Abstract

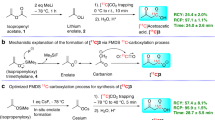

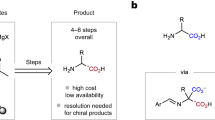

An optimized procedure for preparing fluorine-18 (18F)-labeled peptides by the copper-catalyzed azide-alkyne 1,3-dipolar cyloaddition (CuAAC) is presented here. The two-step radiosynthesis begins with the microwave-assisted nucleophilic 18F-fluorination of a precursor containing a terminal p-toluenesulfonyl, terminal azide and polyethylene glycol backbone. The resulting 18F-fluorinated azide-containing building block is coupled to an alkyne-decorated peptide by the CuAAC. The reaction is accelerated by the copper(I)-stabilizing ligand bathophenanthroline disulfonate and can be performed in either reducing or nonreducing conditions (e.g., to preserve disulfide bonds). After an HPLC purification, 18F-labeled peptide can be obtained with a 31 ± 6% radiochemical yield (n = 4, decay-corrected from 18F-fluoride elution) and a specific activity of 39.0 ± 12.4 Ci μmol−1 within 77 ± 4 min.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Kolb, H.C., Finn, M.G. & Sharpless, K.B. Click chemistry: diverse chemical function from a few good reactions. Angew. Chem. Int. Ed. Engl. 40, 2004–2021 (2001).

Rostovtsev, V.V., Green, L.G., Fokin, V.V. & Sharpless, K.B. A stepwise Huisgen cycloaddition process: copper(I)-catalyzed regioselective 'ligation' of azides and terminal alkynes. Angew. Chem. Int. Ed. Engl. 41, 2596–2599 (2002).

Tornoe, C.W., Christensen, C. & Meldal, M. Peptidotriazoles on solid phase: [1,2,3]-triazoles by regiospecific copper(I)-catalyzed 1,3-dipolar cycloadditions of terminal alkynes to azides. J. Org. Chem. 67, 3057–3064 (2002).

Kolb, H.C. & Sharpless, K.B. The growing impact of click chemistry on drug discovery. Drug Discovery Today 8, 1128–1137 (2003).

Meldal, M. & Tornoe, C.W. Cu-catalyzed azide-alkyne cycloaddition. Chem. Rev. 108, 2952–3015 (2008).

Glaser, M. & Robins, E.G. 'Click labelling' in PET radiochemistry. J. Label. Compd. Radiopharm. 52, 407–414 (2009).

Sirion, U. et al. An efficient F-18 labeling method for PET study: Huisgen 1,3-dipolar cycloaddition of bioactive substances and F-18-labeled compounds. Tetrahedron Lett. 48, 3953–3957 (2007).

Nguyen, Q.D. et al. Positron emission tomography imaging of drug-induced tumor apoptosis with a caspase-3/7 specific [18F]-labeled isatin sulfonamide. Proc. Natl. Acad. Sci. USA 106, 16375–16380 (2009).

Gill, H.S. et al. A modular platform for the rapid site-specific radiolabeling of proteins with 18F exemplified by quantitative positron emission tomography of human epidermal growth factor receptor 2. J. Med. Chem. 52, 5816–5825 (2009).

Ramenda, T., Kniess, T., Bergmann, R., Steinbach, J. & Wuest, F. Radiolabelling of proteins with fluorine-18 via click chemistry. Chem. Commun. (Camb), 7521–7523 (2009).

Marik, J. & Sutcliffe, J.L. Click for PET: rapid preparation of [18F]fluoropeptides using Cu(I) catalyzed 1,3-dipolar cycloaddition. Tetrahedron Lett. 47, 6681–6684 (2006).

Glaser, M. & Arstad, E. 'Click labeling' with 2-[18F]fluoroethylazide for positron emission tomography. Bioconjug. Chem. 18, 989–993 (2007).

Inkster, J.A.H., Guerin, B., Ruth, T.J. & Adam, M.J. Radiosynthesis and bioconjugation of [18F]FPy5yne, a prosthetic group for the 18F labeling of bioactive peptides. J. Label. Compd. Radiopharm. 51, 444–452 (2008).

Hausner, S.H., Marik, J., Gagnon, M.K. & Sutcliffe, J.L. In vivo positron emission tomography (PET) imaging with an alphavbeta6 specific peptide radiolabeled using 18F-'click' chemistry: evaluation and comparison with the corresponding 4-[18F]fluorobenzoyl- and 2-[18F]fluoropropionyl-peptides. J. Med. Chem. 51, 5901–5904 (2008).

