Abstract

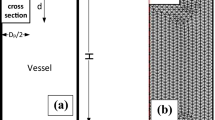

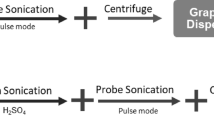

Graphene has promising physical and chemical properties such as high strength and flexibility, coupled with high electrical and thermal conductivities. It is therefore being incorporated into polymer-based composites for use in electronics and photonics applications. A main constraint related to the graphene development is that, being of a strongly hydrophobic nature, almost all dispersions (usually required for its handling and processing toward the desired application) are prepared in poisonous organic solvents such as N-methyl pyrrolidone or N,N-dimethyl formamide. Here, we describe how to prepare exfoliated graphite using a ball mill. The graphene produced is three to four layers thick and ∼500 nm in diameter on average, as measured by electron microscopy and Raman spectroscopy; can be stored in the form of light solid; and is easily dispersed in aqueous media. Our methodology consists of four main steps: (i) the mechanochemical intercalation of organic molecules (melamine) into graphite, followed by suspension in water; (ii) the washing of suspended graphene to eliminate most of the melamine; (iii) the isolation of stable graphene sheets; and (iv) freeze–drying to obtain graphene powder. This process takes 6–7 or 9–10 d for aqueous suspensions and dry powders, respectively. The product has well-defined properties and can be used for many science and technology applications, including toxicology impact assessment and the production of innovative medical devices.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Ferrari, A.C. et al. Science and technology roadmap for graphene, related two-dimensional crystals, and hybrid systems. Nanoscale 7, 4598 (2015).

Whitener, K.E. Jr. & Sheehan, P.E. Raman spectroscopy in graphene. Diamond Relat. Mater. 46, 25 (2014).

Yang, K., Feng, L., Hong, H., Cai, W. & Liu, Z. Preparation and functionalization of graphene nanocomposites for biomedical applications. Nat. Protoc. 8, 2392 (2013).

Yi, M. & Shen, Z. A review on mechanical exfoliation for the scalable production of graphene. J. Mater. Chem. A 3, 11700 (2015).

Ciriminna, R. et al. Commercialization of graphene-based technologies: a critical insight. Chem. Commun. 51, 7090 (2015).

Vazquez, E., Giacalone, F. & Prato, M. Non-conventional methods and media for the activation and manipulation of carbon nanoforms. Chem. Soc. Rev. 43, 58 (2014).

Cielski, A. & Samorì, P. Graphene via sonication assisted liquid-phase exfoliation. Chem. Soc. Rev. 43, 381 (2014).

Du, W., Jiang, X. & Zhu, L. From graphite to graphene: direct liquid-phase exfoliation of graphite to produce single- and few-layered pristine graphene. J. Mater. Chem. A 1, 10592 (2013).

Du, W., Lu, J., Sun, P., Zhu, Y. & Jiang, X. Organic salt-assisted liquid-phase exfoliation of graphite to produce high-quality graphene. Chem. Phys. Lett. 568–569, 198 (2013).

Paredes, J.I. & Villar-Rodil, S. Biomolecule-assisted exfoliation and dispersion of graphene and other two-dimensional materials: a review of recent progress and applications. Nanoscale 8, 15389 (2016).

León, V. et al. Few-layer graphenes from ball milling of graphite with melamine. Chem. Commun. 47, 10936 (2011).

León, V., Rodriguez, A.M., Prieto, P., Prato, M. & Vázquez, E. Exfoliation of graphite with triazine derivatives under ball-milling conditions: preparation of few-layer graphene via selective noncovalent interactions. ACS Nano 8, 563–571 (2014).

Rodríguez, A.M., Muñoz-García, A.B., Crescenzi, O., Vázquez, E. & Pavone, M. Stability of melamine-exfoliated graphene in aqueous media: quantum-mechanical insights at the nanoscale. Phys. Chem. Chem. Phys. 18, 22203 (2016).

Russier, J. et al. Few-layer graphene kills selectively tumor cells from myelomonocytic leukemia patients. Angew. Chem. Int. Ed. Engl. 56, 3014 (2017).

Servant, A. et al. Graphene-based electroresponsive scaffolds as polymeric implants for on-demand drug delivery. Adv. Healthcare Mater. 3, 1334 (2014).

Rauti, R. et al. Graphene oxide nanosheets reshape synaptic function in cultured brain networks. ACS Nano 10, 4459 (2016).

Mottier, A. et al. Surface area of carbon nanoparticles: a dose metric for a more realistic ecotoxicological assessment. Nano Lett. 16, 3514 (2016).

Wick, P. et al. Classification framework for graphene-based materials. Angew. Chem. Int. Ed. Engl. 53, 7714 (2014).

