Abstract

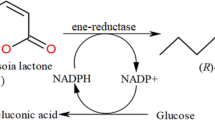

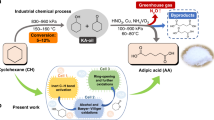

An efficient biocatalytic process based on the use of adsorbent resin (in situ substrate feeding and product removal) makes experiments at high substrate concentration possible by overcoming limitations due to substrate and product inhibition. This process was successfully applied to the preparative scale Baeyer–Villiger biooxidation of (−)-(1S,5R)-bicyclo[3.2.0]hept-2-en-6-one (25 g). Whole cells of recombinant E. coli (1 liter) overexpressing cyclohexanone monooxygenase were used as a biocatalyst and the substrate was preloaded onto the adsorbent resin. The corresponding lactone was obtained in 75–80% yield. Time for cell growth and biotransformation is about 24 h each and oxygen supply can be improved by using a tailor-made bubble column.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Pollard, D.J. & Liese, A. in Industrial Biotransformations 2nd edn. (eds. Liese, A., Seelbach, K. & Wandrey, C.) (Wiley-VCH, Weinheim, 2006).

Pollard, D.J. & Woodley, J.M. Biocatalysis for pharmaceutical intermediates: the future is now. Trends Biotechnol. 25, 66–73 (2007).

Blaser, H.U . & Schmidt, E. Asymmetric Catalysis on an Industrial Scale (Wiley-VCH, Weinheim, 2004).

Wohlgemuth, R. Interfacing biocatalysis and organic synthesis. J. Chem. Technol. Biotechnol. 82, 1055–1062 (2007).

Kim, P.-Y., Pollard, D.J. & Woodley, J.M. Substrate supply for effective biocatalysis. Biotechnol. Prog. 23, 74–82 (2007).

Zambianchi, F. et al. Comparison of cyclohexanone monooxygenase as an isolated enzyme and whole cell biocatalyst for the enantioselective oxidation of 1,3-dithiane. J. Mol. Catal., B Enzym. 31, 4–6 (2004)and references herein.

Vicenzi, J.T. et al. Large-scale stereoselective enzymatic ketone reduction with in situ product removal via polymeric adsorbent resins. Microb. Technol. 20, 494–499 (1997).

D'Arrigo, P., Lattanzio, M., Fantoni, G.P. & Servi, S. Chemo-enzymatic synthesis of the active enantiomer of the anorressant 2-benzylmorpholine. Tetrahedron Asymmetry 9, 4021–4026 (1998).

Nakamura, K., Tanekada, K., Fuji, M. & Ida, Y. Asymmetric synthesis of both enantiomers of secondary alcohols by reduction with a single microbe. Tetrahedron Lett. 43, 3629–3631 (2002).

Conceiçao, G.J.A., Moran, P.J.S. & Rodrigues, J.A.R. Highly efficient extractive biocatalysis in the asymmetric reduction of an acyclic enone by the yeast Pichia stipitis. Tetrahedron Asymmetry 14, 43–45 (2003).

Hilker, I., Alphand, V., Wohlgemuth, R. & Furstoss, R. Microbial transformations 56. Preparative scale asymmetric Baeyer–Villiger oxidation using a highly productive 'two-in-one' resin-based in situ SFPR concept. Adv. Synth. Catal. 346, 203–214 (2004).

Rudroff, F., Alphand, V., Furstoss, R. & Mihovilovic, M.D. Optimizing fermentation conditions of recombinant E. coli expressing cyclopentanone monooxygenase. Org. Process Res. Dev. 10, 599–604 (2006).

ten Brink, G.-J., Arends, I.W.C.E. & Sheldon, R.A. The Baeyer–Villiger reaction: new developments toward greener procedures. Chem. Rev. 104, 4105–4123 (2004).

Mihovilovic, M.D. Enzyme mediated Baeyer–Villiger oxidations. Curr. Org. Chem. 10, 1265–1287 (2006).

Wohlgemuth, R. Modular and scalable biocatalytic tools for practical safety, health, and environmental improvements in the production of specialty chemicals. Biocat. Biotrans. 25, 178–185 (2007).

Kamerbeek, N.M., Janssen, D.B., van Berkel, W.J.H. & Fraaije, M.W. Baeyer–Villiger monooxygenases, an emerging family of flavin-dependent biocatalysts. Adv. Synth. Catal. 345, 667–678 (2003).

de Gonzalo, G., Ottolina, G., Zambianchi, F., Fraaije, M.W. & Carrea, G. Biocatalytic properties of Baeyer–Villiger monooxygenases in aqueous–organic media. J. Mol. Catal., B Enzym. 39, 91–97 (2006).

