Abstract

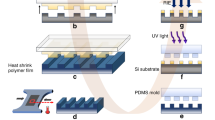

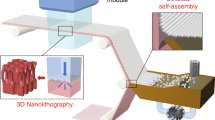

We provide a protocol for transforming the structure of an array of high-aspect-ratio (HAR) micro/nanostructures into various new geometries. Polymeric HAR arrays are replicated from a Bosch-etched silicon master pattern by soft lithography. By using various conditions, the original pattern is coated with metal, which acts as an electrode for the electrodeposition of conductive polymers, transforming the original structure into a wide range of user-defined new designs. These include scaled replicas with sub-100-nm-level control of feature sizes and complex 3D shapes such as tapered or bent columnar structures bearing hierarchical features. Gradients of patterns and shapes on a single substrate can also be produced. This benchtop fabrication protocol allows the production of customized libraries of arrays of closed-cell or isolated HAR micro/nanostructures at a very low cost within 1 week, when starting from a silicon master that otherwise would be very expensive and slow to produce using conventional fabrication techniques.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Kim, P. et al. Structural transformation by electrodeposition on patterned substrates (STEPS): a new versatile nanofabrication method. Nano. Lett. published online, doi:10.1021/nl200426g (25 March 2011).

Ahuja, A. et al. Nanonails: a simple geometrical approach to electrically tunable superlyophobic surfaces. Langmuir 24, 9–14 (2008).

Chu, K.-H., Xiao, R. & Wang, E.N. Uni-directional liquid spreading on asymmetric nanostructured surfaces. Nat. Mater. 9, 413–417 (2010).

Hochbaum, A.I. & Aizenberg, J. Bacteria pattern spontaneously on periodic nanostructure arrays. Nano. Lett. 10, 3717–3721 (2010).

Kang, S.H., Pokroy, B., Mahadevan, L. & Aizenberg, J. Control of shape and size of nanopillar assembly by adhesion-mediated elastocapillary interaction. ACS Nano. 4, 6323–6331 (2010).

Kim, P., Zarzar, L.D., He, X., Grinthal, A. & Aizenberg, J. Hydrogel-actuated integrated responsive systems (HAIRS): moving towards adaptive materials. Curr. Opin. Solid State Mater. Sci. 15, 236–245 (2011).

Kim, P., Zarzar, L.D., Zhao, X., Sidorenko, A. & Aizenberg, J. Microbristle in gels: toward all-polymer reconfigurable hybrid surfaces. Soft Matter 6, 750–755 (2010).

Mishchenko, L. et al. Design of ice-free nanostructured surfaces based on repulsion of impacting water droplets. ACS Nano. 4, 7699–7707 (2010).

Pokroy, B., Epstein, A.K., Persson-Gulda, M.C.M. & Aizenberg, J. Fabrication of bioinspired actuated nanostructures with arbitrary geometry and stiffness. Adv. Mater. 21, 463–469 (2009).

Pokroy, B., Kang, S.H., Mahadevan, L. & Aizenberg, J. Self-organization of a mesoscale bristle into ordered, hierarchical helical assemblies. Science 323, 237–238 (2009).

Schumacher, J.F. et al. Engineered antifouling microtopographies—effect of feature size, geometry, and roughness on settlement of zoospores of the green alga Ulva. Biofouling 23, 55–62 (2007).

Sidorenko, A., Krupenkin, T., Taylor, A., Fratz, P. & Aizenberg, J. Reversible switching of hydrogel-actuated nanostructures into complex micropatterns. Science 315, 487–490 (2007).

Tuteja, A. et al. Designing superoleophobic surfaces. Science 318, 1618–1622 (2007).

Vasquez, Y., Fenton, E.M., Chernow, V.F. & Aizenberg, J. Growth of polygonal rings and wires of CuS on structured surfaces. Crystal Eng. Commun. 13, 1077–1080 (2011).

Zarzar, L.D., Kim, P. & Aizenberg, J. Bio-inspired design of submerged hydrogel-actuated polymer microstructures operating in response to pH. Adv. Mater. 23, 1442–1446 (2011).