Li, Z.B., Wu, Z., Chen, K., Chin, F.T. & Chen, X. Click chemistry for 18F-labeling of RGD peptides and microPET imaging of tumor integrin alphavbeta3 expression. Bioconjug. Chem. 18, 1987–1994 (2007).

Rodionov, V.O., Presolski, S.I., Diaz, D.D., Fokin, V.V. & Finn, M.G. Ligand-accelerated Cu-catalyzed azide-alkyne cycloaddition: a mechanistic report. J. Am. Chem. Soc. 129, 12705–12712 (2007).

Rodionov, V.O., Presolski, S.I., Gardinier, S., Lim, Y.H. & Finn, M.G. Benzimidazole and related ligands for Cu-catalyzed azide-alkyne cycloaddition. J. Am. Chem. Soc. 129, 12696–12704 (2007).

Campbell-Verduyn, L.S., Mirfeizi, L., Dierckx, R.A., Elsinga, P.H. & Feringa, B.L. Phosphoramidite accelerated copper(I)-catalyzed [3 + 2] cycloadditions of azides and alkynes. Chem. Commun. (Camb), 2139–2141 (2009).

Lewis, W.G., Magallon, F.G., Fokin, V.V. & Finn, M.G. Discovery and characterization of catalysts for azide-alkyne cycloaddition by fluorescence quenching. J. Am. Chem. Soc. 126, 9152–9153 (2004).

Chan, T.R., Hilgraf, R., Sharpless, K.B. & Fokin, V.V. Polytriazoles as copper(I)-stabilizing ligands in catalysis. Org. Lett. 6, 2853–2855 (2004).

Soriano Del Amo, D. et al. Biocompatible copper(I) catalysts for in vivo imaging of glycans. J. Am. Chem. Soc. 132, 16893–16899.

Sen Gupta, S. et al. Accelerated bioorthogonal conjugation: a practical method for the ligation of diverse functional molecules to a polyvalent virus scaffold. Bioconjug. Chem. 16, 1572–1579 (2005).

Sutcliffe-Goulden, J.L., O'Doherty, M.J. & Bansal, S.S. Solid phase synthesis of [18F]labelled peptides for positron emission tomography. Bioorg. Med. Chem. Lett. 10, 1501–1503 (2000).

Sutcliffe-Goulden, J.L. et al. Rapid solid phase synthesis and biodistribution of 18F-labelled linear peptides. Eur. J. Nucl. Med. Mol. Imaging 29, 754–759 (2002).

Marik, J., Hausner, S.H., Fix, L.A., Gagnon, M.K. & Sutcliffe, J.L. Solid-phase synthesis of 2-[18F]fluoropropionyl peptides. Bioconjug. Chem. 17, 1017–1021 (2006).

Berndt, M., Pietzsch, J. & Wuest, F. Labeling of low-density lipoproteins using the 18F-labeled thiol-reactive reagent N-[6-(4-[18F]fluorobenzylidene)aminooxyhexyl]maleimide. Nucl. Med. Biol. 34, 5–15 (2007).

Cai, W., Zhang, X., Wu, Y. & Chen, X. A thiol-reactive 18F-labeling agent, N-[2-(4-18F-fluorobenzamido)ethyl]maleimide, and synthesis of RGD peptide-based tracer for PET imaging of alpha v beta 3 integrin expression. J. Nucl. Med. 47, 1172–1180 (2006).

Toyokuni, T. et al. Synthesis of a new heterobifunctional linker, N-[4-(aminooxy)butyl]maleimide, for facile access to a thiol-reactive 18F-labeling agent. Bioconjug. Chem. 14, 1253–1259 (2003).

Wuest, F., Kohler, L., Berndt, M. & Pietzsch, J. Systematic comparison of two novel, thiol-reactive prosthetic groups for 18F labeling of peptides and proteins with the acylation agent succinimidyl-4-[18F]fluorobenzoate ([18F]SFB). Amino Acids 36, 283–295 (2009).

Glaser, M. et al. Methods for 18F-labeling of RGD peptides: comparison of aminooxy [18F]fluorobenzaldehyde condensation with 'click labeling' using 2-[18F]fluoroethylazide, and S-alkylation with [18F]fluoropropanethiol. Amino Acids 37, 717–724 (2009).

Glaser, M. et al. Radiosynthesis and biodistribution of cyclic RGD peptides conjugated with novel [18F]fluorinated aldehyde-containing prosthetic groups. Bioconjug. Chem. 19, 951–957 (2008).

Namavari, M. et al. Direct site-specific radiolabeling of an Affibody protein with 4-[18F]fluorobenzaldehyde via oxime chemistry. Mol. Imaging Biol. 10, 177–181 (2008).

