonium hexafluorosilicate during nanocomposite reactions. In contrast, the lack of formation of ammonium hexafluorosilicate during the usual composite reactions affords a flammable behavior for the RF-(DOBAA)n-RF oligomer in silica nanocomposite. Ammonium hexafluorosilicate is formed as a result of the dehydrofluorination of amido protons [-C(=O)NH-] in RF-(DOBAA)n-RF oligomer, with fluorine atoms in the oligomers catalyzed by both ammonia and silica nanoparticles in the composite reactions. In contrast, the lack of dehydrofluorination in the nanocomposite reaction under acidic conditions affords the usual flammable behavior for the oligomer.

Similar content being viewed by others

Introduction

Traditional organic polymers, such as poly(vinyl chloride), poly(ethylene), poly(propylene) and poly(styrene), are well known for decomposing completely at around 400–500 °C. However, perfluorinated polymers such as poly(tetrafluoroethylene) decompose at higher temperatures (around 600 °C) because of the bond-strengthening effect of fluorine for the C–C and C–F bonds in highly fluorinated compounds.1, 2, 3, 4, 5 From the developmental viewpoint of novel nonflammable materials, hybridizations of these fluorinated polymers with metal alkoxides6, 7, 8, 9, 10 and graphite oxide11 are of particular interest. In fact, some studies on the hybridization of fluorinated polymers with alkoxysilanes6, 7, 8, 9, 10 have been hitherto reported; however, the thermal stability of these hybrids is in general inferior to that of the original silica gels.6, 7, 8, 9, 10 In this study, we report that fluoroalkyl end-capped N-(1,1-dimethyl-3-oxobutyl)acrylamide oligomer [RF-(DOBAA)n-RF] in silica nanocomposite can exhibit a nonflammability, even after calcination at 800 °C, through the formation of ammonium hexafluorosilicate during nanocomposite reactions. In contrast, the lack of formation of ammonium hexafluorosilicate during the usual composite reactions affords a flammable behavior for RF-(DOBAA)n-RF oligomer in silica nanocomposite.

Experimental procedure

Methods

Measurements

19F magic-angle spinning (MAS) nuclear magnetic resonance (NMR) spectra were measured at room temperature using a JEOL JNM-ECA500 spectrometer with a 3.2 mm 19F MAS probe (Jeol, Tokyo, Japan). Fourier transform-infrared (FT-IR) spectra were measured using a Shimadzu FTIR-8400 FT-IR spectrophotometer (Kyoto, Japan). Molecular weights of the fluorinated oligomers were measured using Shodex DS-4 (pump) and Shodex RI-71 (detector) gel permeation chromatography (Tokyo, Japan), calibrated with a polystyrene standard and using tetrahydrofuran (THF) as the eluent. Thermal analyses were recorded by raising the temperature to around 800 °C (with a heating rate of 10 °C min−1) under atmospheric conditions by the use of a Bruker axs TG-DTA2000SA differential thermobalance (Bruker AXS, Kanagawa, Japan). Dynamic light scattering (DLS) was measured using the Otsuka Electronics DLS-7000 HL (Otsuka Electronics, Tokyo, Japan).

Preparation of fluoroalkyl end-capped N-(1,1-dimethyl-3-oxobutyl)acrylamide oligomer/silica gel nanocomposite

A methanol solution (20 ml) of fluoroalkyl end-capped N-(1,1-dimethyl-3-oxobutyl)acrylamide oligomer {RF-[CH2CHC(=O)NHCMe2CH2C(=O)Me]n-RF [RF-(DOBAA)n-RF]; RF=CF(CF3)OC3F7; Mn=3710 (0.50 g)}, which was prepared by the reaction of fluoroalkanoyl peroxide with the corresponding monomer according to our previously reported method,12 was mixed with tetraethoxysilane (0.47 g), silica-nanoparticle methanol solution (30% (wt.): 3.33 g; average particle size: 11 nm (Methanol Silica-sol (TR): Nissan Chemical Industrials, Tokyo, Japan)) and 25% aqueous ammonia solution (0.50 ml). The mixture was stirred with a magnetic stirring bar at room temperature for 2 h. After the solvent was evaporated off, methanol (25 ml) was added to the obtained crude products. The methanol solution was stirred with a magnetic stirring bar at room temperature for 2 days and then centrifuged for 30 min. The expected fluorinated nanocomposite was easily separated from the methanol solution. Fluorinated nanocomposite powders thus obtained were dried in vacuo at 50 °C for 2 days to afford purified particle powders (1.00 g). Other fluoroalkyl end-capped oligomers/silica composites were also prepared under similar conditions.