Riva, S., Fassi, P., Allegrini, P. & Razzetti, G. A process for the preparation of (−)-modafinil (dipharma). European Patent Application, EP 1777295 (2007).

Alphand, V., Carrea, G., Wohlgemuth, R., Furstoss, R. & Woodley, J.M. Towards large-scale synthetic applications of Baeyer–Villiger monooxygenases. Trends Biotechnol. 21, 318–323 (2003).

Simpson, H.D., Alphand, V. & Furstoss, R. Asymmetric biocatalysed Baeyer–Villiger oxidation: improvement using a recombinant Escherichia coli whole cell biocatalyst in the presence of an adsorbent resin. J. Mol. Catal., B Enzym. 16, 101–108 (2001).

Hilker, I., Gutierrez, M.C., Alphand, V., Wohlgemuth, R. & Furstoss, R. Microbiological transformations 57. Facile and efficient resin-based in situ SFPR preparative scale synthesis of an enantiopure 'unexpected' lactone regioisomer via a Baeyer–Villiger oxidation process. Org. Lett. 6, 1955–1958 (2004).

Hilker, I., Alphand, V., Wohlgemuth, R. & Furstoss, R. Microbial transformations 59. First kilogram scale asymmetric microbial Baeyer–Villiger oxidation with optimized productivity using a resin-based in situ SFPR strategy. Biotechnol. Bioeng. 92, 702–710 (2005).

Delhi, J.R. & Gotor, V. Parallel kinetic resolution of racemic mixtures: a new strategy for the preparation of enantiopure compounds? Chem. Soc. Rev. 31, 365–370 (2002).

Andrau, L. et al. An integrated chemoenzymatic synthesis of enantiopure (−)-(1R,5S)-cyclosarkomycin: a sarkomycin precursor. Tetrahedron Lett. 38, 825–826 (1997).

Lebreton, J., Alphand, V. & Furstoss, R. A short chemoenzymatic synthesis of (+)-multifidene and (+)-viridiene. Tetrahedron Lett. 37, 1011–1014 (1996).

Baldwin, C. & Woodley, J. On oxygen limitation in a whole-cell biocatalytic Baeyer–Villiger oxidation process. Biotechnol. Bioeng. 95, 362–369 (2006).

Hilker, I. et al. On the influence of oxygen and cell concentration in an in situ SFPR whole-cell biocatalytic Baeyer–Villiger oxidation process. Biotechnol. Bioeng. 93, 1138–1144 (2006).

Berezina, N., Kozma, E., Furstoss, R. & Alphand, V. Asymmetric Baeyer–Villiger biooxidation of α-substituted cyanocyclohexanones: influence of the substituent length on regio- and enantioselectivity. Adv. Synth. Catal. 349, 2049–2053 (2007).

Acknowledgements

This work was supported by European Community Fifth Framework Program (QLK3-CT2001-00403). The Swiss Federal Office for Education and Science (BBW) and the Foundation Ramón Areces are acknowledged for postdoctoral fellowships.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

One of the authors (RW) is employed by Sigma Aldrich Ldt. Another one (IH) was employed at that time. We collaborated via a European “demonstration” program (EC Framework 5). This company also provided us with most of chemicals and resins.

Rights and permissions

About this article

Cite this article

Hilker, I., Gutiérrez, M., Furstoss, R. et al. Preparative scale Baeyer–Villiger biooxidation at high concentration using recombinant Escherichia coli and in situ substrate feeding and product removal process. Nat Protoc 3, 546–554 (2008). https://doi.org/10.1038/nprot.2007.532

Published:

Issue Date:

DOI: https://doi.org/10.1038/nprot.2007.532

This article is cited by

-

Improving catalytic activity of the Baeyer–Villiger monooxygenase-based Escherichia coli biocatalysts for the overproduction of (Z)-11-(heptanoyloxy)undec-9-enoic acid from ricinoleic acid

Scientific Reports (2018)

-

Chemical applications of Class B flavoprotein monooxygenases

Rendiconti Lincei (2017)

-

Engineering of Baeyer-Villiger monooxygenase-based Escherichia coli biocatalyst for large scale biotransformation of ricinoleic acid into (Z)-11-(heptanoyloxy)undec-9-enoic acid

Scientific Reports (2016)

-

Biocatalysis

Catalysis Letters (2015)

-

Engineering of Biocatalysts and Biocatalytic Processes

Topics in Catalysis (2014)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.