Pelin, M. et al. Differential cytotoxic effects of graphene and graphene oxide on skin keratinocytes. Sci. Rep. 7, 40572 (2017).

Gossner, C.M.-E. et al. The melamine incident: implications for international food and feed safety. Environ. Health Perspectives 117, 1803 (2009).

León, V., Castañeda, G., Herrero, M.A. & Vázquez, E. Gold nanoparticles as analytical tools for the quantification of small quantities of triazine derivatives anchored on graphene in water dispersions. RSC Adv. 7, 21982 (2017).

León, V., González-Domínguez, J.M., Fierro, J.L.G., Prato, M. & Vázquez, E. Production and stability of mechanochemically exfoliated graphene in water and culture media. Nanoscale 8, 14548 (2016).

He, P. et al. Urea-assisted aqueous exfoliation of graphite for obtaining high-quality graphene. Chem. Commun. 51, 4651 (2015).

Rubio, N. et al. Production of water-soluble few-layer graphene mesosheets by dry milling with hydrophobic drug. Langmuir 30, 14999 (2014).

Irin, F. et al. Adsorption and removal of graphene dispersants. J. Colloid Interface Sci. 446, 282 (2015).

Buzaglo, M. et al. Graphite-to-graphene: total conversion. Adv. Mater. 29, 1603528 (2014).

Lin, T. et al. Scotch-tape-like exfoliation of graphite assisted with elemental sulfur and graphene–sulfur composites for high-performance lithium-sulfur batteries. Energ. Environ. Sci. 6, 1283 (2013).

Paton, K.R. et al. Scalable production of large quantities of defect-free few-layer graphene by shear exfoliation in liquids. Nat. Mater. 13, 624 (2014).

Bianco, A. & Prato, M. Safety concerns on graphene and 2D materials: a Flagship perspective. 2D Mater. 2, 030201 (2015).

Burmeister, C.F. & Kwade, A. Process engineering with planetary ball mills. Chem. Soc. Rev. 42, 7660 (2013).

Maugey, M. et al. Substantial improvements of nanotube processability by freeze-drying. J. Nanosci. Nanotechnol. 7, 2633 (2007).

Grabar, K.C., Freeman, R.G., Hommer, M.B. & Natan, M.J. Preparation and characterization of Au colloid monolayers. Anal. Chem. 67, 735 (1995).

Haiss, W., Thanh, N.T.K., Aveyard, J. & Fernig, D.G. Determination of size and concentration of gold nanoparticles from UV-Vis spectra. Anal. Chem. 79, 4215 (2007).

Ferrari, A.C. et al. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 97, 1 (2006).

Mogera, U., Dhanya, R., Pujar, R., Narayana, C. & Kulkarni, G.U. Highly decoupled graphene multilayers: turbostraticity at its best. J. Phys. Chem. Lett. 6, 4437 (2015).

Casiraghi, C. et al. Raman spectroscopy of graphene edges. Nano Lett. 9, 1433 (2009).

Acknowledgements

We acknowledge financial support from the Spanish Ministry of Economy and Competitiveness (MINECO; projects CTQ2014-53600-R and CTQ2016-76721-R), through the EU Graphene-based disruptive technologies Flagship project (no. 696656). J.M.G.-D. gratefully acknowledges Spanish MINECO for his research grant (Formación Postdoctoral). M.P., as the recipient of the AXA Chair, is grateful to the AXA Research Fund for financial support. M.P. was also supported by Diputación Foral de Gipuzkoa (Spain), program Red (101/16).

Author information

Authors and Affiliations

Contributions

J.M.G.-D., V.L., and M.I.L. contributed equally to this work. J.M.G.-D., V.L., and M.I.L. performed the experimental work and optimized the protocol. M.P. contributed to the research plan and to the writing of the manuscript. E.V. planned and supervised the research, and cowrote the paper with contributions from all the other authors. All authors discussed the results and commented the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

About this article

Cite this article

González-Domínguez, J., León, V., Lucío, M. et al. Production of ready-to-use few-layer graphene in aqueous suspensions. Nat Protoc 13, 495–506 (2018). https://doi.org/10.1038/nprot.2017.142

Published:

Issue Date:

DOI: https://doi.org/10.1038/nprot.2017.142

This article is cited by

-

Rapid and efficient testing of the toxicity of graphene-related materials in primary human lung cells

Scientific Reports (2022)

-

Towards a more environmentally sustainable production of graphene-based materials

The International Journal of Life Cycle Assessment (2021)

-

Greener approach towards the synthesis of graphene nanosheet and its application in supercapacitor

Journal of Materials Science: Materials in Electronics (2021)

-

Photo-Fenton-inspired deoxygenation of tea polyphenol–graphene by household bleach

Carbon Letters (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.