Abstract

Engineering surfaces that promote rapid drop detachment1,2 is of importance to a wide range of applications including anti-icing3,4,5, dropwise condensation6 and self-cleaning7,8,9. Here we show how superhydrophobic surfaces patterned with lattices of submillimetre-scale posts decorated with nanotextures can generate a counter-intuitive bouncing regime: drops spread on impact and then leave the surface in a flattened, pancake shape without retracting. This allows a fourfold reduction in contact time compared with conventional complete rebound 1,10,11,12,13. We demonstrate that the pancake bouncing results from the rectification of capillary energy stored in the penetrated liquid into upward motion adequate to lift the drop. Moreover, the timescales for lateral drop spreading over the surface and for vertical motion must be comparable. In particular, by designing surfaces with tapered micro/nanotextures that behave as harmonic springs, the timescales become independent of the impact velocity, allowing the occurrence of pancake bouncing and rapid drop detachment over a wide range of impact velocities.

Similar content being viewed by others

Main

Consider a copper surface patterned with a square lattice of tapered posts decorated with nanostructures14,15,16,17 (Fig. 1a). The post height h is 800 μm and the centre-to-centre spacing w is 200 μm (Supplementary Fig. 1a). The posts have a circular cross-section with a diameter that increases continuously and linearly from 20 μm to 90 μm with depth in the vertical direction. The post surface is fabricated using a wire cutting machine followed by chemical etching15,17,18 to generate nanoflowers of average diameter 3.0 μm. After a thin polymer coating, trichloro(1H,1H,2H,2H-perfluorooctyl)silane, is applied, the surface exhibits a superhydrophobic property with an apparent contact angle of over 165° (Fig. 1a). The advancing and receding contact angles are 167.2° ± 1.1° and 163.9° ± 1.4°, respectively. Water drop impact experiments were conducted using a high-speed camera at the rate of 10,000 frames per second. The unperturbed radius of the drop is r0 = 1.45 mm or 1.10 mm, and the impact velocity (v0) ranges from 0.59 m s−1 to 1.72 m s−1, corresponding to 7.1 < We < 58.5, where  is the Weber number, with ρ being the density and γ the surface tension of water.

is the Weber number, with ρ being the density and γ the surface tension of water.

a, Scanning electronic micrograph of the copper surface patterned with a square lattice of tapered posts. The posts have a circular cross-section whose diameter increases continuously and linearly from 20 μm to 90 μm with depth. The centre-to-centre spacing and the height of the post are 200 μm and 800 μm, respectively. The posts are covered by nanoflowers of average diameter 3.0 μm, exhibiting a contact angle of over 165° and contact angle hysteresis less than 2°. b, Selected snapshots captured by the high-speed camera showing a drop (r0 = 1.45 mm) impacting on the tapered surface at We = 7.1. On touching the surface at t = 0, part of the drop penetrates into the post arrays and recoils back (driven by capillary force) to the top of the surface at t↑ ∼ 2.9 ms (Supplementary Movie 1). After reaching a maximum lateral extension at tmax ∼ 4.8 ms, the drop retracts on the surface and finally detaches from the surface at tcontact (∼16.5 ms). c, Selected snapshots showing a drop impacting on the tapered surface at We = 14.1. The drop bounces off the surface in a pancake shape at ∼3.4 ms. d,e, Selected snapshots showing a drop impinging on the tapered surface and superhydrophobic surface with nanoflower structure alone, respectively, under a tilt angle of 30° at We = 31.2. The drop impinging on the tapered surface exhibits a pancake bouncing (d), whereas the drop on the nanostructured surface follows a conventional bouncing pathway (e). The contact time in the case of pancake bouncing is 3.6 ms, which is fourfold shorter than that on the nanostructured superhydrophobic surface.