Treatment of RF-(DOBAA)n-RF/silica gel nanocomposite with aqueous hydrogen fluoride

RF-(DOBAA)n-RF/silica gel nanocomposite (10 mg) was put on a Teflon-made watch dish, and then aqueous 47% hydrogen fluoride (HF) (2 ml) was slowly dropped on this dish. The reaction mixture was heated to 150 °C to evaporate off the solvent. The white-coloured solid product thus obtained was analyzed using FT-IR measurements.

Results and Discussion

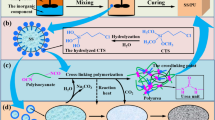

Two kinds of fluoroalkyl end-capped N-(1,1-dimethyl-3-oxobutyl)acrylamide oligomer/silica nanocomposites [RF-(DOBAA)n-RF/SiO2] were prepared by the sol–gel reactions of the corresponding oligomers with tetraethoxysilane under alkaline and acidic conditions, respectively (see Scheme 1).

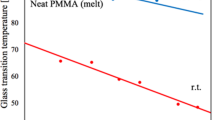

We have already tested these RF-(DOBAA)n-RF/SiO2 nanocomposites13, 14 for thermal stability by the use of thermogravimetric analyses, in which the weight loss of these nanocomposites was measured by raising the temperature to around 800 °C at a 10 °C min−1 heating rate under air atmospheric conditions. The RF-(DOBAA)n-RF/SiO2 nanocomposite prepared under acidic conditions14 showed a clear weight loss (25%) at 800 °C, a value quite similar to that of the elementary analysis of fluorine (24%) in this composite. However, the RF-(DOBAA)n-RF/SiO2 nanocomposite prepared under alkaline conditions exhibited no weight loss up to temperatures of 800 °C, although the content of RF-(DOBAA)n-RF oligomer in this nanocomposite was estimated to be 23% by elementary analysis of fluorine.13 Thus, to clarify the interesting nonflammable characteristic of this nanocomposite, the 19F MAS NMR spectra of RF-(DOBAA)n-RF/SiO2 nanocomposites prepared under both alkaline and acidic conditions were measured, and the results are shown in Figure 1.

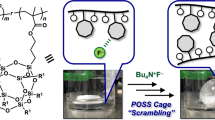

As shown in Figure 1, each RF-(DOBAA)n-RF/SiO2 nanocomposite before calcination showed CF3 and CF2 peaks related to the presence of fluoroalkyl end-capped DOBAA oligomer in the composites. However, unexpectedly, we observed a relatively sharp peak at around −154.8 p.p.m. in the RF-(DOBAA)n-RF/SiO2 nanocomposite prepared under alkaline conditions, which exhibited nonflammability. This peak should be ascribed to (NH4)2SiF6. In fact, Kao and Chen reported that the 19F MAS NMR spectra of (NH4)2SiF6 can show a similar chemical shift around −158 p.p.m.15, 16

We have already reported that the room temperature FT-IR spectra of RF-(DOBAA)n-RF/silica gel nanocomposites possessing nonflammability show the complete disappearance of the carbonyl bands (1709, 1655 and 1543 cm−1) related to the RF-(DOBAA)n-RF oligomer, even before calcinations.14 However, the treatment of this RF-(DOBAA)n-RF/silica gel nanocomposite with aqueous HF afforded FT-IR spectra of RF-(DOBAA)n-RF oligomer similar to those of the original RF-(DOBAA)n-RF oligomer.17 In contrast, these carbonyl bands were clearly observed in the RF-(DOBAA)n-RF/silica gel nanocomposite possessing flammability, and the same FT-IR spectra as that of the original RF-(DOBAA)n-RF oligomer were observed after treatment with aqueous HF.16 Now, interestingly, the FT-IR spectra of the RF-(DOBAA)n-RF/silica gel nanocomposite possessing nonflammability (see Figure 2a) after treatment with aqueous HF showed a clear band at around 700 cm−1 in addition to those of the parent RF-(DOBAA)n-RF oligomer (see Figure 2b), although we could not detect such bands at all in the corresponding flammable RF-(DOBAA)n-RF oligomer (see Figure 2d). The presence of a clear band at around 700 cm−1 could be due to the presence of ammonium hexafluorosilicate in the composite. The RF-(DOBAA)n-RF/silica gel nanocomposite possessing nonflammability after calcination at 800 °C had been treated with aqueous HF. The FT-IR spectra of this treated product (see Figure 3b) showed the formation of ammonium hexafluorosilicate, because the parent ammonium hexafluorosilicate showed the following bands: 3350, 1430 and 725 cm−1. These findings suggest that the nanocomposite reaction of RF-(DOBAA)n-RF oligomer with silica nanoparticles should proceed smoothly under alkaline conditions to afford not only the expected RF-(DOBAA)n-RF/silica nanocomposite but also ammonium hexafluorosilicate, as shown in the plausible reaction mechanism (see Scheme 2).