Laermer, F. & Schilp, A. Robert Bosch GmbH Method of anisotropically etching silicon. US patent US5501893 (1996).

Lipomi, D.J. et al. Fabrication and replication of arrays of single- or multi-component nanostructures by replica molding and mechanical sectioning. ACS Nano. 4, 4017–4026 (2010).

Tran, H.D., Li, D. & Kaner, R.B. One-dimensional conducting polymer nanostructures: bulk synthesis and applications. Adv. Mater. 21, 1487–1499 (2009).

Zang, J. et al. Template-free electrochemical synthesis of superhydrophilic polypyrrole nanofiber network. Macromolecules 41, 7053–7057 (2008).

Debiemme-Chouvy, C. Template-free one-step electrochemical formation of polypyrrole nanowire array. Electrochem. Commun. 11, 298–301 (2009).

Zhang, Y., Lin, C.-T. & Yang, S. Fabrication of hierarchical pillar arrays from thermoplastic and photosensitive SU-8. Small 6, 768–775 (2010).

Zhang, Y., Reed, J.C. & Yang, S. Creating a library of complex metallic nanostructures via harnessing pattern transformation of a single PDMS membrane. ACS Nano. 3, 2412–2418 (2009).

Lee, M.H., Huntington, M.D., Zhou, W., Yang, J.-C. & Odom, T.W. Programmable soft lithography: solvent-assisted nanoscale embossing. Nano. Lett. 11, 311–315 (2011).

Bhushan, B. & Jung, Y.C. Natural and biomimetic artificial surfaces for superhydrophobicity, self-cleaning, low adhesion, and drag reduction. Prog. Mater. Sci. 56, 1–108 (2011).

Kamperman, M., Arzt, E. & del Campo, A. Bioinspired Patterned Adhesives 1st edn (Wiley-VCH Verlag GmbH & Co. KgaA,, 2011).

Jeong, H.E. & Suh, K.Y. Nanohairs and nanotubes: efficient structural elements for gecko-inspired artificial dry adhesives. Nano. Today 4, 335–346 (2009).

Xu, Q., Rioux, R.M., Dickey, M.D. & Whitesides, G.M. Nanoskiving: a new method to produce arrays of nanostructures. Acc. Chem. Res. 41, 1566–1577 (2008).

Yang, M.T., Fu, J., Wang, Y.-K., Desai, R.A. & Chen, C.S. Assaying stem cell mechanobiology on microfabricated elastomeric substrates with geometrically modulated rigidity. Nat. Protoc. 6, 187–212 (2011).

Discher, D.E., Janmey, P. & Wang, Y.-l. Tissue cells feel and respond to the stiffness of their substrate. Science 310, 1139–1143 (2005).

Bettinger, C.J., Langer, R. & Borenstein, J.T. Engineering substrate topography at the micro- and nanoscale to control cell function. Angew. Chem. Int. Ed. 48, 5406–5415 (2009).

Chen, C.S., Mrksich, M., Huang, S., Whitesides, G.M. & Ingber, D.E. Geometric control of cell life and death. Science 276, 1425–1428 (1997).

Davey, M.E. & O'toole, G.A. Microbial biofilms: from ecology to molecular genetics. Microbiol. Mol. Biol. Rev. 64, 847–867 (2000).

Volder, M.D. et al. Diverse 3D microarchitectures made by capillary forming of carbon nanotubes. Adv. Mater. 22, 4384–4389 (2010).

Chandra, D. & Yang, S. Capillary-force-induced clustering of micropillar arrays: is it caused by isolated capillary bridges or by the lateral capillary meniscus interaction force? Langmuir 25, 10430–10434 (2009).

Das, M., Wilson, K., Molnar, P. & Hickman, J.J. Differentiation of skeletal muscle and integration of myotubes with silicon microstructures using serum-free medium and synthetic silane substrate. Nat. Protoc. 2, 1795–1801 (2007).

Fu, J., Mao, P. & Han, J. Continuous-flow bioseparation using microfabricated anisotropic nanofluidic sieving structures. Nat. Protoc. 4, 1681–1698 (2009).