Figure 1b shows selected snapshots of a drop impinging on such a surface at We = 7.1. On touching the surface at t = 0, part of the drop penetrates into the post arrays in a localized region with the radius approximately equivalent to the initial drop radius and recoils back, driven by the capillary force, to the top of the surface at 2.9 ms (Supplementary Movie 1). After reaching a maximum lateral extension19 at 4.8 ms, the drop retracts on the surface and finally detaches from the surface at 16.5 ms ( ). This contact time is in good agreement with previous results for conventional complete rebound 1,10,11,12. However, at higher We, the drop exhibits a distinctively different bouncing behaviour, which we term pancake bouncing, as exemplified by an impact at We = 14.1 (Fig. 1c and Supplementary Movie 2). In this case, the liquid penetration is deeper and the drop detaches from the surface (at 3.4 ms

). This contact time is in good agreement with previous results for conventional complete rebound 1,10,11,12. However, at higher We, the drop exhibits a distinctively different bouncing behaviour, which we term pancake bouncing, as exemplified by an impact at We = 14.1 (Fig. 1c and Supplementary Movie 2). In this case, the liquid penetration is deeper and the drop detaches from the surface (at 3.4 ms  ) immediately after the capillary emptying without experiencing retraction.

) immediately after the capillary emptying without experiencing retraction.

The difference in bouncing dynamics between conventional rebound and pancake bouncing can be quantified by the ratio of the diameter of the drop when it detaches from the surface djump to the maximum spreading width of the drop dmax. The ratio Q = djump/dmax is defined as the pancake quality, with Q > 0.8 referred to as pancake bouncing. At low Weber number (We < 12.6), the pancake quality Q is ∼0.4, corresponding to conventional bouncing1,10,11,12,13 (Fig. 2a). However, for We > 12.6 there is a clear crossover to Q ∼ 1, which corresponds to pancake bouncing. Moreover, a defining feature of pancake bouncing, of particular relevance to applications aimed at rapid drop shedding, is the short contact time1,2 of the drop with the solid surface. In the case of pancake bouncing, the contact time, tcontact, is reduced by a factor of more than four to 3.4 ms as compared with conventional rebound1,10,11,12,13.

a, The variations of t↑,tcontact (left y axis), and pancake quality Q (=djump/dmax; right y axis) with We for drop radius r0 = 1.45 mm. At low We < 12, the drop exhibits conventional bouncing with tcontact much larger than t↑. However, at high We > 12 the drop bounces as a pancake with t↑ ≍ tcontact. b, The variations of t↑,tmax (left y axis) and Q (right y axis) with We. t↑ and tmax are nearly constant over a wide range of We from 8 to 24. Each data point is the average of three measurements. Error bars denote the range of the measurements.

We also performed drop impact experiments on tilted surfaces, a geometry more relevant to practical applications, such as self-cleaning7,8,9, de-icing 3,4,5 and thermal management6,20. Figure 1d shows selected snapshots of a drop impinging on the tapered surface with a tilt angle of 30° at We = 31.2 (Supplementary Movie 3, left). The drop impinging on the tilted tapered surface also exhibits pancake bouncing. Moreover, the drop completely detaches from the surface within 3.6 ms and leaves the field of view without bouncing again. We also compared the drop impact on the tilted surface with nanoflower structure alone. The apparent contact angle of the nanostructured surface is 160° ± 1.8°. It is evident that a drop impinging on such a surface follows a conventional bouncing pathway: the drop spreads to a maximum diameter, recoils back, and finally leaves the surface within 14.5 ms (Fig. 1e and Supplementary Movie 3, right).