The formation of ammonium hexafluorosilicate during composite reactions can afford nonflammability to the RF-(DOBAA)n-RF oligomer. That is, the RF-(DOBAA)n-RF oligomer in the nanocomposite should be encapsulated quite effectively into the nanometer size-controlled silica gel matrices through the molecular-level synergistical combination, which is due not only to the strong interaction between fluorine in the oligomer and silicon in the silica gel nanocomposite but also to the effective interaction between ammonium hexafluorosilicate and the RF-(DOBAA)n-RF oligomer in the silica gel matrices, and this affords nonflammability to the oligomer. Such effective interactions between ammonium hexafluorosilicate and the RF-(DOBAA)n-RF oligomer in the silica gel matrices should enable the RF-(DOBAA)n-RF/silica gel nanocomposite to have complete disappearance of the amido band of the RF-(DOBAA)n-RF oligomer in the FT-IR spectrum measurements before and after calcination at 800 °C. In fact, we have already reported that the 1H MAS NMR spectra of the RF-(DOBAA)n-RF/silica nanocomposite (with the oligomer content in the composite at 23%, as determined by elementary analyses of fluorine), which exhibit no weight loss even after calcinations at 800 °C, can exhibit similar relatively sharp peaks at around 50 to −20 p.p.m.17 These peak areas are almost the same as those before calcination at 800 °C.17 Furthermore, it was previously reported that hexafluorosilicic acid can interact smoothly with amido segments in N,N-dimethylformamide to give a stable hexafluorosilicic acid–N,N-dimethylformamide 1:3 adduct.18, 19 Thus, the surface of smoothly encapsulated RF-(DOBAA)n-RF oligomer into silica gel nanomatrices through effective hydrogen bonding interactions of the amido protons in the oligomers and fluorines in ammonium hexafluorosilicate could possess an extraordinarily high oxidation resistance, explaining the exhibition of nonflammability during calcination at 800 °C.

We have prepared other fluoroalkyl end-capped oligomers/silica composites (with a theoretical content of each oligomer in the composites at 41%) under the same conditions as those in Scheme 1, and we have studied the thermal stability of these fluorinated oligomers/silica composites by the use of thermogravimetric analysis measurements, with results shown in Table 1.

As shown in Table 1, RF-(NIPAM)n-RF oligomer that possesses amido protons and RF-(DOBAA)n-RF oligomer was found to exhibit no weight loss at 800 °C for the nanocomposite reaction under alkaline conditions, although the corresponding NIPAM oligomer/silica composite prepared under acidic conditions exhibited clear weight loss at 800 °C. In contrast, RF-(DMAA)n-RF and RF-(ACMO)n-RF oligomers (see Table 1, footnotes d and e) that possess no amido protons were found to exhibit a clear weight loss behavior at 800 °C, both for the nanocomposite reactions with silica nanoparticles under alkaline conditions and for the corresponding fluorinated oligomers/silica composites prepared under acidic conditions.