Namavari, M. et al. A novel method for direct site-specific radiolabeling of peptides using [18F]FDG. Bioconjug. Chem. 20, 432–436 (2009).

Bruus-Jensen, K. et al. Chemoselective hydrazone formation between HYNIC-functionalized peptides and 18F-fluorinated aldehydes. Nucl. Med. Biol. 33, 173–183 (2006).

Olberg, D.E. et al. A novel prosthetic group for site-selective labeling of peptides for positron emission tomography. Bioconjug. Chem. 19, 1301–1308 (2008).

Olberg, D.E. et al. Site-specific addition of an 18F-N-methylaminooxy-containing prosthetic group to a vinylsulfone modified peptide. J. Label. Compd. Radiopharm. 52, 571–575 (2009).

Schirrmacher, E. et al. Synthesis of p-(di-tert-butyl[18F]fluorosilyl)benzaldehyde ([18F]SiFA-A) with high specific activity by isotopic exchange: a convenient labeling synthon for the 18F-labeling of N-amino-oxy derivatized peptides. Bioconjug. Chem. 18, 2085–2089 (2007).

Schirrmacher, R. et al. 18F-labeling of peptides by means of an organosilicon-based fluoride acceptor. Angew. Chem. Int. Ed. Engl. 45, 6047–6050 (2006).

McBride, W.J. et al. A novel method of 18F radiolabeling for PET. J. Nucl. Med. 50, 991–998 (2009).

Laverman, P. et al. A novel facile method of labeling octreotide with 18F-fluorine. J. Nucl. Med. 51, 454–461 (2010).

McBride, W.J. et al. Improved 18F labeling of peptides with a fluoride-aluminum-chelate complex. Bioconjug. Chem. 21, 1331–1340 (2010).

Hong, V., Presolski, S.I., Ma, C. & Finn, M.G. Analysis and optimization of copper-catalyzed azide-alkyne cycloaddition for bioconjugation. Angew. Chem. Int. Ed. Engl. 48, 9879–9883 (2009).

Berridge, M.S., Apana, S.M. & Hersh, J.M. Teflon radiolysis as the major source of carrier in fluorine-18. J. Label. Compd. Radiopharm. 52, 543–548 (2009).

Fuchtner, F., Preusche, S., Mading, P., Zessin, J. & Steinbach, J. Factors affecting the specific activity of [18F]fluoride from a [18O]water target. Nuklearmedizin 47, 116–119 (2008).

Kaiser, E., Colescott, R.L., Bossinger, C.D. & Cook, P.I. Color test for detection of free terminal amino groups in the solid-phase synthesis of peptides. Anal. Biochem. 34, 595–598 (1970).

Patgiri, A., Menzenski, M.Z., Mahon, A.B. & Arora, P.S. Solid-phase synthesis of short α-helices stabilized by the hydrogen bond surrogate approach. Nat. Protoc. 5, 1857–1865 (2010).

Chan, W.C. & White, P.D. (eds.) Fmoc Solid Phase Peptide Synthesis: A Practical Approach (Oxford University Press, 2000).

Acknowledgements

We thank S. Williams and J.L. Sutcliffe for critical reading of the manuscript and their valuable comments; C. Quan and J. Tom for the peptide synthesis; and J. Tinianow for general assistance with radiolabeling and product characterization.

Author information

Authors and Affiliations

Contributions

H.S.G. and J.M. performed the work and wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Methods

Solid phase extraction (SPE) as a replacement for the HPLC purification of 18F-labeled peptides (DOC 33 kb)

Supplementary Table 1

The ascorbate-based and ascorbate-free CuAAC were each tested in varied reaction conditions. (DOC 152 kb)

Rights and permissions

About this article

Cite this article

Gill, H., Marik, J. Preparation of 18F-labeled peptides using the copper(I)-catalyzed azide-alkyne 1,3-dipolar cycloaddition. Nat Protoc 6, 1718–1725 (2011). https://doi.org/10.1038/nprot.2011.390

Published:

Issue Date:

DOI: https://doi.org/10.1038/nprot.2011.390

This article is cited by

-

A proof-of-concept study on the use of a fluorescein-based 18F-tracer for pretargeted PET

EJNMMI Radiopharmacy and Chemistry (2022)

-

Polyglucose nanoparticles with renal elimination and macrophage avidity facilitate PET imaging in ischaemic heart disease

Nature Communications (2017)

-

Rapid, high efficiency isolation of pancreatic ß-cells

Scientific Reports (2015)

-

Using 5-deoxy-5-[18F]fluororibose to glycosylate peptides for positron emission tomography

Nature Protocols (2014)

-

One-step 18F-labeling of peptides for positron emission tomography imaging using the SiFA methodology

Nature Protocols (2012)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.