We propose that the pancake bouncing of a drop occurring close to its maximum lateral extension results from the rectification of the capillary energy stored in the penetrated liquid14,21,22 into upward motion adequate to lift the entire drop. Moreover, for the drop to leave the surface in a pancake shape, the timescale for the vertical motion between posts should be comparable to that for the lateral spreading. To validate that pancake bouncing is driven by the upward motion rendered by the capillary emptying, we compared the two timescales tcontact and t↑, where t↑ is the time interval between the moment when the drop first touches the surface and when the substrate is completely emptied, during which fluid undergoes the downward penetration and upward capillary emptying processes (Supplementary Fig. 2). As shown in Fig. 2a, in the regime of pancake bouncing, tcontact and t↑ are close, indicating that the pancake bouncing is driven by the upward motion of the penetrated liquid21,22. For smaller We (<12.6), the two timescales diverge: t↑ remains approximately constant whereas tcontact increases sharply. This is because, at low We, the penetrated liquid does not have the kinetic energy sufficient to lift the drop at the end of the capillary emptying. Accordingly, the drop continues to spread and retract in contact with the surface before undergoing conventional bouncing1,10,11,12,13. Next, we plotted the variations of t↑, tmax and Q with We (Fig. 2b), where tmax is the time when the drop reaches its maximum lateral extension10,19. On tapered surfaces, t↑ and tmax are comparable to each other for all of the We measured. However, at low We (<12.6), there is no pancake bouncing owing to insufficient energy to lift the drop, further indicating that the occurrence of pancake bouncing necessitates the simultaneous satisfaction of sufficient impact energy and comparable timescales.

We next compared experimental results for bouncing on straight square posts covered by nanoflower structures. The post height and edge length (b) are 1.2 mm and 100 μm, respectively (Supplementary Fig. 1b). We observed that the pancake bouncing behaviour is sensitive to post spacing and We. Pancake bouncing is absent on post arrays with w = 200 μm (Supplementary Fig. 3), whereas it occurs for surfaces with w = 300 μm and 400 μm. Figure 3a, b compares results for the bouncing of a drop (r0 ∼ 1.45 mm) on the surface with spacing 300 μm at We = 4.7 and 7.9, respectively. In the former case, the drop exhibits a conventional complete rebound, with Q ∼ 0.59 and tcontact ∼ 16.2 ms. In the latter case, the drop shows pancake bouncing with Q ∼ 0.98 and a much reduced contact time tcontact ∼ 6.3 ms (Supplementary Movie 4). Figure 3c shows the variations of t↑, tmax, tcontact and Q with We for this surface. In the region of pancake bouncing (6.3 ≤ We ≤ 9.5), the proximity of tcontact and t↑ and the matching between tmax and t↑ are consistent with the observations on tapered surfaces. In contrast, in the non-pancake bouncing region (We ≤ 6.3), there is a large divergence between tcontact and t↑, because We is too small to allow drop bouncing as a pancake. This further confirms that the occurrence of pancake bouncing necessitates simultaneous satisfaction of the two criteria. In contrast to what is observed for tapered surfaces, a dependence of t↑ on We is noted to appear on straight posts. Moreover, we found the maximum jumping height of drops in a pancake shape on straight posts is threefold smaller than that on tapered surfaces (2.88 mm and 0.9 mm, respectively) and that the contact time (∼6.3 ms) on straight posts is larger than that (∼3.4 ms) on tapered surfaces. All of these observations reveal that the pancake bouncing on tapered surfaces is more pronounced and robust than that on straight posts.

a, Selected snapshots of a drop impinging on straight posts decorated with nanoflowers with a post centre-to-centre spacing of 300 μm at We = 4.7. The drop exhibits conventional rebound with pancake quality Q ∼ 0.59. tmax ∼ 6.0 ms is much larger than t↑ ∼ 3.3 ms. b, Selected snapshots of a drop impinging on post arrays with a post centre-to-centre spacing of 300 μm at We = 7.9. Pancake bouncing is observed with pancake quality Q ∼ 0.98, tmax ∼ 5.2 ms is slightly less than t↑ ∼ 5.7 ms. c, The variations of t↑, tmax, tcontact (left y axis) and Q (right y axis) with We. tmax is a constant over a range of We from 3 to 10. At low We < 6.3, the drop exhibits conventional bouncing with tcontact much larger than t↑. However, at high We > 6.3, the drop bounces in the shape of a pancake with t↑ ≍ tcontact. Unlike on the tapered surfaces, t↑ increases with increasing We. Each data point is the average of three measurements. Error bars denote the range of the measurements.