Not only fluoroalkyl end-capped acrylamide-type oligomers but also fluoroalkyl end-capped oligomers containing sulfo groups [RF-(MES)n-RF] formed by the nanocomposite reactions under alkaline conditions afforded no weight loss behavior at 800 °C (see Table 1, footnote f). However, fluoroalkyl end-capped oligomer containing carboxy groups [RF-(ACA)n-RF] formed by the nanocomposite reaction has been already shown to exhibit a clear weight loss at 800 °C (see Table 1,footnote i and j). This interesting result could be due to the higher acidity of sulfo groups than carboxy groups in fluorinated oligomers, resulting in the smooth dehydrofluorination catalyzed by ammonia and silica nanoparticles. Therefore, the RF-(AMPS)n-RF oligomer failed to accomplish such dehydrofluorination in composite reactions under alkaline conditions, affording no weight loss behavior, because this oligomer possesses betaine-type segments (see Table 1, footnote k). Similarly, as the RF-(MACA)n-RF oligomer possesses carboxy groups and RF-(ACA)n-RF (see Table 1, footnote g), the RF-(MACA)n-RF oligomer can exhibit a clear weight loss behavior by the composite reaction. However, interestingly, as the RF-(MACA)n-(TFMA)n-RF co-oligomer possesses a higher number of acidic carboxy groups than the RF-(MACA)n-RF oligomer due to the presence of electron-withdrawing CF3 groups in the co-oligomer, this fluorinated co-oligomer is expected to exhibit no weight loss behavior at 800 °C for the composite reaction.20 In fact, we have succeeded in observing no weight loss behavior for this composite at 800 °C (see Table 1, footnote h).

In conclusion, these experiments show that fluoroalkyl end-capped oligomers containing amido protons or more acidic protons, such as sulfo groups and carboxy groups, possessing electron-withdrawing CF3 units as neighboring groups can be used as novel fluorinated functional materials possessing a perfectly nonflammable characteristic at 800 °C for the composite reactions with silica nanoparticles. In particular, fluorinated oligomers containing amido protons should enable the smooth dehydrofluorination of amido protons with fluorines in oligomers catalyzed by ammonia and silica nanoparticles, affording ammonium hexafluorosilicate with the effective interaction of amido groups and hexafluorosilicate anions, although the amido protons generally exhibit an extremely weak acidity compared with that of the sulfo and carboxy groups. Thus, this unique technology can result in new developments for oxidation-resistant functional materials in a wide variety of fields.

References

Dolbier, W. R. Jr. Fluorine chemistry at the millennium. J. Fluorine Chem. 126, 157–163 (2005).

Scheirs, J. (Ed.) Modern Fluoropolymers (Wiley, Chichester, 1997).

Ameduri, B. & Boutevin, B. Well-Architectured Fluoropolymers: Synthesis: Properties and Applications (Elsevier, Amsterdam, 2004).

Johns, K. & Stead, G. Fluoroproducts—the extremophiles. J. Fluorine Chem. 104, 5–18 (2000).

Ameduri, B. & Boutevin, B. Copolymerization of fluorinated monomers: recent developments and future trends. J. Fluorine Chem. 104, 53–62 (2000).

Chen, Y. -C., Tsai, C. -C. & Lee, Y. -D. Preparation and properties of silylated PTFE/SiO2 organic-inorganic hybrids via sol-gel process. J. Polym. Sci.: Part A: Polym. Chem. 42, 1789–1807 (2004).

Harmer, M. K., Farneth, W. E. & Sun, Q. High surface area nafion resin/silica nanocomposites: a new class of solid acid catalyst. J. Am. Chem. Soc. 118, 7708–7715 (1996).

Cho, J. -W. & Sul, K. -I. Crystallization of poly(vinylidene fluoride)-SiO2 hybrid composites prepared by a sol-gel process. Fibers and Polymers 2, 135–140 (2001).

Yano, S., Okubo, N. & Takahashi, K. Physical properties of sol-gel derived poly(vinylidene fluoride)/silica hybrid. Macromol. Symp. 108, 279–289 (1996).

Fabbri, P., Messori, M., Montecchi, M., Nannarone, S., Pasquali, L., Pilati, F., Tonelli, C. & Toselli, M. Perfluoropolyether-based organic–inorganic hybrid coatings. Polymer 47, 1055–1062 (2006).

Ansari, S. & Giannelis, E. P Functionalized graphene sheet—poly(vinylidene fluoride) conductive nanocomposites. J. Polym. Sci. Part B: Polym. Phys. 47, 888–897 (2009).