Fu, J. et al. Mechanical regulation of cell function with geometrically modulated elastomeric substrates. Nat. Methods 7, 733–736 (2010).

Qin, D., Xia, Y. & Whitesides, G.M. Soft lithography for micro- and nanoscale patterning. Nat. Protoc. 5, 491–502 (2010).

Maluf, N. An Introduction to Microelectromechanical System Engineering (Artech House, 2000).

Ayón, A.A., Braff, R., Bayt, R., Sawin, H.H. & Schmidt, M.A. Influence of coil power on the etching characteristics in a high density plasma etcher. J. Electrochem. Soc. 146, 2730–2736 (1999).

Ayón, A.A., Braff, R., Lin, C.C., Sawin, H.H. & Schmidt, M.A. Characterization of a time multiplexed inductively coupled plasma etcher. J. Electrochem. Soc. 146, 339–349 (1999).

Acknowledgements

This work was partially supported by the US Department of Energy, Office of Basic Energy Sciences and the Division of Materials Science and Engineering, under award no. DE-SC0005247 (design of HAR structures); the US Army Research Office Multidisciplinary University Research Initiative under award no. W911NF-09-1-0476 (electrodeposition and mechanical properties); and the US Air Force Office of Scientific Research Multidisciplinary University Research Initiative under award no. FA9550-09-1-0669-DOD35CAP (optical properties). This work was carried out in part through the use of the Massachusetts Institute of Technology's Microsystems Technology Laboratories. Part of this work was also performed at the Center for Nanoscale Systems at Harvard University, a member of the National Nanotechnology Infrastructure Network, which is supported by the National Science Foundation (NSF) under NSF award no. ECS-0335765. W.E.A.-M. thanks REU BRIDGE, co-funded by the ASSURE program of the Department of Defense in partnership with the National Science Foundation REU Site program under NSF grant no. DMR-1005022. We thank J.C. Weaver for help in manuscript preparation and E. Macomber for technical assistance with metal deposition equipment.

Author information

Authors and Affiliations

Contributions

P.K. and J.A. co-invented the STEPS method. J.A. supervised the project and advised on the applications of STEPS. M.K. and P.K. designed the masks. M.K. fabricated the reticles and the Si masters. P.K. and W.E.A.-M. performed replication, metallization and electrochemical deposition experiments and the characterization and analysis of the STEPS-modified structures. P.K., W.E.A.-M., M.K. and J.A. wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Fig. 1

SEM images of a uni-directionally bent nanopost array decorated with PPy nanofibers. (TIFF 11721 kb)

Supplementary Fig. 2

SEM images (taken at 45 degree tilt angle) of gradually reinforced 'Y' shaped columnar arrays using STEPS-II protocol (a-c) and the FEM simulation results showing the induced stress under applied compressive load of 100 MPa (d: original structure, e: reinforced structure). Images are adapted with permission from Kim, P. et al., Nano Letters (DOI:10.1021/nl200426g). Copyright 2011 American Chemical Society. (TIFF 11721 kb)

Rights and permissions

About this article

Cite this article

Kim, P., Adorno-Martinez, W., Khan, M. et al. Enriching libraries of high-aspect-ratio micro- or nanostructures by rapid, low-cost, benchtop nanofabrication. Nat Protoc 7, 311–327 (2012). https://doi.org/10.1038/nprot.2012.003

Published:

Issue Date:

DOI: https://doi.org/10.1038/nprot.2012.003

This article is cited by

-

Multifunctional ferrofluid-infused surfaces with reconfigurable multiscale topography

Nature (2018)

-

Rapid Prototyping of Polymeric Nanopillars by 3D Direct Laser Writing for Controlling Cell Behavior

Scientific Reports (2017)

-

High Quality Bioreplication of Intricate Nanostructures from a Fragile Gecko Skin Surface with Bactericidal Properties

Scientific Reports (2017)

-

Replication of flexible polymer membranes with geometry-controllable nano-apertures via a hierarchical mould-based dewetting

Nature Communications (2014)

-

Micro- and nanopatterning by lithographically controlled wetting

Nature Protocols (2012)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.