We propose a simple analytical argument to elucidate the enhanced pancake bouncing observed on tapered posts in comparison with straight posts. The timescale tmax scales as  , independent of the impact velocity 1,10,11,12,19. To calculate t↑, we consider the kinetics involved in the processes of liquid penetration and capillary emptying. Here, we neglect the viscous dissipation23 because the Reynolds number in the impact process is ∼100. The liquid penetrating into the space between posts is subject to a capillary force, which serves to halt and then reverse the flow. The capillary force can be approximated by bnγ cosθY (refs 11, 12, 14), where n is the number of posts wetted, and θY is the intrinsic contact angle of the nanoflower-covered posts. The deceleration (acceleration) of the penetrated liquid moving between the posts scales as a↑∼bγ cosθY/(ρr0w2), where the drop mass ∼ρr03, n ∼ r02/w2, and we assume that the liquid does not touch the base of the surface. Note that the number of posts wetted is independent of We because the penetrating liquid is mainly localized in a region with a lateral extension approximatively equivalent to the initial drop diameter, rather than the maximum spreading diameter (Supplementary Figs 4 and 5). For straight posts, the acceleration is constant. Thus,

, independent of the impact velocity 1,10,11,12,19. To calculate t↑, we consider the kinetics involved in the processes of liquid penetration and capillary emptying. Here, we neglect the viscous dissipation23 because the Reynolds number in the impact process is ∼100. The liquid penetrating into the space between posts is subject to a capillary force, which serves to halt and then reverse the flow. The capillary force can be approximated by bnγ cosθY (refs 11, 12, 14), where n is the number of posts wetted, and θY is the intrinsic contact angle of the nanoflower-covered posts. The deceleration (acceleration) of the penetrated liquid moving between the posts scales as a↑∼bγ cosθY/(ρr0w2), where the drop mass ∼ρr03, n ∼ r02/w2, and we assume that the liquid does not touch the base of the surface. Note that the number of posts wetted is independent of We because the penetrating liquid is mainly localized in a region with a lateral extension approximatively equivalent to the initial drop diameter, rather than the maximum spreading diameter (Supplementary Figs 4 and 5). For straight posts, the acceleration is constant. Thus,  and the ratio of the two timescales can be expressed as

and the ratio of the two timescales can be expressed as

which scales as  . Our experimental observations show, as discussed previously, that the occurrence of pancake bouncing requires t↑ and tmax to be comparable, that is, k ∼ 1. The dependence of k on We indicates that this condition can be satisfied only over a limited range of We.

. Our experimental observations show, as discussed previously, that the occurrence of pancake bouncing requires t↑ and tmax to be comparable, that is, k ∼ 1. The dependence of k on We indicates that this condition can be satisfied only over a limited range of We.

Interestingly, k and We become decoupled by designing surfaces with tapered posts. As the post diameter b now increases linearly with the depth z below the surface (that is, b ∼ βz, where β is a structural parameter), the acceleration of the penetrated liquid moving between posts is linearly proportional to penetration depth (that is,  ). As a result, the surface with tapered posts acts as a harmonic spring with

). As a result, the surface with tapered posts acts as a harmonic spring with  . Therefore, the ratio of timescales becomes

. Therefore, the ratio of timescales becomes

which is independent of We.