Sawada, H., Yoshino, Y., Kurachi, M., Kawase, T., Takishita, K. & Tanedani, T. Recognition of hydrophilic amino and N,N-dimethylamino compounds by the self-assembled aggregates of fluoroalkylated end-capped N-(1,1-dimethyl-3-oxobutyl)acrylamide oligomer. Polymer 41, 397–400 (2000).

Sawada, H., Narumi, T., Kodama, S., Kamijo, M., Ebara, R., Sugiya, M. & Iwasaki, Y. A fluoroalkyl end-capped N-(1,1-dimethyl-3-oxobutyl)acrylamide oligomer/silica gel nanocomposite with no weight loss even at 800 °C equal to an original silica gel. Colloid Polym. Sci. 285, 977–983 (2007).

Sawada, H., Tashima, T. & Kodama, S. Preparation of a variety of fluoroalkyl end-capped N-(1,1-dimethyl-3-oxobutyl)acrylamide oligomer/silica nanocomposites possessing no weight loss characteristic at 800 °C. Polym. Adv. Technol. 19, 739–747 (2008).

Kao, H.- M. & Chen, Y.- C. 27Al and 19F Solid-state NMR studies of zeolite H-β dealuminated with ammonium hexafluorosilicate. J. Phys. Chem. B 107, 3367–3375 (2003).

Kao, H. -M. & Chang, P .-C. Direct solid-state NMR spectroscopic evidence for the NH4AlF4 crystalline phase derived from zeolite HY dealuminated with ammonium hexafluorosilicate. J. Phys. Chem. B 110, 19104–19107 (2006).

Sawada, H., Kakehi, H., Tashima, T., Nishiyame, Y., Miura, M. & Isu, N. Fluoroalkyl end-capped oligomer possessing a nonflammable characteristic in silica gel matrices even at 800°C under atmospheric conditions. J. Appl. Polym. Sci. 112, 3482–3487 (2009).

Yoshimura, C. & Miyamoto, M. Nonaqueous conductimetric titration of alkaline earth metals and aluminum with hexafluorosilicic acid-N,N-dimethylformamide adduct. Bunseki Kagaku 29, 829–833 (1980).

Yoshimura, C. & Hujino, T. Nonaqueous conductimetric titration of molybdenum with hexafluorosilicic acid, N-N-dimethylformamide adduct. Bunseki Kagaku 33, 48–53 (1983).

Piletska, E. V., Guerreiro, A. P., Romero-Guerra, M., Chianella, I., Turner, A. P. F. & Piletsky, S. A. Design of molecular imprinted polymers compatible with aqueous environment. Anal. Chim. Acta. 607, 54–60 (2008): This paper shows that the pKa of monomers (their polymers) of 2-trifluoromethacrylic acid, methacrylic acid and acrylic acid are 2.7 (5.7), 4.65 (6.7) and 4.25 (6.6), respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sawada, H., Tashima, T., Kakehi, H. et al. Fluoroalkyl end-capped oligomers possessing nonflammable and flammable characteristics in silica gel matrices after calcination at 800 °C under atmospheric conditions. Polym J 42, 167–171 (2010). https://doi.org/10.1038/pj.2009.316

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2009.316

Keywords

This article is cited by

-

Preparation of fluoroalkyl end-capped vinyltrimethoxysilane oligomeric silica/boric acid/poly(N-methyl benzamide)-b-poly(propylene oxide) block copolymer nanocomposites – no weight loss behavior of the block copolymer in the nanocomposites even after calcination at 800 °C

Journal of Sol-Gel Science and Technology (2018)

-

Preparation and thermal stability of initiator fragments end-capped oligomers/silica nanocomposites

Colloid and Polymer Science (2016)

-

Reaction of fluorinated aliphatic alcohols with calcium chloride: formation of the fluorinated alcohol/calcium fluoride nanocomposites—thermal stability and application to the surface modification of these nanocomposites

Journal of Coatings Technology and Research (2016)

-

Facile creation of superoleophobic and superhydrophilic surface by using fluoroalkyl end-capped vinyltrimethoxysilane oligomer/calcium silicide nanocomposites—development of these nanocomposites to environmental cyclical type-fluorine recycle through formation of calcium fluoride

Colloid and Polymer Science (2015)

-

Preparation and properties of fluorinated carboxylic acid/silica nanocomposite-encapsulated low molecular weight compounds

Colloid and Polymer Science (2014)