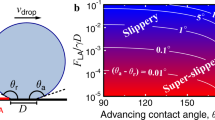

To pin down the key surface features and drop parameters for the occurrence of pancake bouncing, we plotted the variation of k with  in the design diagram (Fig. 4). Filled symbols represent pancake bouncing (defined by Q > 0.8) and open symbols denote conventional bouncing. Region 1 corresponds to the pancake bouncing occurring on straight posts with 1.0 < k < 1.7. The data show that

in the design diagram (Fig. 4). Filled symbols represent pancake bouncing (defined by Q > 0.8) and open symbols denote conventional bouncing. Region 1 corresponds to the pancake bouncing occurring on straight posts with 1.0 < k < 1.7. The data show that  as predicted by equation (1). Such a dependence of k on We explains the limited range of We for which such rebound is observed in our experiments. The two slanting lines bounding Region 1 for pancake bouncing on straight posts correspond to

as predicted by equation (1). Such a dependence of k on We explains the limited range of We for which such rebound is observed in our experiments. The two slanting lines bounding Region 1 for pancake bouncing on straight posts correspond to  and 1.5 in equation (1). For almost all of the experiments reported in the literature11,13,14,15,17, this parameter takes values between 0.01 and 0.144, smaller than the threshold demonstrated in our work by at least one order of magnitude. On such surfaces, either the liquid penetration is insignificant (for example, owing to too narrow and/or too short posts) or the capillary energy stored cannot be rectified into upward motion adequate to lift the drop (for example, owing to an unwanted Cassie-to-Wenzel transition 14,22,24,25,26,27). Region 2 shows that the introduction of tapered posts significantly widens the range of timescale and Weber number for pancake bouncing, way beyond Region 1. In this Region, the pancake bouncing can occur over a wider range of k from 0.5 to 1.7 and We from 8.0 to 58.5. As emphasized above, for small We with moderate liquid penetration, the two timescales tmax and t↑ are independent of We. They become weakly dependent on We for relatively large We due to the penetrated liquid hitting the base of the surface (Supplementary Movie 5), but the emergence of pancake bouncing is rather insensitive to the post height as long as this is sufficient to allow for adequate capillary energy storage (Supplementary Fig. 6). For much shorter posts, for example the tapered surface with a post height of 0.3 mm, we did not observe the pancake bouncing owing to insufficient energy storage.

and 1.5 in equation (1). For almost all of the experiments reported in the literature11,13,14,15,17, this parameter takes values between 0.01 and 0.144, smaller than the threshold demonstrated in our work by at least one order of magnitude. On such surfaces, either the liquid penetration is insignificant (for example, owing to too narrow and/or too short posts) or the capillary energy stored cannot be rectified into upward motion adequate to lift the drop (for example, owing to an unwanted Cassie-to-Wenzel transition 14,22,24,25,26,27). Region 2 shows that the introduction of tapered posts significantly widens the range of timescale and Weber number for pancake bouncing, way beyond Region 1. In this Region, the pancake bouncing can occur over a wider range of k from 0.5 to 1.7 and We from 8.0 to 58.5. As emphasized above, for small We with moderate liquid penetration, the two timescales tmax and t↑ are independent of We. They become weakly dependent on We for relatively large We due to the penetrated liquid hitting the base of the surface (Supplementary Movie 5), but the emergence of pancake bouncing is rather insensitive to the post height as long as this is sufficient to allow for adequate capillary energy storage (Supplementary Fig. 6). For much shorter posts, for example the tapered surface with a post height of 0.3 mm, we did not observe the pancake bouncing owing to insufficient energy storage.

The variation of the timescale ratio k = t↑/tmax with  , showing different pancake bouncing regions. Filled symbols denote that the drop jumps as a pancake. Region 1 corresponds to the pancake bouncing on straight posts with 1.0 < k < 1.7 andWe in a restricted range. The two slanting lines correspond to −w2/br0cosθY = 0.45 and 1.5 (based on equation (1), with a fitting prefactor C = 0.6). Region 2 corresponds to pancake bouncing on tapered surfaces over a much wider range of k from 0.5 to 1.7 and We from 8.0 to 58.5. Note that k is independent of We over a wide range. It becomes weakly dependent on We for higher impact velocities owing to the penetrated liquid hitting the base of the surface.

, showing different pancake bouncing regions. Filled symbols denote that the drop jumps as a pancake. Region 1 corresponds to the pancake bouncing on straight posts with 1.0 < k < 1.7 andWe in a restricted range. The two slanting lines correspond to −w2/br0cosθY = 0.45 and 1.5 (based on equation (1), with a fitting prefactor C = 0.6). Region 2 corresponds to pancake bouncing on tapered surfaces over a much wider range of k from 0.5 to 1.7 and We from 8.0 to 58.5. Note that k is independent of We over a wide range. It becomes weakly dependent on We for higher impact velocities owing to the penetrated liquid hitting the base of the surface.

The pancake bouncing is also observed on a multi-layered, two-tier, superhydrophobic porous (MTS) surface (Supplementary Fig. 7). The top layer of the MTS surface consists of a post array with post centre-to-centre spacing of ∼260 μm and the underlying layers comprise a porous medium21,22 of pore size ∼200 μm, naturally forming a graded pathway for drop penetration and capillary emptying. The typical contact time of the drop with the MTS surface is tcontact ∼ 5.0 ms (Supplementary Movie 6) and the range of We is between 12 and 35 for pancake bouncing. These values are comparable to those on tapered surfaces. Taken together, our observations on tapered post surfaces and MTS surfaces demonstrate that the counter-intuitive pancake bouncing is a general and robust phenomenon. Moreover, there is enormous scope for designing structures to optimize pancake bouncing for multifunctional applications3,4,5,28,29,30.

Methods

Preparation of tapered surface and straight post arrays.

The tapered surface with a size of 2.0 × 2.0 cm2 was created based on type 101 copper plate with a thickness of 3.18 mm by combining a wire-cutting method and multiple chemical etching cycles. Square posts arranged in a square lattice were first cut with a post centre-to-centre spacing of 200 μm. The post edge length and height are 100 μm and 800 μm, respectively. Then the as-fabricated surface was ultrasonically cleaned in ethanol and deionized water for 10 min, respectively, followed by washing with diluted hydrochloric acid (1 M) for 10 s to remove the native oxide layer. To achieve a tapered surface with a post diameter of 20 μm at the top, six cycles of etching were conducted. In each cycle, the as-fabricated surface was first immersed in a freshly mixed aqueous solution of 2.5 mol l−1 sodium hydroxide and 0.1 mol l−1 ammonium persulphate at room temperature for ∼60 min, followed by thorough rinsing with deionized water and drying in a nitrogen stream. As a result of chemical etching, CuO nanoflowers with an average diameter ∼3.0 μm were produced. Note that the etching rate at the top of the posts is roughly eightfold of that at the bottom of the surface owing to the formation of an etchant solution concentration gradient generated by the restricted spacing between the posts. To facilitate further etching, after each etching cycle the newly etched surface was washed with diluted hydrochloric acid (1 M) for 10 s to remove the oxide layer formed during the former etching cycle. Then another etching cycle was performed to sharpen the posts. In preparing the straight post arrays, only one etching cycle was conducted. All of the surfaces were modified by silanization through immersion in a 1 mM n-hexane solution of trichloro(1H,1H,2H,2H-perfluorooctyl)silane for ∼60 min, followed by heat treatment at ∼150 °C in air for 1 h to render surfaces superhydrophobic.

Preparation of MTS surface.

The MTS surface is fabricated on a copper foam with density 0.45 g cm−3, porosity 94% and thickness 0.16 cm. The nanostructure formation on the MTS surface and silanization were conducted using the same procedures described above.

Contact angle measurements.

The static contact angle on the as-prepared substrate was measured from sessile water drops with a ramé-hart M200 Standard Contact Angle Goniometer. Deionized water drops of 4.2 μl, at room temperature with 60% relative humidity, were deposited at a volume rate of 0.5 μl s−1. The apparent, advancing (θa) and receding contact angles (θr) on the tapered surface with centre-to-centre spacing of 200 μm are 165.6° ± 1.3°, 167.2° ± 1.1° and 163.9° ± 1.4°, respectively. The apparent (equivalent to the intrinsic contact angle on a tapered surface), advancing (θa) and receding contact angle (θr) on the surface with nanoflower structure alone are 160° ± 1.8°, 162.4° ± 2.8°, and 158.8° ± 1.7°, respectively. At least five individual measurements were performed on each substrate.

Impact experiments.

The whole experimental set-up was placed in ambient environment, at room temperature with 60% relative humidity. Water drops of ∼13 μl and 6 μl (corresponding to radii ∼1.45 mm and 1.10 mm, respectively) were generated from a fine needle equipped with a syringe pump (KD Scientific) from pre-determined heights. The dynamics of drop impact was recorded by a high-speed camera (Fastcam SA4, Photron) at the frame rate of 10,000 fps with a shutter speed 1/93,000 s, and the deformation of drops during impingement was recorded using ImageJ software (Version 1.46, National Institutes of Health).

References

Richard, D., Clanet, C. & Quéré, D. Contact time of a bouncing drop. Nature 417, 811 (2002).

Bird, J. C., Dhiman, R., Kwon, H-M. & Varanasi, K. K. Reducing the contact time of a bouncing drop. Nature 503, 385–388 (2013).

Jung, S., Tiwari, M. K., Doan, N. V. & Poulikakos, D. Mechanism of supercooled droplet freezing on surfaces. Nature Commun. 3, 615 (2012).

Mishchenko, L. et al. Design of ice-free nanostructured surfaces based on repulsion of impacting water droplets. ACS Nano. 4, 7699–7707 (2010).

Stone, H. A. Ice-phobic surfaces that are wet. ACS Nano. 6, 6536–6540 (2012).

Chen, X. et al. Nanograssed micropyramidal architectures for continuous dropwise condensation. Adv. Funct. Mater. 21, 4617–4623 (2011).

Blossey, R. Self-cleaning surfaces — virtual realities. Nature Mater. 2, 301–306 (2003).

Tuteja, A. et al. Designing superoleophobic surfaces. Science 318, 1618–1622 (2007).

Deng, X., Mammen, L., Butt, H. J. & Vollmer, D. Candle soot as a template for a transparent robust superamphiphobic coating. Science 335, 67–70 (2012).

Okumura, K., Chevy, F., Richard, D., Quéré, D. & Clanet, C. Water spring: A model for bouncing drops. Europhys. Lett. 62, 237–243 (2003).

Reyssat, M., Pépin, A., Marty, F., Chen, Y. & Quéré, D. Bouncing transitions on microtextured materials. Europhys. Lett. 74, 306–312 (2006).

Bartolo, D. et al. Bouncing or sticky droplets: Impalement transitions on superhydrophobic micropatterned surfaces. Europhys. Lett. 74, 299–305 (2006).

McCarthy, M. et al. Biotemplated hierarchical surfaces and the role of dual length scales on the repellency of impacting droplets. Appl. Phys. Lett. 100, 263701 (2012).

Moulinet, S. & Bartolo, D. Life and death of a fakir droplet: Impalement transitions on superhydrophobic surfaces. Eur. Phys. J. E. 24, 251–260 (2007).

Jung, Y. C. & Bhushan, B. Dynamic effects of bouncing water droplets on superhydrophobic surfaces. Langmuir 24, 6262–6269 (2008).

Cha, T. G., Yi, J. W., Moon, M. W., Lee, K. R. & Kim, H. Y. Nanoscale patterning of microtextured surfaces to control superhydrophobic robustness. Langmuir 26, 8319–8326 (2010).

Tran, T. et al. Droplet impact on superheated micro-structured surfaces. Soft Matter 9, 3272–3282 (2013).

Chen, X. et al. Synthesis and characterization of superhydrophobic functionalized Cu(OH)2 nanotube arrays on copper foil. Appl. Surf. Sci. 255, 4015–4019 (2009).

Clanet, C. et al. Maximal deformation of an impacting drop. J. Fluid Mech. 517, 199–208 (2004).

Vakarelski, I. U., Patankar, N. A., Marston, J. O., Chan, D. Y. C. & Thoroddsen, S. T. Stabilization of leidenfrost vapour layer by textured superhydrophobic surfaces. Nature 489, 274–277 (2012).

Lembach, A. N. et al. Drop impact, spreading, splashing, and penetration into electrospun nanofiber mats. Langmuir 26, 9516–9523 (2010).

Deng, X., Schellenberger, F., Papadopoulos, P., Vollmer, D. & Butt, H. J. Liquid drops impacting superamphiphobic coatings. Langmuir 29, 7847–7856 (2013).

Xu, L., Zhang, W. W. & Nagel, S. R. Drop splashing on a dry smooth surface. Phys. Rev. Lett. 94, 184505 (2005).

Wenzel, R. N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 28, 988–994 (1936).

Cassie, A. B. D. & Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 40, 546–551 (1944).

Lafuma, A. & Quéré, D Superhydrophobic states. Nature Mater. 2, 457–460 (2003).

Verho, T. et al. Reversible switching between superhydrophobic states on a hierarchically structured surface. Proc. Natl Acad. Sci. 109, 10210–10213 (2012).

Yarin, A. Drop impact dynamics: Splashing, spreading, receding, bouncing. Annu. Rev. Fluid Mech. 38, 159–192 (2006).

Quéré, D. Wetting and roughness. Ann. Rev. Mater. Res. 38, 71–99 (2008).

Zheng, Y. et al. Directional water collection on wetted spider silk. Nature 463, 640–643 (2010).

Acknowledgements

We are grateful for support from the Hong Kong Early Career Scheme Grant (No. 125312), National Natural Science Foundation of China (No. 51276152), CityU9/CRF/13G, the National Basic Research Program of China (2012CB933302) and Center of Super-Diamond and Advanced Films (COSDAF) at CityU to Z.W., ERC Advanced Grant, MiCE, to J.M.Y., and RGC Grant 603510 to T.Q. Experimental assistance was provided by Y. Liu and L. Xu. The authors gratefully thank D. Quéré for many useful discussions.

Author information

Authors and Affiliations

Contributions

Z.W., Y.L. and L.M. conceived the research. Z.W. and J.M.Y. supervised the research. Y.L. designed and carried out the experiments. Y.L., L.M. and X.X. analysed the data. L.M., J.M.Y., X.X. and T.Q. developed the model. Z.W., J.M.Y. and L.M. wrote the manuscript. Y.L. and L.M. contributed equally to this work.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 1540 kb)

Supplementary Movie

Supplementary Movie 1 (MOV 2487 kb)

Supplementary Movie

Supplementary Movie 2 (MOV 5093 kb)

Supplementary Movie

Supplementary Movie 3 (MOV 4283 kb)

Supplementary Movie

Supplementary Movie 4 (MOV 2113 kb)

Supplementary Movie

Supplementary Movie 5 (MOV 1343 kb)

Supplementary Movie

Supplementary Movie 6 (MOV 1306 kb)

Rights and permissions

About this article

Cite this article

Liu, Y., Moevius, L., Xu, X. et al. Pancake bouncing on superhydrophobic surfaces. Nature Phys 10, 515–519 (2014). https://doi.org/10.1038/nphys2980

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nphys2980

This article is cited by

-

An energy-free strategy to elevate anti-icing performance of superhydrophobic materials through interfacial airflow manipulation

Nature Communications (2024)

-

Fabrication of Polydimethylsiloxane Superhydrophobic Coatings with Self-healing Properties Using the Template Method

Journal of Materials Engineering and Performance (2024)

-

Golden section criterion to achieve droplet trampoline effect on metal-based superhydrophobic surface

Nature Communications (2023)

-

Suppression of wetting transition on evaporative fakir droplets by using slippery superhydrophobic surfaces with low depinning force

Scientific Reports (2023)

-

Tailoring vapor film beneath a Leidenfrost drop

Nature Communications (2023)